The act of individuals offering their time and effort to enhance or protect metallic surfaces through various treatment processes constitutes a valuable contribution. This encompasses tasks such as cleaning, polishing, coating, and applying protective layers to metal objects. A specific instance includes individuals assisting in a museum conservation lab to clean and preserve antique metal artifacts.

This type of community involvement offers significant advantages. It provides organizations with access to skilled or unskilled labor that may be otherwise unaffordable. Furthermore, it fosters a sense of civic responsibility and promotes the preservation of valuable items or the enhancement of public spaces. Historically, such contributions have been integral to maintaining infrastructure and cultural heritage.

The remainder of this discussion will focus on the practical aspects of organizing and managing such initiatives, including safety protocols, training requirements, and the benefits for both the contributing individuals and the receiving organizations. Furthermore, this article will explore the different metal finishing techniques volunteers can be involved in.

Considerations for Volunteer Metal Finishing Initiatives

The following outlines essential considerations for organizations engaging in metal finishing activities with unpaid contributors.

Tip 1: Prioritize Safety Training: Comprehensive safety training is paramount. All contributors must receive detailed instruction on handling chemicals, operating machinery, and using personal protective equipment appropriate for metal finishing tasks.

Tip 2: Define Clear Roles and Responsibilities: Establish well-defined roles and responsibilities for each individual. This prevents confusion and ensures tasks are completed effectively and safely. Documented procedures are essential.

Tip 3: Provide Adequate Supervision: Adequate supervision by experienced personnel is critical. Supervisors should monitor work progress, address questions, and ensure adherence to safety protocols and quality standards.

Tip 4: Utilize Appropriate Equipment: Equipment must be suitable for the specific metal finishing tasks and in good working order. Regular maintenance and safety inspections are crucial.

Tip 5: Manage Chemical Exposure: Implement strict protocols for managing chemical exposure. This includes proper ventilation, handling procedures, and waste disposal methods. Material Safety Data Sheets (MSDS) must be readily available.

Tip 6: Maintain a Clean and Organized Workspace: A clean and organized workspace reduces the risk of accidents and promotes efficiency. Regular cleaning and proper storage of materials are essential.

Tip 7: Establish Quality Control Measures: Quality control measures should be in place to ensure the final product meets established standards. This includes inspections at various stages of the metal finishing process.

These considerations promote a safe, efficient, and productive metal finishing initiative, ensuring high-quality outcomes.

The subsequent section provides insights on potential challenges and their mitigation strategies.

1. Safety protocols

The implementation of comprehensive safety protocols is not merely advisable, but fundamentally essential when individuals contribute their time to metal finishing endeavors. The inherent risks associated with handling potentially hazardous materials and machinery necessitate strict adherence to established guidelines to protect participant well-being and ensure a responsible operational environment.

- Chemical Handling Procedures

Metal finishing often involves the use of corrosive or toxic chemicals for cleaning, etching, or coating. Safety protocols mandate the use of appropriate personal protective equipment (PPE), such as gloves, eye protection, and respirators. Strict procedures for handling, storing, and disposing of chemicals are crucial to prevent accidental exposure, spills, and environmental contamination. For instance, in a restoration project of vintage automobiles, individuals handling rust removal solutions must be thoroughly trained on proper ventilation and spill containment methods.

- Machinery Operation and Guarding

Many metal finishing processes employ machinery such as grinders, polishers, and plating equipment. Safety protocols require that all machinery is equipped with functional safety guards and interlocks to prevent accidental contact with moving parts. Operators must receive comprehensive training on safe operating procedures, emergency shut-off procedures, and routine maintenance. In a community workshop setting, this might include training on the safe operation of a buffing wheel and the importance of keeping hands clear of the rotating abrasive.

- Ventilation and Air Quality Control

Metal finishing processes can generate dust, fumes, and vapors that pose respiratory hazards. Safety protocols require adequate ventilation systems to remove these contaminants from the air. Regular monitoring of air quality is essential to ensure that exposure levels remain within permissible limits. For example, a facility offering electroplating services would need a robust ventilation system to extract fumes from the plating tanks and prevent them from accumulating in the workspace.

- Emergency Response Procedures

Despite the best preventative measures, accidents can still occur. Safety protocols must include clearly defined emergency response procedures for handling chemical spills, injuries, or equipment malfunctions. This includes providing readily accessible first-aid kits, emergency eyewash stations, and emergency contact information. Regular drills can help ensure that individuals are prepared to respond effectively in the event of an emergency. A well-defined emergency response plan in a metalworking studio would include procedures for addressing burns from hot metal and contacting emergency services.

The meticulous implementation of these facets of safety protocols is indispensable for any contribution to metal finishing. By prioritizing safety, organizations not only protect their participants but also create a more sustainable and responsible operational environment that promotes both the longevity of projects and the well-being of those involved. The absence of robust safety measures can lead to severe consequences, undermining the ethical and practical value of these activities.

2. Skill assessment

Skill assessment is a foundational element for the effective and safe integration of individuals into metal finishing processes. The varying degrees of complexity within metal finishing necessitate a clear understanding of each individual’s capabilities to ensure appropriate task assignment and minimize the potential for errors or accidents.

- Identification of Baseline Competencies

Skill assessment begins with identifying the existing competencies of each individual. This includes evaluating their experience with hand tools, machinery, and chemical handling. For instance, an individual with prior experience in automotive repair may possess relevant skills applicable to surface preparation, while another with experience in jewelry making might exhibit proficiency in polishing techniques. Identifying these baseline competencies allows for tailored training and task assignments that align with individual strengths.

- Matching Skills to Task Requirements

Metal finishing encompasses a diverse range of tasks, each requiring specific skill sets. Skill assessment enables the matching of individuals to tasks that align with their abilities. An organization might assign individuals with limited experience to simpler tasks such as cleaning and degreasing components, while those with advanced skills could be entrusted with more complex operations like welding or electroplating. This strategic allocation maximizes efficiency and promotes a sense of accomplishment.

- Determining Training Needs

A critical outcome of skill assessment is the identification of training needs. Gaps in knowledge or expertise can be addressed through targeted training programs designed to enhance the individual’s capabilities and ensure they can safely and effectively perform their assigned tasks. For example, an individual assigned to operate a milling machine might require training on machine setup, tool selection, and safety protocols. Comprehensive training programs enhance overall quality and minimize the likelihood of errors.

- Ensuring Safety and Compliance

Skill assessment plays a vital role in ensuring safety and regulatory compliance. By evaluating an individual’s understanding of safety protocols and their ability to adhere to established procedures, organizations can minimize the risk of accidents and prevent non-compliance with industry standards. For instance, those involved in chemical plating operations must demonstrate proficiency in handling hazardous materials and understand emergency response procedures. A thorough assessment process helps create a safe and compliant working environment.

These interconnected facets of skill assessment collectively contribute to the success of metal finishing projects. By strategically evaluating and matching individuals to tasks, organizations can optimize efficiency, minimize risks, and foster a culture of safety and competence. The systematic approach to skill assessment not only benefits the organization but also empowers participants by providing them with the skills and knowledge necessary to contribute meaningfully.

3. Material knowledge

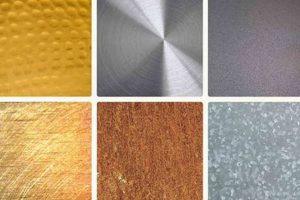

A robust understanding of material properties is paramount in metal finishing, particularly when the work is undertaken by individuals contributing their time. The selection of appropriate finishing techniques, the application of coatings, and the prevention of damage are all intrinsically linked to possessing a solid grasp of the metals being treated. Without this knowledge, volunteers risk irreversible harm to the objects they intend to improve or preserve. For example, applying an inappropriate abrasive to a soft metal like aluminum can result in gouging and surface degradation, while using an incompatible chemical cleaner on a sensitive alloy may cause corrosion. The success and longevity of any metal finishing project depend heavily on making informed decisions based on the specific material characteristics.

Practical application of material knowledge extends beyond mere identification. It encompasses understanding how different metals react to various treatments. Consider the restoration of antique brass hardware. An individual lacking material knowledge might employ a harsh chemical dip, which could strip the original patina and diminish the item’s historical value. In contrast, a contributor with appropriate training would recognize the brass and opt for gentler, mechanical polishing techniques to preserve the patina while removing surface oxidation. Similarly, when applying protective coatings, knowledge of the metal’s porosity and reactivity is critical for selecting a compatible coating that will adhere properly and provide long-term protection. Accurate material identification is a necessary first step, often requiring careful visual inspection, chemical spot tests, or even more advanced analytical techniques when the metal is uncertain. Correctly identifying the substrate material facilitates informed decision-making throughout the metal finishing process, ensuring the application of appropriate cleaning, polishing, or protective treatments.

In conclusion, material knowledge is not merely an ancillary skill; it is a core competency for anyone involved in metal finishing, especially within volunteer programs. The lack of this knowledge poses a significant risk to the integrity of the items being treated and can undermine the entire purpose of the initiative. Addressing this challenge requires comprehensive training programs that equip individuals with the necessary skills to identify metals, understand their properties, and select appropriate finishing techniques. By prioritizing material knowledge, organizations can ensure the success and sustainability of their volunteer metal finishing projects, and more importantly, safeguard the value and longevity of the objects entrusted to their care.

4. Equipment operation

The responsible and proficient operation of equipment forms a cornerstone of successful volunteer metal finishing initiatives. The capacity to safely and effectively utilize various tools and machinery directly impacts the quality of the final product, participant safety, and the overall efficiency of the project.

- Training and Competency Assessment

Before operating any equipment, comprehensive training is imperative. This training should cover not only the operational aspects of the machinery but also safety protocols, emergency procedures, and routine maintenance. Competency assessments, both theoretical and practical, are necessary to ensure individuals possess the requisite skills to operate the equipment safely and effectively. This mitigates the risk of accidents and damage to equipment or materials. For example, operating a polishing lathe requires understanding speed control, material compatibility, and proper use of safety guards; demonstrated competence should be required prior to unsupervised use.

- Maintenance and Pre-Operational Checks

Regular maintenance of equipment is crucial for optimal performance and longevity. Volunteers should be trained to conduct pre-operational checks, including inspecting for damaged components, verifying fluid levels, and ensuring safety mechanisms are functional. Proper maintenance not only enhances the equipment’s reliability but also minimizes the risk of malfunctions that could lead to accidents. An example includes checking the abrasive wheel on a grinding machine for cracks or damage prior to use, and verifying that the safety shield is properly positioned.

- Adherence to Safety Protocols

Stringent adherence to safety protocols is non-negotiable. This includes wearing appropriate personal protective equipment (PPE) such as eye protection, gloves, and respirators when operating machinery. Understanding and following lockout/tagout procedures is also critical during maintenance or repair operations. A clear understanding of emergency shutdown procedures is also essential. In a plating operation, PPE minimizes the risk of contact with corrosive materials and airborne contaminants.

- Supervision and Monitoring

Adequate supervision and monitoring are essential, particularly during initial phases of volunteer involvement. Experienced personnel should oversee equipment operation to provide guidance, answer questions, and ensure adherence to safety protocols and quality standards. Supervision also facilitates the identification of potential issues or unsafe practices before they escalate into incidents. Regular monitoring and constructive feedback enhances volunteer skill development and promotes a safe working environment.

These facets underscore the critical link between equipment operation and the success of volunteer metal finishing projects. By prioritizing training, maintenance, safety, and supervision, organizations can empower individuals to contribute meaningfully while minimizing risks and maximizing the quality of their work. These best practices promote a sustainable and rewarding experience for both the individuals and the organization.

5. Quality control

Quality control is an indispensable element within the context of volunteer metal finishing, directly influencing the reliability and consistency of outcomes. The inherent variability associated with volunteer labor necessitates rigorous control measures to mitigate the potential for errors and ensure adherence to established standards. This encompasses implementing inspection protocols at various stages of the process, from initial surface preparation to final coating application. Without stringent quality control, the risk of substandard results increases substantially, potentially compromising the integrity and longevity of the finished product. For example, if volunteers are tasked with polishing metal components for a historical restoration project, inconsistencies in polishing pressure or technique could result in uneven surfaces and detract from the artifact’s authenticity. Quality control serves as a safeguard, ensuring the diligent application of specified procedures and the early detection of deviations, thereby preventing the propagation of defects throughout the process.

The practical significance of integrating quality control into volunteer metal finishing is multifaceted. Firstly, it minimizes material waste and rework, translating into cost savings for the organization. Secondly, it enhances the overall reputation and credibility of the program, demonstrating a commitment to delivering high-quality results. Thirdly, it fosters a culture of accountability and continuous improvement among the participants, promoting skill development and a greater appreciation for the importance of precision and attention to detail. Consider a volunteer-run workshop that fabricates metal brackets for a community garden project. Implementing quality control measures, such as dimensional checks and weld inspections, would ensure the brackets meet the required specifications and can withstand the intended load. This, in turn, enhances the safety and durability of the garden infrastructure.

In summary, quality control is not merely a supplementary aspect of volunteer metal finishing but rather an intrinsic component that underpins its success and sustainability. Challenges in implementation may arise from the variable skill levels of volunteers and the need for ongoing training and supervision. However, the benefits of a robust quality control system far outweigh the associated costs, ensuring that volunteer contributions translate into tangible and lasting value for both the organization and the wider community. This also builds trust between the organization and it’s stakeholders, with the final products or services exceeding expectations.

6. Project alignment

Project alignment is a critical determinant of success in volunteer metal finishing initiatives. A clear, shared understanding of project goals, scope, and expected outcomes is essential for focusing volunteer efforts and maximizing their effectiveness. Disparities between volunteer expectations and project realities can lead to dissatisfaction, reduced engagement, and ultimately, compromised quality. For example, if a group of volunteers believes they will be restoring antique firearms, while the actual task involves cleaning industrial machinery, a significant disconnect arises, hindering motivation and productivity. Proper project alignment ensures that all involved parties are working towards a common objective, fostering a sense of purpose and shared accomplishment.

The practical implementation of project alignment involves several key steps. Firstly, a detailed project description, outlining specific tasks, required skills, and anticipated timelines, should be provided to prospective volunteers. Secondly, a preliminary meeting or orientation session can facilitate open communication and allow volunteers to ask clarifying questions. Thirdly, ongoing feedback and progress updates are crucial for maintaining alignment throughout the project lifecycle. Consider a scenario where volunteers are contributing to the construction of metal art installations for a public park. Regular communication, clear instructions, and visual representations of the final product would ensure that each volunteer understands their role and how it contributes to the overall aesthetic and structural integrity of the installation.

In summary, project alignment serves as the foundation for successful volunteer metal finishing endeavors. By ensuring a shared understanding of goals, scope, and expectations, organizations can optimize volunteer contributions, minimize misunderstandings, and foster a positive and productive working environment. Challenges related to volunteer recruitment, training, and motivation can be effectively addressed through a proactive approach to project alignment, resulting in enhanced outcomes and a strengthened sense of community engagement. Conversely, a lack of alignment can lead to inefficiency, frustration, and ultimately, project failure.

7. Community benefit

The integration of initiatives focused on the enhancement of metallic surfaces through volunteer labor provides a multitude of advantages to local communities, extending beyond the mere improvement of material objects. This engagement fosters social cohesion, provides opportunities for skill development, and contributes to the preservation of shared cultural heritage.

- Preservation of Public Assets

Volunteer metal finishing initiatives often focus on the maintenance and restoration of public assets, such as park structures, historical monuments, and community tools. By dedicating time and skills to these projects, individuals contribute to the longevity and aesthetic appeal of shared resources. For example, volunteers might restore wrought iron fences in a public garden, ensuring their structural integrity and enhancing the visual environment for all residents.

- Skill Development and Empowerment

Engaging in metal finishing provides opportunities for volunteers to acquire valuable skills in areas such as cleaning, polishing, coating, and welding. This skill development can enhance employability and foster a sense of empowerment among participants. A community workshop, for instance, could offer metalworking training to unemployed individuals, equipping them with skills applicable to various industries.

- Promotion of Cultural Heritage

Metal finishing plays a crucial role in the preservation of cultural artifacts and historical objects. Volunteer efforts in museums and historical societies can contribute to the long-term care of these items, ensuring their availability for future generations. Volunteers might assist in cleaning and conserving antique metal tools or restoring historic metal signage, safeguarding the community’s collective memory.

- Enhancement of Community Spaces

Metal finishing projects can contribute to the beautification and improvement of community spaces, such as parks, community centers, and public art installations. Volunteers might create metal sculptures for a park or fabricate metal components for a community playground, enhancing the visual appeal and functionality of these spaces. This improves the overall quality of life for residents.

These multifaceted contributions underscore the significant community benefits derived from volunteer metal finishing. By engaging individuals in the preservation, restoration, and enhancement of metal objects and structures, these initiatives promote social cohesion, empower individuals, and enrich the shared cultural landscape. The sustainable impact of these projects extends far beyond the immediate task at hand, fostering a sense of civic pride and collective responsibility.

Frequently Asked Questions About Volunteer Metal Finishing

The following section addresses common inquiries regarding participation in initiatives focused on the refinement and preservation of metallic surfaces through contributed labor. These answers aim to provide clarity on the scope, safety, and requirements associated with such activities.

Question 1: Is prior experience required to participate in initiatives focused on metal refinement?

Prior experience is not always mandatory. Many organizations offer training programs tailored to individuals with varying skill levels. Basic tasks, such as cleaning and surface preparation, may not require extensive prior knowledge. However, more advanced techniques, like welding or electroplating, typically necessitate prior training or certification.

Question 2: What safety precautions are necessary when refining or preserving metal surfaces?

Stringent adherence to safety protocols is paramount. This includes wearing appropriate personal protective equipment (PPE) such as gloves, eye protection, and respirators. Understanding and following guidelines for chemical handling, machine operation, and ventilation are also critical. Training on these procedures is generally provided.

Question 3: What types of metal finishing activities might be involved?

The scope of activities can vary widely, depending on the project and organization. Common tasks include cleaning, polishing, grinding, welding, painting, coating, and electroplating. Some projects might focus on restoring antique metal objects, while others involve fabricating new metal components.

Question 4: How does participation in such work benefit the contributing individual?

Engagement in these initiatives offers opportunities for skill development, community involvement, and personal satisfaction. Individuals can acquire valuable technical skills, contribute to the preservation of cultural heritage, and enhance their sense of civic responsibility.

Question 5: Are there any age restrictions associated with contributing to metal surface refinement projects?

Age restrictions may apply, depending on the nature of the tasks and the policies of the organization. Minors are generally restricted from operating heavy machinery or handling hazardous chemicals. Parental consent and supervision may be required for younger individuals participating in less demanding activities.

Question 6: How does one locate and apply for opportunities related to metal surface treatment using volunteer effort?

Opportunities can be found through local community centers, historical societies, museums, and online volunteer databases. Contacting relevant organizations directly is also advisable. Application processes typically involve submitting an application form and attending an orientation session.

In summary, engagement offers a means for individuals to contribute valuable skills to communities while enriching their own expertise and civic engagement.

The subsequent discussion will explore specific case studies and examples of successful volunteer-led metal finishing projects.

Conclusion

The preceding discussion has explored multifaceted aspects of volunteer metal finishing, encompassing considerations from safety protocols and skill assessment to material knowledge, equipment operation, quality control, project alignment, and community benefit. The initiatives underscore the potential for individuals to meaningfully contribute to preservation, restoration, and community enhancement through engagement with metallic materials.

The ongoing success and sustainability of volunteer metal finishing efforts will depend on prioritizing education, training, and adherence to established standards. As communities strive to preserve their heritage and improve shared resources, the responsible and informed engagement of individual contributors remains a vital asset. Continued investment in these programs promises to yield both tangible improvements to the physical environment and lasting social benefits.