The process of completing the interior surfaces of a garage, typically with materials like drywall, plywood, or metal sheeting, to provide a more refined and functional space is a common home improvement project. This undertaking enhances the usability of the area, offering benefits beyond simply providing a space for vehicles.

Improving garage interiors delivers several advantages. A finished garage offers protection against the elements, helps insulate the space, and provides a more aesthetically pleasing environment. This can increase property value, create a more comfortable workspace, and provide opportunities for storage or hobby areas. Historically, garages were often left unfinished; however, modern homeowners increasingly recognize the value of transforming them into versatile, usable square footage.

The following sections will detail considerations for material selection, insulation installation, framing preparation, and the overall execution of improving garage interiors. This will include surface preparation, fire safety, and code considerations for a safe and compliant finished space.

Tips for Enhancing Garage Interior Surfaces

Achieving a professional and functional garage interior necessitates careful planning and execution. The following recommendations provide guidance on improving garage interior surfaces effectively and safely.

Tip 1: Material Selection: Prioritize materials that offer durability and resistance to moisture. Drywall specifically designed for garages, plywood, or metal sheeting are appropriate options. Consideration should be given to the potential for impact and the need for cleanability.

Tip 2: Framing Inspection and Preparation: Ensure existing wall studs are structurally sound and properly spaced. Add additional framing if necessary to comply with local building codes or to facilitate the installation of insulation and surface materials.

Tip 3: Insulation Installation: Implement appropriate insulation techniques to regulate temperature and reduce energy costs. Batt insulation, spray foam insulation, or rigid foam boards offer thermal resistance and can contribute to a more comfortable garage environment.

Tip 4: Fire Safety Considerations: Apply fire-resistant materials, such as Type X drywall, particularly in areas that adjoin living spaces. Confirm that materials meet local fire safety codes and regulations.

Tip 5: Surface Preparation: Thoroughly clean and prime surfaces before applying any finishing materials. This ensures proper adhesion and enhances the longevity of the completed interior surface.

Tip 6: Electrical Considerations: Plan electrical wiring and outlets before applying wall coverings. Ensure all electrical work is performed by a qualified electrician and complies with relevant codes.

Tip 7: Ventilation Enhancement: Improve garage ventilation to reduce moisture buildup and prevent mold growth. Install vents or consider a ventilation fan to promote airflow.

Adhering to these guidelines ensures a durable, safe, and aesthetically pleasing garage interior. Careful planning and execution are crucial to maximizing the value and utility of the garage space.

The following sections will further elaborate on specific finishing techniques and provide additional resources for improving garage spaces.

1. Framing Integrity

The structural framework of a garage is paramount to a successful completion of the interior surfaces. The integrity of this framework directly influences the quality and longevity of the finished walls. It dictates the ability of the walls to withstand environmental stresses, support fixtures, and contribute to the overall safety of the structure.

- Stud Alignment and Spacing

Proper alignment and spacing of studs are critical for a flat and secure wall surface. Deviations from standard spacing (typically 16 or 24 inches on center) can lead to uneven surfaces and difficulty in attaching finishing materials like drywall or plywood. Inadequate stud alignment can result in buckling or bowing of the wall surface over time.

- Structural Soundness of Lumber

The lumber used for framing must be free from rot, insect damage, or significant warping. Compromised lumber can weaken the wall structure and potentially lead to collapse. A thorough inspection of all framing members is essential to ensure their load-bearing capacity is not compromised. Replacing damaged or substandard lumber is a prerequisite to improving garage interiors.

- Proper Fastening Techniques

Using appropriate fasteners (nails or screws) and proper fastening techniques is essential to creating a rigid and durable wall frame. Insufficient fastening can result in loose studs, which compromises the integrity of the wall. Additionally, incorrect fastener placement can weaken the lumber and reduce its load-bearing capacity.

- Adherence to Building Codes

Local building codes dictate minimum requirements for framing construction, including stud size, spacing, and fastening methods. Adherence to these codes ensures the safety and structural integrity of the garage. Failure to comply with building codes can result in costly rework and potential legal ramifications.

The aforementioned elements are fundamental to a durable and aesthetically pleasing garage interior. Neglecting these framing aspects compromises the overall quality and longevity of the completed project. Prioritizing framing integrity at the outset ensures the finished walls are structurally sound, visually appealing, and compliant with relevant building regulations.

2. Insulation Type

The selection of insulation directly influences the performance and suitability of improved garage interiors. It determines the thermal resistance of the walls, impacting energy efficiency and overall comfort within the space. The appropriate insulation type mitigates temperature fluctuations, prevents condensation, and reduces energy consumption for heating or cooling. In regions with extreme climates, proper insulation is critical to prevent damage to stored items and to ensure a usable workspace.

The choice of insulation affects the ease and method of finishing the walls. For instance, batt insulation requires a framed cavity for installation, whereas spray foam insulation adheres directly to the wall surface and can conform to irregular shapes. The selected insulation must be compatible with the chosen wall finishing material, be it drywall, plywood, or metal sheeting. Inadequate insulation can lead to moisture accumulation, promoting mold growth and causing deterioration of the wall structure. Real-world examples of improperly insulated garages demonstrate compromised structural integrity and increased energy costs.

Selecting the correct insulation is an integral step in any completion of garage interiors. Considering factors such as climate, budget, and desired performance characteristics is crucial. The selection should balance thermal performance with ease of installation and compatibility with finishing materials. Failure to select the appropriate insulation type can result in long-term performance issues and reduced usability of the finished garage. The long-term benefits, including energy savings and improved comfort, justify careful consideration of this crucial component.

3. Material Choice

The selection of appropriate materials is a fundamental consideration when undertaking work on garage interior surfaces. The chosen material directly impacts the durability, functionality, and aesthetic appeal of the finished space. Careful evaluation of available options, taking into account specific needs and environmental factors, is essential for a successful outcome.

- Durability and Resistance to Impact

Garages are often subject to impacts from vehicles, tools, and stored items. Materials such as plywood or reinforced drywall offer superior resistance to damage compared to standard drywall. The selection of a more robust material minimizes the risk of punctures or dents, prolonging the lifespan of the finished wall. In high-traffic areas or garages used for workshops, impact resistance becomes a primary consideration.

- Moisture Resistance and Mold Prevention

Garages can be susceptible to moisture intrusion, either from vehicle-related sources (melting snow, mud) or from condensation. Materials like cement board or moisture-resistant drywall are less prone to water damage and mold growth compared to standard drywall. Selecting these materials mitigates the risk of structural damage and maintains a healthier indoor environment. In regions with high humidity, moisture resistance is a crucial factor in the material selection process.

- Fire Resistance and Safety Compliance

Fire safety is a paramount concern, particularly in garages attached to residential structures. Type X drywall, which offers enhanced fire resistance compared to standard drywall, is often required by building codes. The selection of appropriate fire-resistant materials provides crucial protection in the event of a fire, slowing its spread and allowing occupants more time to evacuate. Compliance with local fire safety codes is a non-negotiable aspect of the completion of garage interiors.

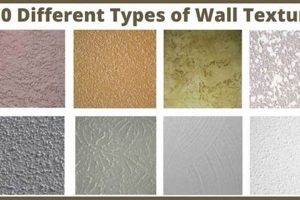

- Aesthetic Considerations and Surface Finish

While functionality is a primary concern, the aesthetic appearance of the finished garage interior also contributes to its overall value and usability. Materials like painted drywall offer a clean and refined look, while options like metal sheeting provide a more industrial aesthetic. The choice of material impacts the ease of painting, cleaning, and maintaining the finished surface. Selecting a material that aligns with the desired aesthetic and is easy to maintain enhances the long-term satisfaction with the completed space.

The interplay between these facets underscores the importance of informed material selection when improving garage interiors. Each material offers a unique combination of attributes, and the optimal choice depends on a careful assessment of specific needs and priorities. A well-considered selection process ensures a finished garage that is not only functional and durable but also aesthetically pleasing and safe.

4. Fire Resistance

Fire resistance is a critical consideration when undertaking improvements to garage interiors, particularly in attached garages where a fire can rapidly spread to the main dwelling. The materials selected and the methods employed directly affect the ability of the garage to contain a fire, providing occupants with additional time to escape and reducing property damage.

- Type X Drywall

Type X drywall is a fire-resistant gypsum board that incorporates additives to enhance its ability to withstand high temperatures for a specified period. It is typically thicker than standard drywall and is designed to slow the spread of fire. In many jurisdictions, building codes mandate the use of Type X drywall on garage walls and ceilings that adjoin living spaces, providing a crucial barrier against fire penetration. For example, a one-hour fire-rated wall assembly using Type X drywall can delay the passage of flames, allowing for safer evacuation.

- Fire-Rated Insulation

While insulation primarily serves to regulate temperature, certain types also contribute to fire resistance. Mineral wool insulation, for instance, is naturally fire resistant and does not readily burn or contribute to the spread of flames. Utilizing fire-rated insulation in conjunction with Type X drywall creates a more robust fire barrier. Fiberglass insulation can also provide some level of fire resistance, depending on its density and composition. In contrast, some foam insulations can be highly flammable and require a fire-resistant covering to meet code requirements.

- Fire-Blocking Materials

Fire-blocking involves the installation of materials within wall cavities to prevent the vertical spread of fire. These materials, typically wood or fire-rated caulk, effectively seal gaps and create barriers that hinder the movement of flames and smoke. Building codes often specify the placement of fire-blocking at specific intervals within wall studs, particularly around electrical and plumbing penetrations. Proper fire-blocking can significantly reduce the speed at which a fire can spread from the garage into the living areas of a home. For instance, strategically placed fire-blocking can confine a small garage fire, preventing it from reaching the attic or upper floors.

- Fire-Rated Doors and Seals

The door that connects the garage to the house should be a fire-rated door, typically with a 20-minute fire-resistance rating. This means the door is designed to withstand fire exposure for at least 20 minutes, providing a crucial barrier between the garage and the living space. Additionally, the door should have a self-closing mechanism and be properly sealed to prevent the passage of smoke and gases. The use of intumescent seals, which expand when exposed to heat, further enhances the fire resistance of the door assembly. Neglecting this aspect can negate the fire-resistance benefits of the walls and ceiling, creating a pathway for fire and smoke to enter the home.

The integration of these fire-resistant elements is essential when undertaking garage improvements. Compliance with local building codes is paramount, but exceeding minimum requirements can provide an added layer of safety. A well-planned and executed approach to fire resistance minimizes the risk of fire spread, protecting lives and property and demonstrating a commitment to safety.

5. Proper Sealing

Achieving a fully finished garage interior necessitates meticulous attention to sealing all gaps and penetrations. This practice directly impacts the effectiveness of insulation, the prevention of moisture intrusion, and the overall energy efficiency of the space. Improper sealing compromises the benefits gained from other improvements, such as insulation and fire-resistant materials.

- Air Leak Prevention

Sealing air leaks minimizes drafts and prevents conditioned air from escaping, reducing energy consumption and improving comfort within the garage. Gaps around windows, doors, and wall penetrations (pipes, wiring) are prime locations for air leakage. Caulking, weather stripping, and expanding foam are effective tools for addressing these issues. Addressing air leaks prevents heat loss in winter and heat gain in summer, thereby lowering utility bills and creating a more consistent temperature. For example, sealing gaps around an uninsulated garage door can significantly reduce heat loss during colder months.

- Moisture Barrier Enhancement

Proper sealing creates a barrier against moisture intrusion, preventing water damage, mold growth, and corrosion. Areas prone to moisture exposure, such as the foundation-wall interface and around plumbing fixtures, require careful sealing with waterproof materials. This proactive approach prevents water from seeping into the wall cavity, which can lead to structural damage and unhealthy living conditions. Sealing cracks in the foundation and applying a waterproof sealant to the base of the walls are examples of effective moisture control techniques. A practical scenario involves sealing a garage floor to prevent moisture from rising through the concrete, reducing the risk of mold growth on the walls.

- Pest Intrusion Mitigation

Sealing gaps and cracks prevents pests, such as insects and rodents, from entering the garage, protecting stored items and maintaining a sanitary environment. Small openings around pipes, wires, and the foundation provide entry points for pests seeking shelter and food. Caulking, expanding foam, and metal mesh can effectively seal these entry points, creating a barrier against unwanted intruders. For example, sealing gaps around a garage door and the foundation prevents rodents from nesting inside the walls. This practice is crucial in maintaining a clean and pest-free environment, particularly when storing food or other attractants in the garage.

- Fire Safety Enhancement

Proper sealing can impede the spread of fire and smoke, providing valuable time for occupants to evacuate and reducing property damage. Sealing gaps around electrical boxes, plumbing penetrations, and where the wall meets the ceiling or floor prevents flames and smoke from spreading through the wall cavity. Fire-rated caulk and expanding foam are specifically designed to resist heat and flame penetration. Properly sealing these areas can contain a fire within a limited space, preventing it from rapidly spreading to other parts of the building. An example would be sealing the gap between a garage and the house to limit the spread of smoke and give the homeowners valuable time to escape safely.

In summary, proper sealing is integral to successful work on garage interiors. It reinforces the benefits of insulation, protects against moisture and pests, and enhances fire safety. This comprehensive approach ensures a finished garage that is not only aesthetically pleasing but also energy-efficient, durable, and safe. Neglecting proper sealing compromises the overall quality and longevity of the completed project, diminishing its value and increasing the risk of future problems.

Frequently Asked Questions About Completing Garage Interiors

The following questions address common concerns and considerations regarding the finishing of garage walls.

Question 1: Is it necessary to insulate garage walls before finishing them?

Insulating garage walls is highly recommended, as it provides thermal regulation, reduces energy costs, and enhances the overall comfort of the space. Insulation also helps prevent moisture condensation, minimizing the risk of mold growth. However, the necessity of insulation may depend on local climate conditions and the intended use of the garage.

Question 2: What type of drywall is best suited for garage walls?

Type X drywall, which offers enhanced fire resistance, is generally recommended for garage walls, especially those adjacent to living spaces. Moisture-resistant drywall is also advisable, particularly in garages prone to humidity or water exposure.

Question 3: Are there specific building code requirements for finishing garage walls?

Yes, local building codes often dictate specific requirements for completing garage interiors. These requirements may include regulations regarding fire resistance, insulation, electrical wiring, and ventilation. Consultation with local building authorities is crucial to ensure compliance.

Question 4: How can moisture be prevented from damaging finished garage walls?

Several strategies can mitigate moisture damage, including the use of moisture-resistant materials, proper sealing of gaps and cracks, and adequate ventilation. The installation of a vapor barrier between the insulation and the interior wall finish is also recommended.

Question 5: Is it essential to hire a professional for finishing garage walls?

While it is possible to complete this project independently, engaging a professional contractor ensures proper installation and adherence to building codes. Professionals possess the expertise and tools to handle complex aspects of the project, such as electrical wiring and structural modifications.

Question 6: How does improving garage interiors impact property value?

Completing garage interiors typically increases property value by transforming an otherwise underutilized space into a functional and aesthetically pleasing area. A finished garage can enhance a property’s appeal to potential buyers and can serve as a valuable selling point.

These FAQs provide a foundational understanding of essential aspects related to improving garage interiors. Careful planning and execution, coupled with adherence to building codes, ensure a safe, functional, and valuable addition to any property.

The subsequent section will provide further guidance on specific techniques and resources for achieving a professionally finished garage space.

Concluding Remarks

The preceding exploration detailed significant considerations for how to finish walls in garage, underscoring the importance of framing integrity, insulation selection, material choice, fire resistance, and proper sealing. Adhering to these principles ensures a safe, functional, and aesthetically pleasing space that adds value to the property.

The meticulous completion of garage interiors represents a substantial investment in both property value and usability. Prioritizing code compliance and employing robust materials and techniques establishes a durable and lasting enhancement to the overall structure. Further consultation with building professionals may be beneficial to guarantee adherence to local regulations and optimal project outcomes.