Surface preparation is a crucial step in achieving a professional and aesthetically pleasing paint job. This process involves smoothing and refining wall surfaces to ensure optimal adhesion and a flawless final appearance for the applied coating. Different coating products necessitate specific levels of surface smoothness to achieve their intended aesthetic and functional results.

Proper preparation enhances the longevity and visual appeal of painted surfaces. By creating a uniform base, imperfections are minimized, and the coating material can bond effectively, resisting chipping, peeling, and other forms of damage. This painstaking process reduces the necessity for rework and guarantees a superior, lasting result. Historically, this phase was frequently overlooked, leading to unsatisfactory outcomes that necessitated costly corrections.

Understanding the relationship between substrate condition and the selected coating is paramount. The ensuing discussion explores various methods and materials employed in refining surfaces, detailing the considerations necessary for selecting the appropriate approach to ensure a professional and durable painted surface.

Surface Preparation Guidelines

Achieving a high-quality painted finish requires meticulous surface preparation. The following guidelines detail essential steps to ensure optimal results.

Tip 1: Assess Existing Surface Condition: Prior to commencement, thoroughly evaluate the substrate for imperfections, including cracks, holes, and unevenness. Address any deficiencies before proceeding.

Tip 2: Select Appropriate Abrasive Grade: The grade of the abrasive material dictates the level of surface refinement. Use coarser grits (e.g., 80-120) for initial leveling and finer grits (e.g., 180-220) for smoothing and creating optimal conditions for coating application.

Tip 3: Employ Consistent Sanding Techniques: Maintain uniform pressure and motion across the entire surface to avoid creating localized depressions or ridges. Overlapping strokes ensure a consistent finish.

Tip 4: Utilize Proper Sanding Tools: Hand sanding is suitable for small areas and detail work. For larger surfaces, consider using an electric sander to expedite the process and ensure a more uniform result. Orbital sanders are particularly effective for producing smooth, swirl-free surfaces.

Tip 5: Remove Dust and Debris Thoroughly: After preparation, meticulously remove all dust and debris using a vacuum cleaner with a brush attachment, followed by wiping the surface with a tack cloth. Residual particles compromise coating adhesion and visual appearance.

Tip 6: Prime Prepared Surfaces: Application of a primer is crucial for sealing the prepared surface, promoting coating adhesion, and ensuring color uniformity. Select a primer appropriate for the selected coating and substrate.

Effective surface preparation is foundational for achieving a durable and aesthetically pleasing painted surface. Adhering to these guidelines ensures optimal coating performance and longevity.

The subsequent sections will delve into specific preparation techniques for various coating materials and substrates, further enhancing understanding of this critical process.

1. Surface smoothness required

Surface smoothness is a critical determinant in the preparation process, significantly influencing the ultimate appearance and performance of a painted finish. The degree of smoothness needed is intrinsically linked to the coating material’s characteristics and intended aesthetic. Understanding this relationship is paramount for achieving professional and durable results.

- Coating Sheen Level

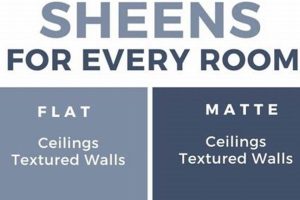

Higher sheen coatings, such as gloss or semi-gloss, necessitate a more refined surface than matte or eggshell finishes. Glossy coatings accentuate imperfections; therefore, meticulous sanding with fine-grit abrasives is essential to minimize visible flaws. Matte coatings, conversely, possess a greater capacity to conceal minor irregularities, permitting a slightly less rigorous preparation.

- Substrate Material

The substrate’s inherent texture influences the level of preparation required. Smooth surfaces, such as previously painted drywall, may only necessitate light sanding to ensure proper adhesion. Conversely, rougher surfaces, such as textured plaster, necessitate more extensive preparation to achieve the desired level of smoothness. This may involve multiple passes with varying abrasive grits and the application of a skim coat to fill imperfections.

- Light Exposure Conditions

Areas subject to direct or intense lighting require a higher degree of surface smoothness. Strong light sources emphasize surface irregularities, making imperfections more noticeable. In these situations, careful sanding and meticulous dust removal are crucial for achieving a flawless finish. Conversely, in dimly lit areas, minor imperfections may be less apparent, reducing the stringency of the preparation.

- Application Method

The method of coating application can also influence the need for smoothness. Spray application generally requires a smoother surface than brush or roller application. Spraying tends to accentuate surface imperfections, necessitating more thorough sanding and preparation. Brush or roller application, however, may provide a slight texture that can help conceal minor irregularities.

The level of smoothness required is not a static value but rather a function of several interconnected factors. Careful consideration of the coating sheen, substrate material, light exposure, and application method allows for tailoring the sanding process to achieve optimal results. Therefore, before beginning the sanding process, it is imperative to evaluate all relevant parameters to determine the appropriate level of surface refinement.

2. Abrasive grit selection

Abrasive grit selection constitutes a pivotal element in the preparation of wall surfaces for coating application. The choice of abrasive grit directly impacts the resultant smoothness and texture of the prepared surface, consequently influencing the adhesion, appearance, and longevity of the applied coating. Inadequate grit selection can lead to a variety of undesirable outcomes, including visible scratches, poor coating adhesion, and premature coating failure. For instance, employing excessively coarse abrasives on surfaces intended for high-gloss finishes invariably produces noticeable scratches, compromising the aesthetic quality. Conversely, using extremely fine abrasives on surfaces requiring significant leveling may prove inefficient and fail to adequately address imperfections.

The practical application of abrasive grit selection manifests in diverse scenarios. Preparing previously painted surfaces for a fresh coat often necessitates a medium-grit abrasive (e.g., 120-180) to lightly roughen the existing coating, promoting adhesion of the new layer. Conversely, new drywall surfaces typically benefit from finer abrasives (e.g., 220-320) to achieve a smooth, paint-ready finish without damaging the underlying paper. Additionally, the presence of imperfections, such as patching compounds or textured surfaces, necessitates a staged approach, commencing with coarser grits for initial leveling followed by progressively finer grits for surface refinement. Understanding the coating material’s properties is also critical. High-gloss coatings demand exceptionally smooth surfaces, requiring multiple passes with fine-grit abrasives and careful dust removal to minimize imperfections.

In summary, appropriate abrasive grit selection is not merely a procedural step but a fundamental determinant of coating success. Careful consideration of the substrate material, existing surface condition, and intended coating properties is crucial for making informed decisions regarding grit selection. Challenges associated with improper grit selection underscore the importance of adherence to established guidelines and best practices, ensuring a durable and aesthetically pleasing painted surface. Furthermore, the ability to adapt grit selection based on specific project requirements highlights the practical significance of this understanding in achieving optimal coating performance.

3. Sanding technique consistency

Consistent sanding technique is inextricably linked to the successful preparation of wall surfaces for coating application. Variations in pressure, stroke pattern, or sanding duration across a given surface can lead to unevenness, visible sanding marks, and inconsistent coating adhesion. The desired coating type and sheen level further amplify the significance of maintaining a uniform approach. High-gloss coatings, for example, accentuate surface imperfections, rendering inconsistencies in sanding technique readily apparent. Matte finishes, while more forgiving, can still exhibit subtle variations in texture and color if the underlying surface preparation is not uniform.

In practical terms, inconsistent sanding can manifest as “shiny spots” in areas subjected to excessive pressure, or as swirl marks resulting from haphazard orbital sander movement. These imperfections disrupt the smooth, uniform base required for optimal coating adhesion and a flawless final appearance. Real-world examples abound: a newly painted wall exhibiting uneven gloss levels due to localized over-sanding, or a surface with visible scratch patterns beneath a semi-gloss finish stemming from inconsistent sanding direction. Addressing such issues often necessitates extensive rework, including additional sanding, patching, and re-coating, thereby increasing labor costs and project timelines. The practical significance of this understanding lies in preventing such costly errors through adherence to standardized sanding protocols.

Effective sanding technique consistency involves maintaining a uniform pressure, employing overlapping strokes, and adhering to a consistent sanding pattern. Regular assessment of the surface texture and periodic cleaning of the abrasive material further contribute to uniformity. Ultimately, consistent sanding technique represents a critical component of wall preparation, directly influencing the final outcome and contributing significantly to the longevity and aesthetic appeal of the applied coating. Addressing this aspect proactively minimizes the risk of rework and ensures a professional, high-quality painted finish.

4. Dust removal imperative

Thorough removal of sanding residue is a non-negotiable step in wall preparation. The presence of residual particles between the prepared surface and the applied coating directly impedes adhesion, compromising the integrity and longevity of the finish. Sanding generates fine dust composed of substrate material, abrasive particles, and potentially, remnants of previous coatings. This particulate matter creates a barrier that prevents the coating from forming a direct and secure bond with the wall surface. The effect of this barrier becomes visibly apparent over time as the coating begins to chip, peel, or blister. Example: A wall coated with a high-gloss paint after inadequate dust removal might initially appear satisfactory, only to develop surface defects within months due to compromised adhesion. The “Dust removal imperative” ensures surface cleanliness, which is directly related to the final finish type.

Effective dust removal necessitates the utilization of appropriate tools and techniques. A vacuum cleaner equipped with a brush attachment is crucial for extracting loose particles from the surface and crevices. Wiping the prepared surface with a tack cloth further captures remaining fine dust, creating an optimal condition for coating application. The sequence of vacuuming followed by tack cloth wiping is essential to prevent redistributing dust onto previously cleaned areas. The choice of tack cloth material is also a critical consideration; cloths designed for coating preparation are treated to enhance dust absorption and minimize residue transfer. An example would be to ensure using specialized tack cloths when preparing surfaces for epoxy coatings. They reduce risk of contamination which helps to increase the durability and appeal of the finished product.

In conclusion, the “Dust removal imperative” is not merely a procedural formality but a fundamental prerequisite for achieving a durable and aesthetically pleasing painted surface. Failure to adequately remove sanding residue directly compromises coating adhesion and leads to premature finish failure. This understanding is especially relevant when working with high-performance coatings and demanding applications where longevity and visual appearance are paramount. By adhering to established dust removal protocols and employing appropriate tools and techniques, successful wall preparation is attainable, thereby maximizing the performance and aesthetic potential of the chosen coating material.

5. Primer compatibility crucial

Primer selection is intrinsically linked to the process of preparing walls for a specific paint finish. The compatibility between the primer, the prepared surface, and the topcoat dictates the adhesion, uniformity, and long-term durability of the entire coating system. Inadequate consideration of primer compatibility can negate the benefits of meticulous sanding and lead to premature coating failure. For instance, applying an oil-based primer over a surface previously coated with latex paint, without proper sanding and surface preparation, frequently results in poor adhesion and subsequent peeling. Similarly, using a primer formulated for porous surfaces on a non-porous, glossy surface can lead to inadequate absorption and compromised topcoat performance. These instances illustrate that effective sanding, while essential, is insufficient without a compatible primer to mediate between the substrate and the finish coat.

The practical significance of primer compatibility extends beyond basic adhesion. Primers are designed to address specific surface characteristics, such as porosity, staining, or existing imperfections. For example, if a wall exhibits water stains, a stain-blocking primer is crucial to prevent these stains from bleeding through the topcoat, regardless of the sanding efforts applied. Furthermore, certain primers enhance the smoothness of the sanded surface, creating an ideal base for high-gloss or high-sheen finishes that demand a flawless substrate. The correct primer also promotes uniform topcoat color and sheen, preventing variations that can arise from inconsistent surface absorption. Therefore, primer selection must be informed by both the prepared surface condition and the desired aesthetic outcome. A properly selected and applied primer transforms a merely “sanded” wall into a professionally prepared canvas for the final coat.

In summary, achieving optimal results from sanding walls necessitates a comprehensive understanding of primer compatibility. The primer acts as the crucial link between the prepared surface and the chosen finish, influencing adhesion, stain resistance, and aesthetic uniformity. Challenges arising from incompatible primer choices underscore the need for careful assessment and informed selection. By prioritizing primer compatibility as an integral component of surface preparation, the benefits of sanding are maximized, resulting in a durable and visually appealing finished product.

Frequently Asked Questions

This section addresses common inquiries regarding the proper methods and considerations for surface preparation in painting projects.

Question 1: What grit sandpaper is generally recommended for preparing walls prior to painting?

The appropriate sandpaper grit depends on the existing surface condition and the desired finish. Typically, 120-180 grit sandpaper is suitable for lightly sanding previously painted surfaces, while 220-320 grit is preferred for new drywall or smoother surfaces.

Question 2: Is sanding always necessary before painting?

Sanding is not always mandatory, but it is highly recommended to ensure proper adhesion and a smooth finish. Skipping this step may result in poor adhesion, peeling, and an uneven appearance, particularly with high-gloss coatings.

Question 3: How important is dust removal after sanding walls?

Dust removal is crucial. Residual dust particles prevent the coating from properly adhering to the surface, leading to potential defects. A vacuum cleaner and tack cloth are effective tools for removing dust.

Question 4: Can sanding alone correct significant imperfections in walls?

Sanding is effective for minor imperfections. Significant imperfections, such as large holes or cracks, require patching and filling prior to sanding.

Question 5: Does the type of paint finish influence the sanding process?

Yes. High-gloss finishes require a smoother, more meticulously prepared surface than matte finishes. Therefore, finer grit sandpaper and more thorough sanding are typically necessary for high-gloss coatings.

Question 6: Should a primer be applied after sanding walls?

Applying a primer after sanding is strongly recommended. Primer seals the surface, promotes adhesion, and ensures color uniformity, leading to a more durable and aesthetically pleasing result.

Proper surface preparation is a fundamental aspect of achieving a high-quality paint finish. Adhering to best practices regarding sanding techniques, dust removal, and primer application is essential for optimal results.

The following section explores advanced surface preparation techniques and addresses specialized scenarios in coating application.

Sanding Walls for Paint Finish Type

The foregoing discussion elucidates the significance of surface preparation as a foundational element in achieving optimal outcomes in coating applications. The meticulous refinement achieved through sanding directly influences the adhesion, appearance, and longevity of the applied coating. Surface smoothness, abrasive grit selection, sanding technique consistency, dust removal, and primer compatibility are interdependent factors that demand careful consideration.

The pursuit of enduring and aesthetically pleasing painted surfaces necessitates a comprehensive understanding of these principles. The long-term performance of any coating system is inextricably linked to the diligence and expertise applied during the preparation phase. Continued adherence to best practices and ongoing refinement of techniques remain paramount in ensuring the attainment of superior results.