This specific finishing process results in a distinctive aesthetic often characterized by a particular color and texture achieved through specialized chemical treatments or coating applications. As an example, architectural hardware frequently undergoes this procedure to enhance its durability and visual appeal.

The significance of this treatment lies in its ability to provide increased resistance to corrosion, wear, and environmental factors, extending the lifespan of the treated item. Historically, this type of surface treatment has been employed to improve both the functional performance and the perceived value of various products, ranging from consumer goods to industrial components.

Understanding the properties and applications of this type of finish is crucial for informed decision-making across diverse fields. Subsequent sections will delve into the specifics of its composition, application techniques, and comparative advantages within various industries.

Achieving Optimal Results

The following guidelines are intended to provide practical advice for maximizing the effectiveness and longevity of items treated with this particular finish. Adherence to these recommendations will ensure sustained performance and aesthetic integrity.

Tip 1: Surface Preparation is Critical: Prior to application, ensure the substrate is thoroughly cleaned and free from contaminants such as oil, grease, or rust. Inadequate preparation can compromise adhesion and lead to premature failure.

Tip 2: Controlled Application Environment: Maintain a consistent temperature and humidity level during the application process. Environmental variations can affect the uniformity and quality of the finish.

Tip 3: Adhere to Recommended Thickness: Apply the coating within the manufacturer’s specified thickness range. Insufficient coating may provide inadequate protection, while excessive thickness can lead to cracking or peeling.

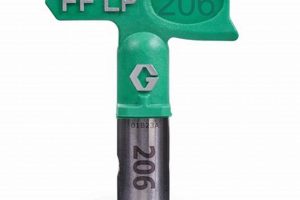

Tip 4: Utilize Appropriate Application Equipment: Select the correct spray gun, brush, or roller based on the type of coating being applied and the size of the surface area. Using improper equipment can result in an uneven or inconsistent finish.

Tip 5: Implement Regular Cleaning Protocols: Establish a routine cleaning schedule using mild, non-abrasive cleaning agents. This prevents the accumulation of dirt and grime, which can dull the finish and accelerate degradation.

Tip 6: Avoid Harsh Chemicals and Abrasives: Refrain from using strong solvents, acids, or abrasive cleaners, as these can damage the coating and reduce its protective properties. Opt for pH-neutral cleaning solutions whenever possible.

Tip 7: Implement Preventative Maintenance: Periodically inspect the finish for signs of damage, such as scratches, chips, or corrosion. Promptly address any issues to prevent further deterioration and extend the lifespan of the coating.

By implementing these guidelines, users can maximize the benefits of this specific finish, ensuring long-lasting protection and an enhanced aesthetic appearance.

The subsequent sections will explore common issues, and troubleshooting related to this finish.

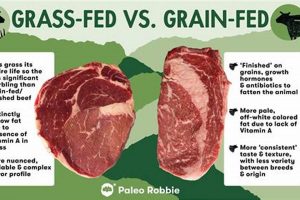

1. Appearance

The resultant visual characteristic is a primary attribute of components treated with this finish. The “Appearance” dictates initial impressions and can influence perceived value. The finishing process directly affects surface reflectivity, color, and texture. For example, in architectural applications, the selection of this treatment may be driven by its ability to provide a consistent, non-glare surface for optimal visibility under various lighting conditions. The process impacts product aesthetics. This treatment is selected to achieve a particular look.

Variations in the application process can yield different visual outcomes. A brushed may offer a matte, directional appearance, whereas a polished process achieves a high-gloss, reflective surface. The choice depends on specific design requirements and functional needs. Moreover, the consistency and uniformity of the appearance is a key indicator of quality control in the application process. Parts manufactured in consistent way contribute to high-quality products.

In summary, the achievable visual outcome of this surface preparation is central to its appeal. Considerations of reflectivity, color, and texture are critical factors in material selection and application. Ultimately, the desired finished look drives the specific application techniques and quality control measures implemented during the treatment process.

2. Corrosion Resistance

Corrosion resistance is a critical performance attribute conferred by surface treatments. In the context, this parameter dictates the lifespan and operational reliability of treated components exposed to corrosive environments.

- Protective Barrier Formation

A primary function of this treatment is the creation of a robust barrier between the substrate material and the external environment. This barrier mitigates direct contact with corrosive agents such as moisture, salts, and atmospheric pollutants. In marine applications, for example, components treated with this method exhibit extended service life compared to untreated counterparts, where direct contact with ocean salt causes accelerated corrosion.

- Electrochemical Protection

The application may involve the introduction of a sacrificial layer that preferentially corrodes, protecting the underlying substrate. This electrochemical protection mechanism, analogous to galvanic protection, is particularly effective in preventing localized corrosion, such as pitting. For example, using aluminum as a protective layer where the corrosion happens on the aluminum instead of the steel.

- Passivation Enhancement

In materials that naturally form a passive layer (e.g., stainless steel), this finishing technique can enhance the stability and effectiveness of this layer. By promoting the formation of a more uniform and adherent passive film, this method increases resistance to corrosion initiation and propagation. This technique allows the metal to withstand environmental stress.

- Surface Modification

The treatment can alter the surface chemistry and microstructure of the substrate, making it inherently more resistant to corrosion. This modification may involve creating a hydrophobic surface, which repels water and reduces the potential for moisture-induced corrosion. For example, some products using this coating have high water resistance.

Collectively, these mechanisms contribute to the enhanced corrosion resistance offered by this type of surface preparation. The specific combination of protective mechanisms will vary depending on the composition and application process, but the overarching goal remains consistent: to prolong the service life of treated components in challenging environments.

3. Durability

The concept of durability, in the context of this specific finish, refers to the capacity of a treated component to withstand wear, abrasion, impact, and other forms of mechanical stress without significant degradation of its functional or aesthetic properties. The application of this finishing technique directly contributes to increased durability by creating a protective layer that shields the underlying material from external forces. For example, tools treated with this finishing process exhibit extended operational lifespans, resisting scratches and surface damage that would otherwise compromise their performance. This enhanced resistance translates to reduced maintenance costs and prolonged product longevity.

Further analysis reveals that the level of durability achieved is directly influenced by the specific composition of the finishing material and the adherence to strict application protocols. Variations in these parameters can result in significant differences in the resulting protective capabilities. Consider, for instance, the automotive industry, where components exposed to harsh road conditions and environmental factors require exceptional durability. Properly executed surface preparation applications ensure that these components maintain their structural integrity and aesthetic appeal, even under extreme operating conditions. Practical applications are far-reaching.

In summary, durability is a paramount consideration when selecting this particular finish. It is a key determinant of a component’s ability to withstand environmental and mechanical stresses, thus ensuring long-term performance and cost-effectiveness. Understanding the relationship between the treatment and the resultant durability is crucial for engineers and designers aiming to optimize product lifespan and minimize maintenance requirements. The treatment improves the quality of any material.

4. Application Method

The method by which this finish is applied significantly influences its ultimate performance and aesthetic characteristics. Variations in application techniques, such as spraying, dipping, or powder coating, directly impact the uniformity, thickness, and adhesion of the finish to the substrate material. For instance, an uneven application can lead to inconsistencies in corrosion resistance and accelerated wear in localized areas. Therefore, selecting an appropriate application method is a critical determinant of the overall quality and durability of the final product.

Consider the case of applying this type of surface treatment to intricate components with complex geometries. Spray application, employing electrostatic deposition, is often preferred to ensure complete coverage and minimal material waste. Alternatively, for high-volume production of simpler parts, dipping may be a more efficient and cost-effective option. Understanding the specific requirements of the component and the capabilities of each application method is essential for achieving optimal results. Improper application may lead to problems.

In conclusion, the application method is an integral component of this finishing process, dictating not only the visual outcome but also the protective qualities of the treatment. Adherence to established protocols and careful selection of the appropriate technique are paramount for achieving consistent, high-quality results. Addressing challenges associated with specific application methods, such as controlling overspray or maintaining uniform coating thickness, is crucial for ensuring the long-term performance and aesthetic integrity of treated components. Future research may explore new application technologies to further improve the efficiency and effectiveness of this treatment.

5. Material Compatibility

Material compatibility represents a critical consideration when implementing this specific finish. The successful application and performance of this treatment are intrinsically linked to the underlying substrate material’s properties and its interaction with the applied coating. Careful assessment of compatibility ensures optimal adhesion, corrosion resistance, and overall durability.

- Substrate Adhesion

The ability of the finish to effectively bond to the substrate material is paramount. Incompatibility can lead to poor adhesion, resulting in peeling, cracking, or premature failure of the coating. For example, applying this finish designed for steel to a polymer substrate will likely result in poor adhesion due to differing surface energies and chemical properties. Proper surface preparation and primer selection are essential for promoting strong adhesion across diverse material types.

- Chemical Reactivity

Chemical reactions between the finish and the substrate can compromise the integrity of either or both materials. In some instances, the finish may promote corrosion of the substrate, negating its intended protective effect. For instance, applying an acidic finish to a zinc-based alloy may induce galvanic corrosion. Thorough testing and material selection are necessary to avoid such adverse reactions.

- Thermal Expansion Mismatch

Differences in the thermal expansion coefficients of the finish and the substrate can induce stress at the interface, particularly under fluctuating temperature conditions. This stress can lead to cracking, delamination, or loss of adhesion. Consider a scenario where a rigid finish with a low expansion coefficient is applied to a substrate with a high expansion coefficient. During thermal cycling, the substrate will expand and contract more significantly than the finish, leading to stress concentration and eventual failure. Careful material selection and application techniques can mitigate these effects.

- Surface Properties

The substrate’s native surface characteristicsroughness, porosity, and surface energyinfluence the finish’s ability to wet, spread, and adhere effectively. An overly rough or contaminated surface may impede uniform coverage, while a low-energy surface may repel the finish, preventing proper bonding. Surface pre-treatments, such as etching, cleaning, or application of adhesion promoters, are often necessary to optimize surface properties for compatibility. Some surfaces can cause blistering.

In summary, the selection of materials for both the substrate and the finishing treatment must be carefully considered in relation to each other. Successful implementation requires a thorough understanding of the physical, chemical, and mechanical properties of both materials, as well as the environmental conditions to which the finished component will be exposed. Neglecting these considerations can lead to premature failure and compromised performance, undermining the intended benefits. Further research in advanced materials and surface modification techniques is continuously expanding the possibilities for achieving optimal material compatibility in diverse applications of this type of finish.

6. Maintenance

The longevity and continued performance of components treated with this particular finish are directly contingent upon implementing appropriate maintenance protocols. Neglecting proper maintenance can significantly diminish the protective qualities of the finish, leading to premature degradation and potential failure of the underlying material. Therefore, understanding and adhering to recommended maintenance practices is crucial for maximizing the lifespan and optimizing the performance of treated items.

- Regular Cleaning Regimens

Establishing a consistent cleaning schedule is essential for removing surface contaminants that can compromise the integrity of the finish. The accumulation of dirt, grime, and environmental pollutants can create micro-environments conducive to corrosion or abrasion. Utilizing mild, non-abrasive cleaning agents is recommended to prevent damage to the protective coating. For example, architectural hardware treated with this finish should be routinely cleaned with a soft cloth and a pH-neutral cleaning solution to maintain its aesthetic appeal and prevent the buildup of corrosive substances.

- Inspection and Early Intervention

Periodic inspections are necessary to identify signs of damage or degradation, such as scratches, chips, or localized corrosion. Early detection of these issues allows for timely intervention, preventing minor problems from escalating into more severe forms of deterioration. In the automotive industry, for example, regular inspections of components treated with this finish can help identify early signs of rust, allowing for prompt repairs that prevent extensive corrosion damage and preserve structural integrity. The goal is to correct the problem.

- Protective Coating Reapplication

Over time, the protective qualities may diminish due to wear and tear or environmental exposure. Periodic reapplication of the finish can restore its original protective capabilities and extend the lifespan of the treated component. The frequency of reapplication depends on factors such as the severity of the operating environment and the type of finish used. For instance, in marine applications, where components are exposed to highly corrosive saltwater environments, more frequent reapplication of the protective coating may be necessary to maintain adequate corrosion resistance.

- Environmental Considerations

The surrounding environment impacts this protective application. For example, applications located in areas with high humidity require different cleaning schedules compared to arid climates. This can be the deciding factor in maintaining the quality of the surface.

These maintenance facets collectively underscore the importance of proactive care in preserving the benefits conferred by this surface treatment. By implementing consistent cleaning practices, conducting regular inspections, and performing timely reapplications when necessary, the lifespan and performance of treated components can be significantly enhanced. Failure to prioritize maintenance can result in accelerated degradation, increased repair costs, and compromised functionality. Proper care can add value.

7. Cost Considerations

The economic implications of selecting this specific finish are multifaceted, encompassing initial investment, long-term operational expenses, and potential lifecycle cost reductions. A comprehensive evaluation of these factors is essential for informed decision-making and optimizing the overall economic value.

- Initial Material and Application Costs

The upfront investment in materials and application processes represents a significant portion of the total cost. The price of the finishing material itself, as well as the labor and equipment required for its application, contribute to this initial expense. For instance, specialized application techniques, such as electrostatic spraying or vacuum deposition, may entail higher initial costs compared to simpler methods like dipping or brushing. However, these advanced techniques often yield superior performance characteristics, justifying the increased initial investment. Comparing these alternatives will help determine best cost effective value for product.

- Life Cycle Cost Analysis

A comprehensive assessment of the overall lifecycle costs associated with this type of finish is crucial for making informed economic decisions. This analysis should consider factors such as the durability of the finish, its resistance to corrosion and wear, and the frequency and cost of required maintenance or repairs. While a less expensive finish may offer lower initial costs, its reduced lifespan and increased maintenance requirements can lead to higher overall costs over time. A life cycle assessment will help determine the value of the finish.

- Impact on Production Efficiency

The selection of a specific finishing method can have a direct impact on production efficiency and throughput. Application techniques that require extensive preparation, curing times, or specialized equipment can increase production cycle times and reduce overall efficiency. Choosing a finish that can be applied quickly and efficiently, without compromising quality or performance, can significantly reduce manufacturing costs. Efficient application saves money.

- Potential for Cost Savings through Extended Lifespan

The enhanced durability and corrosion resistance afforded by this type of finish can result in significant cost savings over the lifespan of the treated component. By extending the service life of the component and reducing the need for frequent replacements or repairs, this treatment can provide a substantial return on investment. Consider, for example, a bridge structure treated with a high-performance corrosion-resistant finish. The extended lifespan of the bridge, coupled with reduced maintenance requirements, can result in significant cost savings compared to using a less durable finish that requires more frequent repairs or replacement. These savings offset up front costs.

These considerations highlight the complex interplay of economic factors associated with the decision to employ this specialized finish. By carefully evaluating these aspects, engineers, designers, and procurement specialists can make informed choices that optimize the overall economic value and performance of treated components.

Frequently Asked Questions

The following addresses common inquiries regarding the properties, application, and performance characteristics of this specific finish. These answers aim to provide clarity and dispel misconceptions.

Question 1: What is the typical thickness range of this applied treatment, and how does thickness affect performance?

The typical thickness range varies depending on the application and substrate material, generally ranging from 0.001 to 0.005 inches. Thickness directly impacts corrosion resistance, durability, and aesthetic appearance. Insufficient thickness compromises protection, while excessive thickness can lead to cracking or adhesion issues.

Question 2: How does this finish compare to anodizing in terms of corrosion resistance and durability?

This method and anodizing both enhance corrosion resistance, but their mechanisms differ. Anodizing creates an oxide layer on aluminum, while this treatment typically involves applying a protective coating. The choice depends on the substrate material and environmental conditions. In certain environments, one may offer superior durability compared to the other.

Question 3: Can this surface preparation be applied to dissimilar metals, and what precautions should be taken?

Yes, but careful consideration must be given to galvanic corrosion. Applying this treatment to dissimilar metals can create an electrochemical cell, accelerating corrosion of the more anodic metal. Proper selection of the finish and the use of barrier coatings are crucial to mitigate this risk.

Question 4: What are the common causes of failure in components treated with this finish, and how can they be prevented?

Common failure modes include inadequate surface preparation, improper application, and exposure to harsh chemicals or abrasive materials. These can be prevented by following recommended application protocols, using appropriate cleaning agents, and implementing regular inspection and maintenance procedures.

Question 5: Is this specific finish environmentally friendly, and are there any regulatory restrictions on its use?

The environmental impact depends on the specific formulation of the finishing material and the application process. Some finishes contain volatile organic compounds (VOCs) or heavy metals that are subject to regulatory restrictions. Selecting environmentally friendly alternatives and adhering to best practices for waste management are essential.

Question 6: What is the typical lifespan of this applied treatment, and how can its lifespan be extended?

The lifespan varies depending on the application environment and maintenance practices. Generally, components treated with this finish can last for several years, or even decades, with proper care. Implementing regular cleaning, inspection, and reapplication of the finish can significantly extend its service life.

Understanding these key aspects facilitates informed decisions regarding its application. Consistent adherence to best practices maximizes effectiveness.

The subsequent section will delve into case studies illustrating the practical applications and benefits.

Conclusion

This exposition has illuminated various facets of 626 finish, detailing its properties, application methods, material compatibility, maintenance requirements, and cost considerations. Each of these areas plays a vital role in determining the suitability of 626 finish for a given application.

The appropriate selection and implementation of 626 finish, guided by a thorough understanding of its characteristics, enables enhanced product performance and longevity. Further research and development in this field will likely yield even more advanced applications and benefits, solidifying its importance in the realm of material science and engineering.

![Status Check: Is Gate Manga Really Finished? [Answered] Best Final Touch: Elevate Your Projects with Professional Finishing Status Check: Is Gate Manga Really Finished? [Answered] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/02/th-226-300x200.jpg)