A natural substance created by honeybees, this material serves as a protective and aesthetic coating for wooden surfaces. It’s a solid at room temperature but softens with heat, allowing for easy application. Commonly used in furniture restoration and woodworking, it provides a lustrous sheen and enhances the wood’s natural grain.

The advantages of employing this treatment include its non-toxic nature and ease of application. It creates a barrier against moisture and minor scratches, extending the lifespan of treated items. Its historical usage dates back centuries, prized for its ability to protect and beautify wood, proving its long-standing value in wood preservation.

The subsequent sections will delve into specific application techniques, detailing preparation methods, optimal usage scenarios, and maintenance procedures for surfaces treated with this time-tested material.

Application and Maintenance Guidance

The following guidelines ensure optimal results and longevity when using this natural treatment for wooden surfaces.

Tip 1: Surface Preparation is Paramount. Prior to application, the wood must be clean, dry, and free of existing finishes. Sanding to a smooth surface, followed by thorough dust removal, ensures proper adhesion.

Tip 2: Employ a Soft Cloth or Brush. Application should be performed using a clean, lint-free cloth or a natural-bristle brush. This prevents contamination and allows for even distribution.

Tip 3: Apply Thin, Even Coats. Overapplication can result in a sticky or uneven finish. Multiple thin coats, allowed to dry between applications, are preferable.

Tip 4: Buff to a Lustrous Sheen. After the final coat has dried, buff the surface with a clean, soft cloth to achieve the desired level of gloss. Manual buffing is recommended for optimal control.

Tip 5: Reapplication as Needed. The frequency of reapplication depends on usage and environmental factors. Regularly inspect the surface and reapply when the finish appears dull or worn.

Tip 6: Avoid Harsh Cleaners. Maintain the finish by dusting regularly and wiping with a damp cloth. Abrasive cleaners or solvents can damage the coating and the wood beneath.

Tip 7: Consider Environmental Conditions. Extreme temperature fluctuations and humidity levels can affect the finish. Implement climate control measures where appropriate.

Adherence to these recommendations will yield a durable, aesthetically pleasing finish that enhances and protects wooden items.

The subsequent section will summarize key benefits and suggest appropriate use cases for this traditional wood finishing technique.

1. Natural Composition

The natural composition is a defining characteristic when using the product for wood finish, fundamentally influencing its properties, application, and long-term effects on treated surfaces. This aspect distinguishes it from synthetic alternatives, impacting both environmental considerations and the aesthetic qualities of the final finish.

- Source Material Purity

The raw product, derived from honeycomb structures, consists primarily of esters of fatty acids and various long-chain alcohols. Impurities, such as pollen or propolis, can affect the color and texture of the finish. The degree of purity directly correlates with the clarity and smoothness of the resulting coating. For instance, a finish derived from highly filtered material will typically exhibit a cleaner, more transparent appearance on light-colored woods.

- Absence of Volatile Organic Compounds (VOCs)

Unlike many synthetic wood finishes, a characteristic element of this approach is the lack of VOCs. This characteristic results in significantly reduced off-gassing, creating a healthier environment during application and subsequent use. For example, its use in children’s toys or furniture is favored due to this low toxicity profile, minimizing potential exposure to harmful chemicals.

- Biodegradability and Sustainability

Being a natural product, it exhibits biodegradability, reducing its environmental impact upon disposal. Sustainable harvesting practices further enhance its ecological profile. An example of this is the use of it from apiaries that prioritize bee health and responsible harvesting methods, ensuring the continued availability of the resource without harming bee populations.

- Interaction with Wood Fibers

The natural waxes penetrate the wood fibers to a limited extent, providing a degree of protection from moisture and minor scratches. This interaction enhances the wood’s natural grain and luster without forming a thick, impermeable layer. Consider its use on fine wood furniture, where the aim is to enhance the natural beauty of the wood rather than creating a high-gloss, plastic-like finish.

The combined effect of these facets underscores the significance of its natural composition. This characteristic not only defines its inherent properties but also governs its application, environmental impact, and the overall aesthetic achieved on treated wooden surfaces. This highlights a preference for natural, sustainable materials in woodworking and furniture finishing.

2. Protective Barrier

A crucial function served by the application of this material to wooden surfaces is the creation of a protective barrier. The deposition of this barrier serves as a primary defense against environmental factors and physical damage. This relationship operates through the wax’s hydrophobic properties, resisting the penetration of water and moisture. For example, in wooden furniture exposed to fluctuating humidity levels, this barrier mitigates the risk of warping, cracking, and fungal growth, extending the lifespan of the item. The importance of this protective component lies in its ability to shield the underlying wood structure from degradation, preserving its structural integrity and aesthetic appeal.

Further, the wax’s inherent properties provide a degree of resistance to minor scratches and abrasions. While not impenetrable, the wax layer absorbs some of the impact, preventing damage to the wood substrate. This is particularly relevant for surfaces subjected to regular use, such as tabletops or wooden toys. As an illustrative example, application to a wooden countertop provides a temporary shield against incidental scratches caused by everyday items, thus maintaining the surface’s appearance over time. This functionality underscores the practical significance of understanding this relationship; it is not merely an aesthetic choice, but a practical measure to prolong the life and maintain the condition of wooden objects.

In summary, the protective barrier formed from applying the product is a multifaceted benefit. It defends against moisture, minimizes minor physical damage, and preserves structural integrity and aesthetic qualities. Despite its limitations in providing absolute protection, it offers a tangible advantage in mitigating the effects of environmental factors and daily wear. This characteristic makes it a desirable choice for preserving and protecting a variety of wooden artifacts. While challenges remain in enhancing its durability for high-traffic areas, its proven effectiveness under normal conditions remains a valuable aspect in wood conservation.

3. Aesthetic Enhancement

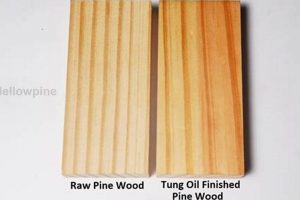

The application of this treatment to wooden surfaces results in a significant aesthetic enhancement. This enhancement stems from its capacity to both accentuate the inherent beauty of the wood grain and impart a subtle, lustrous sheen. The wax penetrates the surface, enriching the color and providing depth to the wood’s natural patterns. For example, on oak furniture, the application of this material highlights the characteristic medullary rays, creating a visually appealing effect. This highlights its importance as it transforms raw or unfinished wood into polished, visually engaging pieces.

Furthermore, the finish contributes to a tactile improvement, imparting a smooth, silky feel to the treated surface. This tactile quality enhances the overall sensory experience, adding a layer of refinement to the wood. Consider, for instance, the application to hand-carved wooden items; here, the smooth finish not only protects the intricate details but also invites interaction. This sensory dimension adds to its value as a finishing treatment, moving beyond mere visual appeal to encompass a more complete sensory satisfaction. This demonstrates the practical application of integrating aesthetic and tactile elements.

In summary, aesthetic enhancement through the utilization of this substance extends beyond surface-level polishing. It involves a transformation that highlights the inherent characteristics of the wood, creates an appealing visual effect, and enhances the tactile experience. While maintaining the desired level of sheen and preserving its tactile smoothness may require periodic reapplication, the aesthetic benefits justify its use in woodworking and furniture finishing. The understanding of this aesthetic element is key to leveraging this material to its fullest potential.

4. Application Simplicity

The straightforward application process is a significant advantage of this material as a wood finish. Its user-friendliness renders it accessible to both experienced craftspeople and novice woodworkers, broadening its potential for use in various settings.

- Minimal Pre-treatment Requirements

Unlike many synthetic finishes that demand rigorous surface preparation, the wax requires only basic cleaning and sanding to ensure proper adhesion. This reduced preparatory work translates to time savings and simplifies the overall finishing process. For instance, on a previously unfinished wooden surface, a light sanding is often sufficient before applying the wax. This ease of preparation enhances its appeal for quick projects or repairs.

- Direct Application Method

The wax is typically applied directly to the wood surface using a cloth or brush. This direct application eliminates the need for specialized equipment such as spray guns or complex mixing procedures. An example includes the restoration of antique furniture, where the wax can be easily rubbed onto the surface to protect and enhance the existing patina. This method significantly contributes to its accessibility, minimizing the learning curve and equipment investment.

- Buffing for Desired Sheen

Achieving the desired level of gloss is typically accomplished through manual buffing, eliminating reliance on power tools or specialized techniques. The degree of sheen is directly controlled by the intensity and duration of the buffing process. For example, a light buffing will produce a subtle satin finish, while a more vigorous buffing will yield a higher gloss. This user-controlled finish allows for customization based on specific preferences.

- Easy Reapplication

Maintaining the finish involves a simple process of cleaning and reapplying the wax as needed. The ease of reapplication makes it ideal for maintaining the appearance and protection of wooden surfaces over time. Should a table’s surface exhibit wear, a renewed coating of the wax can be applied and buffed, thus restoring the finish without complete refinishing. This cyclical pattern contributes to its long-term viability as a wood finishing option.

The combination of minimal pre-treatment, direct application, simple buffing techniques, and ease of reapplication underscores its significance as a readily applicable wood finish. The reduced complexity translates to time efficiency, lower equipment costs, and accessibility for a broad range of users. These benefits enhance its appeal in both professional woodworking and DIY projects, making it a viable alternative to more complex finishing systems.

5. Restoration Usage

The application of this material in the restoration of wooden artifacts is a widespread practice, prized for its gentle approach and ability to revive and protect aged surfaces without causing irreversible alterations. It functions not only as a protective coating but also as a means to subtly enhance the aesthetic qualities of antique pieces, making it a valuable tool for conservators and restoration professionals.

- Reversibility and Minimal Intervention

A primary benefit in restoration is its reversibility. Unlike permanent synthetic finishes, the wax can be removed without damaging the original surface. This aligns with conservation ethics that prioritize minimal intervention. For example, if an antique table has been inappropriately refinished, the wax can be carefully removed to reveal and preserve the original patina. This principle supports ethical conservation practices.

- Surface Consolidation and Protection

The wax penetrates porous wood surfaces, consolidating weakened fibers and providing a protective barrier against moisture and pollutants. This is particularly useful for aged wood, which can become brittle and susceptible to damage. Its application to a delicate, flaking veneer on a historical cabinet can stabilize the surface and prevent further deterioration. This consolidates and protects the structural integrity of fragile items.

- Enhancement of Existing Patina

Rather than covering or altering the original surface, this treatment enhances the existing patina, preserving the historical character of the piece. The wax accentuates the natural aging of the wood, adding depth and richness to the color. Its application to a well-worn antique chair can rejuvenate the finish while retaining the signs of age that contribute to its value. This is a non-invasive method that preserves the unique aspects of historical value.

- Compatibility with Traditional Techniques

This substance aligns with traditional woodworking and finishing techniques, making it compatible with the materials and methods used in the original construction of antique furniture. This avoids the introduction of incompatible substances that could cause long-term damage. The use of it on a 18th-century desk would be consistent with the finishing methods employed at the time, ensuring a harmonious restoration. This demonstrates a respect for traditional materials and processes.

The facets of reversibility, surface consolidation, patina enhancement, and compatibility with traditional techniques underscore its suitability in restoration. It allows for a gentle and respectful approach to preserving wooden artifacts, ensuring that their historical integrity and aesthetic value are maintained for future generations. Its role in this field goes beyond simple refinishing, instead representing a commitment to conservation and the preservation of cultural heritage.

6. Maintenance Requirements

The longevity and appearance of wooden surfaces treated with this material are directly contingent upon adherence to appropriate maintenance protocols. The nature of the finish dictates that it is not a permanent, one-time application; rather, it requires periodic attention to sustain its protective and aesthetic qualities. This necessity arises from the inherent properties of the wax itself, which, while providing a barrier against moisture and minor abrasions, is susceptible to wear and degradation over time. For instance, a dining table finished with this substance and subjected to daily use will invariably require more frequent maintenance compared to a decorative item displayed in a low-traffic environment. The cause of this differential lies in the effects of constant handling, cleaning, and exposure to varying temperatures, all of which compromise the integrity of the wax layer.

Regular dusting, periodic cleaning with a gentle, pH-neutral cleaner, and subsequent reapplication of the wax are essential maintenance steps. The absence of these procedures precipitates a gradual decline in the finish’s effectiveness, manifesting as a dulling of the sheen, increased susceptibility to scratches, and potential water damage. Consider the scenario of a wooden floor treated with this wax; without regular care, the finish will wear thin, exposing the wood to moisture and increasing the risk of warping or staining. Consistent monitoring of the finish’s condition allows for timely intervention, preventing extensive damage and minimizing the need for costly restoration work. Furthermore, the application technique during maintenance is as critical as the frequency; thin, even coats are preferable to thick, uneven applications, promoting uniform protection and avoiding a sticky or clouded appearance.

In summary, the maintenance requirements are an integral component of achieving satisfactory and enduring results with this finish. Understanding the factors that contribute to its degradation and implementing a proactive maintenance strategy is paramount. Although the relatively simple application is a significant benefit, the ongoing need for upkeep must be acknowledged. Adhering to established best practices for cleaning and reapplying this product ensures the continued preservation and aesthetic enhancement of wooden surfaces, optimizing the investment in both material and labor.

7. Historical Significance

The historical context of material use in woodworking underscores its enduring utility and value. Its presence across diverse cultures and time periods reveals a consistent recognition of its protective and aesthetic properties.

- Ancient Civilizations and Usage

Evidence indicates that ancient civilizations, including the Egyptians and Romans, employed wax for various purposes, including the protection of wooden artifacts. Excavations have uncovered objects with wax coatings, demonstrating its early adoption as a sealant and preservative. This historical application reveals an early understanding of its ability to protect against moisture and decay.

- Medieval Craftsmanship and Applications

During the medieval period, craftspeople routinely incorporated wax into furniture making and woodworking. Guild records detail its use in finishing techniques for both practical and decorative purposes. Armorers employed wax coatings to protect wooden components of shields and other military equipment. Its application in this era confirms its established role as a versatile material in craft traditions.

- Renaissance Furniture and Polishing Techniques

Renaissance artisans elevated the use of wax in furniture making, employing sophisticated polishing techniques to achieve lustrous finishes. Detailed treatises from the period describe methods for preparing and applying the wax to enhance the grain and color of the wood. The elaborate furniture pieces from this era exhibit the refinement of this finishing method, highlighting its aesthetic contribution.

- 18th and 19th Century Applications

Throughout the 18th and 19th centuries, wax remained a staple in furniture finishing and restoration. Cabinet makers and restorers continued to rely on it for its gentle protective properties and ability to revive aged surfaces. Its continued use through these centuries testifies to its enduring practicality and reliability in wood preservation.

The consistent utilization of this wax across centuries and cultures affirms its historical significance as a wood finishing material. From ancient protective coatings to refined Renaissance techniques, its legacy reflects its adaptability and enduring value in preserving and enhancing wooden objects. Its ongoing use in modern restoration practices underscores its timeless relevance.

Frequently Asked Questions About Bees Wax for Wood Finish

The following section addresses common inquiries and misconceptions regarding the application, performance, and maintenance of this natural material used to protect and enhance wood surfaces.

Question 1: What are the primary limitations of this finish compared to synthetic alternatives?

While it provides a protective barrier against moisture and minor abrasions, this material offers limited resistance to heat, chemicals, and heavy wear. Synthetic finishes generally exhibit superior durability and resistance to these factors.

Question 2: How frequently should surfaces treated with this material be re-coated?

The reapplication frequency depends on usage and environmental conditions. Surfaces subjected to heavy use or exposed to direct sunlight or moisture may require reapplication every few months, while low-traffic items may only need treatment annually.

Question 3: Is this material suitable for outdoor use?

It is generally not recommended for outdoor applications due to its limited UV resistance and vulnerability to extreme weather conditions. Exposure to direct sunlight can cause the wax to melt or degrade, compromising its protective properties.

Question 4: Can this product be applied over existing finishes?

Its effectiveness is maximized when applied directly to bare wood. Applying it over existing finishes may result in poor adhesion and an uneven appearance. The existing finish should ideally be removed prior to application.

Question 5: What cleaning products are safe to use on surfaces treated with this material?

Only gentle, pH-neutral cleaning solutions are recommended. Harsh chemicals, abrasive cleaners, and solvents can damage the wax finish and the wood beneath. A damp cloth is often sufficient for routine cleaning.

Question 6: How does the cost of it compare to other wood finishing options?

The cost of this product is typically lower than that of many synthetic finishes, although this can vary depending on the quality and purity of the wax. However, the need for more frequent reapplication may offset the initial cost savings over time.

In summary, while offering a natural and aesthetically pleasing finish, this product requires careful consideration of its limitations and appropriate maintenance practices.

The subsequent section will explore case studies demonstrating the successful application and long-term performance of this material in various woodworking projects.

Conclusion

The preceding examination of this natural material underscores its multifaceted utility in wood finishing. From its protective properties to its capacity for aesthetic enhancement, and from its historical significance to its accessibility, its value is evident. However, a comprehensive understanding of its limitations, appropriate applications, and maintenance requirements is crucial for achieving desired outcomes.

The sustained relevance of this finish, despite the advent of synthetic alternatives, points to a continuing appreciation for natural materials and traditional woodworking practices. Future utilization will likely hinge on balancing its environmental benefits and aesthetic qualities with the practical demands of durability and longevity, ensuring its ongoing role in preserving and enhancing wooden artifacts.