The process combines distinct surface treatment methods applied to metallic components, often resulting in enhanced properties. This approach integrates techniques such as cleaning, coating, and polishing to achieve a desired aesthetic or functional outcome on the metal substrate. An example is the application of a protective layer, followed by a decorative finish, to improve corrosion resistance and visual appeal.

Such integration is vital for industries requiring durable and visually appealing metal products. Benefits include improved product lifespan, enhanced resistance to environmental factors, and increased market value. Historically, these combined methods evolved from separate processes, gradually converging to offer more comprehensive and efficient solutions for metal protection and enhancement.

The subsequent sections will delve into specific surface treatment techniques and their respective advantages, followed by an exploration of how these methods are applied across various industrial sectors to meet diverse performance and aesthetic requirements.

Essential Considerations for Optimized Results

This section outlines several critical factors to consider for achieving optimal outcomes in integrated metal surface treatments.

Tip 1: Material Compatibility: Prior to commencing any surface treatment, verifying compatibility between the base metal and the selected finishing process is paramount. Incompatible combinations can lead to adhesion failures, galvanic corrosion, or compromised mechanical properties.

Tip 2: Surface Preparation is Critical: Adequate surface preparation, including cleaning and degreasing, is fundamental. Contaminants impede proper coating adhesion, reducing the effectiveness of subsequent treatments and potentially causing premature failure.

Tip 3: Controlled Process Parameters: Strict adherence to specified process parameters, such as temperature, current density (in electrochemical processes), and immersion time, is essential. Deviations can result in uneven coatings, inadequate protection, or altered surface characteristics.

Tip 4: Proper Rinsing Techniques: Effective rinsing between treatment stages is necessary to remove residual chemicals and prevent cross-contamination. Insufficient rinsing can lead to undesirable reactions or the formation of unwanted byproducts that compromise the final finish.

Tip 5: Quality Control Measures: Implementation of robust quality control procedures, including visual inspections, adhesion tests, and thickness measurements, ensures consistent product quality and adherence to specified performance criteria.

Tip 6: Environmental Considerations: Selection of environmentally responsible finishing methods and waste disposal practices is increasingly important. Compliance with relevant environmental regulations minimizes the impact on the environment and promotes sustainable practices.

Tip 7: Documenting the Process: Maintain detailed records of all process parameters, materials used, and quality control results. This documentation facilitates troubleshooting, process optimization, and consistent replication of desired results.

Adhering to these recommendations contributes to improved product durability, enhanced corrosion resistance, and aesthetically pleasing finishes, ultimately maximizing the benefits of comprehensive metal surface treatment strategies.

The concluding section will synthesize the information presented, emphasizing the value proposition of a systematic approach to metal surface treatments in diverse applications.

1. Integration

Integration, in the context of sophisticated metal surface treatments, refers to the deliberate combination of multiple, distinct processes to achieve a synergistic effect that transcends the capabilities of individual treatments. It is a core principle, not merely an optional add-on. The efficacy and suitability of the ultimate surface rely directly on how seamlessly each stage complements the others. Consider the medical device industry, where biocompatibility is paramount. Applying a titanium coating (for osseointegration) followed by passivation (to reduce ion release) exemplifies integration. One process alone might be insufficient, but their sequence provides both functionality and safety.

The cause-and-effect relationship is also pronounced. Insufficient degreasing (a preparation step) will inevitably lead to poor adhesion of subsequent coatings, regardless of their inherent quality. Likewise, proper integration necessitates careful selection of treatment chemistries; incompatible solutions can lead to unwanted reactions or the formation of detrimental byproducts. The aerospace sector offers another relevant instance. Applying a conversion coating (for corrosion resistance) prior to painting (for aesthetics and UV protection) extends the lifespan of aircraft components exposed to harsh environmental conditions. This structured integration creates a durable finish.

Ultimately, integration’s importance lies in the potential to achieve targeted performance characteristics beyond the scope of single surface treatments. Challenges, however, arise in process control and compatibility testing. Without a clear understanding of the interplay between each stage, the benefits of integrating multiple surface treatments can be negated. The industry needs to consider how to build a quality finish with various processes.

2. Protection

Protection is a fundamental objective in comprehensive metal surface treatment strategies. The application of various finishing techniques aims to shield the underlying metal substrate from degradation caused by environmental factors, chemical exposure, or mechanical wear. The selection and combination of finishing methods directly influence the degree and type of protection afforded to the metal component. For example, a combination of anodization, followed by powder coating, on aluminum components used in outdoor structures provides robust protection against corrosion and UV radiation. The anodized layer forms a hard, adherent oxide film, while the powder coating acts as a barrier to moisture and pollutants. This multilayer approach extends the service life of the component, reducing maintenance costs and ensuring structural integrity.

Consider the context of marine environments, where metal components are exposed to high levels of salinity. In this scenario, a multi-layered protective system might involve applying a zinc-rich primer to provide sacrificial cathodic protection, followed by an epoxy coating to act as a barrier against seawater intrusion, and finally, a topcoat with UV inhibitors to resist degradation from sunlight. The effectiveness of this combined approach hinges on the compatibility of the different layers and the quality of their application. Inadequate surface preparation or improper curing of the coatings can compromise the overall protection, leading to premature corrosion or failure.

In essence, protection is an intrinsic component of comprehensive metal surface treatment. The strategic selection and integration of finishing techniques are critical for achieving the desired level of protection against specific environmental challenges. Understanding the mechanisms of corrosion, wear, and other forms of degradation, along with the protective capabilities of various finishing methods, is essential for implementing effective and durable metal protection strategies. Failure to prioritize protection can result in accelerated deterioration of metal components, leading to costly repairs, safety hazards, and reduced product lifespan.

3. Aesthetics

Aesthetics, concerning comprehensive metal surface treatments, transcends mere visual appeal; it represents a critical factor influencing product perception, brand identity, and market value. Integrating aesthetic considerations into the finishing process requires a strategic approach that aligns functional requirements with desired visual characteristics.

- Color and Gloss Control

Precise control over color and gloss is essential for achieving a desired aesthetic. The application of paint or powder coatings allows for a wide range of color options and gloss levels, enabling customization to meet specific brand guidelines or customer preferences. For example, the automotive industry utilizes advanced color-matching technologies to ensure consistent paint finishes across vehicle components. Deviation from specified color standards can negatively impact product acceptance and brand perception.

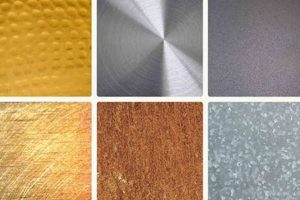

- Surface Texture and Patterning

Surface texture and patterning contribute significantly to the overall aesthetic impression. Techniques such as texturing, brushing, or etching can create unique visual effects and tactile experiences. Brushed stainless steel appliances, for instance, offer a contemporary aesthetic while also concealing fingerprints and smudges. The selection of appropriate surface textures must consider both aesthetic appeal and functional requirements, such as grip or wear resistance.

- Uniformity and Consistency

Maintaining uniformity and consistency in the surface finish is crucial for achieving a professional and high-quality aesthetic. Variations in color, gloss, or texture can detract from the overall appearance and indicate a lack of quality control. Automated finishing processes and stringent quality assurance procedures are employed to ensure consistent results. Premium consumer electronics often undergo meticulous inspection to detect any surface imperfections that might compromise their perceived value.

- Durability of Aesthetic Properties

The longevity of aesthetic properties is a critical consideration. The selected finishing materials and processes must withstand environmental factors, such as UV radiation, humidity, and abrasion, to maintain their visual appeal over time. Clear coats with UV inhibitors are frequently applied to protect painted surfaces from fading or discoloration. Failure to ensure the durability of aesthetic properties can lead to premature degradation of the surface finish, diminishing the product’s perceived value and necessitating costly repairs.

The facets discussed underscore that aesthetic aspects are integral to the comprehensive approach within integrated metal surface treatments. These are crucial for creating parts that are both visually appealing and able to maintain aesthetic qualities long term.

4. Durability

Durability, in the context of integrated metal finishing, signifies the capacity of a treated surface to withstand wear, corrosion, and other forms of degradation over extended periods. This characteristic is not merely a desirable attribute; it is a crucial performance parameter directly influenced by the selection and execution of finishing processes. The efficacy of such processes is measured by the prolonged integrity of the metal substrate and the sustained functionality of the treated component. Consider, for instance, offshore oil platforms. The steel structures are exposed to highly corrosive marine environments. An integrated finishing system that incorporates abrasive blasting for surface preparation, followed by the application of multiple layers of specialized coatings, is essential to prevent structural failure and maintain operational safety. Without these measures, the metal would corrode rapidly, leading to catastrophic consequences.

The connection between the surface treatment process and product lifespan becomes particularly apparent in aerospace engineering. Turbine blades in jet engines operate under extreme conditions of temperature, pressure, and mechanical stress. An integrated metal finishing approach, incorporating processes like thermal barrier coating deposition to protect against heat and shot peening to enhance fatigue resistance, is crucial for ensuring the durability and reliability of these critical components. Any degradation in the coating system can compromise the performance and longevity of the turbine blades, potentially leading to engine failure. In essence, the correct type of finishing is the bedrock for such components.

Therefore, durability, in the context of united metal finishing, is not an ancillary benefit but rather a primary objective. Its achievement hinges on a thorough understanding of the service environment, the potential degradation mechanisms, and the capabilities of various finishing processes. Challenges remain in the development of finishing systems that can provide long-term durability under increasingly demanding operating conditions. Continuous research and development efforts are focused on creating more resilient coatings, optimizing surface preparation techniques, and improving process control to maximize the durability of metal components across a diverse range of applications, linking back to the theme of integrated metal finishing as a crucial aspect of product design and engineering.

5. Compliance

The integration of metal finishing processes necessitates strict adherence to a complex web of environmental, health, and safety regulations. Compliance is not merely a procedural formality but a fundamental element of responsible and sustainable operation within the metal finishing industry. Failure to meet these regulatory requirements can result in significant legal and financial repercussions, as well as damage to corporate reputation.

- Environmental Regulations

Environmental regulations govern the discharge of pollutants into the air, water, and soil. Metal finishing processes often involve the use of hazardous chemicals that require careful management and disposal. Compliance with regulations such as the Clean Water Act and the Clean Air Act necessitates the implementation of pollution control technologies and waste minimization strategies. For instance, facilities must monitor and treat wastewater to remove heavy metals and other contaminants before discharge. Exceeding permitted discharge limits can lead to substantial fines and operational shutdowns.

- Worker Safety Standards

Worker safety standards are designed to protect employees from hazards associated with metal finishing operations. Exposure to chemicals, machinery, and physical hazards can result in injuries and illnesses. Compliance with Occupational Safety and Health Administration (OSHA) regulations mandates the implementation of safety protocols, such as the use of personal protective equipment (PPE), proper ventilation systems, and hazard communication programs. Failure to provide a safe working environment can result in employee injuries, OSHA citations, and increased insurance costs.

- Chemical Management and Reporting

Chemical management and reporting requirements ensure the proper handling and tracking of hazardous chemicals used in metal finishing processes. Regulations such as the Emergency Planning and Community Right-to-Know Act (EPCRA) require facilities to report the storage, use, and release of certain chemicals. Accurate record-keeping and reporting are essential for demonstrating compliance and preventing accidental releases. Improper chemical management can lead to environmental contamination, worker exposure, and regulatory penalties.

- Waste Disposal Regulations

Waste disposal regulations govern the handling and disposal of hazardous waste generated by metal finishing operations. Improper disposal of waste can contaminate soil and groundwater, posing risks to human health and the environment. Compliance with the Resource Conservation and Recovery Act (RCRA) requires facilities to properly characterize, treat, and dispose of hazardous waste. This may involve using licensed waste disposal companies, implementing waste minimization techniques, and recycling materials where possible. Non-compliance with waste disposal regulations can result in significant fines and legal action.

These facets underscore the integral role of compliance in united metal finishing. Environmental regulations, worker safety standards, chemical management, and waste disposal protocols are not isolated considerations but essential components of a responsible and sustainable approach to metal surface treatment. The proactive implementation of compliance measures ensures the long-term viability and ethical operation of metal finishing facilities.

6. Customization

The application of surface treatments to metals is frequently dictated by the end use of the component, necessitating a high degree of customization. These customized solutions are the result of the combined processes. The specific demands of the application, be it enhanced corrosion resistance, improved wear properties, or a particular aesthetic finish, require tailoring the entire treatment sequence. For instance, in the medical implant industry, the surface finish of a titanium hip implant demands a specific roughness to promote osseointegration, a process that must also be biocompatible. This differs vastly from the requirements of a decorative trim component on a vehicle, where aesthetics and weather resistance are prioritized. The ability to adapt finishing processes to meet such diverse requirements is paramount.

The interconnected nature of various finishing processes allows for fine-tuning the final product. Pre-treatment methods, such as cleaning and etching, influence the adhesion and uniformity of subsequent coatings. The choice of coating material, its thickness, and the application method can be adjusted to achieve the desired level of protection or aesthetic appeal. Furthermore, post-treatment processes, like polishing or sealing, can further modify the surface properties. An example is the firearms industry, where surface treatments must provide both corrosion resistance for use in harsh environments and a non-reflective finish for tactical applications. The precise sequence of treatments, including phosphating and specialized coatings, are selected and controlled to meet these specifications.

In summary, the importance of customization within integrated metal finishing arises from the diverse performance requirements of metal components across various industries. The ability to tailor treatment sequences allows for optimizing the surface properties to meet specific needs, enhancing product performance, durability, and aesthetics. The efficacy of such customization relies on a deep understanding of the underlying metallurgical principles, the properties of finishing materials, and the control of process parameters. The strategic application of customized solutions underscores the critical role of surface engineering in modern manufacturing.

7. Efficiency

In comprehensive metal surface treatment, efficiency represents a critical factor influencing operational costs, throughput, and environmental impact. Optimizing resource utilization and minimizing waste generation are paramount in achieving sustainable and cost-effective finishing processes.

- Reduced Processing Time

Streamlining processing time directly contributes to enhanced efficiency. Integrating multiple treatment steps into a single, continuous operation reduces handling and waiting times. An example is the combination of cleaning, etching, and coating processes within a single automated line, minimizing work-in-progress inventory and accelerating production cycles. The reduced cycle time lowers labor costs and increases overall output.

- Minimized Material Consumption

Efficient material usage is essential for reducing waste and lowering raw material costs. Implementing precise chemical dosing systems and optimized coating application techniques minimizes material waste. For instance, electrostatic spray coating can significantly reduce overspray compared to conventional methods, leading to substantial savings in coating material. The decrease in material consumption lowers both direct costs and waste disposal expenses.

- Energy Optimization

Energy consumption constitutes a significant portion of operational costs in metal finishing. Implementing energy-efficient technologies, such as high-efficiency heaters, variable-frequency drives for pumps and fans, and optimized ventilation systems, reduces energy consumption. For example, utilizing regenerative thermal oxidizers to capture and reuse heat from exhaust streams can significantly reduce energy costs. Minimizing energy usage lowers operational expenses and reduces the carbon footprint of the finishing process.

- Waste Reduction and Recycling

Minimizing waste generation and maximizing recycling efforts are critical for environmental sustainability and cost reduction. Implementing closed-loop rinsing systems, chemical recovery technologies, and waste segregation practices reduces waste volumes and facilitates recycling. For instance, electrodialysis can be used to recover valuable metals from plating solutions, reducing the need for disposal and generating a valuable resource. Decreased waste generation lowers disposal costs and minimizes environmental impact.

These facets highlight that efficiency is multifaceted within comprehensive metal finishing strategies. Streamlining processes, minimizing material consumption, optimizing energy usage, and reducing waste generation are all interconnected elements that contribute to a more sustainable and cost-effective finishing operation. Continuous improvement efforts focused on these areas are essential for maintaining competitiveness and environmental responsibility within the metal finishing industry.

Frequently Asked Questions About Integrated Metal Finishing

The following section addresses common inquiries concerning integrated metal finishing processes, providing clarity on key aspects and dispelling potential misconceptions.

Question 1: What distinguishes integrated metal finishing from individual surface treatment processes?

Integrated metal finishing combines multiple distinct surface treatments in a coordinated sequence to achieve synergistic effects. Individual surface treatments are applied in isolation, targeting a specific property. The integrated approach aims for optimized performance through the deliberate combination of different treatments.

Question 2: How does process integration impact the cost of metal finishing?

While the initial investment for integrated systems can be higher, long-term cost savings are often realized through improved efficiency, reduced material waste, and enhanced product durability. Properly integrated processes can minimize rework, extend product lifespan, and lower maintenance expenses.

Question 3: What are the primary considerations for selecting appropriate surface treatment combinations?

Material compatibility, desired performance characteristics (corrosion resistance, wear resistance, aesthetics), and environmental regulations are crucial factors. A thorough understanding of the interplay between different treatments and the intended application is essential for informed decision-making.

Question 4: How is quality control maintained in an integrated metal finishing system?

Stringent quality control measures are implemented at each stage of the process, including regular inspections, adhesion tests, and thickness measurements. Statistical process control (SPC) techniques are used to monitor process parameters and ensure consistent product quality.

Question 5: What are the environmental implications of integrated metal finishing?

Integrated systems can minimize environmental impact through reduced chemical usage, efficient waste management, and the implementation of closed-loop recycling processes. Selecting environmentally friendly finishing methods and adhering to stringent regulatory requirements are critical.

Question 6: How does customization play a role in integrated metal finishing?

Customization is integral to tailoring integrated finishing processes to specific application requirements. By adjusting process parameters, material selection, and treatment sequences, the surface properties of metal components can be optimized to meet diverse performance and aesthetic demands.

These FAQs offer an outline to the fundamentals of integrated metal finishing, with its benefits. For more detailed information, consulting with experienced surface treatment professionals is highly recommended.

The next section concludes this article, summarizing the main benefits from integrated metal finishing.

Concluding Remarks on United Metal Finishing

The preceding discussion has systematically explored the core tenets of united metal finishing, detailing its essential elements such as integration, protection, aesthetics, durability, compliance, customization, and efficiency. Through examining these aspects, it becomes evident that united metal finishing represents a comprehensive approach to surface treatment, demanding a strategic integration of processes to achieve superior performance and longevity of metal components.

The information presented underscores the importance of a holistic perspective in metal surface engineering. It is crucial for industries to move beyond individual treatment methods and embrace integrated systems tailored to specific application requirements. The future of metal finishing lies in sustainable practices, advanced material science, and a commitment to continuous improvement, ensuring the sustained value and reliability of metal products across diverse sectors. It is expected that the future of metal finishing will lead to a more robust product.

![Top Asheville Metal Finishing: [Your Brand] Quality Best Final Touch: Elevate Your Projects with Professional Finishing Top Asheville Metal Finishing: [Your Brand] Quality | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-666-300x200.jpg)