A resilient coating designed for flooring applications, offers exceptional durability and resistance to wear and tear. These products are typically formulated to withstand heavy foot traffic, impacts, and scratches, providing a long-lasting protective layer for various floor surfaces. For instance, in a high-traffic commercial space, such a finish prevents premature wear and maintains the floor’s aesthetic appeal for an extended period.

The significance of employing a robust floor protectant lies in its ability to minimize maintenance requirements and extend the lifespan of the underlying flooring material. Historically, simpler coatings offered limited protection, necessitating frequent refinishing. Modern, advanced formulas provide enhanced resistance to abrasion, chemicals, and staining, resulting in reduced upkeep costs and a consistently presentable surface. This resistance translates to cost savings over time, both in terms of labor and material replacement.

The following sections will delve into the specific types of these highly durable coatings, their application methods, suitability for different flooring materials, and factors to consider when selecting the optimal product for a given environment. Understanding these aspects is crucial for achieving the best possible performance and longevity from a floor finishing solution.

Guidance on Durable Floor Protection

The following recommendations aim to provide optimal strategies for leveraging highly resilient floor coatings to maximize protection and longevity. Careful consideration of these points will lead to enhanced performance and a more enduring finish.

Tip 1: Surface Preparation is Paramount: Ensure the flooring surface is thoroughly cleaned, sanded, and free from any contaminants before application. Improper preparation will compromise adhesion and reduce the effectiveness of the protective layer. For example, failing to remove old wax can lead to uneven coverage and premature peeling.

Tip 2: Choose the Correct Formulation: Select a product specifically designed for the type of flooring material in question. Different formulations offer varying levels of adhesion and flexibility. Using a product intended for hardwood on vinyl, for example, may result in cracking or discoloration.

Tip 3: Apply Multiple Thin Coats: Multiple thin coats are superior to a single thick coat. Thin coats allow for proper curing and minimize the risk of bubbles or imperfections. Allow sufficient drying time between coats, as specified by the manufacturer.

Tip 4: Control Environmental Conditions: Maintain optimal temperature and humidity levels during application and curing. Extreme temperatures or high humidity can negatively affect the curing process, leading to a weaker and less durable finish. Consult the product’s technical data sheet for recommended environmental parameters.

Tip 5: Use Appropriate Application Tools: Employ high-quality applicators, such as microfiber pads or specialized rollers, to ensure even and consistent coverage. Avoid using brushes that shed bristles, as these can become embedded in the coating.

Tip 6: Allow Adequate Curing Time: Refrain from subjecting the finished floor to heavy traffic until it has fully cured. Premature use can damage the surface and compromise its long-term durability. Refer to the manufacturer’s instructions for recommended curing times.

Tip 7: Implement a Regular Maintenance Schedule: Implement a routine cleaning schedule using appropriate cleaning products designed for finished floors. Harsh chemicals and abrasive cleaners can damage the protective layer and reduce its lifespan.

Adhering to these guidelines ensures the protective qualities of resilient floor coatings are fully realized, resulting in a longer-lasting and more aesthetically pleasing floor surface.

The subsequent sections will explore case studies and real-world applications of these durable floor coatings, demonstrating their effectiveness in various environments.

1. Abrasion Resistance

Abrasion resistance is a critical attribute of durable floor finishes, directly impacting their ability to withstand wear from foot traffic, moving furniture, and other abrasive forces. A floor coating’s resistance to abrasion is a primary determinant of its lifespan and overall performance.

- Resistance to Surface Wear

A high degree of abrasion resistance prevents the floor finish from being easily scratched, scuffed, or worn down. This is particularly important in high-traffic areas such as hallways, lobbies, and commercial spaces. A floor with poor abrasion resistance will quickly show signs of wear, requiring frequent refinishing.

- Impact on Aesthetic Appeal

Abrasion-resistant floor coatings maintain their appearance over time, preserving the aesthetic appeal of the flooring. Reduced scratching and scuffing translates to a consistently presentable surface, minimizing the need for cosmetic repairs or replacements. A floor that looks new for longer contributes positively to the overall environment.

- Influence on Maintenance Requirements

Floor finishes with superior abrasion resistance require less frequent maintenance. Their durability minimizes the need for regular polishing or recoating, reducing both labor costs and downtime. A more durable finish translates directly to lower long-term maintenance expenses.

- Material Composition and Testing

The abrasion resistance of a floor coating is determined by its chemical composition and the quality of its raw materials. Standardized tests, such as the Taber Abrasion Test, are used to measure a finish’s ability to withstand abrasive forces. These tests provide quantifiable data that can be used to compare the abrasion resistance of different products.

The degree to which a floor finish exhibits resistance to abrasion directly correlates with its suitability for various applications. Selecting a product with appropriate abrasion resistance ensures both long-term performance and cost-effectiveness, protecting the underlying flooring and maintaining its visual appeal.

2. Chemical Protection

A crucial characteristic of resilient floor coatings is their capacity to resist damage from chemical exposure. This protection stems from the finish’s composition, which acts as a barrier against corrosive substances, preventing them from penetrating and damaging the underlying flooring material. The absence of adequate chemical resistance can lead to discoloration, staining, softening, or even structural degradation of the floor. For instance, in laboratory settings or industrial environments where exposure to acids, solvents, or cleaning agents is frequent, a floor finish lacking chemical resistance would rapidly deteriorate, requiring costly repairs or replacements.

The significance of chemical protection is particularly evident in environments where spills and exposure to harsh substances are common. Hospitals, for example, routinely use disinfectants that can degrade certain floor finishes. Similarly, automotive repair shops expose floors to oils, grease, and various solvents. The selection of a floor finish with a high degree of chemical resistance in these settings is not merely an aesthetic consideration but a functional necessity. The correct choice minimizes the risk of permanent damage, reduces the frequency of cleaning and maintenance, and preserves the integrity of the flooring surface over extended periods.

Ultimately, the chemical resistance of a floor finish is a critical determinant of its long-term performance and cost-effectiveness. While abrasion resistance addresses physical wear, chemical protection safeguards against damage from chemical interactions. Selecting a finish that offers both robust abrasion resistance and substantial chemical protection ensures a durable and resilient flooring solution suitable for a wide range of demanding environments. Failure to consider chemical resistance can result in premature floor failure and increased operational expenses.

3. Application Method

The durability and performance of a high-strength floor coating are intrinsically linked to its application method. An improperly applied finish, regardless of its inherent protective qualities, will fail to deliver optimal results. The application process directly influences the coating’s adhesion, uniformity, and ultimate resistance to wear and chemical exposure. For instance, a two-component epoxy finish, known for its exceptional hardness and chemical resistance, requires precise mixing and a specific application technique to ensure proper curing and bonding. Failure to adhere to these parameters can result in a finish that is brittle, prone to peeling, or susceptible to chemical attack.

Different coating types necessitate distinct application techniques and equipment. Water-based polyurethanes, for example, are typically applied with a microfiber applicator or a high-quality roller to achieve a smooth, even coat. Solvent-based finishes, on the other hand, may require specialized spray equipment to ensure consistent coverage and minimize the risk of bubbling or solvent entrapment. Moreover, the preparation of the substrate is paramount; a floor that is not properly cleaned, sanded, and primed will compromise the adhesion of even the most robust coating. Consider a concrete floor that has not been adequately prepared; the presence of dust, grease, or previous coatings will prevent the new finish from bonding correctly, leading to premature failure.

In summary, the application method is not merely a procedural step but an integral component of achieving the desired performance from a hard-wearing floor finish. Proper technique, adherence to manufacturer’s instructions, and meticulous surface preparation are essential for realizing the coating’s full potential and ensuring a long-lasting, protective floor surface. Ignoring these factors can negate the benefits of even the most advanced and resilient floor coatings, resulting in wasted resources and compromised floor integrity.

4. Curing time

The curing time of a “hard as nails floor finish” is a critical factor determining its ultimate performance and durability. This period, during which the coating undergoes chemical reactions to achieve its hardened state, directly influences its resistance to abrasion, chemicals, and impact. Insufficient curing compromises the structural integrity of the finish, rendering it more susceptible to damage. For example, a polyurethane finish that is subjected to heavy foot traffic before it is fully cured may exhibit premature scratches and scuffs, negating its intended protective qualities. The specific duration of the curing time varies depending on the type of finish, environmental conditions (temperature and humidity), and the thickness of the applied coat.

Adherence to the manufacturer’s recommended curing time is paramount for ensuring optimal results. Rushing the curing process can lead to a finish that is soft, tacky, or prone to peeling. Conversely, allowing adequate time for curing allows the finish to develop its full hardness and resilience. In practical terms, this means restricting access to the finished floor for the specified period, even if the surface appears dry to the touch. In commercial settings, this might involve scheduling application during off-peak hours or implementing temporary barriers to prevent foot traffic. Similarly, in residential applications, careful planning is necessary to minimize disruption and allow the finish to cure undisturbed. Ignoring the curing time can lead to costly repairs or premature replacement of the flooring.

In conclusion, curing time is an indispensable component of a “hard as nails floor finish,” directly impacting its protective capabilities and longevity. While the temptation to expedite the process may be strong, particularly in time-sensitive situations, adhering to the recommended curing time is essential for realizing the full potential of the finish and ensuring a durable, long-lasting floor surface. Challenges related to managing access and scheduling must be addressed to prevent compromising the integrity of the finished floor. The connection between proper curing and ultimate performance underscores the importance of diligent application practices for achieving a truly resilient floor coating.

5. Floor Compatibility

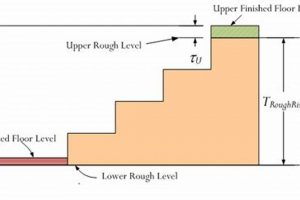

Floor compatibility is a foundational element in the selection and application of a resilient floor coating. The interaction between the coating and the substrate directly determines the success and longevity of the finish. Incompatibility leads to adhesion failures, compromised durability, and premature degradation of both the coating and the underlying floor. A finish designed for hardwood, for instance, is unlikely to perform adequately on a concrete or vinyl surface due to differences in porosity, flexibility, and chemical composition. The result is often peeling, cracking, or a lack of proper bonding, effectively negating the intended protective benefits of the finish. The selection process must, therefore, begin with a thorough assessment of the existing floor material and its characteristics.

Consider the practical implications of mismatched floor and coating types. Applying an oil-based polyurethane to a previously waxed floor, without proper stripping and preparation, exemplifies a scenario of incompatibility. The wax residue prevents the polyurethane from bonding directly to the floor, resulting in a weak and easily damaged finish. Conversely, using a rigid epoxy coating on a flexible vinyl floor can lead to cracking and delamination as the vinyl expands and contracts with temperature fluctuations. Each flooring material possesses unique properties that dictate the appropriate type of coating and the necessary surface preparation steps. Understanding these nuances is crucial for achieving a durable and aesthetically pleasing outcome. Surface preparation, including cleaning, sanding, and priming, is also essential to ensure the finish adheres properly to the substrate. Failure to prepare the floor adequately diminishes the coating’s ability to bond, resulting in a finish that is prone to peeling, bubbling, or other forms of failure.

In conclusion, floor compatibility is not simply a matter of preference; it is a fundamental prerequisite for a successful application of any “hard as nails floor finish.” The interplay between the coating and the substrate dictates the long-term performance and durability of the flooring system. Challenges in achieving compatibility can often be mitigated through proper surface preparation and the selection of coatings specifically formulated for the target floor material. Addressing this consideration early in the selection process can prevent costly mistakes and ensure a resilient, long-lasting floor that meets the demands of its intended environment.

6. Maintenance needs

The long-term performance of a resilient floor coating is inextricably linked to its maintenance requirements. While a “hard as nails floor finish” is inherently designed for durability, neglecting appropriate maintenance procedures will inevitably compromise its lifespan and protective qualities. Understanding the specific maintenance needs associated with a given floor finish is crucial for preserving its integrity and ensuring a consistently presentable surface.

- Regular Cleaning Protocols

The implementation of regular cleaning schedules is paramount for maintaining the integrity of a floor finish. The frequency and type of cleaning required depend on the environment and the specific coating. For instance, a commercial space with heavy foot traffic necessitates more frequent cleaning than a residential setting. The use of appropriate cleaning agents, specifically those recommended by the finish manufacturer, is also crucial. Harsh chemicals and abrasive cleaners can damage the protective layer, reducing its lifespan and compromising its resistance to stains and scratches. Regular sweeping, vacuuming, and damp mopping with suitable cleaning solutions form the foundation of effective maintenance.

- Protective Measures and Preventative Actions

Beyond routine cleaning, preventative measures play a significant role in minimizing maintenance needs. The use of walk-off mats at entryways helps to trap dirt and debris, preventing them from being tracked onto the finished floor. Furniture pads placed under chair legs and other heavy objects prevent scratches and dents. Promptly cleaning up spills prevents staining and potential damage from corrosive substances. Educating occupants about proper floor care practices contributes to a culture of preventative maintenance and extends the lifespan of the finish.

- Periodic Inspection and Remedial Action

Regular inspections allow for the early detection of potential problems, such as scratches, scuffs, or areas of wear. Addressing these issues promptly prevents them from escalating into more significant damage. Minor scratches can often be repaired with touch-up kits or specialized repair products. Heavily worn areas may require recoating or refinishing. Early intervention minimizes the extent of the repairs needed and preserves the overall integrity of the floor finish.

- Recoating and Refinishing Schedules

Even with diligent cleaning and preventative measures, a resilient floor finish will eventually require recoating or refinishing. The frequency of these procedures depends on the traffic volume, the environment, and the type of finish. Recoating involves applying a fresh layer of finish to the existing surface, typically after lightly sanding or abrading the old finish to promote adhesion. Refinishing, on the other hand, involves sanding down to the bare floor and applying a completely new finish. Establishing a proactive recoating or refinishing schedule prevents the floor from deteriorating to the point where more extensive and costly repairs are required.

The maintenance needs associated with a “hard as nails floor finish” represent an ongoing investment in its long-term performance. A proactive and diligent approach to maintenance ensures that the finish continues to provide the intended protection and aesthetic benefits for years to come. Conversely, neglecting maintenance can negate the inherent durability of even the most resilient floor coatings, resulting in premature failure and increased long-term costs.

7. Longevity potential

The “longevity potential” of a “hard as nails floor finish” directly reflects its capacity to maintain its protective and aesthetic properties over an extended period. This characteristic is paramount in determining the long-term value and cost-effectiveness of the flooring solution.

- Resistance to Environmental Factors

The capacity to withstand prolonged exposure to environmental factors significantly influences longevity. Resistance to UV radiation prevents fading and discoloration, while imperviousness to moisture inhibits warping and degradation. Floor finishes in high-humidity environments, such as bathrooms or coastal regions, require enhanced moisture resistance to prevent premature failure. A finish that demonstrates robust resistance to these elements maintains its integrity and appearance for a longer duration, thereby maximizing its lifespan.

- Durability Under High-Traffic Conditions

The ability to endure heavy foot traffic without significant wear and tear is a critical component of longevity. A finish designed for high-traffic areas, such as commercial lobbies or retail spaces, must possess exceptional abrasion resistance to prevent scratching, scuffing, and general surface degradation. The selection of a finish with appropriate durability for the anticipated traffic volume directly impacts its lifespan and the frequency of required maintenance or replacement. A durable finish minimizes the need for costly interventions, thereby extending the overall lifespan of the flooring investment.

- Chemical Stability and Resistance to Spills

The chemical stability of a floor finish directly affects its longevity, particularly in environments where spills are common. Resistance to various chemicals, including cleaning agents, solvents, and acidic substances, prevents staining, discoloration, and structural damage. A finish that exhibits high chemical resistance maintains its integrity and appearance even after repeated exposure to potentially harmful substances. This is particularly important in industrial settings, laboratories, or healthcare facilities where spills are likely to occur. Choosing a chemically stable finish ensures its long-term durability and minimizes the risk of damage from accidental spills.

- Adherence and Bonding Strength

The strength and durability of the bond between the finish and the underlying floor material are essential for achieving long-term performance. A finish that adheres strongly to the substrate resists peeling, cracking, and delamination, even under heavy use or changing environmental conditions. Proper surface preparation and the selection of compatible materials are crucial for achieving a strong and durable bond. A finish with excellent adherence maintains its integrity over time, preventing premature failure and extending its overall lifespan. This is a cornerstone element for maximizing longevity potential.

These interconnected elements collectively determine the “longevity potential” of a “hard as nails floor finish.” A finish that demonstrates superior performance across these facets offers a durable, resilient, and cost-effective flooring solution capable of withstanding the demands of its intended environment for an extended period. Proper selection and application, coupled with appropriate maintenance, are essential for realizing the full “longevity potential” of any floor finish.

Frequently Asked Questions

The following questions address common concerns and misconceptions regarding resilient floor coatings, offering clarity on their application, performance, and limitations.

Question 1: What is the expected lifespan of a “hard as nails floor finish” in a high-traffic commercial environment?

The lifespan varies depending on the specific product formulation, the volume and type of traffic, and the maintenance practices employed. However, a properly applied and maintained high-quality finish can typically last between 5 to 10 years in a commercial setting. Factors such as the presence of abrasive materials, the frequency of cleaning, and the type of cleaning agents used can significantly influence this duration.

Question 2: Can a “hard as nails floor finish” be applied over existing flooring, or is removal necessary?

The feasibility of applying a new finish over existing flooring depends on the condition of the existing surface and the compatibility of the materials. In some cases, it may be possible to apply a new finish after thorough cleaning, sanding, and priming. However, if the existing flooring is damaged, unstable, or incompatible with the new finish, removal may be necessary to ensure proper adhesion and long-term performance. Always consult with a flooring professional to assess the specific situation and determine the most appropriate course of action.

Question 3: What types of flooring materials are best suited for a “hard as nails floor finish”?

Resilient floor coatings are compatible with a wide range of flooring materials, including hardwood, concrete, vinyl, and tile. However, the specific formulation of the finish should be carefully selected to match the properties of the underlying floor. For example, a flexible finish may be more suitable for vinyl floors, while a rigid finish may be appropriate for concrete. Understanding the characteristics of the flooring material and choosing a compatible finish are essential for achieving optimal results.

Question 4: Is a “hard as nails floor finish” resistant to staining from common household or industrial chemicals?

The degree of chemical resistance varies depending on the specific formulation of the floor finish. Some finishes offer excellent resistance to a wide range of chemicals, while others may be more susceptible to damage from certain substances. Reviewing the product’s technical data sheet and understanding its chemical resistance properties is crucial for selecting a finish that is appropriate for the intended environment. Promptly cleaning up spills and using appropriate cleaning agents can also help to prevent staining and damage.

Question 5: What are the key factors to consider when selecting a “hard as nails floor finish” for a specific application?

Key factors to consider include the traffic volume, the type of flooring material, the potential for exposure to chemicals or moisture, the desired aesthetic appearance, and the budget. Carefully evaluating these factors and selecting a finish that meets the specific requirements of the application are essential for achieving long-term performance and satisfaction. Consulting with a flooring professional can provide valuable guidance in navigating the selection process.

Question 6: How does the application process impact the overall performance and longevity of a “hard as nails floor finish”?

The application process plays a critical role in determining the performance and longevity of a floor finish. Proper surface preparation, the use of appropriate application techniques, and adherence to the manufacturer’s instructions are essential for achieving optimal results. Improperly applied finishes may exhibit poor adhesion, uneven coverage, and reduced resistance to wear and chemicals. Investing in professional installation or carefully following detailed instructions is crucial for maximizing the benefits of a high-quality floor finish.

These frequently asked questions provide a foundational understanding of the capabilities and considerations surrounding durable floor coatings. Addressing these points proactively contributes to informed decision-making and successful implementation.

The subsequent section will provide real-world case studies illustrating the application and performance of these coatings in diverse environments.

Conclusion

This exploration has illuminated the critical attributes of a “hard as nails floor finish,” emphasizing its role in providing durable protection and aesthetic enhancement for a wide variety of flooring surfaces. Key considerations, including abrasion resistance, chemical protection, application methods, curing times, floor compatibility, maintenance needs, and longevity potential, directly influence the ultimate performance and value of such a coating. A comprehensive understanding of these aspects is paramount for informed decision-making.

Selecting the appropriate floor finish represents a significant investment. Prioritizing durability and carefully evaluating the specific demands of the intended environment will maximize the lifespan and overall return on that investment. Further research into the latest advancements in floor coating technology is encouraged to ensure optimal performance and long-term satisfaction.