This entity represents a business operating in the metal finishing sector, situated specifically in the Astoria neighborhood. It likely provides services such as plating, coating, polishing, or other treatments to enhance the properties of metal components or products. Such establishments contribute to various industries by improving the durability, appearance, or functionality of metallic items.

The existence of such businesses offers several advantages to the local and regional economy. They support manufacturing and construction sectors by providing specialized services that are often critical for product quality and longevity. Historically, metal finishing has been vital to industries ranging from automotive and aerospace to consumer goods, playing a role in technological advancements and economic growth.

Understanding the specific operational capabilities, certifications, and target markets of this particular metal finishing service provider is crucial for determining its role within the broader industrial landscape. Further research can illuminate its specific contributions to the local economy and the industries it serves.

Operational Recommendations for Metal Finishing Businesses

The following recommendations are intended to assist metal finishing businesses in optimizing their processes and ensuring compliance.

Tip 1: Implement Rigorous Quality Control Procedures: Consistent quality is paramount. Establish a multi-stage inspection process encompassing material input, in-process monitoring, and final product assessment to identify and rectify deviations from established standards.

Tip 2: Prioritize Environmental Compliance: Adherence to environmental regulations is non-negotiable. Invest in technologies and processes that minimize waste generation, reduce emissions, and facilitate responsible disposal of hazardous materials. Maintain detailed records of all environmental compliance activities.

Tip 3: Invest in Employee Training and Certification: A skilled workforce is essential. Provide ongoing training programs for employees covering all aspects of metal finishing processes, safety protocols, and equipment maintenance. Encourage employees to pursue relevant certifications.

Tip 4: Maintain Equipment Proactively: Regular maintenance prevents costly downtime and ensures consistent performance. Implement a scheduled maintenance program for all equipment, including inspection, lubrication, and component replacement. Keep detailed maintenance logs.

Tip 5: Optimize Process Parameters: Precise control of process parameters, such as temperature, pH, and current density, is critical for achieving desired results. Utilize data analysis and statistical process control techniques to identify and optimize process parameters.

Tip 6: Ensure Proper Ventilation and Safety Measures: Protect worker health and safety. Implement adequate ventilation systems to remove hazardous fumes and particles. Provide employees with appropriate personal protective equipment (PPE) and enforce its use.

Tip 7: Track and Analyze Key Performance Indicators (KPIs): Monitor performance metrics, such as production output, defect rates, and material consumption. Analyze KPIs to identify areas for improvement and track progress towards operational goals.

These recommendations emphasize the importance of quality, environmental responsibility, employee development, and operational efficiency within the metal finishing industry. Implementing these practices can lead to improved profitability, reduced risk, and enhanced competitiveness.

The aforementioned tips provide a foundation for establishing and maintaining a successful metal finishing operation. Further investigation into specific industry best practices and regulatory requirements is essential for long-term sustainability.

1. Quality standards

Quality standards are inextricably linked to the viability and reputation of any metal finishing business, including those operating in Astoria. These standards, whether formally codified through certifications like ISO 9001 or implicitly maintained through rigorous internal controls, directly impact the consistency, durability, and overall performance of finished metal products. A metal finishing business adhering to high quality standards minimizes defects, reduces rework, and ensures customer satisfaction, leading to repeat business and positive word-of-mouth referrals. The absence of such standards inevitably results in inconsistencies, increased scrap rates, and potential product failures in the field, damaging the business’s reputation and leading to financial losses.

Consider, for example, a hypothetical scenario where Empire Metal Finishing Astoria plates components for medical devices. Stringent quality standards, including precise control of plating thickness, surface finish, and corrosion resistance, are paramount. Failure to meet these standards could compromise the integrity of the medical devices, potentially leading to patient harm and significant legal ramifications. Conversely, by consistently exceeding industry benchmarks for quality, the business can secure contracts with demanding clients in highly regulated sectors, gaining a competitive advantage and establishing a strong market presence. The ability to demonstrably meet or exceed quality expectations is often a pre-requisite for participation in certain supply chains, making it a fundamental aspect of operational success.

In conclusion, quality standards are not merely an optional add-on but a critical foundation upon which a metal finishing business like Empire Metal Finishing Astoria builds its long-term sustainability. Maintaining these standards requires continuous investment in training, equipment, and process control, and it necessitates a commitment to ongoing improvement. The challenges lie in consistently implementing these standards across all operations and adapting to evolving industry requirements. However, the benefits of enhanced reputation, increased market share, and reduced operational costs far outweigh the effort required.

2. Service range

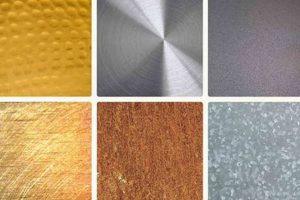

The service range defines the breadth of capabilities a metal finishing business such as Empire Metal Finishing Astoria possesses. This range directly dictates the market segments it can serve and the complexity of projects it can undertake. A limited service range may restrict the business to handling basic finishing tasks, whereas a comprehensive range encompassing diverse processes such as electroplating, powder coating, anodizing, and polishing allows for servicing a wider array of industries and applications. The selection of services offered influences operational infrastructure, staffing requirements, and the necessary investment in specialized equipment. Therefore, the scope of services has a cascading effect on the overall strategic direction of the business.

Consider the scenario where a local aerospace manufacturer requires cadmium plating for certain aircraft components and anodizing for others. If Empire Metal Finishing Astoria only offers electroplating services, the manufacturer would need to seek out a second vendor for the anodizing process. This fragmented approach can lead to increased logistical complexities, communication challenges, and potentially longer lead times. Conversely, if Empire Metal Finishing Astoria possesses both electroplating and anodizing capabilities, it becomes a more attractive single-source solution for the manufacturer, simplifying the supply chain and potentially securing a larger share of the aerospace company’s finishing requirements. The service range, therefore, directly impacts the competitive positioning and revenue potential of the business.

Ultimately, the service range is a strategic decision that should align with market demands and the business’s overall growth objectives. Expanding the service range requires careful evaluation of investment costs, regulatory requirements, and the availability of skilled labor. However, a well-defined and appropriately diverse service range is critical for establishing Empire Metal Finishing Astoria as a versatile and reliable partner for businesses across various industries, thereby contributing to its long-term success and sustainability within the competitive metal finishing market.

3. Industry Certifications

Industry certifications represent a critical aspect of any metal finishing business, serving as tangible validation of adherence to specific quality, environmental, and operational standards. The presence, absence, or type of certifications held by a business like Empire Metal Finishing Astoria can significantly influence its market position, credibility, and ability to secure contracts with certain clients.

- Quality Management Systems (e.g., ISO 9001)

These certifications demonstrate a commitment to consistently delivering high-quality services and products. ISO 9001, for instance, requires establishing and maintaining a robust quality management system, encompassing processes for quality control, documentation, and continuous improvement. Empire Metal Finishing Astoria’s possession of such a certification assures potential clients that its operations are structured to minimize defects and maximize consistency.

- Environmental Management Systems (e.g., ISO 14001)

In the metal finishing industry, environmental responsibility is paramount due to the use of potentially hazardous materials and processes. ISO 14001 certification signifies that the business has implemented a system to manage its environmental impact, reduce waste, and comply with relevant regulations. For Empire Metal Finishing Astoria, this certification can be a key differentiator, especially when serving clients who prioritize sustainability and responsible sourcing.

- Industry-Specific Certifications (e.g., Nadcap, AS9100)

Certain industries, such as aerospace and defense, have specific certification requirements for their suppliers. Nadcap and AS9100 are examples of certifications that demonstrate compliance with stringent industry standards. If Empire Metal Finishing Astoria aims to serve these sectors, obtaining the relevant industry-specific certifications is essential for gaining access to these markets and meeting customer expectations.

- Process-Specific Approvals

Beyond general management system certifications, process-specific approvals may be required by certain clients or regulatory bodies. These approvals demonstrate competency in performing specific metal finishing processes, such as plating or coating, according to defined standards. Empire Metal Finishing Astoria may need to obtain these approvals to demonstrate its capabilities in specialized areas and meet specific customer requirements.

Ultimately, the industry certifications held by Empire Metal Finishing Astoria provide valuable insights into its operational capabilities, commitment to quality, and adherence to environmental and regulatory standards. These certifications serve as a form of objective validation, allowing potential clients to assess the business’s suitability for their specific needs and requirements. The acquisition and maintenance of relevant certifications can be a significant investment, but one that can yield substantial benefits in terms of enhanced credibility, increased market access, and improved operational performance.

4. Environmental compliance

Environmental compliance constitutes a critical operational element for Empire Metal Finishing Astoria. Metal finishing processes often involve hazardous materials, including heavy metals and corrosive chemicals. Improper handling and disposal can lead to environmental contamination, posing risks to human health and ecosystems. Therefore, adherence to environmental regulations is not merely a legal obligation but a fundamental requirement for responsible business operation.

Failure to comply with environmental regulations can result in substantial financial penalties, legal action, and reputational damage for Empire Metal Finishing Astoria. Regulatory agencies, such as the Environmental Protection Agency (EPA) and state-level counterparts, enforce stringent rules regarding wastewater discharge, air emissions, and waste management. For example, exceeding permitted levels of heavy metals in wastewater discharge can trigger fines and necessitate costly remediation efforts. Similarly, inadequate control of air emissions can lead to violations and potential operational shutdowns. Maintaining comprehensive records, implementing pollution control technologies, and conducting regular audits are essential for ensuring ongoing compliance. Real-world examples abound of metal finishing businesses facing severe consequences for non-compliance, underscoring the gravity of the situation.

Conversely, proactive environmental management can yield significant benefits for Empire Metal Finishing Astoria. By investing in cleaner production technologies, minimizing waste generation, and implementing robust recycling programs, the business can reduce its environmental footprint and enhance its operational efficiency. Achieving certifications like ISO 14001 demonstrates a commitment to environmental stewardship, which can improve its standing with customers and stakeholders. The practical significance of this understanding lies in the recognition that environmental compliance is not a burden but an opportunity for innovation, cost savings, and long-term sustainability. Challenges remain in navigating the complex regulatory landscape and implementing effective environmental management practices, but the rewards of responsible environmental performance far outweigh the costs.

5. Local impact

The local impact of Empire Metal Finishing Astoria stems from its operational footprint and economic interactions within the Astoria community. As a business entity, it generates employment opportunities, contributing to the local labor market. The scale of this impact is directly proportional to the size of its workforce and the types of jobs it offers, ranging from skilled technicians to administrative staff. Furthermore, it contributes to the local tax base, providing revenue that supports public services and infrastructure. The business also impacts the local economy through its procurement of goods and services from other local businesses, fostering a network of interconnected economic activity. This interconnectedness amplifies its overall economic contribution to the Astoria region.

Beyond direct economic contributions, the environmental practices of Empire Metal Finishing Astoria significantly affect the local community. Responsible waste management, adherence to environmental regulations, and the implementation of pollution control measures mitigate potential negative impacts on air and water quality, directly affecting the health and well-being of local residents. Conversely, non-compliance with environmental standards can result in pollution, negatively impacting public health and potentially devaluing property values in the surrounding area. Consider, for example, the difference between a facility investing in advanced filtration systems to minimize air emissions versus one that releases untreated pollutants into the atmosphere. The former actively contributes to a healthier local environment, while the latter poses a direct threat to the community.

In conclusion, the local impact of Empire Metal Finishing Astoria is a multifaceted consideration encompassing economic, social, and environmental dimensions. Its role as an employer, taxpayer, and consumer of local goods and services contributes to the economic vitality of Astoria. Its environmental practices directly influence the health and well-being of local residents. Understanding and proactively managing these impacts is crucial for ensuring the long-term sustainability of the business and its positive contribution to the Astoria community. The challenge lies in balancing economic growth with environmental responsibility and social well-being, but the rewards of responsible corporate citizenship are substantial.

6. Turnaround Time

Turnaround time, representing the duration between the initiation of a metal finishing request and the completion of the finished product, constitutes a critical performance indicator for Empire Metal Finishing Astoria. Efficient turnaround time directly influences client satisfaction, operational throughput, and overall profitability. Delays can disrupt supply chains, increase costs for clients, and damage the business’s reputation, while optimized turnaround times offer a competitive advantage.

- Process Optimization and Scheduling

Turnaround time is heavily influenced by the efficiency of internal processes, encompassing surface preparation, plating or coating application, quality control inspections, and final packaging. Streamlined workflows, optimized equipment utilization, and effective scheduling are crucial for minimizing delays at each stage. For example, implementing a just-in-time inventory management system for chemicals and consumables can prevent production bottlenecks caused by material shortages. Likewise, utilizing automated equipment for repetitive tasks can reduce processing time and increase throughput. The ability of Empire Metal Finishing Astoria to accurately estimate processing times and adhere to schedules directly impacts its ability to meet client deadlines and maintain a consistent workflow.

- Equipment Maintenance and Reliability

Equipment downtime due to maintenance or repairs significantly extends turnaround time. Proactive maintenance programs, including regular inspections, lubrication, and component replacement, are essential for ensuring equipment reliability and minimizing unexpected disruptions. For instance, a plating tank requiring unscheduled repairs can halt production, leading to delays in fulfilling orders. Similarly, malfunctions in coating application equipment can result in inconsistent finishes, necessitating rework and extending turnaround time. By prioritizing equipment maintenance and investing in reliable machinery, Empire Metal Finishing Astoria can mitigate downtime and maintain consistent operational performance.

- Workforce Skills and Training

The expertise and training of the workforce directly impact the speed and quality of metal finishing processes. Skilled technicians can efficiently operate equipment, troubleshoot problems, and ensure adherence to quality standards, minimizing the need for rework and reducing turnaround time. Conversely, inadequately trained personnel may make errors, require additional supervision, and contribute to delays. For example, a trained operator can precisely control plating parameters to achieve desired coating thickness in a single pass, while an inexperienced operator may require multiple attempts, extending processing time. Investing in comprehensive training programs and ongoing skill development is essential for ensuring a competent workforce capable of optimizing turnaround time.

- Logistics and Transportation

The efficiency of logistics and transportation impacts the overall turnaround time, particularly for clients located outside the immediate Astoria area. Delays in transporting materials to and from the facility can extend the time required to complete orders. Strategic partnerships with reliable transportation providers, optimized routing strategies, and efficient loading and unloading procedures can minimize transportation-related delays. For example, coordinating pick-up and delivery schedules with clients and utilizing real-time tracking systems can improve visibility and ensure timely arrival of materials. By streamlining logistics and transportation processes, Empire Metal Finishing Astoria can enhance its overall turnaround time and improve client satisfaction.

In summary, turnaround time is a multifaceted performance metric that reflects the overall operational efficiency and client-centric focus of Empire Metal Finishing Astoria. Effective management of process optimization, equipment maintenance, workforce skills, and logistics is crucial for minimizing turnaround time, enhancing competitiveness, and fostering long-term client relationships. By continuously monitoring and improving these key areas, the business can ensure timely delivery of high-quality metal finishing services, solidifying its position within the Astoria community and beyond.

Frequently Asked Questions Regarding Metal Finishing Services in Astoria

The following questions address common inquiries regarding metal finishing processes and services, particularly in relation to businesses operating in the Astoria region.

Question 1: What range of metal finishing services are typically offered by a business operating in Astoria?

Service offerings can vary. Commonly provided services include electroplating (e.g., chrome, nickel, zinc), powder coating, anodizing (particularly for aluminum), polishing, and passivation. The availability of specific processes depends on the facility’s equipment and expertise.

Question 2: How does Empire Metal Finishing Astoria ensure adherence to environmental regulations?

Compliance necessitates rigorous waste management protocols, including proper disposal of hazardous materials and wastewater treatment. Facilities are typically subject to inspections by regulatory agencies. ISO 14001 certification may indicate a commitment to environmental management systems.

Question 3: What quality control measures are implemented during metal finishing processes?

Quality control involves multi-stage inspections, encompassing material input, in-process monitoring, and final product assessment. Techniques such as coating thickness measurement, adhesion testing, and corrosion resistance testing are frequently employed to ensure adherence to specifications.

Question 4: How does the location in Astoria influence the services provided by a metal finishing business?

The Astoria location may offer logistical advantages for businesses operating in the New York City metropolitan area, facilitating faster turnaround times for local clients. The business may cater to specific industries prevalent in the region.

Question 5: What factors determine the turnaround time for metal finishing projects?

Turnaround time is influenced by several factors, including the complexity of the project, the type of metal finishing process required, the volume of parts, and the facility’s operational capacity. Clear communication and accurate project specifications are crucial for efficient scheduling.

Question 6: What certifications are relevant for metal finishing businesses and what do they signify?

ISO 9001 certification demonstrates adherence to quality management system standards. Nadcap accreditation is relevant for businesses serving the aerospace industry. Other industry-specific certifications may be required depending on the target market.

Understanding these core aspects provides a foundation for evaluating metal finishing services and making informed decisions.

The subsequent section will delve into the importance of supplier relationships.

Conclusion

This exploration has sought to provide a comprehensive understanding of Empire Metal Finishing Astoria. The discussion addressed key operational aspects including quality standards, service range, industry certifications, environmental compliance, local economic impact, and processing turnaround time. A thorough appreciation of these factors is essential for assessing the capabilities and potential contributions of this business within the metal finishing industry.

Effective metal finishing businesses support vital sectors of the economy. Continued attention to quality, environmental responsibility, and operational efficiency is paramount. Future success is contingent upon a commitment to continuous improvement and proactive adaptation to evolving industry demands.