The process of enhancing the surface characteristics of metallic components to achieve specific performance and aesthetic requirements is a critical aspect of manufacturing. This involves applying various techniques to alter the metal’s surface, resulting in improved resistance to corrosion, increased hardness, enhanced conductivity, or a more appealing visual appearance. For example, components subjected to harsh environmental conditions may undergo a treatment to prevent rust and degradation, thus extending their service life.

The implementation of advanced surface treatments offers significant advantages across numerous industries. These benefits include prolonged product lifespan, reduced maintenance costs, improved functionality, and greater market appeal. Historically, these treatments were primarily focused on functional improvements; however, modern applications increasingly emphasize both functional and aesthetic enhancements, reflecting evolving consumer expectations and competitive pressures.

The following discussion will delve into specific methods employed to achieve optimal surface properties, covering topics such as electroplating, powder coating, and anodizing, as well as the quality control measures essential for ensuring consistent and reliable results.

Essential Considerations for Enhanced Metal Surface Treatment

Achieving optimal outcomes in metal surface treatment requires careful attention to several key factors. The following tips offer guidance for practitioners seeking to maximize the effectiveness and longevity of their finished products.

Tip 1: Material Selection: The base metal’s properties significantly influence the final result. Prior to any surface treatment, a thorough assessment of the metal’s composition and inherent characteristics is essential to ensure compatibility and optimal adhesion of the applied coating or finish. For instance, certain alloys may require specific pre-treatment processes to remove impurities or improve surface roughness.

Tip 2: Surface Preparation: Adequate surface preparation is paramount. This includes removing contaminants such as oil, grease, rust, and scale. Techniques like abrasive blasting, chemical etching, and degreasing are often employed to create a clean, uniform surface that promotes strong adhesion and prevents premature failure of the applied finish. Inadequate preparation invariably leads to compromised results.

Tip 3: Controlled Environment: Maintaining a controlled environment during the application process is critical. Factors such as temperature, humidity, and air cleanliness can significantly impact the quality of the final finish. Deviation from optimal conditions can result in inconsistencies, imperfections, and reduced performance. Environmental controls are particularly crucial for processes like powder coating and electroplating.

Tip 4: Process Optimization: Each surface treatment method requires precise control of process parameters. For example, electroplating necessitates careful regulation of current density, bath composition, and immersion time. Deviation from established parameters can lead to variations in coating thickness, uniformity, and adherence. Regular monitoring and adjustments are essential for consistent quality.

Tip 5: Proper Curing/Drying: After application, many surface treatments require a curing or drying process to achieve their final properties. Adherence to recommended curing schedules, including temperature and duration, is essential. Insufficient or improper curing can result in soft, brittle, or poorly adhered finishes. Verify cure schedules with materials providers.

Tip 6: Quality Control and Inspection: Implementing rigorous quality control measures is crucial to identify and address any defects or inconsistencies in the finished product. This includes visual inspections, thickness measurements, adhesion tests, and corrosion resistance assessments. Regular inspections ensure that the surface treatment meets the required specifications and performance standards.

Tip 7: Documentation and Traceability: Maintaining thorough documentation of all process parameters, materials used, and inspection results is essential for traceability and continuous improvement. Detailed records allow for the identification of potential issues, the optimization of process parameters, and the resolution of customer complaints. Traceability ensures accountability and facilitates process refinement.

By adhering to these considerations, manufacturers can significantly enhance the quality and performance of their metal products, thereby extending their service life and reducing overall costs. Attention to detail in material selection, preparation, application, and quality control are vital to achieve outstanding and enduring results.

The subsequent sections will explore specific surface treatment methods in greater detail, providing a comprehensive overview of their respective applications and best practices.

1. Corrosion Resistance

Corrosion resistance is a fundamental attribute directly linked to the quality and effectiveness of metal surface treatments. The degradation of metallic materials due to electrochemical reactions with their environment can lead to structural failure, performance decline, and safety hazards. Consequently, the ability of a metal finishing process to impart robust corrosion protection is a key determinant of its overall value and suitability for a given application. The selection and application of appropriate finishing techniques, such as electroplating, powder coating, or conversion coatings, directly influence the metal’s ability to withstand corrosive agents like moisture, salts, and acidic substances.

The specific mechanism by which finishing enhances corrosion resistance varies depending on the technique employed. For instance, electroplating with a noble metal like chromium provides a barrier layer that physically isolates the underlying base metal from the corrosive environment. Alternatively, sacrificial coatings, such as galvanizing with zinc, corrode preferentially, thereby protecting the base metal until the sacrificial layer is depleted. In the automotive industry, the extensive use of e-coating and powder coating on vehicle body panels significantly extends the lifespan of the vehicle by mitigating rust formation. Similarly, the application of anodizing to aluminum alloys used in aerospace components provides a durable, corrosion-resistant surface crucial for maintaining structural integrity in demanding operational conditions.

In conclusion, corrosion resistance is an indispensable component of high-quality metal finishing. Its achievement relies on the careful selection of appropriate materials, meticulous surface preparation, and precise control of the application process. Understanding the principles of corrosion and the mechanisms by which various finishing techniques provide protection is essential for engineers and manufacturers seeking to maximize the durability, reliability, and longevity of metal components in diverse operational environments. The ongoing development of advanced corrosion-resistant coatings and finishing processes remains a critical area of research and innovation.

2. Surface Hardness

Surface hardness, the resistance of a material to localized plastic deformation, stands as a critical metric in evaluating the efficacy of metal finishing processes. The ability to enhance surface hardness directly correlates with improved wear resistance, extended component lifespan, and enhanced performance in demanding operational environments. Consequently, the selection of a metal finishing technique that effectively increases surface hardness is often paramount in achieving the objectives of enhanced component reliability and durability.

- Wear Resistance Enhancement

Increased surface hardness directly translates to improved wear resistance. Harder surfaces are more resistant to abrasion, erosion, and galling, phenomena that can lead to premature component failure. Case hardening, for example, diffuses elements such as carbon or nitrogen into the metal’s surface, creating a hard outer layer while retaining a ductile core. This is crucial in gears and bearings, where surfaces are subjected to high contact stresses and relative motion.

- Scratch Resistance

Surface hardness plays a significant role in a component’s resistance to scratching and marring. Coatings or treatments that enhance hardness provide a barrier against superficial damage that can compromise both aesthetic appearance and functional integrity. Diamond-like carbon (DLC) coatings, renowned for their extreme hardness, are used on cutting tools and automotive components to maintain edge sharpness and prevent surface degradation.

- Erosion Resistance

In environments where components are exposed to particulate matter or fluid impingement, surface hardness becomes a critical factor in mitigating erosion. Harder surfaces can withstand the abrasive effects of these particles, minimizing material loss and preserving dimensional accuracy. Turbine blades in jet engines, often coated with hard ceramic materials, exemplify this application, preventing erosion caused by high-speed airflow and ingested particles.

- Improved Fatigue Life

While perhaps less direct, improved surface hardness can indirectly influence fatigue life. By reducing surface imperfections and minimizing plastic deformation, harder surfaces can delay the onset of fatigue cracks, leading to extended component service life under cyclic loading. Shot peening, a process that induces compressive residual stresses and work hardening at the surface, is commonly used in aerospace and automotive industries to improve fatigue resistance in critical components.

The benefits derived from enhanced surface hardness underscore its importance in the context of metal finishing. The selection of appropriate hardening treatments, coupled with precise control over process parameters, is essential for achieving the desired performance characteristics and ensuring the longevity of metal components in diverse engineering applications. The synergistic relationship between surface hardness and metal finishing demonstrates its fundamental role in achieving superior component reliability and durability.

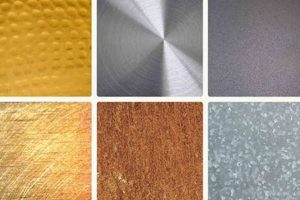

3. Aesthetic Appeal

Aesthetic appeal, while seemingly subjective, is a significant factor in determining the perceived value and market success of many products. In the context of metal finishing, it represents the visual and tactile qualities of a treated surface that contribute to its overall attractiveness and desirability. The attainment of a visually pleasing surface is often as important as functional enhancements, particularly in consumer-facing applications.

- Color and Luster Control

Precise control over color and luster is a key aspect of aesthetic finishing. Techniques like anodizing, powder coating, and painting allow for the application of a wide range of colors and finishes, from matte to high-gloss. Consistent color matching and uniform luster are critical for achieving a professional and appealing look, especially in applications where parts are assembled together. Automotive finishes, appliance coatings, and architectural metalwork exemplify the importance of color and luster control in achieving visual harmony and brand recognition.

- Surface Smoothness and Uniformity

Surface smoothness and uniformity contribute significantly to the tactile and visual perception of quality. Superior metal finishing processes minimize surface imperfections such as scratches, pits, and orange peel. Polishing, buffing, and grinding are often employed to create smooth, uniform surfaces that are pleasing to the touch and reflect light evenly. High-end consumer electronics, precision instruments, and decorative hardware all demand exceptional surface smoothness and uniformity.

- Texture and Pattern Application

The application of specific textures and patterns can enhance both the aesthetic and functional properties of a metal surface. Embossing, etching, and laser marking allow for the creation of decorative patterns, logos, or functional textures that improve grip or reduce glare. These techniques are widely used in the automotive industry for interior trim, in the electronics industry for device housings, and in architectural applications for decorative panels. The strategic use of texture can add depth, visual interest, and tactile appeal to a finished product.

- Cleanliness and Absence of Defects

The absence of visible defects, such as blemishes, stains, or fingerprints, is essential for achieving a high-quality aesthetic finish. Rigorous cleaning and handling procedures are necessary to prevent contamination during and after the finishing process. In critical applications, such as medical devices and aerospace components, even microscopic defects can compromise both the appearance and the functional integrity of the finished product. Meticulous attention to detail and stringent quality control are paramount in ensuring a flawless aesthetic finish.

In conclusion, aesthetic appeal is an integral component of effective metal finishing. The careful control of color, luster, surface smoothness, texture, and cleanliness contributes significantly to the perceived value and market success of finished products. While functional enhancements remain essential, the visual and tactile qualities imparted by metal finishing are increasingly important in meeting consumer expectations and differentiating products in competitive markets. A commitment to achieving superior aesthetic results reflects a dedication to quality and enhances the overall desirability of metal components across diverse applications.

4. Dimensional Accuracy

Dimensional accuracy, the degree to which a finished component conforms to specified dimensions, is a critical attribute directly impacted by metal finishing processes. Attaining and maintaining precise dimensions is paramount in ensuring proper fit, functionality, and interchangeability of parts, particularly in complex assemblies. The selection and execution of metal finishing techniques must account for their potential to alter the dimensions of the base metal, either through material addition (e.g., plating) or material removal (e.g., etching).

- Material Deposition Techniques

Techniques involving material deposition, such as electroplating, electroless plating, and coating processes, inevitably add material to the component surface. The thickness and uniformity of the deposited layer directly influence the final dimensions. Achieving tight tolerances necessitates precise control over deposition parameters, including current density, bath chemistry, and immersion time. Variations in coating thickness can lead to dimensional deviations, potentially compromising the fit and function of the finished part. For example, in the manufacturing of precision gears, even minor variations in plating thickness can affect gear meshing and performance.

- Material Removal Techniques

Conversely, material removal processes, such as etching and chemical milling, reduce the dimensions of the base metal. These techniques are often employed to create intricate patterns or to achieve specific surface finishes. Precise control over the etching rate and process duration is essential to prevent excessive material removal, which can lead to dimensional inaccuracies. In the production of printed circuit boards, precise etching is crucial for creating conductive pathways with the required dimensions and spacing.

- Heat Treatment Effects

Many metal finishing processes involve heat treatment, either as a pre-treatment step or as a post-treatment process to improve mechanical properties or coating adhesion. Heat treatment can cause dimensional changes due to thermal expansion and contraction of the metal. Understanding the thermal behavior of the base metal and carefully controlling the heating and cooling rates are crucial for minimizing dimensional distortion. In the aerospace industry, heat treatment of large structural components requires meticulous process control to maintain dimensional integrity.

- Masking and Fixturing

The use of masking and fixturing is often necessary to protect specific areas of a component from the finishing process or to maintain dimensional stability during treatment. Accurate masking ensures that only the intended surfaces are affected, preventing unwanted material deposition or removal. Robust fixturing minimizes distortion and prevents dimensional changes due to mechanical stress during processing. In the painting and coating of automotive parts, precise masking is essential for achieving clean lines and sharp edges.

The relationship between dimensional accuracy and metal finishing is a critical consideration in manufacturing. The selection and implementation of finishing processes must account for their potential impact on dimensions, with precise control and careful monitoring to ensure that the final product meets the required specifications. Failure to address dimensional accuracy can lead to functional problems, assembly issues, and ultimately, product failure. The pursuit of dimensional accuracy is thus an integral component of achieving truly effective metal finishing.

5. Adhesion Strength

Adhesion strength, the measure of the bond between a coating or finish and the substrate material, is a paramount characteristic in the context of high-quality metal finishing. The long-term performance and reliability of any surface treatment are intrinsically linked to the ability of the finish to remain firmly attached to the underlying metal. A finish with inadequate adhesion is prone to premature failure, undermining the intended benefits of corrosion resistance, wear protection, or aesthetic enhancement.

- Surface Preparation and Adhesion

Surface preparation methods directly impact adhesion strength. Contaminants such as oils, oxides, and loose particles impede the formation of a strong bond. Techniques like abrasive blasting, chemical etching, and degreasing remove these contaminants, creating a clean, chemically active surface that promotes intimate contact between the finish and the substrate. Insufficient surface preparation is a common cause of adhesion failures, leading to peeling, blistering, or chipping of the finish. For instance, applying paint to a rusty surface without proper preparation will inevitably result in poor adhesion and premature coating failure.

- Material Compatibility and Interdiffusion

The chemical and physical compatibility between the finish and the substrate material is crucial for achieving optimal adhesion. Certain material combinations may be inherently incompatible due to differences in thermal expansion coefficients or electrochemical potentials. In such cases, the use of intermediate layers or conversion coatings can improve adhesion by promoting interdiffusion and mechanical interlocking. The effectiveness of galvanizing steel, for example, relies on the formation of a zinc-iron alloy layer at the interface, which provides a strong metallurgical bond between the zinc coating and the steel substrate.

- Application Technique and Process Control

The application technique employed and the degree of process control exercised directly influence adhesion strength. Inconsistent coating thickness, improper curing schedules, or deviations from recommended application parameters can weaken the bond between the finish and the substrate. Precise control over temperature, humidity, and application pressure is essential for achieving uniform coating coverage and optimal adhesion. In powder coating, for instance, ensuring proper electrostatic charging and uniform powder distribution is critical for creating a tightly adhered finish.

- Testing and Quality Assurance

Rigorous testing and quality assurance procedures are essential for verifying adhesion strength and identifying potential weaknesses in the finishing process. Standardized tests, such as pull-off tests, scratch tests, and bend tests, provide quantitative measures of adhesion performance. Regular inspection of finished parts for defects such as blistering, peeling, or cracking can help to identify process deviations and prevent adhesion failures. The use of non-destructive testing methods, such as ultrasonic inspection, can also be employed to assess adhesion integrity without damaging the finished part.

The interconnectedness of these facets highlights the multi-faceted nature of adhesion strength in the context of metal finishing. A holistic approach that considers surface preparation, material compatibility, application technique, and rigorous testing is essential for achieving high-quality finishes that exhibit exceptional adhesion and long-term durability. The pursuit of superior adhesion strength is a fundamental objective in the field of metal finishing, underpinning the performance and reliability of finished metal products across a wide range of applications.

Frequently Asked Questions

This section addresses common inquiries regarding the procedures used to achieve enhanced metal surfaces and related considerations.

Question 1: What constitutes “superior metal finishing”?

The term refers to processes that optimize a metal’s surface properties to meet specific performance or aesthetic criteria. This can involve enhancing corrosion resistance, increasing hardness, improving conductivity, or altering visual appearance through techniques like electroplating, powder coating, or anodizing.

Question 2: How does surface preparation affect the quality of metal finishing?

Surface preparation is critical. Contaminants such as oil, grease, rust, and scale must be removed to ensure proper adhesion and prevent premature failure of the applied finish. Techniques like abrasive blasting, chemical etching, and degreasing are often employed.

Question 3: What role does material selection play in the success of metal finishing?

The base metal’s properties significantly influence the final result. A thorough assessment of the metal’s composition and inherent characteristics is essential to ensure compatibility and optimal adhesion of the applied coating or finish. Certain alloys may require specific pre-treatment processes.

Question 4: How is corrosion resistance achieved in metal finishing?

Corrosion resistance is achieved through various techniques, including applying barrier coatings that isolate the base metal from the environment, or using sacrificial coatings that corrode preferentially to protect the underlying metal. The selection of the appropriate method depends on the specific application and environment.

Question 5: What quality control measures are essential for consistent metal finishing?

Rigorous quality control measures are crucial to identify and address any defects or inconsistencies in the finished product. This includes visual inspections, thickness measurements, adhesion tests, and corrosion resistance assessments. Regular inspections ensure the surface treatment meets required specifications and performance standards.

Question 6: How does metal finishing contribute to dimensional accuracy?

Metal finishing processes can either add (e.g., plating) or remove (e.g., etching) material, potentially affecting dimensional accuracy. Precise control over process parameters, along with masking and fixturing, is necessary to maintain the desired dimensions within specified tolerances.

Effective surface enhancement hinges on careful material selection, thorough preparation, controlled application, and stringent quality assurance. Attention to detail ensures the durability and performance of finished metal products.

The following section delves into the applications of these methods across diverse industries.

Superior Metal Finishing

This discourse has explored the multifaceted nature of achieving enhanced metallic surfaces. From the critical role of surface preparation and material selection to the intricacies of process control and quality assurance, each element contributes significantly to the ultimate performance and longevity of finished components. The discussion underscored the importance of corrosion resistance, surface hardness, aesthetic appeal, dimensional accuracy, and adhesion strength as key performance indicators in the realm of metal treatment.

The pursuit of superior metal finishing is not merely an exercise in surface modification; it represents a strategic investment in product quality, operational efficiency, and long-term value. As industries continue to demand increasingly stringent performance standards and aesthetic requirements, the adoption of advanced metal finishing techniques will become ever more critical for maintaining competitiveness and ensuring the sustained success of manufactured goods. Continued research and innovation in this field remain essential for unlocking new possibilities and addressing the evolving challenges of modern engineering.

![Top Asheville Metal Finishing: [Your Brand] Quality Best Final Touch: Elevate Your Projects with Professional Finishing Top Asheville Metal Finishing: [Your Brand] Quality | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-666-300x200.jpg)