A protective coating applied to metallic surfaces, this treatment enhances aesthetic appeal and provides a barrier against environmental factors. For instance, the treatment can be applied to bronze sculptures to enrich their patina and guard against oxidation.

This protective layer is important in preserving the integrity and appearance of metalwork across various applications. Its benefits include amplified sheen, resistance to moisture and fingerprints, and retardation of corrosion processes, extending the lifespan of treated objects. Historically, similar treatments have been employed to safeguard metal artifacts from degradation.

The subsequent sections will delve into the specific types of materials used in this process, the application techniques involved, and the maintenance required to ensure its longevity and effectiveness. Furthermore, the discussion will explore its application across diverse industries and artistic endeavors.

Guidance on Protective Treatments for Metallic Surfaces

This section provides guidelines to maximize the effectiveness and longevity of a protective coating designed for metallic surfaces.

Tip 1: Surface Preparation is Paramount: Prior to application, meticulous cleaning is essential. All traces of grease, dirt, and oxidation must be removed to ensure proper adhesion. Consider using appropriate solvents or abrasive techniques tailored to the specific metal.

Tip 2: Select the Appropriate Formulation: Different metals and environmental conditions necessitate specific formulations. Understand the composition and properties of the product and ensure its compatibility with the substrate metal.

Tip 3: Apply Thin, Even Coats: Multiple thin coats are preferable to a single thick coat. This minimizes the risk of drips, runs, or uneven distribution, leading to a more uniform and aesthetically pleasing result.

Tip 4: Allow Adequate Drying Time: Adhere strictly to the manufacturer’s recommended drying and curing times. Premature handling or exposure to the elements can compromise the integrity and effectiveness of the treatment.

Tip 5: Buff to Enhance the Sheen: After complete curing, a gentle buffing with a soft cloth can enhance the reflective properties and improve the overall appearance of the treated surface.

Tip 6: Regular Maintenance is Essential: Periodic cleaning with a mild, non-abrasive cleaner is recommended to remove surface contaminants and maintain the protective barrier. Reapplication may be necessary depending on the exposure conditions.

Tip 7: Consider Environmental Factors: In areas with high humidity or exposure to corrosive elements, more frequent maintenance and reapplication may be required to ensure adequate protection.

By adhering to these guidelines, the protective benefits and aesthetic qualities of the treatment can be maximized, resulting in long-lasting protection and enhanced appearance.

The final section will summarize the key aspects of this protective treatment and offer concluding remarks.

1. Protection

The primary purpose of a metal wax finish is to provide a protective barrier against environmental degradation. This protective function manifests in several key areas, including resistance to oxidation, moisture ingress, and the corrosive effects of atmospheric pollutants. The wax component creates a physical shield, preventing direct contact between the metal substrate and potentially damaging elements. For example, architectural bronze exposed to acid rain benefits significantly from this protection, exhibiting reduced pitting and discoloration over time. The extent and duration of this protection are directly related to the wax’s composition, application thickness, and the severity of the environmental conditions.

Furthermore, the protective nature of a metal wax finish extends beyond simply preventing corrosion. It also mitigates the impact of handling, reducing the likelihood of fingerprints, scratches, and other surface imperfections. This is particularly valuable in applications involving high-touch surfaces, such as handrails, door hardware, and display pieces. The application of the finish not only preserves the metal’s aesthetic qualities but also minimizes the need for frequent cleaning and polishing, reducing long-term maintenance costs. Museums often employ similar treatments to protect metal artifacts from the damaging effects of handling by visitors.

In summary, the protective aspect of a metal wax finish is paramount to its overall utility. It acts as a critical defense against environmental and physical damage, extending the lifespan and maintaining the aesthetic integrity of metallic surfaces. While the specific benefits vary depending on the formulation and application, the fundamental goal remains consistent: to safeguard the underlying metal from premature degradation. The selection of an appropriate wax and the meticulous execution of the application process are therefore crucial for maximizing its protective capabilities.

2. Appearance

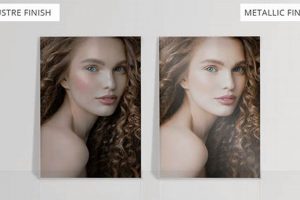

The application of a metal wax finish significantly influences the visual characteristics of the treated surface. The finish is not merely a protectant; it is also an aesthetic enhancer, capable of altering the metal’s reflectivity, color depth, and overall texture.

- Enhanced Sheen and Luster

The finish imparts a degree of sheen to the metal surface, ranging from a subtle satin to a highly reflective gloss. This enhancement accentuates the metal’s inherent beauty, making it appear richer and more vibrant. Consider, for example, polished brass hardware on furniture. A quality finish will amplify the warmth of the brass, creating a more luxurious feel, without appearing artificial.

- Color Depth and Clarity

The finish often deepens the perceived color of the metal. On darker metals like bronze or blackened steel, the finish can create a greater sense of depth and dimension. It can also enhance the clarity of any existing patina, bringing out subtle variations in color and texture. This is particularly noticeable in antique metalwork, where a well-applied finish can revive the original appearance without compromising its historical character.

- Surface Uniformity and Texture

The application can mitigate minor surface imperfections, creating a more uniform appearance. It fills in minute scratches and irregularities, resulting in a smoother, more refined texture. On textured metals, such as hammered copper, the finish can accentuate the surface details, highlighting the artisan’s craftsmanship. However, excessive buildup can obscure fine details, so proper application technique is crucial.

- Protection Against Fingerprints and Smudging

A key aspect of improved appearance is resistance to fingerprints and smudging. The finish creates a barrier that prevents oils from the skin from adhering to the metal surface, maintaining a cleaner and more presentable look. This is particularly beneficial in high-traffic areas or on frequently handled objects, such as elevator doors or display cases.

The impact on visual appeal is a critical factor in selecting and applying a metal wax finish. The finish transforms the appearance of metals from purely functional to aesthetically pleasing. The ability to enhance shine, depth of color, and uniformity allows metals to serve dual roles as durable materials and objects of design.

3. Application

The method by which a metal wax finish is applied directly dictates its effectiveness and aesthetic outcome. The process is not merely a superficial coating; it is a carefully orchestrated procedure involving surface preparation, application technique, and environmental control. The success of the finish depends as much on the quality of the materials as it does on the skill and precision of the application.

- Surface Preparation

Proper surface preparation is fundamental. All contaminants, including dirt, grease, and existing corrosion, must be removed. The metal surface should be clean, dry, and free from any residues that could impede adhesion. Depending on the metal and its condition, preparation may involve mechanical abrasion, chemical cleaning, or a combination of both. For instance, on aged brass, a solvent wash followed by a gentle abrasive cleaning ensures optimal bonding of the subsequent protective layer.

- Application Techniques

The chosen application method significantly impacts the final result. Options include brushing, spraying, and hand-application with a cloth. Brushing is suitable for intricate details or smaller surfaces, while spraying provides a more uniform coating over larger areas. Hand-application is often preferred for delicate or historically significant items, allowing for greater control and precision. Regardless of the technique, thin, even coats are crucial for preventing drips, runs, and uneven coverage. Proper technique ensures consistent protection and appearance across the entire surface.

- Environmental Conditions

Environmental factors during application are critical. Temperature and humidity levels can affect the wax’s viscosity, drying time, and adhesion properties. Ideally, application should occur in a well-ventilated area with moderate temperature and low humidity. Extreme conditions can lead to premature drying, poor adhesion, or the formation of a cloudy or uneven finish. For example, applying in direct sunlight can cause the wax to dry too quickly, resulting in a brittle and less effective protective layer.

- Curing and Buffing

The curing process, during which the wax hardens and bonds to the metal, is essential for durability. Adherence to the manufacturer’s recommended curing time is paramount. Premature handling or exposure to the elements can compromise the finish’s integrity. After curing, gentle buffing with a soft cloth can enhance the sheen and remove any residual surface imperfections. The buffing process also helps to further consolidate the wax, increasing its resistance to abrasion and wear.

The application of a metal wax finish is a multi-faceted process that demands meticulous attention to detail. Effective surface preparation, appropriate application techniques, controlled environmental conditions, and proper curing and buffing are all essential for achieving a durable, aesthetically pleasing, and long-lasting protective layer. The success of the finish is directly proportional to the care and skill invested in each stage of the application process.

4. Durability

The lifespan and protective effectiveness of a metal wax finish are intrinsically linked to its durability. The ability of the wax layer to withstand environmental stressors, physical abrasion, and chemical exposure directly influences its long-term performance. A durable finish maintains its integrity over time, preserving the metal’s appearance and safeguarding it from corrosion. For instance, a wax applied to outdoor bronze sculptures must endure fluctuating temperatures, UV radiation, and moisture exposure; a failure to do so results in accelerated degradation of both the finish and the underlying metal.

The composition of the metal wax finish plays a crucial role in determining its durability. High-quality waxes formulated with specific polymers and additives offer enhanced resistance to wear and tear. These formulations create a more resilient barrier against scratches, fingerprints, and environmental contaminants. Consider, for example, the application of protective finishes on automotive trim, which must withstand constant exposure to road salts, detergents, and mechanical stress from washing. The selection of appropriate materials and application techniques is paramount in ensuring the finish’s prolonged effectiveness in such demanding environments. Furthermore, proper application techniques, such as applying multiple thin coats, are necessary to maximize the finish’s inherent protective qualities.

In conclusion, durability represents a key factor in the evaluation and selection of a metal wax finish. Understanding the relationship between the finish’s composition, application, and environmental factors is crucial for optimizing its longevity and protective capabilities. Although achieving maximum durability can present challenges due to varying environmental conditions and usage patterns, a well-chosen and properly applied finish significantly extends the lifespan and maintains the aesthetic appeal of metal surfaces. This understanding underscores the practical significance of considering durability as a primary criterion in the implementation of these protective treatments.

5. Maintenance

Maintenance is integral to the long-term performance and preservation of a metal wax finish. It ensures the protective barrier remains intact and aesthetically pleasing, extending the lifespan of the treated metal object or surface. Neglecting maintenance can compromise the finish, leading to premature degradation and necessitating costly repairs or reapplication.

- Regular Cleaning Procedures

Routine cleaning removes surface contaminants that can erode the wax layer or detract from its appearance. Mild, non-abrasive cleaners are recommended to prevent damage to the finish. For instance, cleaning architectural bronze components with a soft cloth and a pH-neutral detergent removes atmospheric pollutants without stripping the protective wax coating. The frequency of cleaning depends on environmental factors and usage, with high-traffic areas requiring more frequent attention.

- Inspection for Damage

Periodic inspection identifies areas where the wax finish may be compromised, such as scratches, abrasions, or areas of thinning. Early detection allows for targeted intervention, preventing localized damage from spreading and undermining the overall integrity of the finish. In the case of metal sculptures, observing discoloration or localized corrosion indicates a breach in the wax layer, necessitating prompt attention.

- Reapplication Strategies

Reapplication of the wax finish is essential to replenish the protective barrier as it wears down over time. The frequency of reapplication varies depending on the environment, usage, and the specific properties of the wax. For example, metalwork exposed to direct sunlight or harsh weather conditions requires more frequent reapplication than items kept indoors. The process typically involves cleaning the surface and applying a thin, even coat of wax, followed by buffing.

- Repair Techniques

Localized damage to the wax finish may necessitate spot repairs rather than complete reapplication. Techniques involve carefully cleaning the affected area and applying a small amount of wax to blend with the surrounding finish. For example, scratches on metal furniture can be addressed by carefully applying wax to the damaged area and gently buffing to restore a uniform appearance. This approach minimizes the need for extensive refinishing, preserving the original character of the item.

Effective maintenance practices are paramount for realizing the full potential of a metal wax finish. These practices contribute to the longevity, appearance, and protective capabilities of the finish, safeguarding the underlying metal from deterioration and ensuring its continued aesthetic appeal. Diligent maintenance represents a cost-effective strategy for preserving valuable metal assets and minimizing the need for future repairs or replacements.

6. Composition

The composition of a metal wax finish dictates its performance characteristics, longevity, and suitability for specific applications. A thorough understanding of the constituent ingredients and their interactions is essential for selecting the appropriate finish for a given metal substrate and environmental conditions.

- Wax Type

The primary constituent, the wax itself, determines the finish’s hardness, melting point, and resistance to environmental factors. Natural waxes, such as beeswax and carnauba wax, offer good gloss and protection but may be less durable than synthetic waxes. Synthetic waxes, including microcrystalline waxes and polyethylene waxes, exhibit enhanced durability, chemical resistance, and thermal stability. The selection of wax type depends on the desired balance of aesthetics, protection, and longevity. For example, carnauba wax is often favored for its high gloss in furniture applications, while microcrystalline wax is preferred for its greater resistance to oxidation on outdoor sculptures.

- Solvents

Solvents serve as carriers for the wax, facilitating its application and ensuring uniform coverage. The choice of solvent influences the drying time, viscosity, and potential toxicity of the finish. Mineral spirits, naphtha, and turpentine are commonly used solvents, each possessing distinct evaporation rates and solvency power. Low-VOC (volatile organic compound) solvents are increasingly preferred to minimize environmental impact and worker exposure. The solvent must be compatible with both the wax and the metal substrate to prevent damage or discoloration. In conservation applications, solvents with known archival properties are selected to ensure long-term stability.

- Additives

Additives modify the properties of the wax finish, enhancing its performance in specific areas. Hardening agents, such as resins and polymers, increase the finish’s durability and abrasion resistance. UV inhibitors protect the finish from degradation caused by sunlight exposure. Corrosion inhibitors prevent the formation of rust and oxidation on the metal surface. Dyes and pigments impart color to the finish, allowing for customization of the metal’s appearance. The careful selection of additives allows for fine-tuning the finish’s properties to meet the specific requirements of the application. For example, the addition of corrosion inhibitors is crucial in marine environments where metal is exposed to saltwater.

- Polymers

Polymers can significantly enhance the durability and protective qualities of a metal wax finish. Acrylic polymers, for example, increase resistance to scratching and abrasion, while silicone polymers improve water repellency and ease of application. Polymers create a more robust and flexible film, reducing the likelihood of cracking or chipping over time. The inclusion of polymers in the composition can also improve the finish’s adhesion to the metal substrate, leading to longer-lasting protection. In industrial applications, such as the coating of metal tools, polymers are essential for ensuring the finish can withstand rigorous use.

In summary, the composition of a metal wax finish is a complex interplay of waxes, solvents, additives, and polymers. The careful selection and balancing of these ingredients are critical for achieving the desired aesthetic and protective qualities. Understanding the specific role of each component enables informed decision-making in the selection and application of metal wax finishes, ensuring optimal performance and longevity. Further advancements in material science continue to drive innovations in metal wax finish compositions, leading to more durable, environmentally friendly, and aesthetically pleasing coatings.

7. Compatibility

The concept of compatibility is central to the successful application of a metal wax finish. Compatibility, in this context, refers to the harmonious interaction between the chosen wax formulation, the metal substrate to which it is applied, and the environmental conditions to which the finished product is exposed. A lack of compatibility can lead to a range of undesirable outcomes, including poor adhesion, discoloration, accelerated corrosion, and premature failure of the protective coating. The specific metal alloy, its surface preparation, and the intended use environment all influence the selection of a compatible metal wax finish. For example, a wax formulated for bronze may be unsuitable for aluminum due to differences in surface chemistry and porosity.

Practical significance stems from the need to ensure long-term protection and aesthetic preservation of metal objects. For instance, applying an incompatible wax to silver can lead to tarnishing due to electrochemical reactions between the wax components and the silver surface. In the realm of architectural metalwork, selecting a wax that is incompatible with the local climate (e.g., high humidity, UV exposure) can result in cracking, peeling, or chalking of the finish. Careful consideration of the metal’s composition, intended use, and environmental exposure is therefore critical for selecting a compatible wax formulation. Manufacturers typically provide compatibility charts and guidelines to assist users in making informed decisions. Furthermore, testing a small, inconspicuous area before applying the wax to the entire surface is advisable to confirm compatibility and avoid widespread damage.

In summary, ensuring compatibility between the metal substrate, the wax formulation, and the intended environment is paramount for achieving optimal performance and longevity of a metal wax finish. Challenges arise from the wide variety of metal alloys, wax formulations, and environmental conditions encountered in practice. However, a thorough understanding of these factors, coupled with adherence to manufacturer guidelines and prudent testing, mitigates the risk of incompatibility and ensures the successful application of the protective coating. This focus on compatibility aligns with the broader goal of preserving and enhancing the value of metal assets through effective surface treatments.

Frequently Asked Questions Regarding Metal Wax Finish

This section addresses common inquiries concerning the application, properties, and maintenance of a protective treatment for metallic surfaces.

Question 1: What constitutes a metal wax finish?

It is a protective and aesthetic coating applied to metal surfaces, typically composed of waxes, solvents, and additives designed to enhance sheen, provide a barrier against corrosion, and improve resistance to fingerprints and smudges.

Question 2: What are the primary benefits?

The key benefits include enhanced aesthetic appeal, protection against oxidation and corrosion, increased resistance to scratches and fingerprints, and improved ease of cleaning and maintenance.

Question 3: On which types of metal can it be used?

It can be applied to a wide range of metals, including but not limited to brass, bronze, copper, steel, stainless steel, aluminum, and silver. However, compatibility should always be verified before application.

Question 4: How often should it be reapplied?

The frequency of reapplication depends on environmental factors, usage, and the specific product used. Objects exposed to harsh conditions or frequent handling may require more frequent reapplication than those in protected environments.

Question 5: What is the proper method for cleaning a metal surface with this protective layer?

Cleaning should be performed using a soft cloth and a mild, pH-neutral detergent. Abrasive cleaners or scouring pads should be avoided, as they can damage the finish.

Question 6: How can its durability be maximized?

Durability can be maximized through proper surface preparation, the application of thin, even coats, adherence to recommended drying times, and regular maintenance with appropriate cleaning products.

In conclusion, understanding the characteristics and proper application of a protective treatment is essential for achieving optimal results and ensuring the long-term preservation of metal surfaces.

The next section will provide a glossary of terms related to surface treatments and metal finishing.

Conclusion

This discussion has explored the multifaceted aspects of metal wax finish. It encompasses the materials used, the techniques employed, the benefits conferred, and the maintenance required. The assessment has underscored its importance in preserving and enhancing the aesthetic and structural integrity of metallic surfaces.

Effective utilization of metal wax finish requires diligent attention to detail and a thorough understanding of its properties. Continued research and development in this area promise further advancements, leading to improved formulations and application methods. The responsible and informed use of this protective treatment is essential for safeguarding valuable metal assets and promoting sustainable practices.