The application of surface treatments to metallic components within the Denver metropolitan area is a specialized industry. This encompasses processes designed to alter the surface properties of a metal, enhancing characteristics such as corrosion resistance, wear resistance, or aesthetic appeal. Common examples include anodizing aluminum parts used in aerospace applications or applying powder coatings to steel structures for increased durability in outdoor environments.

This sector plays a critical role in supporting numerous industries, ranging from aerospace and automotive manufacturing to construction and electronics. The improvements imparted by these surface treatments extend the lifespan of components, reduce maintenance requirements, and improve overall product performance. Historically, the development of advanced finishing techniques has significantly contributed to the advancement of material science and engineering practices within the region.

The following sections will delve into specific types of metal finishing processes available in the Denver area, examining the factors that influence the selection of appropriate techniques, and exploring the regulatory environment governing these operations.

Key Considerations for Metal Finishing Services in Denver

Selecting the appropriate metal finishing service requires careful evaluation of specific project requirements and provider capabilities. These considerations contribute to optimal results and long-term performance.

Tip 1: Material Compatibility: Verify that the chosen finishing process is compatible with the base metal. Incompatible processes can lead to adhesion failures, corrosion, or degradation of the substrate material.

Tip 2: Performance Requirements: Define the desired performance characteristics, such as corrosion resistance, wear resistance, hardness, or aesthetic appeal. Different finishing processes offer varying levels of protection and visual impact.

Tip 3: Process Certification: Confirm that the service provider maintains relevant certifications, such as ISO 9001 or industry-specific approvals. Certifications demonstrate adherence to quality standards and process control.

Tip 4: Environmental Compliance: Inquire about the provider’s environmental practices and adherence to local and federal regulations. Responsible waste management and emissions control are crucial for minimizing environmental impact.

Tip 5: Turnaround Time and Capacity: Assess the provider’s ability to meet project deadlines and handle the required volume of parts. Consider lead times, processing capacity, and potential bottlenecks.

Tip 6: Cost Analysis: Obtain detailed cost estimates that include all aspects of the finishing process, such as surface preparation, application, curing, and quality control. Evaluate the total cost of ownership, considering both initial expenses and long-term benefits.

Tip 7: Sample Testing and Validation: Request sample parts to be processed and subjected to rigorous testing. This allows for verification of performance characteristics and ensures that the selected process meets the specified requirements.

By carefully considering these factors, organizations can make informed decisions and select metal finishing services that deliver optimal performance, durability, and value.

The subsequent sections will explore specific applications and case studies within the Denver area, illustrating the practical benefits of these processes.

1. Materials science

Materials science is fundamental to effective metal finishing processes within the Denver area. It provides the foundational knowledge necessary to understand how different metals and alloys interact with various surface treatments. The selection of appropriate finishing techniques, such as anodizing, powder coating, or plating, depends heavily on the material properties of the substrate. For example, the success of chromate conversion coatings on aluminum alloys relies on understanding the electrochemical behavior of the alloy components. Improper material selection or a mismatched finishing process can lead to premature failure, corrosion, or reduced performance of the finished component. As an example, applying an inappropriate coating to a high-strength steel part can induce hydrogen embrittlement, leading to catastrophic failure under stress.

The study of materials science also allows for optimizing surface preparation techniques, which are crucial for ensuring proper adhesion of the finishing layer. Understanding the surface energy, chemical reactivity, and microstructure of the metal enables the selection of appropriate cleaning, etching, or activation processes. For instance, grit blasting steel prior to powder coating increases the surface area and creates a mechanical key for improved coating adhesion. Furthermore, materials science informs the development of new and improved finishing processes, leading to enhanced performance characteristics. The formulation of advanced coatings with improved corrosion resistance or wear resistance relies heavily on the principles of materials science.

In conclusion, the integration of materials science principles is essential for ensuring the success and longevity of metal finishing applications in Denver. A thorough understanding of material properties, surface interactions, and process parameters is necessary to achieve optimal performance, prevent premature failure, and meet stringent quality requirements. Continuous advancements in materials science will continue to drive innovation and improvement in the field of metal finishing, leading to more durable, efficient, and sustainable surface treatment solutions.

2. Corrosion resistance

In the Denver metropolitan area, environmental conditions present a significant challenge to the longevity of metallic structures and components. Metal finishing processes play a crucial role in mitigating the effects of corrosion, thereby extending the lifespan and maintaining the integrity of these assets.

- Climatic Factors

Denver experiences a wide range of temperature fluctuations, coupled with exposure to ultraviolet radiation and varying levels of precipitation. These climatic factors accelerate corrosive processes. Metal finishing techniques such as powder coating, anodizing, and galvanizing are applied to create protective barriers against these environmental aggressors. Failure to adequately address corrosion can lead to structural weakening, aesthetic degradation, and eventual component failure.

- Industrial Emissions and Chemical Exposure

The Denver area has a history of industrial activity that can result in localized air and soil pollution. Exposure to industrial emissions and chemical runoff can exacerbate corrosion rates, particularly for certain metals and alloys. Specialized metal finishing processes, including electroplating with corrosion-resistant metals or the application of chemical conversion coatings, provide enhanced protection against these specific corrosive agents. Without such interventions, equipment and infrastructure in these zones are susceptible to accelerated deterioration.

- De-icing Salts and Roadway Chemicals

During winter months, the application of de-icing salts and other roadway chemicals is common practice. These chemicals introduce chloride ions, which are highly corrosive to many metals, particularly steel and aluminum. Metal finishing solutions for transportation infrastructure, such as bridges and vehicles, often incorporate multi-layered protective systems that combine barrier coatings with sacrificial anodes to mitigate the effects of chloride-induced corrosion. The selection of appropriate coatings is critical to maintaining the safety and functionality of transportation systems.

- Electrochemical Considerations

Corrosion is fundamentally an electrochemical process involving the flow of electrons between different points on a metal surface or between dissimilar metals in contact. Metal finishing techniques, such as cathodic protection and the application of insulating coatings, disrupt these electrochemical reactions, thereby inhibiting corrosion. A thorough understanding of electrochemical principles is essential for designing effective corrosion prevention strategies in the Denver context.

The strategic application of appropriate metal finishing solutions is essential for ensuring the long-term durability and reliability of metallic assets in Denver’s diverse and challenging environment. Continuous research and development in the field of corrosion science are driving the development of innovative metal finishing techniques that provide enhanced protection and extend the lifespan of critical infrastructure and equipment.

3. Surface preparation

The effectiveness of any metal finishing process within the Denver area is directly contingent upon the quality of surface preparation. Surface preparation encompasses a series of operations designed to create an optimal substrate for the adhesion and performance of subsequently applied coatings or treatments.

- Cleaning and Degreasing

The removal of contaminants such as oils, greases, oxides, and particulate matter is paramount. Contaminants impede the adhesion of coatings, resulting in premature failure. Examples include the use of alkaline cleaners to remove machining oils from fabricated steel components, or solvent degreasing to eliminate fingerprints from aluminum prior to anodizing. Inadequate cleaning leads to blistering, peeling, and reduced corrosion resistance.

- Mechanical Abrasion

Techniques such as abrasive blasting, grinding, and polishing are employed to remove existing coatings, corrosion products, and surface imperfections. These processes create a roughened surface profile that enhances mechanical interlocking between the substrate and the applied coating. For instance, steel structures are often grit blasted to remove mill scale and provide an anchor pattern for subsequent painting. Insufficient abrasion reduces coating adhesion and increases the risk of corrosion underfilm.

- Chemical Etching and Activation

Chemical treatments modify the surface chemistry of the metal, promoting adhesion and enhancing corrosion resistance. Examples include the use of acid etches to create a microporous surface on aluminum prior to anodizing, or the application of conversion coatings such as phosphate or chromate treatments. Improper chemical etching can lead to inconsistent coating adhesion and reduced corrosion protection.

- Masking and Fixturing

Protecting specific areas of a part from being coated by using masking tapes, plugs, or custom fixtures. This helps to ensure that critical dimensions, threads, or other features are not affected by the finishing process. Precision masking is essential in industries such as aerospace and electronics where dimensional tolerances are tight. Using the wrong masking can lead to defects, rework, and increased costs.

These surface preparation methods, individually or in combination, are indispensable prerequisites for achieving durable and high-quality metal finishes in Denver. Effective surface preparation minimizes the risk of coating failure, optimizes corrosion resistance, and ensures the long-term performance of finished metal components.

4. Environmental compliance

Environmental compliance is a crucial aspect of metal finishing operations within the Denver area. Strict adherence to regulations is essential for minimizing environmental impact and ensuring sustainable business practices.

- Wastewater Treatment and Discharge

Metal finishing processes generate wastewater containing heavy metals, acids, and other pollutants. Compliance requires proper treatment of wastewater to remove these contaminants before discharge into municipal sewer systems or the environment. Permitting under the Clean Water Act and local regulations mandates specific discharge limits for various pollutants. Examples include the use of chemical precipitation, filtration, and ion exchange to remove metals from wastewater. Failure to comply can result in significant fines and operational shutdowns.

- Air Emissions Control

Some metal finishing processes, such as spray painting and electroplating, release volatile organic compounds (VOCs) and other air pollutants. Compliance requires the implementation of air pollution control technologies to minimize emissions. Examples include the use of carbon adsorption systems to capture VOCs from paint booths and the installation of scrubbers to remove acid mists from electroplating operations. Facilities must obtain air permits and demonstrate compliance with emission limits. Non-compliance can lead to penalties and legal action.

- Hazardous Waste Management

Metal finishing operations generate hazardous waste, including spent chemicals, sludges, and contaminated materials. Compliance requires proper storage, handling, and disposal of hazardous waste in accordance with the Resource Conservation and Recovery Act (RCRA) and state regulations. Examples include the use of lined containers for storing corrosive chemicals, proper labeling of hazardous waste containers, and transportation of waste to permitted treatment, storage, and disposal facilities. Failure to manage hazardous waste properly can result in environmental contamination and legal liability.

- Chemical Reporting and Inventory

Facilities are required to report the quantities and types of chemicals stored and used on site. This reporting ensures that local emergency responders and regulatory agencies are aware of potential hazards. The Emergency Planning and Community Right-to-Know Act (EPCRA) requires facilities to submit annual reports to state and local authorities. Maintaining an accurate chemical inventory and submitting timely reports is essential for compliance. Failure to do so can result in fines and penalties.

These environmental compliance measures are integral to responsible metal finishing operations in Denver. Adherence to regulations protects the environment, safeguards public health, and ensures the long-term viability of the industry.

5. Quality Control in Denver's Metal Finishing Sector

Quality control is an indispensable component of metal finishing within the Denver area. The effectiveness of applied surface treatments hinges directly on the implementation of rigorous quality control procedures at every stage of the process. These procedures, if properly executed, ensure that finished products meet specified performance criteria, dimensional tolerances, and aesthetic requirements. Deficiencies in quality control invariably lead to premature coating failure, corrosion, or dimensional inaccuracies, resulting in increased costs and compromised product integrity. For example, if inadequate testing is conducted after a plating process, parts may exhibit insufficient corrosion resistance, leading to failure in the field and necessitating costly replacements.

The specific quality control measures implemented vary depending on the type of metal finishing process and the intended application of the finished product. Common techniques include visual inspection, adhesion testing, thickness measurement, and corrosion testing. Visual inspection detects surface defects such as scratches, blisters, or discoloration. Adhesion testing verifies the bond strength between the coating and the substrate. Thickness measurement ensures that the coating meets specified thickness requirements. Corrosion testing, such as salt spray testing, assesses the resistance of the finished product to corrosive environments. In the aerospace industry, for instance, stringent quality control protocols mandate comprehensive testing to ensure that finished components meet the demanding performance standards required for flight safety.

In conclusion, quality control is not merely an ancillary activity but rather an integral and essential aspect of metal finishing operations in Denver. The diligent application of robust quality control procedures safeguards product quality, enhances durability, and mitigates risks associated with premature failure. Continuous improvement in quality control techniques is essential for maintaining competitiveness and meeting the evolving needs of diverse industries within the region.

6. Process selection

The selection of an appropriate metal finishing process is a critical determinant of performance and longevity for components treated within the Denver area. Process selection directly influences corrosion resistance, wear resistance, aesthetic properties, and adherence to environmental regulations. Incorrect process selection can lead to premature failure, increased maintenance costs, and non-compliance with applicable standards.

- Material Compatibility

The base material’s properties dictate the range of viable finishing options. For instance, anodizing is suitable for aluminum alloys but not for ferrous metals. Similarly, certain high-strength steels may be susceptible to hydrogen embrittlement during electroplating. In Denver’s diverse industrial landscape, understanding material compatibility is paramount for achieving desired performance characteristics. Selecting an incompatible process results in poor adhesion, accelerated corrosion, or structural weakening of the component.

- Service Environment

The intended service environment significantly influences process selection. Components exposed to harsh chemicals or abrasive conditions necessitate finishes with enhanced resistance to these specific challenges. For example, equipment used in Denver’s mining industry requires coatings capable of withstanding extreme abrasion and corrosive substances. Components used outdoors must resist UV degradation and temperature fluctuations. Ignoring the service environment can lead to rapid degradation and functional failure of the finished part.

- Performance Requirements

Specific performance requirements, such as hardness, conductivity, or lubricity, necessitate careful process selection. If a component requires high hardness for wear resistance, processes like hard chrome plating or nitriding may be considered. Electrical conductivity requirements may favor processes like electroless nickel plating. Lubricity requirements may necessitate the use of coatings containing PTFE or molybdenum disulfide. In Denver’s precision manufacturing sector, meeting stringent performance specifications is crucial for product success. Selecting an inappropriate process can compromise the component’s functionality and reliability.

- Cost and Throughput

Economic considerations and production volume influence process selection. Certain processes are more cost-effective for high-volume applications, while others are better suited for low-volume or specialized components. Factors such as processing time, material costs, and labor requirements contribute to the overall cost of the finishing process. In Denver’s competitive market, balancing cost-effectiveness with performance requirements is essential for maintaining profitability. Selecting an overly expensive process for a high-volume application can significantly increase production costs.

Effective process selection for metal finishing in Denver requires a comprehensive understanding of material properties, service environments, performance requirements, and economic factors. A systematic approach to process selection, involving consultation with experienced finishing specialists, is essential for achieving optimal results and maximizing the value of finished components. The successful integration of these considerations leads to durable, reliable, and cost-effective metal finishing solutions tailored to the specific needs of Denver’s diverse industries.

Frequently Asked Questions About Metal Finishing in Denver

This section addresses common inquiries regarding the application of surface treatments to metallic components within the Denver metropolitan area. The information provided aims to clarify key aspects of the industry.

Question 1: What are the primary benefits of metal finishing?

Surface treatments enhance corrosion resistance, improve wear resistance, increase hardness, modify electrical conductivity, and enhance aesthetic appeal. The specific benefits vary depending on the finishing process and the base material.

Question 2: What factors influence the selection of a metal finishing process?

Material compatibility, service environment, performance requirements, cost considerations, and production volume all influence process selection. A thorough evaluation of these factors is crucial for achieving optimal results.

Question 3: What types of metals can be finished?

A wide range of metals, including steel, aluminum, magnesium, titanium, and copper alloys, can be finished. The suitability of a particular finishing process depends on the properties of the metal.

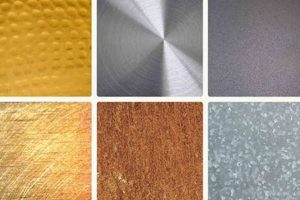

Question 4: What are common metal finishing processes used in Denver?

Common processes include anodizing, electroplating, powder coating, painting, chemical conversion coating, and thermal spraying. The selection depends on the desired properties and the application.

Question 5: How does environmental compliance affect metal finishing operations?

Metal finishing operations are subject to strict environmental regulations regarding wastewater treatment, air emissions control, and hazardous waste management. Compliance is essential for minimizing environmental impact and ensuring sustainable business practices.

Question 6: How can quality be ensured in metal finishing processes?

Quality control measures include visual inspection, adhesion testing, thickness measurement, and corrosion testing. These procedures ensure that finished products meet specified performance criteria and dimensional tolerances.

Metal finishing processes are vital for ensuring the durability and performance of metallic components across diverse industries. A comprehensive understanding of these processes is essential for making informed decisions and achieving optimal results.

The following section will provide resources for finding qualified metal finishing providers within the Denver area.

Conclusion

The preceding discussion has elucidated various facets of surface treatments applied to metals within the Denver region. These processes encompass a broad spectrum of techniques aimed at enhancing material properties, improving performance characteristics, and ensuring adherence to regulatory standards. Effective implementation of such techniques requires a comprehensive understanding of material science, process parameters, and environmental considerations.

Ultimately, the value of sophisticated metal finishing in Denver lies in its capacity to extend the service life of essential components, improve the reliability of critical infrastructure, and support the competitiveness of local industries. Continued investment in research and development, coupled with a commitment to best practices, will be essential for maintaining the region’s leadership in this specialized field.

![Top Asheville Metal Finishing: [Your Brand] Quality Best Final Touch: Elevate Your Projects with Professional Finishing Top Asheville Metal Finishing: [Your Brand] Quality | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-666-300x200.jpg)