The application of specialized surface treatments to metallic components destined for use in aircraft, spacecraft, and related equipment is a critical process. These treatments enhance the performance characteristics of the underlying metal, providing improved resistance to corrosion, wear, and extreme temperature fluctuations. For example, aluminum alloys used in aircraft wings are often treated to increase their hardness and prevent environmental degradation, ensuring structural integrity and extending service life.

The significance of this specialized field stems from the demanding operational environment of aerospace vehicles. Components are subjected to intense stress, wide temperature ranges, and potentially corrosive atmospheres. Surface treatments provide a crucial layer of defense, safeguarding against premature failure and ensuring operational safety. Historically, the development of more advanced alloys and increasingly sophisticated surface treatments has been a driving force in the advancement of aerospace technology, enabling the construction of lighter, stronger, and more durable aircraft.

The following sections will delve into the specific types of processes employed, the materials commonly treated, the rigorous quality control measures implemented, and the evolving landscape of environmentally conscious practices within this vital industry sector.

Essential Considerations for Surface Treatment of Aerospace Components

This section provides crucial guidelines for optimizing processes related to surface treatments for aerospace applications, ensuring component longevity and performance.

Tip 1: Material Selection is Paramount: Thoroughly evaluate the specific alloy being treated and its compatibility with the chosen process. Incompatible combinations can lead to unexpected degradation or compromised performance. For example, certain high-strength steels may be susceptible to hydrogen embrittlement during electroplating, requiring careful process control.

Tip 2: Precise Process Control is Non-Negotiable: Strict adherence to established process parameters is essential. Variations in temperature, current density, or chemical concentrations can significantly impact the quality and uniformity of the final coating. Implement robust monitoring and control systems to maintain process stability.

Tip 3: Surface Preparation is Critical: Adequate surface preparation is crucial for ensuring proper adhesion of the coating. Thorough cleaning, degreasing, and etching remove contaminants and create a suitable surface profile for optimal bonding. Inadequate preparation can lead to premature coating failure.

Tip 4: Coating Thickness Uniformity is Vital: Ensure consistent coating thickness across the entire component surface. Non-uniform coatings can create stress concentrations and compromise corrosion resistance. Implement appropriate racking techniques and process adjustments to achieve uniform deposition.

Tip 5: Rigorous Quality Control is Mandatory: Implement a comprehensive quality control program that includes regular inspections, non-destructive testing, and destructive testing (when appropriate). Verify coating thickness, adhesion, and corrosion resistance to ensure compliance with specifications.

Tip 6: Environmental Compliance is Essential: Adhere to all applicable environmental regulations and strive to minimize waste generation and hazardous chemical usage. Explore alternative, environmentally friendly processes and materials whenever possible.

Tip 7: Documentation and Traceability are Key: Maintain detailed records of all processes performed, including process parameters, materials used, and inspection results. Ensure full traceability of each component throughout the process chain.

Proper attention to material selection, process control, surface preparation, coating uniformity, and rigorous quality control are all indispensable elements for achieving superior results. Adhering to these guidelines minimizes risks, promotes product integrity, and ensures compliance with stringent aerospace standards.

The subsequent sections will address detailed aspects of the technologies and best practices applied in this field.

1. Corrosion Resistance

Corrosion resistance is a fundamental performance requirement for aerospace components. The operational environment exposes materials to a variety of corrosive agents, including salt spray, humidity, and atmospheric pollutants. The integrity of these components is paramount, necessitating specialized treatments to mitigate corrosion-related failures.

- Anodizing of Aluminum Alloys

Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of aluminum alloys. This thicker oxide layer provides a barrier against corrosive elements, preventing the underlying metal from degradation. A common example is the anodized aluminum skin of aircraft fuselages, which resists corrosion in harsh atmospheric conditions. The process ensures long-term structural integrity and reduces maintenance requirements.

- Cadmium Plating of Steel Components

Cadmium plating serves as a sacrificial coating on steel components, protecting the base metal from corrosion even if the coating is scratched or damaged. Cadmium corrodes preferentially, delaying the onset of steel corrosion. This is particularly important for fasteners and landing gear components, which are subject to high stress and exposure to corrosive environments. The ability to sacrificially protect extends the lifespan of critical parts.

- Passivation of Stainless Steel

Stainless steel is inherently corrosion-resistant due to its chromium content, which forms a passive oxide layer on the surface. Passivation treatments enhance this natural resistance by removing free iron from the surface, promoting the formation of a more uniform and stable chromium oxide layer. This process is critical for stainless steel tubing and hydraulic components used in aircraft systems, ensuring reliability and preventing leaks caused by corrosion.

- Application of Protective Coatings

Specialized paints and coatings provide a barrier against corrosive agents. These coatings can incorporate corrosion inhibitors and are formulated to withstand the extreme conditions encountered in aerospace applications. Examples include epoxy primers and polyurethane topcoats used on aircraft exteriors. These multilayer systems offer robust protection and extend the service life of airframes.

The selection and implementation of appropriate corrosion resistance techniques are vital to the performance and safety of aerospace vehicles. These methods, whether through controlled oxidation, sacrificial action, or barrier coatings, address the inherent vulnerability of metallic components to environmental degradation, ensuring the sustained functionality and airworthiness of aircraft and spacecraft.

2. Wear Reduction

Wear reduction is a crucial function of specialized surface treatments applied to aerospace components. The operational environments of aircraft and spacecraft subject metallic parts to significant frictional forces and abrasive conditions. Without effective wear reduction strategies, components would experience premature degradation, leading to increased maintenance, reduced operational lifespans, and potential safety risks. Treatments aim to minimize material loss due to friction, abrasion, erosion, and galling.

Surface treatments accomplish wear reduction through several mechanisms. Hard coatings, such as titanium nitride (TiN) applied via physical vapor deposition (PVD), increase the surface hardness of components, thereby enhancing resistance to abrasive wear. Lubricious coatings, like molybdenum disulfide (MoS2), reduce the coefficient of friction between contacting surfaces, minimizing frictional wear. Case hardening processes, such as carburizing or nitriding, increase the hardness of the surface layer while maintaining a tougher core, providing a balance between wear resistance and structural integrity. An example is the application of hard chrome plating to landing gear components, increasing their resistance to the abrasive forces encountered during landing and takeoff. Similarly, turbine blades operating in high-temperature, high-speed environments may receive specialized coatings to minimize erosion from particulate matter.

In summary, wear reduction is an integral aspect of aerospace materials engineering. The specific process selected depends on factors such as the base metal, the operating environment, and the type of wear mechanism prevalent in a given application. The implementation of effective strategies directly contributes to enhanced component durability, extended service life, and improved safety in demanding aerospace applications. The ongoing development of more advanced surface treatment technologies promises to further mitigate wear and enhance the performance of future aerospace systems.

3. Surface Hardness

Surface hardness is a critical property directly influenced by processes in aerospace metal finishing. It dictates a component’s ability to resist deformation, indentation, and wear, thereby influencing its lifespan and performance in demanding aerospace applications.

- Enhancing Wear Resistance

Increased surface hardness directly translates to improved wear resistance. Components such as gears, bearings, and sliding surfaces are particularly susceptible to wear. Surface treatments that enhance hardness, like nitriding or carburizing, significantly extend the service life of these parts. An example includes the hardened surfaces of aircraft engine turbine blades, which withstand the abrasive effects of high-speed gas flow and particulate matter.

- Improving Fatigue Strength

Surface hardness plays a role in improving fatigue strength. Hardening processes can induce compressive residual stresses at the surface, which counteract tensile stresses generated during cyclic loading. This is particularly important for airframe components subject to repeated stress cycles during flight. Shot peening, a surface treatment used to increase hardness and induce compressive stresses, is a common technique applied to wing structures and landing gear.

- Protecting Against Foreign Object Damage (FOD)

Surface hardness enhances resistance to damage from foreign objects. Debris, such as stones or tools, can impact aircraft components, causing scratches, dents, and potential structural damage. Hard coatings, like titanium nitride (TiN), applied via physical vapor deposition (PVD), provide a robust barrier against FOD. These coatings are often applied to critical engine components and flight control surfaces.

- Enabling Tighter Tolerances and Improved Functionality

Surface hardness enables the maintenance of tighter tolerances and improved functionality. Components that experience wear or deformation can deviate from their specified dimensions, leading to reduced performance or even failure. Hardening treatments ensure dimensional stability, enabling components to maintain their intended shape and function throughout their service life. This is particularly relevant for precision instruments, actuators, and hydraulic systems.

The application of surface treatments to enhance hardness represents a crucial aspect of aerospace metal finishing. By improving wear resistance, fatigue strength, and resistance to FOD, these treatments contribute significantly to the reliability, durability, and safety of aircraft and spacecraft components. The selection of appropriate hardening processes is dictated by the specific requirements of the application, the base metal properties, and the operating environment. These processes enhance the performance characteristics of the underlying metal, ensuring structural integrity and extending service life.

4. Fatigue Strength

Fatigue strength, the ability of a material to withstand cyclic loading without failure, is a paramount concern in aerospace engineering. Aerospace metal finishing processes play a crucial role in enhancing or, if improperly executed, diminishing this critical property. The repetitive stress experienced by aircraft components during flight, from engine vibrations to aerodynamic forces on wings, makes fatigue a primary cause of structural failure. Therefore, the selection and meticulous application of appropriate processes are non-negotiable for ensuring airworthiness.

Surface treatments, such as shot peening, are specifically designed to improve fatigue life by introducing compressive residual stresses on the surface of a metal part. These compressive stresses counteract the tensile stresses induced by cyclic loading, thereby delaying the initiation and propagation of fatigue cracks. Conversely, processes like certain types of improper welding or uncontrolled grinding can introduce tensile residual stresses, significantly reducing fatigue strength. Anodizing, while beneficial for corrosion resistance, can also negatively impact fatigue life in certain alloys if not carefully controlled to prevent the formation of micro-cracks. Real-life examples include wing spars, landing gear components, and turbine blades, all of which undergo specific processes to maximize their ability to endure repeated stress cycles. Proper coating adhesion, another facet of these processes, prevents delamination that can act as a fatigue crack initiation point.

In conclusion, the intersection of fatigue strength and aerospace metal finishing is a complex and critical area. The correct application of surface treatments is essential for enhancing the fatigue resistance of aerospace components and ensuring structural integrity. Conversely, poorly controlled or inappropriate processes can have detrimental effects, leading to premature failure and potential catastrophic consequences. A thorough understanding of the effects of each process on the fatigue behavior of specific alloys is therefore imperative for maintaining the safety and reliability of aircraft and spacecraft.

5. Thermal Protection

The relationship between thermal protection and aerospace metal finishing is pivotal for the sustained operation and survival of spacecraft and high-speed aircraft. Metal finishing techniques are not merely cosmetic enhancements; they are often critical for enabling thermal management strategies that safeguard structural integrity and prevent catastrophic failure. The extreme thermal environments encountered during atmospheric reentry or high-speed flight necessitate specialized surface treatments designed to either reflect, absorb, or dissipate heat, depending on the specific application. For instance, the Space Shuttle relied on ceramic tiles, a form of advanced metal finishing, to protect its aluminum airframe from the intense heat generated during reentry into Earth’s atmosphere. The absence or degradation of these tiles could lead to localized overheating and structural damage. Similarly, hypersonic vehicles employ specialized coatings, often involving complex multi-layer systems, to manage heat flux and prevent material ablation. These coatings require precise application and adherence to strict specifications to ensure they perform as intended.

Further, the effective implementation of thermal protection measures through metal finishing is not limited to external surfaces. Internal components, such as engine parts and hydraulic systems, are also subject to extreme temperature gradients. Processes like thermal barrier coatings (TBCs) applied to turbine blades in jet engines are critical for allowing the engines to operate at higher temperatures, thus increasing efficiency and thrust. These TBCs are often composed of ceramic materials that are deposited onto the metal substrate using sophisticated techniques, requiring precise control over composition, thickness, and microstructure. The selection of appropriate metal finishing techniques for thermal protection also depends on factors such as the material properties of the underlying substrate, the anticipated operating temperatures, and the duration of exposure to extreme thermal conditions. The application of these coatings must be carefully integrated into the overall design process, taking into account factors such as thermal expansion coefficients and potential for thermal stress.

In conclusion, thermal protection represents a vital function within the broader context of aerospace metal finishing. Its success hinges on the precise selection and application of appropriate processes that address specific thermal challenges. Failures in thermal protection can have severe consequences, ranging from reduced component lifespan to catastrophic mission failure. As aerospace technology advances, the demand for more sophisticated and effective thermal management solutions will continue to drive innovation in the field of aerospace metal finishing. Meeting these demands requires a multidisciplinary approach, combining expertise in materials science, thermal engineering, and manufacturing processes to develop and implement cutting-edge thermal protection technologies.

Frequently Asked Questions Regarding Aerospace Metal Finishing

This section addresses common inquiries concerning aerospace metal finishing, offering concise and authoritative answers to enhance understanding.

Question 1: What distinguishes aerospace metal finishing from general metal finishing processes?

Aerospace metal finishing adheres to significantly more stringent quality control standards and material specifications than general metal finishing. This is due to the critical performance and safety requirements of aerospace components. Processes are typically more tightly controlled, and materials are subject to rigorous testing to ensure compliance with industry and regulatory standards.

Question 2: Why is surface preparation so crucial in aerospace metal finishing?

Surface preparation is paramount to ensure proper adhesion of the applied coating or treatment. Any contaminants or imperfections on the substrate surface can compromise the integrity of the finish, leading to premature failure and potentially catastrophic consequences. Thorough cleaning, degreasing, and etching are essential steps.

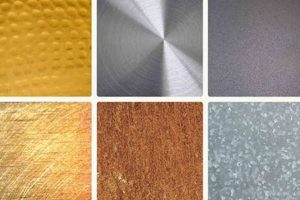

Question 3: What are some common types of surface treatments used in the aerospace industry?

Common surface treatments include anodizing (for aluminum alloys), cadmium plating (for steel), passivation (for stainless steel), application of protective coatings (paints, epoxies, polyurethanes), and thermal spray coatings. The specific treatment selected depends on the material, the application, and the performance requirements.

Question 4: How does aerospace metal finishing contribute to corrosion resistance?

Corrosion resistance is a primary objective. Finishes act as a barrier, preventing corrosive agents from reaching the underlying metal. Sacrificial coatings, like cadmium, corrode preferentially, protecting the base metal. Passivation enhances the natural corrosion resistance of stainless steel.

Question 5: What role does non-destructive testing (NDT) play in aerospace metal finishing?

NDT methods are routinely employed to verify the quality and integrity of the applied finish without damaging the component. Techniques like ultrasonic testing, eddy current testing, and X-ray radiography are used to detect defects, measure coating thickness, and assess adhesion.

Question 6: How are environmental regulations impacting the aerospace metal finishing industry?

Environmental regulations are driving the development and adoption of more sustainable processes and materials. Efforts are underway to replace hazardous substances like hexavalent chromium with less toxic alternatives and to minimize waste generation through process optimization and recycling. Compliance with regulations is essential for maintaining operational permits and minimizing environmental impact.

These responses offer a foundational understanding. Deeper exploration of specific processes and applications is recommended for a more comprehensive perspective.

The subsequent section will address case studies highlighting the impact.

Aerospace Metal Finishing

This exploration has elucidated the indispensable role of aerospace metal finishing in ensuring the performance, longevity, and safety of aircraft and spacecraft. The processes involved, characterized by stringent standards and precise execution, directly impact critical properties such as corrosion resistance, wear reduction, fatigue strength, and thermal protection. The specific treatments employed, ranging from anodizing and cadmium plating to advanced thermal barrier coatings, are tailored to the unique demands of each application and material.

Given the ever-evolving landscape of aerospace technology and the increasing emphasis on sustainability, ongoing research and development in this field are paramount. Further innovation in materials, processes, and quality control measures will be essential to meet the challenges of future aerospace endeavors and to uphold the highest standards of safety and reliability. The industry must continue to prioritize rigorous process control, adherence to environmental regulations, and a relentless pursuit of improved performance characteristics.

![Top Asheville Metal Finishing: [Your Brand] Quality Best Final Touch: Elevate Your Projects with Professional Finishing Top Asheville Metal Finishing: [Your Brand] Quality | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-666-300x200.jpg)