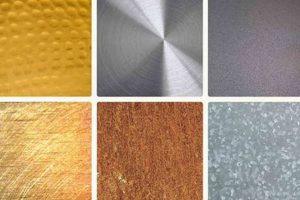

This entity represents a business specializing in surface treatment processes applied to metallic components. These processes alter the surface properties of metals to enhance aesthetics, improve corrosion resistance, increase wear resistance, or prepare the surface for subsequent treatments like painting or coating. Examples of such treatments include plating (e.g., chrome, nickel), anodizing, powder coating, and passivation.

Operations of this nature contribute significantly to various industries, extending the lifespan and enhancing the performance of metallic products. The application of specific finishing techniques can address performance issues, prevent premature failure due to environmental factors, and add value to manufactured goods. Historically, these processes have been integral to manufacturing, evolving with advancements in materials science and industrial techniques to meet increasingly stringent requirements for product durability and aesthetics.

The following sections will delve into specific aspects related to such operations, including common finishing techniques, quality control measures, and environmental considerations pertinent to the industry.

Surface Treatment Optimization

The following guidance addresses key areas for optimizing metal finishing processes, derived from industry best practices and aimed at enhancing efficiency and quality.

Tip 1: Material Compatibility: Prioritize the selection of finishing processes compatible with the base metal substrate. Incompatibility can lead to adhesion failures, accelerated corrosion, or other detrimental effects on the finished product.

Tip 2: Surface Preparation: Implement thorough cleaning and pre-treatment procedures. Contaminants like oils, oxides, and scale must be removed to ensure proper adhesion and uniform coating thickness.

Tip 3: Process Control: Maintain strict control over process parameters, including bath chemistry, temperature, and current density. Fluctuations in these parameters can impact the quality and consistency of the finished surface.

Tip 4: Rinsing Efficiency: Optimize rinsing procedures to remove residual chemicals from treated parts. Inadequate rinsing can cause staining, corrosion, or interference with subsequent processes.

Tip 5: Quality Inspection: Employ rigorous quality control measures, including visual inspection, thickness testing, and adhesion testing, to verify that finished parts meet specified requirements. Early detection of defects can prevent costly rework or rejections.

Tip 6: Waste Management: Implement environmentally responsible waste management practices. Proper treatment and disposal of process chemicals and byproducts are essential for regulatory compliance and environmental protection.

Tip 7: Equipment Maintenance: Establish a preventative maintenance schedule for all equipment, including tanks, pumps, rectifiers, and ventilation systems. Regular maintenance minimizes downtime and ensures consistent process performance.

Adhering to these recommendations promotes consistent, high-quality metal finishing, resulting in improved product performance and longevity.

The subsequent sections will address the specific challenges and future trends in the industry.

1. Surface Preparation

Effective surface preparation is a critical precursor to any successful metal finishing process. The quality of the final finish, including its adhesion, durability, and aesthetic appearance, is directly dependent on the thoroughness and accuracy of the initial surface preparation steps. For metal finishing companies, a robust surface preparation protocol is paramount for delivering consistent, high-quality results.

- Removal of Contaminants

Surface contaminants such as oils, grease, dirt, oxides, and mill scale can impede the adhesion of coatings and compromise corrosion resistance. Mechanical cleaning methods, including abrasive blasting and grinding, are commonly employed to remove heavy contaminants. Chemical cleaning, involving the use of solvents, alkaline cleaners, or acid pickling, removes residual oils and light oxides. Proper contaminant removal is essential for achieving a uniform and durable finish.

- Surface Activation

Surface activation enhances the reactivity of the metal surface, promoting better adhesion of subsequent coatings. Activation may involve techniques such as etching, which roughens the surface microscopically, creating a larger surface area for bonding. Chemical treatments can also modify the surface chemistry to improve its receptivity to coatings. These processes are tailored to the specific metal being treated and the desired finish.

- Rinsing and Neutralization

Following cleaning and activation, thorough rinsing is crucial to remove residual chemicals that could interfere with the finishing process or cause corrosion. Neutralization steps may be necessary to eliminate any remaining acidic or alkaline residues. Deionized water is often used for final rinsing to minimize the introduction of new contaminants.

- Inspection and Quality Control

Before proceeding with the metal finishing process, a thorough inspection of the prepared surface is essential. Visual inspection, along with techniques like water break tests to assess surface cleanliness, ensures that the surface meets the required standards. Any deficiencies identified at this stage can be addressed before incurring the costs of applying the finish.

These critical surface preparation processes directly influence the quality and longevity of any metal finishing product. It’s essential that metal finishing operations maintain stringent control over the materials and methods employed in surface preparation. Quality assurance, which begins with surface preparation, is central to the company’s reputation and success.

2. Process Chemistry

The efficacy and consistency of a metal finishing operation are inextricably linked to its process chemistry. Metal finishing involves a diverse array of chemical reactions and solutions designed to alter the surface properties of metallic substrates. Effective management and control of these chemical processes directly impact the quality, durability, and aesthetic appeal of the finished products. The specific chemistries utilized are determined by the base metal, the desired finish, and regulatory requirements. For example, electroplating processes necessitate precise control of electrolyte composition, current density, and temperature to ensure uniform metal deposition. Similarly, anodizing requires careful management of acid concentrations and voltage to achieve the desired oxide layer thickness and color. Inadequate control of these chemical parameters can lead to defects such as pitting, blistering, or inconsistent coating thickness, resulting in product rejection and increased costs. Furthermore, the selection and management of process chemistries must adhere to environmental regulations, necessitating the use of less hazardous materials and efficient waste treatment systems.

Consider the scenario of applying a zinc phosphate coating for corrosion protection. The phosphate bath’s composition, including zinc ions, phosphate ions, and accelerators, must be meticulously maintained within specified limits. Deviations in concentration or pH can lead to incomplete coating formation, reduced corrosion resistance, and potential substrate attack. Real-time monitoring and adjustments of the bath chemistry are crucial for consistent results. Similarly, the etching process preceding painting requires careful control of acid concentration and immersion time. Over-etching can damage the substrate, while under-etching hinders paint adhesion. In practical application, metal finishing operations employ advanced analytical techniques, such as titration, spectroscopy, and electrochemical analysis, to monitor and control process chemistry. Furthermore, expert technical staff are essential for troubleshooting process issues and implementing corrective actions.

In summary, process chemistry is a foundational element of metal finishing. Strict control over chemical parameters is essential for achieving consistent product quality, ensuring regulatory compliance, and optimizing operational efficiency. Challenges include the increasing stringency of environmental regulations, the need for sustainable chemistries, and the growing complexity of modern finishing processes. Understanding and effectively managing process chemistry is paramount for maintaining a competitive advantage in the metal finishing industry.

3. Quality Control

In metal finishing operations, rigorous quality control is not merely a procedural step but an intrinsic element dictating product reliability and customer satisfaction. Effective quality control systems ensure that finished metal surfaces meet stringent specifications for appearance, durability, and performance, safeguarding against defects and premature failure.

- Incoming Material Inspection

The quality control process commences with the inspection of incoming raw materials, including base metals and process chemicals. Verification of material certifications, chemical composition analysis, and physical property testing confirm that materials meet required standards. This prevents substandard materials from entering the production stream, mitigating the risk of defects in the finished product.

- In-Process Monitoring

Throughout the metal finishing process, continuous monitoring of key parameters, such as bath chemistry, temperature, pH, and current density, ensures that process conditions remain within specified control limits. Statistical process control (SPC) techniques are employed to track process variability and identify potential deviations before they lead to non-conformances. Timely intervention prevents the propagation of defects and minimizes process downtime.

- Finished Product Inspection

The final stage of quality control involves a comprehensive inspection of finished metal parts. Visual examination detects surface imperfections, such as scratches, blemishes, or discoloration. Destructive and non-destructive testing methods, including coating thickness measurements, adhesion testing, corrosion resistance testing, and hardness testing, verify that finished parts meet all specified requirements. Acceptance sampling plans are utilized to ensure that the entire production lot conforms to acceptable quality levels.

- Documentation and Traceability

Detailed documentation of all quality control activities, including inspection results, process parameters, and corrective actions, provides a complete audit trail. Traceability systems enable the identification of the source of any defects, facilitating root cause analysis and preventative measures. Comprehensive documentation supports continuous improvement efforts and ensures compliance with regulatory requirements.

These multi-faceted quality control measures, when rigorously implemented, enable metal finishing operations to deliver consistent, high-quality products that meet or exceed customer expectations. Effective quality control minimizes the risk of product failures, reduces warranty claims, and enhances the company’s reputation for reliability and excellence. An absence of robust quality control can lead to high rates of rejection, customer dissatisfaction, and financial losses. It is, therefore, an integral function that secures the success and sustainability of a metal finishing enterprise.

4. Equipment Maintenance

Effective equipment maintenance is fundamental to the operational efficiency and financial stability of a metal finishing enterprise. The specialized machinery employed in these processes, including plating tanks, rectifiers, pumps, filtration systems, and ventilation systems, requires regular upkeep to ensure consistent performance, minimize downtime, and prevent costly repairs. A preventative maintenance program addresses potential issues before they escalate into major problems, safeguarding productivity and product quality. For instance, a malfunctioning rectifier can lead to inconsistent plating thickness, resulting in rejected parts and wasted resources. Similarly, a poorly maintained ventilation system can expose workers to hazardous fumes, creating safety risks and potential regulatory violations. The failure to adhere to a scheduled maintenance program can also invalidate equipment warranties, increasing financial exposure in the event of a breakdown.

Consider a scenario where a plating tanks heating system fails due to neglected maintenance. The resulting temperature fluctuations disrupt the plating process, leading to uneven metal deposition and substandard corrosion resistance. This necessitates the stripping and re-plating of affected parts, increasing labor costs and material consumption. In contrast, a proactively maintained heating system, with regular inspections and component replacements, prevents such disruptions and ensures consistent product quality. Furthermore, consistent equipment maintenance can extend the lifespan of critical assets, reducing the frequency of costly replacements. For example, regular cleaning and calibration of chemical dosing systems maintain the accuracy of chemical additions, optimizing process efficiency and minimizing chemical waste. A well-maintained and up-to-date inventory of spare parts is also essential for rapid repairs and minimal downtime.

In conclusion, equipment maintenance is not merely a cost center but a strategic investment that enhances productivity, ensures product quality, and promotes workplace safety. The economic benefits derived from preventative maintenance significantly outweigh the costs associated with reactive repairs and unplanned downtime. Understanding and prioritizing equipment maintenance is therefore paramount for the long-term success and sustainability of a metal finishing operation. As operational complexities increase, employing a computerized maintenance management system (CMMS) becomes increasingly valuable for scheduling tasks, tracking costs, and analyzing equipment performance.

5. Environmental Compliance

Metal finishing operations, inherently involving the use of chemicals and generation of waste, face stringent environmental regulations. Strict adherence to these regulations is not merely a legal obligation but a critical factor influencing the sustainability and long-term viability of any such business. Regulations address wastewater discharge, air emissions, hazardous waste management, and worker safety. Non-compliance can result in substantial fines, operational shutdowns, and reputational damage, impacting profitability and market access. Effective environmental management systems, including waste minimization strategies, pollution prevention technologies, and comprehensive monitoring programs, are essential for maintaining compliance. The selection of less hazardous chemicals, implementation of closed-loop recycling systems, and proper treatment of wastewater are examples of proactive measures that minimize environmental impact and reduce regulatory scrutiny.

Consider the case of wastewater discharge: Metal finishing processes generate wastewater containing heavy metals, acids, and other pollutants. These contaminants must be treated to meet stringent discharge limits before being released into publicly owned treatment works (POTWs) or directly into surface waters. Treatment technologies, such as chemical precipitation, ion exchange, and reverse osmosis, are employed to remove pollutants from wastewater. Continuous monitoring of effluent quality and adherence to discharge permits are critical for preventing water pollution. Similarly, air emissions from metal finishing processes, including volatile organic compounds (VOCs) and acid fumes, are subject to regulation. Control technologies, such as scrubbers and carbon adsorbers, reduce air emissions to acceptable levels. Regular monitoring and maintenance of these control systems are essential for maintaining air quality and protecting worker health.

In conclusion, environmental compliance is an integral component of responsible metal finishing operations. A proactive approach to environmental management, encompassing waste minimization, pollution prevention, and continuous monitoring, is crucial for maintaining regulatory compliance, minimizing environmental impact, and ensuring long-term sustainability. The successful implementation of an environmental management system reduces risk, enhances operational efficiency, and strengthens the company’s reputation as a responsible corporate citizen. Failure to prioritize environmental compliance can have severe consequences, undermining the financial stability and jeopardizing the future of the enterprise.

6. Cost Optimization

Cost optimization within a metal finishing business necessitates a multifaceted approach that addresses material costs, labor efficiency, energy consumption, and waste management. The effective management of these factors directly impacts profitability and competitiveness within the industry. For instance, the selection of more cost-effective chemical formulations, without compromising finish quality, can significantly reduce material expenses. Implementation of automated processes and efficient workflow layouts can minimize labor requirements and improve productivity. Energy-efficient equipment upgrades, such as variable frequency drives on pumps and optimized heating systems, can lower energy consumption and reduce operating costs. Effective waste treatment and recycling programs not only ensure regulatory compliance but also reduce disposal fees and potentially recover valuable resources. Neglecting any of these areas can lead to increased operational expenses and diminished profitability.

Examining specific processes reveals opportunities for cost optimization. Consider the electroplating process: precise control of plating bath chemistry and current density can minimize metal usage and prevent overplating. Implementing drag-out reduction techniques, such as air knives or drip tanks, recovers valuable plating solutions, reducing chemical consumption and wastewater treatment costs. Similarly, in powder coating operations, optimized spray booth designs and powder recovery systems minimize powder waste and improve coating efficiency. The adoption of lean manufacturing principles, such as value stream mapping and 5S methodologies, can identify and eliminate wasteful activities throughout the entire metal finishing process. These incremental improvements, when combined, yield substantial cost savings over time.

In conclusion, cost optimization is a continuous endeavor requiring diligent monitoring, data analysis, and proactive implementation of improvement initiatives. It requires a commitment from all levels of the organization. The successful integration of cost-saving measures not only enhances profitability but also strengthens the company’s competitive position and fosters a culture of efficiency and sustainability. Challenges include the need for capital investment in new technologies, the resistance to change among employees, and the difficulty in quantifying the benefits of certain optimization measures. Overcoming these challenges requires strong leadership, effective communication, and a clear understanding of the potential return on investment.

Frequently Asked Questions

This section addresses common inquiries concerning the services and operational procedures of a metal finishing entity. The following questions and answers are designed to provide clarity and address potential concerns.

Question 1: What range of metal finishing services are offered?

A comprehensive array of metal finishing services is provided, including but not limited to electroplating (various metals), anodizing, powder coating, passivation, and surface preparation techniques such as abrasive blasting and chemical cleaning. Specific capabilities are contingent upon the facility’s equipment and expertise.

Question 2: What types of metals can be finished?

A variety of metals can be accommodated, encompassing steel, aluminum, stainless steel, copper, brass, and titanium alloys. Feasibility is dependent upon the selected finishing process and compatibility between the metal substrate and the applied coating.

Question 3: What quality control measures are implemented?

Stringent quality control protocols are enforced throughout the entire finishing process, beginning with incoming material inspection and extending through in-process monitoring to finished product inspection. Non-destructive testing methods, such as coating thickness measurements and adhesion testing, are employed to ensure conformance to specified requirements.

Question 4: What environmental regulations are adhered to?

Strict compliance with all applicable environmental regulations is maintained, including those pertaining to wastewater discharge, air emissions, and hazardous waste management. Waste minimization strategies, pollution prevention technologies, and comprehensive monitoring programs are implemented to minimize environmental impact.

Question 5: What is the typical turnaround time for a finishing project?

Turnaround time varies depending on the complexity of the project, the type of finish required, and the volume of parts to be processed. A project timeline is typically provided upon receipt of detailed specifications and quantity requirements.

Question 6: How are pricing and quotes determined?

Pricing is influenced by factors such as the size and geometry of the parts, the type of metal finish specified, the volume of parts, and any specific handling or packaging requirements. Quotes are provided based on a thorough review of the project specifications.

This FAQ section offers a general overview of pertinent information. For further clarification or inquiries specific to a project, direct contact with the entity is recommended.

The following section will address trends and future outlook within the metal finishing industry.

Conclusion

This exploration has dissected various critical facets surrounding Boyko’s Metal Finishing Co., encompassing operational efficiency, quality assurance, regulatory compliance, and cost management. The discussion underscored the importance of meticulous surface preparation, precise process chemistry control, rigorous quality control protocols, and proactive equipment maintenance. Environmental compliance and cost optimization were presented as non-negotiable elements for sustained success.

The future viability of Boyko’s Metal Finishing Co. hinges on continuous improvement, adaptation to evolving environmental standards, and the integration of innovative technologies. A commitment to excellence in all operational domains is paramount for maintaining a competitive edge and ensuring long-term sustainability in a demanding industrial landscape.