Surface treatment of metallic components within the Carolinas region is a specialized industry focused on enhancing material properties and aesthetics. This involves processes like plating, coating, and polishing applied to metal parts to improve corrosion resistance, durability, and appearance. An example includes applying a protective zinc coating to steel components used in outdoor infrastructure projects.

This regional sector plays a vital role in supporting various industries, including automotive, aerospace, and manufacturing. The application of these techniques contributes significantly to extending the lifespan of metal products, reducing maintenance costs, and enhancing overall performance. Historically, these techniques have evolved from basic protective measures to highly sophisticated processes meeting stringent industry standards.

The subsequent sections will delve into the specific methods employed, quality control measures implemented, and the environmental considerations that guide this important sector. The types of surface treatments and associated technological advances impacting operational efficiency will also be examined.

Enhancing Metal Component Longevity

The following guidelines address critical aspects of ensuring optimal results in processes conducted by businesses specializing in surface treatment of metallic parts within the Carolinas region. Adherence to these points promotes quality and durability.

Tip 1: Material Selection Assessment: Before commencing any surface treatment, thoroughly analyze the base metal composition. Different metals require specific pre-treatment and finishing processes to ensure proper adhesion and prevent adverse reactions. For example, aluminum alloys may require a different etching process than steel alloys.

Tip 2: Surface Preparation is Paramount: Adequate surface preparation is crucial for optimal coating adhesion. This includes cleaning, degreasing, and potentially abrasive blasting to remove contaminants and create a suitable surface profile. Failure to properly prepare the surface can lead to premature coating failure.

Tip 3: Control Coating Thickness: Maintaining precise control over coating thickness is vital for achieving desired performance characteristics. Overly thick coatings can be brittle and prone to cracking, while insufficient thickness may compromise corrosion resistance. Employ calibrated measuring instruments for accurate thickness control.

Tip 4: Environmental Control During Application: Carefully monitor environmental conditions, such as temperature and humidity, during coating application. Deviations from recommended parameters can negatively impact coating properties. Implement environmental control measures within the application area.

Tip 5: Post-Treatment Procedures: Certain surface treatments require specific post-treatment procedures, such as curing or passivation, to fully activate their protective properties. Adhere strictly to recommended post-treatment protocols to ensure optimal performance.

Tip 6: Quality Control and Inspection: Implement rigorous quality control measures at each stage of the surface treatment process. Conduct regular inspections to identify and rectify any defects or inconsistencies. This minimizes the risk of product failure and ensures consistent quality.

Tip 7: Adherence to Industry Standards: Comply with relevant industry standards and regulations to ensure the quality and performance of surface-treated components. Standards provide guidelines for material selection, process control, and testing. Compliance demonstrates commitment to quality and customer satisfaction.

Following these guidelines contributes to extending the service life of metal components and enhancing overall product value. Meticulous attention to detail during each stage of the surface treatment process is essential for achieving superior and lasting results.

The next section will cover common challenges encountered and strategies for their mitigation.

1. Corrosion Resistance

Corrosion resistance is a paramount consideration in the treatment of metal surfaces, especially within the diverse industrial landscape of the Carolinas. It directly impacts the longevity, performance, and safety of components used in various sectors. Effective surface treatments are crucial for mitigating the corrosive effects of environmental factors and operational stresses.

- Protective Coatings

Coatings serve as a barrier between the metal substrate and the corrosive environment. Techniques such as electroplating, powder coating, and specialized paints are employed to create a protective layer. An example includes applying a zinc coating to steel structures used in coastal environments to prevent saltwater corrosion. The effectiveness of these coatings depends on proper application techniques and the selection of materials appropriate for the specific environment.

- Material Selection

The inherent corrosion resistance of the base metal significantly influences the overall performance of the finished product. Stainless steel and aluminum alloys, for example, exhibit superior corrosion resistance compared to carbon steel. Careful consideration of the operational environment and potential corrosive agents is essential when selecting the base metal. In some applications, specialized alloys containing chromium, nickel, or molybdenum may be used to enhance corrosion resistance.

- Pre-Treatment Processes

Surface preparation techniques, such as cleaning, degreasing, and etching, are critical for ensuring proper adhesion of protective coatings. These pre-treatment processes remove contaminants that can compromise the integrity of the coating and accelerate corrosion. For instance, removing mill scale from steel surfaces prior to painting significantly improves paint adhesion and corrosion resistance. Proper surface preparation is often a determining factor in the long-term performance of surface-treated metal components.

- Electrochemical Protection

Methods like cathodic protection and anodic protection can be used to prevent corrosion in certain applications. Cathodic protection involves making the metal structure the cathode of an electrochemical cell, thus suppressing corrosion. This technique is commonly used to protect pipelines and underground storage tanks. Anodic protection, conversely, creates a passive layer on the metal surface to inhibit corrosion. These electrochemical methods provide long-term corrosion protection in specific environments.

The application of these corrosion resistance strategies, carefully tailored to the specific requirements of each metal and its intended use, reinforces the critical role played by facilities that focus on refining metal surfaces within the Carolinas. The utilization of these processes results in enhanced product durability, reduced maintenance costs, and increased safety, contributing to the overall economic strength of the region.

2. Aesthetic Enhancement

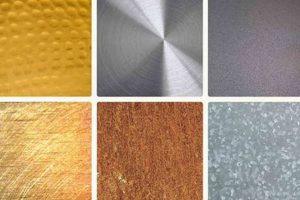

Aesthetic enhancement, in the context of surface treatments performed within the Carolinas region, extends beyond mere visual appeal. It encompasses the creation of a desired visual and tactile experience that directly influences product perception, market value, and brand identity. The application of specialized finishing processes plays a crucial role in achieving these aesthetic goals.

- Color and Texture Application

The application of specific colors and textures through processes like powder coating, painting, and anodizing directly impacts the visual appeal of metal components. The selection of appropriate colors and textures can enhance product visibility, convey brand messaging, and improve consumer perception. For example, a vibrant, textured powder coating on automotive parts can create a premium aesthetic while also providing increased durability. The uniformity and consistency of color application are critical for maintaining a professional appearance.

- Surface Polishing and Buffing

Polishing and buffing techniques are used to create a smooth, reflective surface on metal parts. These processes remove imperfections and enhance the luster of the metal, resulting in a high-end aesthetic. The level of polishing can be adjusted to achieve different levels of reflectivity, from a matte finish to a mirror-like shine. Applications range from decorative trim on appliances to architectural elements in building design. The skill and precision involved in polishing contribute significantly to the overall aesthetic quality of the finished product.

- Decorative Plating

Decorative plating involves depositing a thin layer of a precious metal, such as gold, silver, or chrome, onto a base metal. This process enhances the appearance of the component and provides a luxurious aesthetic. Decorative plating is commonly used in the production of jewelry, automotive trim, and consumer electronics. The thickness and quality of the plating layer are crucial for ensuring durability and preventing tarnishing. Specialized plating techniques can also be used to create unique patterns and textures on the metal surface.

- Branding and Engraving

The integration of branding elements, such as logos and trademarks, through engraving, etching, or laser marking, adds a personalized touch to metal components. These techniques allow for the creation of intricate designs and precise markings that enhance brand recognition. The placement and execution of these markings are carefully considered to maintain the overall aesthetic balance of the product. Branding and engraving contribute to the perceived value and authenticity of the finished item.

The interplay between these aesthetic enhancement techniques and the core processes defines the value proposition offered by businesses specializing in enhancing metal components located within the Carolinas. The ability to deliver visually appealing and durable finishes contributes significantly to the success of manufacturers across diverse industries and strengthens product appeal.

3. Material Durability

Material durability is a critical performance attribute directly influenced by metal surface treatment processes. These processes, employed extensively within the Carolinas region, serve to enhance the resistance of metal components to wear, fatigue, and environmental degradation, thereby extending their service life and reducing maintenance requirements.

- Wear Resistance Enhancement

Surface treatments like hard chrome plating and nitriding increase the hardness of the metal surface, providing enhanced resistance to abrasive wear. This is particularly relevant for components subjected to friction, such as gears and bearings. Hard chrome plating, for example, creates a very hard surface layer that withstands repeated contact and reduces wear rates. The application of these treatments significantly extends the operational life of machinery and equipment.

- Fatigue Strength Improvement

Surface treatments such as shot peening introduce compressive residual stresses into the metal surface. These compressive stresses counteract tensile stresses induced during cyclic loading, thus delaying the onset of fatigue cracks. Shot peening is commonly used in the aerospace industry to improve the fatigue life of critical components. The resulting enhancement in fatigue strength increases the reliability and safety of metal structures and parts.

- Corrosion Protection and Lifespan Extension

Coatings like galvanizing and powder coating provide a barrier that protects the underlying metal from corrosive environments. Galvanizing, for instance, forms a zinc layer that corrodes preferentially, protecting the steel substrate. Powder coating creates a durable, chemically resistant layer that shields the metal from moisture, chemicals, and ultraviolet radiation. Effective corrosion protection directly translates to a prolonged service life and reduced replacement costs.

- Impact and Abrasion Resistance

Specialized coatings, such as those incorporating ceramic particles or hard polymers, provide resistance to impact and abrasion. These coatings are used in applications where metal surfaces are exposed to harsh conditions or physical impact. For example, mining equipment often receives such coatings to withstand the abrasive effects of rock and ore. These treatments safeguard the metal from damage and maintain its structural integrity.

In summary, the application of appropriate surface treatment techniques directly contributes to enhanced material durability, resulting in improved performance and extended service life. Businesses specializing in refining metal surfaces within the Carolinas play a key role in supporting industries that demand high-performance, long-lasting metal components.

4. Industry Standards

Compliance with established industry standards is a fundamental aspect of operations focused on refining metallic surfaces within the Carolinas region. These standards provide a framework for ensuring quality, safety, and consistency across a range of processes and applications.

- Adherence to ASTM Specifications

The American Society for Testing and Materials (ASTM) develops and publishes technical standards for a wide range of materials, products, systems, and services. Businesses operating in the surface treatment sector within the Carolinas routinely follow relevant ASTM specifications to ensure the quality and performance of their coatings and finishes. For example, ASTM B117 provides a standardized test method for salt spray testing, which is used to evaluate the corrosion resistance of plated or coated metals. Compliance with these standards ensures that the applied finishes meet specified performance criteria.

- Conformity to ISO Certifications

The International Organization for Standardization (ISO) develops and publishes international standards that are widely recognized across various industries. ISO 9001, a standard for quality management systems, is often adopted by organizations to demonstrate their commitment to quality and customer satisfaction. Furthermore, standards like ISO 14001, focused on environmental management systems, are critical for ensuring environmentally responsible practices. Accreditation to these standards signifies that a business operates with documented procedures and a focus on continuous improvement.

- Meeting Automotive Industry Requirements

The automotive sector has stringent requirements for surface treatments due to the demanding operating conditions of vehicles. Standards such as those established by automotive manufacturers (e.g., Ford, GM, Chrysler) define specific performance criteria for coatings and finishes used on automotive components. These criteria may include requirements for corrosion resistance, abrasion resistance, and adhesion. Facilities that service the automotive industry must meet these standards to ensure the quality and reliability of the parts they treat. Specific automotive standards might address paint adhesion, chemical resistance, or UV stability, depending on the component and its location on the vehicle.

- Compliance with Environmental Regulations

Surface treatment processes often involve the use of chemicals that can have environmental impacts. Therefore, adherence to environmental regulations, such as those established by the Environmental Protection Agency (EPA), is crucial. These regulations may govern the disposal of hazardous waste, air emissions, and water discharge. Compliance with these regulations ensures that businesses operate in an environmentally responsible manner and minimize their impact on the surrounding ecosystem. Furthermore, adherence to REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulations is essential for ensuring safe chemical usage.

The strict adherence to industry standards is integral to the operations within the Carolinas that focus on metal refinement. These standards not only ensure the delivery of high-quality, reliable products but also promote safety and environmental stewardship, thereby contributing to the sustainability and competitiveness of the regional manufacturing sector.

5. Quality Control

Quality control forms an indispensable element within the operations of establishments focused on the refining of metallic surfaces in the Carolinas region. Deficiencies in quality control directly correlate with potential product failures, increased costs, and reputational damage for both the individual company and the regional sector as a whole. The application of rigorous quality control measures acts as a preventative mechanism, ensuring that processes conform to established standards and that the final products meet specified performance criteria. An example includes the implementation of statistical process control (SPC) to monitor the consistency of coating thickness during electroplating, thereby minimizing deviations that could compromise corrosion resistance.

The practical implications of effective quality control extend across multiple facets of operations. Non-destructive testing (NDT) methods, such as ultrasonic testing or radiography, are deployed to detect internal flaws or inconsistencies in the base metal or applied coatings without causing damage to the component. This proactive approach allows for the identification and rectification of defects before the component enters service, reducing the risk of premature failure. Additionally, meticulous record-keeping and traceability systems enable the tracking of materials and processes used in the treatment of each component, facilitating root cause analysis in the event of a quality issue. The emphasis on documentation and traceability enhances accountability and promotes continuous improvement in process control.

In conclusion, quality control functions as an integrated safeguard within the operations dedicated to the surface treatment of metals in the Carolinas. While the implementation of comprehensive quality control protocols presents challenges related to resource allocation and personnel training, the long-term benefitsenhanced product reliability, reduced warranty claims, and sustained customer satisfactionfar outweigh the initial investment. The commitment to rigorous quality control is not merely an operational requirement; it represents a strategic imperative for maintaining competitiveness and ensuring the continued success of the regional industry.

6. Technology Integration

The integration of advanced technologies is transforming the landscape of metal finishing processes within the Carolinas. These advancements directly impact efficiency, precision, and environmental sustainability. Automated systems, for example, are replacing manual processes in areas such as cleaning, coating application, and quality inspection, resulting in reduced labor costs and improved consistency. Robotic systems can perform tasks with greater precision and repeatability than human operators, minimizing variations in coating thickness and surface finish. The adoption of these technologies directly addresses the need for increased productivity and enhanced quality demanded by competitive markets.

Furthermore, the use of advanced sensor technologies and data analytics enables real-time monitoring and control of critical process parameters. Sensors can continuously measure temperature, pH, and chemical concentrations in plating baths, allowing for immediate adjustments to maintain optimal conditions. Data analytics tools then analyze this data to identify trends and patterns that can be used to optimize process performance and predict potential problems. For instance, analysis of historical data on coating thickness and corrosion resistance can reveal correlations between process parameters and product quality, enabling proactive measures to prevent defects. The implementation of these technologies facilitates a shift from reactive problem-solving to proactive process management.

The integration of technology within the metal finishing sector of the Carolinas is not without challenges. The initial investment costs associated with new equipment and software can be substantial, and workforce training is required to operate and maintain these advanced systems. However, the long-term benefits, including increased productivity, reduced waste, improved quality, and enhanced environmental compliance, outweigh these initial costs. The continued adoption and skillful application of technological advancements are essential for maintaining a competitive edge and ensuring the long-term sustainability of the regional metal finishing industry.

7. Environmental Compliance

Environmental compliance is not merely an adjunct to metal finishing operations within the Carolinas; it is an intrinsic component governing operational practices and influencing technological adoption. The inherent nature of metal finishing processes, often involving hazardous chemicals and the generation of regulated waste streams, necessitates strict adherence to federal, state, and local environmental regulations. Failure to comply can result in significant penalties, including fines, operational shutdowns, and reputational damage. The regulations enforced by agencies like the Environmental Protection Agency (EPA) and state-level environmental agencies set specific limits for air emissions, wastewater discharge, and solid waste management, directly impacting the processes, equipment, and materials utilized by metal finishing businesses.

The adoption of specific technologies and operational practices within metal finishing facilities is directly influenced by the need to meet environmental compliance requirements. For example, facilities may invest in advanced wastewater treatment systems to remove heavy metals and other pollutants from their effluent before discharge, ensuring compliance with stringent water quality standards. Similarly, facilities may implement air pollution control technologies, such as scrubbers and filters, to minimize emissions of volatile organic compounds (VOCs) and other hazardous air pollutants. The selection of alternative, less hazardous chemicals and the implementation of closed-loop systems to recycle process fluids are also driven by the need to reduce environmental impact and comply with regulations. The transition from traditional solvent-based coatings to water-based or powder coatings is another example of how environmental compliance shapes technological choices.

Environmental compliance within the Carolina metal finishing sector is a dynamic and ongoing process, requiring continuous monitoring, adaptation, and improvement. The complexity of environmental regulations and the potential for technological advancements necessitate a proactive approach to compliance. Businesses must invest in training, auditing, and process optimization to ensure that they meet their environmental obligations. While the costs associated with environmental compliance can be substantial, they are ultimately outweighed by the benefits of protecting human health, preserving natural resources, and maintaining a positive public image. The ability to demonstrate a strong commitment to environmental stewardship is increasingly becoming a competitive advantage for metal finishing businesses operating in the Carolinas region.

Frequently Asked Questions about Carolina Metal Finishing

The following section addresses common inquiries regarding surface treatment processes applied to metallic components within the Carolinas region. It provides concise, informative answers to frequently asked questions.

Question 1: What distinguishes surface treatment within the Carolinas from similar services offered elsewhere?

The regional sector often exhibits specialized expertise tailored to the prevalent industries and environmental conditions of the Carolinas. This specialization may involve unique coating formulations optimized for the region’s climate or specific industry standards that are particularly relevant to local manufacturers.

Question 2: What are the most common types of metal finishing processes utilized in the region?

Common processes include electroplating, powder coating, anodizing, and various forms of chemical conversion coating. The selection of a specific process depends on factors such as the base metal, desired performance characteristics, and aesthetic requirements.

Question 3: How does metal finishing contribute to extending the lifespan of metal products?

Surface treatments enhance corrosion resistance, improve wear resistance, and increase surface hardness, thereby mitigating the degradation of metal components and prolonging their operational life.

Question 4: Are there specific environmental regulations that companies specializing in metal finishing in the Carolinas must adhere to?

Yes, companies must comply with federal, state, and local environmental regulations governing air emissions, wastewater discharge, and hazardous waste management. Compliance is essential for sustainable operations and responsible environmental stewardship.

Question 5: What factors determine the cost of metal finishing services?

Cost factors include the type of metal being treated, the complexity of the component’s geometry, the chosen finishing process, the required surface area, and any specific performance requirements. Economies of scale can also influence pricing.

Question 6: How does a business select the appropriate metal finishing process for a given application?

The selection process should involve a thorough assessment of the operational environment, performance requirements, and aesthetic considerations. Consulting with experienced metal finishing professionals is advisable to ensure optimal results.

In summary, the effectiveness and suitability of these processes are determined by a careful consideration of both the desired outcome and regulatory requirements.

The next article section will explore future trends impacting the industry.

Conclusion

The preceding analysis has explored various facets of carolina metal finishing, emphasizing its importance in enhancing material properties, ensuring regulatory compliance, and supporting diverse industries. This examination underscores the critical role of adhering to industry standards, implementing rigorous quality control measures, and integrating advanced technologies to achieve optimal outcomes. The sector’s commitment to environmental stewardship and continuous improvement is paramount for long-term sustainability.

The ongoing evolution of surface treatment technologies necessitates a continued focus on innovation and adaptation within this regional industry. Stakeholders must remain informed about emerging trends, invest in skilled personnel, and prioritize environmentally responsible practices to maintain competitiveness and contribute to the broader economic vitality of the Carolinas. Continued diligence and strategic investment are essential for navigating the complexities of this specialized field.