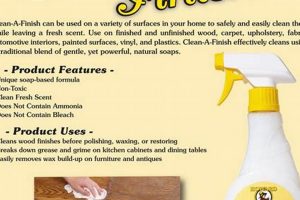

This phrase identifies a sector of manufacturing and construction specializing in the final treatments and enhancements applied to materials. These processes often include painting, coating, polishing, and other surface refinements intended to improve aesthetics, durability, and functionality. Consider, for instance, a local construction project requiring the application of protective coatings to steel beams, or the specialized polishing of custom-built furniture; both exemplify aspects of the described work.

The significance of these operations lies in their contribution to product longevity, visual appeal, and overall value. Historically, skilled tradesmen performed these tasks, passing down techniques refined over generations. Today, the sector blends traditional craftsmanship with modern technologies, playing a vital role in industries ranging from construction and manufacturing to art and design. The benefits extend beyond mere aesthetics, impacting material resistance to environmental factors and enhancing the performance of finished goods.

With this foundational understanding established, subsequent discussion will delve into specific applications, techniques, and the broader economic impact associated with this field of expertise. The focus will shift to explore the nuances of various finishing methods and their relevance across diverse sectors.

Guidance on Material Enhancement

Effective application of finishing processes requires meticulous planning and execution. The following guidelines are offered to ensure optimal results and long-term durability of treated materials.

Tip 1: Material Selection is Paramount. Choose materials compatible with the intended finish. Incompatible combinations may result in adhesion failures, discoloration, or premature degradation of the finish.

Tip 2: Surface Preparation is Critical. Thoroughly clean and prepare the surface before applying any finish. Remove all contaminants, such as dirt, oil, rust, or existing coatings, to ensure proper adhesion.

Tip 3: Understand Environmental Conditions. Temperature, humidity, and ventilation play significant roles in the curing and drying processes. Adhere to recommended environmental parameters specified by the finish manufacturer.

Tip 4: Apply Appropriate Application Techniques. Different finishes require specific application methods, such as brushing, spraying, or dipping. Utilizing the correct technique is essential for achieving uniform coverage and desired thickness.

Tip 5: Adhere to Recommended Drying Times. Allow sufficient drying time between coats and before exposing the finished surface to operational conditions. Insufficient drying can lead to surface defects and reduced durability.

Tip 6: Prioritize Safety Measures. Many finishing products contain volatile organic compounds (VOCs) and other hazardous materials. Wear appropriate personal protective equipment (PPE), such as respirators, gloves, and eye protection, and ensure adequate ventilation.

Tip 7: Regular Maintenance is Essential. Periodic cleaning and maintenance are necessary to prolong the lifespan of the finish and prevent deterioration. Follow the manufacturer’s recommendations for specific maintenance procedures.

Adhering to these guidelines enhances the quality, durability, and longevity of finished materials, resulting in improved performance and reduced maintenance costs. Consistent application of best practices contributes to a higher standard of workmanship.

The subsequent section will provide further insights into advanced finishing techniques and their application in specialized industries.

1. Surface Preparation

Surface preparation constitutes a fundamental and inseparable element within any finishing process. It is the critical precursor that directly influences the success and longevity of any applied coating, treatment, or enhancement. Within the context of finishing operations, inadequate surface preparation invariably leads to adhesion failures, premature corrosion, or compromised aesthetic results. Examples of such failures manifest in peeling paint on improperly cleaned metal structures or delamination of protective coatings on untreated wooden surfaces. Effective surface preparation, therefore, addresses the removal of contaminants, creation of a suitable profile for adhesion, and stabilization of the substrate to receive the intended finish.

The methodologies employed for surface preparation vary considerably depending on the substrate material and the nature of the intended finish. Common techniques include abrasive blasting (e.g., sandblasting, shot blasting), chemical cleaning (e.g., acid etching, degreasing), and mechanical abrasion (e.g., grinding, sanding). The selection of the appropriate technique is dictated by factors such as the type of contaminant present, the desired surface profile, and any potential impact on the substrate’s structural integrity. For instance, preparing steel for powder coating requires a different approach than preparing wood for varnish, with specific consideration for rust removal versus wood grain enhancement. Proper implementation minimizes the risk of defects like blistering, cracking, or uneven application, resulting in an enhanced, durable final product.

In summary, meticulous surface preparation is not merely a preliminary step but a determinant of the overall success of any finishing endeavor. Its impact reverberates through the entire process, influencing the aesthetic qualities, protective properties, and long-term performance of the finished product. A thorough understanding of material properties, appropriate preparation techniques, and potential environmental factors is crucial to achieving optimal results and maximizing the value of finishing investments.

2. Material Compatibility

Material compatibility is a cornerstone of finishing operations, directly affecting the integrity, durability, and aesthetic outcome. The success of any finishing treatment hinges on the interaction between the substrate material and the applied finish. Incompatibility leads to premature failure, necessitating costly rework and compromising the intended performance characteristics.

- Adhesion Properties

Effective adhesion depends on the chemical and physical bonding between the finish and the substrate. Different materials possess varying surface energies and chemical compositions, requiring specific finishes formulated to promote optimal adhesion. For instance, applying an epoxy coating designed for metal to a polyethylene surface, which lacks the necessary polarity for bonding, will likely result in poor adhesion and subsequent peeling. Baltimore finishing enterprises must carefully select coatings that exhibit strong adhesive properties relative to the substrate in question to ensure a lasting bond and prevent premature degradation.

- Chemical Reactivity

The potential for chemical reactions between the finishing product and the substrate material is a critical consideration. Certain finishes may react with specific metals, leading to corrosion or discoloration. Similarly, some solvents present in coatings can degrade or dissolve certain plastics. For example, acidic etching solutions used to prepare metal surfaces for painting may corrode aluminum substrates if not properly controlled. A thorough understanding of the chemical properties of both the substrate and the finishing product is essential to prevent undesirable reactions and maintain the integrity of the finished product.

- Thermal Expansion Coefficients

Disparities in the thermal expansion coefficients between the substrate and the finish can induce stress and cracking when subjected to temperature fluctuations. When a material with a high thermal expansion coefficient is coated with a material with a low coefficient, temperature changes can cause the coating to expand and contract at different rates, leading to stress and eventual failure. This is especially important in exterior applications where materials are exposed to wide temperature ranges. Appropriate selection of materials with closely matched expansion coefficients is crucial in ensuring the long-term integrity of finished products.

- Porosity and Absorption

The porosity and absorption characteristics of the substrate material influence the penetration and effectiveness of the applied finish. Porous materials, such as wood or concrete, may require multiple coats or specialized sealers to prevent excessive absorption and ensure a uniform finish. In contrast, non-porous materials, such as glass or polished metal, require finishes that readily adhere to smooth surfaces. Baltimore finishing specialists must consider these properties when selecting appropriate application techniques and finish formulations to optimize coverage and durability.

In conclusion, material compatibility represents a critical determinant of success within the context of Baltimore finishing works. Adherence to best practices in material selection, informed by a comprehensive understanding of adhesion properties, chemical reactivity, thermal expansion, and porosity considerations, is paramount to achieving durable, aesthetically pleasing, and long-lasting results.

3. Application Techniques

Application techniques are intrinsically linked to the success of any operation within the “baltimore finishing works” sector. These techniques represent the practical methods by which finishing materials are applied to substrates, and their efficacy directly influences the final product’s quality, durability, and aesthetic appeal. The incorrect selection or execution of an application technique frequently leads to defects such as uneven coatings, blistering, or premature failure of the finish, negating the value of high-quality materials and skilled labor. For instance, improperly atomizing paint in a spray application can result in an orange-peel texture, requiring costly rework or compromising the protective qualities of the coating. Therefore, mastering and adhering to appropriate application techniques is paramount for achieving desired outcomes within Baltimore’s finishing industry.

Practical applications of finishing techniques within “baltimore finishing works” span a diverse range of industries, each demanding specialized skills and equipment. In the maritime sector, for example, anti-fouling coatings are applied to ship hulls using airless spray systems, requiring precise control over coating thickness and uniformity to prevent marine growth and maintain vessel performance. Similarly, in architectural metal fabrication, powder coating is often employed using electrostatic spray guns, demanding meticulous surface preparation and precise control over oven temperature and curing time to achieve a durable and aesthetically pleasing finish. Furthermore, in the restoration of historical buildings, traditional brush techniques may be employed to apply coatings that are compatible with the original materials and methods, preserving the building’s historical character while providing long-term protection. These examples highlight the importance of selecting and executing application techniques appropriate to the specific project requirements and material properties.

In conclusion, the connection between application techniques and “baltimore finishing works” is undeniable. The appropriate application of finishing materials constitutes a critical element in achieving durable, aesthetically pleasing, and functional results. While challenges such as material compatibility, environmental control, and operator skill influence the outcome, a comprehensive understanding and skilled execution of application techniques remain essential for success within Baltimore’s vibrant finishing industry and beyond, safeguarding the value and longevity of finished products across various sectors.

4. Environmental Control

Environmental control is an inextricable element of successful finishing operations. Its effect on the quality, durability, and safety of finished products cannot be overstated. Fluctuations in temperature, humidity, and air quality directly influence the curing process, adhesion, and overall performance of coatings, paints, and other applied finishes. Within facilities engaged in “baltimore finishing works,” failure to maintain appropriate environmental conditions leads to defects such as blistering, cracking, uneven application, and compromised protective qualities. The presence of airborne contaminants, moreover, introduces further risks, potentially causing surface imperfections and jeopardizing the integrity of the finished product. For example, inadequate ventilation during spray painting results in the accumulation of volatile organic compounds (VOCs), posing a health hazard to workers while also potentially affecting the finish quality. Controlling these factors is, therefore, essential for ensuring consistent, high-quality results within the finishing industry.

Practical applications of environmental control within “baltimore finishing works” manifest in diverse forms, contingent upon the specific finishing processes employed. Temperature and humidity control are vital in powder coating operations, where precise oven temperatures are required to ensure proper curing and adhesion. Similarly, controlled humidity levels are essential in wood finishing to prevent warping, cracking, or uneven stain absorption. Adequate ventilation systems equipped with filtration mechanisms are crucial for removing particulate matter and VOCs from the air in spray painting and coating facilities. The implementation of these measures not only safeguards the health and safety of workers but also contributes to the overall efficiency and cost-effectiveness of the finishing process by reducing defects and minimizing rework. For instance, specialized paint booths with integrated ventilation and filtration systems are commonplace in automotive refinishing, ensuring a clean and controlled environment for achieving a flawless finish.

In summation, environmental control constitutes a foundational requirement for “baltimore finishing works.” Its effective implementation safeguards product quality, enhances worker safety, and promotes operational efficiency. While challenges persist in maintaining optimal environmental conditions across diverse finishing applications, a comprehensive understanding of the interplay between environmental factors and finishing processes is paramount for achieving consistently superior results. Adherence to established environmental control standards and investment in appropriate equipment and procedures are, therefore, indispensable for businesses operating within Baltimore’s finishing sector, ensuring competitiveness and long-term sustainability.

5. Durability Enhancement

Durability enhancement represents a central objective within “baltimore finishing works,” encompassing a spectrum of processes designed to extend the lifespan and resilience of materials and products. These processes mitigate degradation caused by environmental factors, wear and tear, and other destructive forces. Effective durability enhancement strategies translate directly into reduced maintenance costs, extended service life, and improved overall value for clients engaging these specialized services.

- Protective Coatings

The application of protective coatings stands as a primary method for durability enhancement. These coatings, ranging from paints and varnishes to specialized epoxies and polyurethanes, form a barrier against moisture, chemicals, UV radiation, and physical abrasion. In marine applications, for example, specialized coatings prevent corrosion and biofouling on ship hulls, extending their operational lifespan. Similarly, powder coatings applied to metal structures provide resistance to rust and chipping, ensuring structural integrity in demanding environments. The selection of the appropriate coating type is crucial, aligning with the specific environmental conditions and performance requirements of the finished product.

- Surface Hardening Treatments

Surface hardening treatments enhance the resistance of materials to wear, abrasion, and impact. Techniques such as case hardening for steel components alter the surface microstructure, creating a hard, wear-resistant layer while maintaining a tougher core. In the context of “baltimore finishing works,” these treatments find application in industries such as manufacturing, where components are subjected to repeated stress and friction. By increasing surface hardness, these treatments reduce wear rates and prolong the functional life of critical parts.

- Corrosion Inhibition

Corrosion represents a significant threat to the integrity of metallic structures and components. Corrosion inhibition techniques, including the application of corrosion-resistant alloys, surface passivation treatments, and the use of sacrificial anodes, mitigate the effects of corrosion. These techniques are particularly relevant in coastal environments, such as Baltimore, where exposure to saltwater accelerates corrosion processes. Bridge infrastructure, marine vessels, and industrial equipment benefit from effective corrosion inhibition strategies, preventing structural weakening and extending service life.

- Material Stabilization

Material stabilization processes aim to reduce dimensional changes and prevent degradation caused by environmental factors. Wood stabilization, for example, involves treatments that reduce moisture absorption and prevent warping, cracking, and decay. These processes are crucial in the restoration of historical buildings and the manufacturing of high-quality furniture. Similarly, UV stabilizers are added to plastics to prevent degradation caused by sunlight exposure, extending the lifespan of outdoor equipment and components. In “baltimore finishing works,” material stabilization ensures the longevity and aesthetic appeal of finished products.

These facets of durability enhancement, when implemented effectively within “baltimore finishing works,” contribute to the production of more resilient, long-lasting products. The careful selection and application of appropriate finishing techniques, tailored to the specific material and environmental conditions, ultimately translate into increased value for clients and a reduction in life-cycle costs. The ongoing development of innovative finishing technologies further expands the possibilities for enhancing the durability of a wide range of materials and products.

6. Aesthetic Refinement

Aesthetic refinement constitutes a crucial component of operations falling under “baltimore finishing works,” serving as the catalyst for enhanced market value, improved customer perception, and the creation of visually appealing products and structures. The pursuit of aesthetic excellence is not merely a superficial concern, but a strategic imperative directly influencing commercial success. When applied effectively, aesthetic refinement elevates ordinary materials into objects of visual distinction, contributing to brand recognition and consumer preference. The importance of this aspect is evident in various sectors; for instance, meticulously applied automotive coatings enhance the visual appeal and perceived quality of vehicles, while expertly crafted furniture finishes contribute to the ambiance and value of interior spaces. These examples highlight the transformative power of aesthetic refinement in elevating the perceived value of products and environments.

The application of aesthetic refinement within “baltimore finishing works” necessitates a blend of technical skill, artistic vision, and meticulous attention to detail. Surface preparation, color selection, application techniques, and finishing processes all play pivotal roles in achieving desired aesthetic outcomes. Consider the meticulous restoration of historical architectural elements; skilled artisans employ specialized techniques to replicate original finishes, preserving the historical integrity and aesthetic character of the structure. In contrast, modern metal fabrication often incorporates powder coating processes to achieve a durable and visually appealing finish, contributing to the architectural appeal of contemporary buildings. These practical applications demonstrate the breadth and depth of aesthetic refinement within the context of specialized Baltimore operations.

In conclusion, aesthetic refinement is an indispensable element of “baltimore finishing works,” impacting both the functional and commercial aspects of manufactured and constructed goods. While challenges such as material compatibility, environmental constraints, and evolving aesthetic trends necessitate continuous innovation, the commitment to aesthetic excellence remains a cornerstone of success in Baltimore’s finishing sector. This dedication ensures that finished products not only meet functional requirements but also possess a refined visual appeal that resonates with consumers and contributes to enduring market value.

Frequently Asked Questions Regarding Baltimore Finishing Works

The following section addresses common inquiries concerning specialized treatment and refinement processes within the Baltimore region. These questions aim to provide clarity and insight into the scope, methodologies, and benefits associated with these operations.

Question 1: What distinguishes “Baltimore Finishing Works” from general construction or manufacturing activities?

This specific sector focuses on the final treatments and enhancements applied to materials following initial construction or manufacturing phases. It encompasses processes such as painting, coating, polishing, and other surface refinements designed to improve aesthetics, durability, and functionality. These specialized operations differ significantly from initial construction or manufacturing processes.

Question 2: What types of industries commonly utilize “Baltimore Finishing Works” services?

A diverse range of industries relies on these specialized services. These include, but are not limited to, construction, manufacturing, automotive, aerospace, marine, and architectural design. Any sector requiring surface refinement, protection, or aesthetic enhancement of materials and products frequently engages these operations.

Question 3: What factors influence the selection of a specific finishing process?

The selection process is influenced by several critical factors. These include the type of substrate material, the intended use of the finished product, environmental conditions, required durability, and desired aesthetic qualities. A thorough assessment of these factors is essential for determining the optimal finishing process.

Question 4: How does surface preparation impact the success of finishing operations?

Surface preparation is a critical determinant of success. Proper cleaning, removal of contaminants, and creation of a suitable surface profile are essential for ensuring proper adhesion of the finish. Inadequate surface preparation invariably leads to adhesion failures, premature corrosion, or compromised aesthetic results.

Question 5: What role does environmental control play in achieving optimal finishing results?

Environmental control is paramount for maintaining consistent quality and ensuring the proper curing and adhesion of finishes. Temperature, humidity, and air quality directly influence the outcome of finishing operations. Maintaining optimal environmental conditions minimizes defects and ensures long-term durability.

Question 6: What are the key benefits of investing in high-quality finishing processes?

Investing in high-quality finishing processes yields several significant benefits. These include enhanced durability, extended product lifespan, improved aesthetic appeal, increased resistance to environmental factors, and reduced maintenance costs. These benefits contribute to the overall value and longevity of finished products.

In summary, “Baltimore Finishing Works” represents a specialized sector playing a vital role in enhancing the quality, durability, and aesthetic appeal of materials and products across diverse industries. Understanding the processes, factors, and benefits associated with these operations is essential for making informed decisions and achieving optimal results.

The subsequent section will explore emerging trends and technological advancements within the finishing industry.

Concluding Remarks on Baltimore Finishing Works

The preceding discourse has illuminated the multifaceted nature of baltimore finishing works, underscoring its critical role in diverse sectors. From surface preparation and material compatibility to application techniques, environmental control, durability enhancement, and aesthetic refinement, the processes encompassed within this industry have been examined. The discussion has emphasized the interplay of these factors and their collective impact on the final quality and longevity of finished products.

Recognizing the importance of specialized treatment and refinement processes is paramount for industries seeking to optimize product performance, extend service life, and enhance visual appeal. Continued investment in innovative finishing technologies and adherence to best practices will undoubtedly shape the future of baltimore finishing works, ensuring its enduring contribution to the region’s economic landscape and the quality of manufactured and constructed goods. Further exploration of these techniques will foster innovation and improvement to the quality of our future products and works.