A protective coating applied to wooden surfaces, specifically floors, designed to enhance durability and aesthetic appeal. This specialized product forms a barrier against wear, scratches, and spills, extending the lifespan of the flooring material. As an example, a residential application might involve two coats of the product following sanding to bare wood, creating a resilient and visually appealing surface.

The significance of this surface treatment lies in its capacity to preserve the integrity of wooden floors. It shields against the damaging effects of daily use, preventing premature aging and reducing the need for frequent repairs or replacements. Historically, such treatments were based on oil-based formulations, but advancements in polymer chemistry have led to water-based alternatives that offer improved performance and reduced environmental impact. The benefits include increased resistance to abrasion, chemical agents, and ultraviolet light, alongside a variety of sheen levels to achieve desired aesthetic outcomes.

The subsequent sections will delve into the specific types of formulations available, the application processes recommended by manufacturers, and the maintenance procedures that will maximize the lifespan and performance of treated wood floors. Considerations for selecting the appropriate product based on floor type, traffic volume, and desired aesthetic properties will also be addressed.

Application and Maintenance Guidance

Maximizing the effectiveness of a hardwood floor finish requires careful adherence to best practices during application and subsequent maintenance.

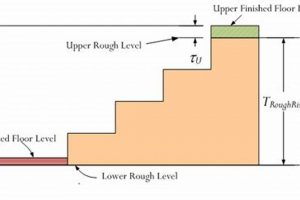

Tip 1: Surface Preparation is Paramount: Thoroughly sand and clean the wood surface prior to application. Remove all traces of previous coatings, dirt, and debris. Inadequate preparation can lead to adhesion failures and compromised aesthetic outcomes.

Tip 2: Adhere to Recommended Environmental Conditions: Application should occur within the temperature and humidity ranges specified by the manufacturer. Deviations from these parameters can affect curing time and film formation, potentially resulting in an unsatisfactory finish.

Tip 3: Employ Proper Application Techniques: Utilize appropriate applicators, such as microfiber rollers or T-bars, designed for the specific product. Apply thin, even coats, avoiding excessive build-up or pooling. Over-application can prolong drying times and increase the risk of solvent entrapment.

Tip 4: Allow Adequate Drying Time Between Coats: Strictly adhere to the manufacturer’s recommended drying times between coats. Insufficient drying can compromise the integrity of subsequent layers and lead to a soft, easily damaged finish.

Tip 5: Ensure Proper Ventilation During Application and Curing: Provide adequate ventilation to facilitate the evaporation of solvents and promote proper curing. Inadequate ventilation can result in prolonged off-gassing and potential health hazards.

Tip 6: Implement a Regular Cleaning Regimen: Use cleaning products specifically formulated for hardwood floors. Avoid abrasive cleaners, harsh chemicals, and excessive water, which can damage the finish and penetrate the wood. Routine sweeping or vacuuming will remove abrasive particles that can scratch the surface.

Tip 7: Consider the Use of Area Rugs and Furniture Pads: Place area rugs in high-traffic areas to minimize wear and tear. Apply felt pads to the feet of furniture to prevent scratches and dents.

By carefully following these guidelines, the longevity and aesthetic appeal of wood floors can be significantly enhanced. Consistent maintenance and adherence to best practices ensure a lasting and durable surface.

The following sections will explore specific product lines, offering detailed insights into their respective properties and recommended applications, along with strategies for addressing common challenges.

1. Durability

Durability, in the context of wood floor coatings, signifies the capacity to withstand wear and tear over extended periods. It is a paramount consideration in selecting a product, influencing the floor’s lifespan and maintenance requirements. The inherent durability of a coating directly correlates with its ability to resist scratches, abrasions, chemical exposure, and the effects of prolonged use.

- Abrasion Resistance

Abrasion resistance refers to the coating’s ability to withstand damage from foot traffic, furniture movement, and the introduction of abrasive particles such as sand or dirt. A highly abrasion-resistant coating maintains its integrity, preventing the development of visible scratches and preserving the floor’s aesthetic appearance. In high-traffic commercial settings, for example, selecting a coating with superior abrasion resistance is crucial to minimize the need for frequent refinishing.

- Scratch Resistance

Scratch resistance is distinct from abrasion resistance, focusing specifically on the coating’s capacity to prevent surface scratches from sharp objects or sudden impacts. A scratch-resistant coating maintains a smooth, unblemished surface, enhancing the floor’s visual appeal. Consider a residential setting with pets; a coating lacking scratch resistance will exhibit noticeable damage from pet claws, necessitating more frequent maintenance.

- Chemical Resistance

Chemical resistance is the coating’s ability to withstand exposure to household cleaners, spills, and other chemical agents without degradation. A chemically resistant coating prevents staining, discoloration, and weakening of the film, preserving its protective properties and appearance. In kitchen environments, for instance, resistance to spills of common household chemicals is essential to maintain the floor’s integrity.

- Impact Resistance

Impact resistance denotes the coating’s capacity to withstand sudden impacts without cracking, chipping, or delaminating. An impact-resistant coating maintains its structural integrity, preventing damage from dropped objects or heavy furniture. In a workshop setting, a coating with high impact resistance is crucial to withstand the potential for tools or materials being dropped on the floor.

The factors discussed collectively influence the long-term performance of wood floors. Coatings formulated with advanced polymers and cross-linking agents generally exhibit enhanced durability, providing superior resistance to the aforementioned forms of damage. A comprehensive assessment of these factors, in conjunction with the intended use environment, enables informed decisions regarding the selection of an wood floor coating that meets specific performance requirements, ensuring a durable and aesthetically pleasing floor surface.

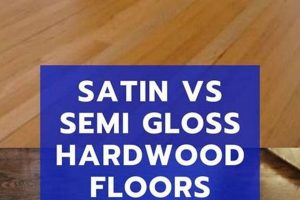

2. Appearance

The visual characteristics imparted by a hardwood floor coating are critical considerations in achieving the desired aesthetic. The selected finish fundamentally shapes the room’s ambiance and complements its architectural style. Appearance considerations extend beyond mere sheen level to encompass grain definition, color enhancement, and perceived depth.

- Sheen Level

Sheen, or gloss, refers to the amount of light reflected from the floor’s surface. Options range from matte (minimal reflection) to high-gloss (significant reflection). Matte finishes tend to conceal imperfections and offer a subtle, natural look, appropriate for rustic or informal settings. High-gloss finishes enhance light and create a sense of formality, often used in contemporary or traditional designs. The choice of sheen directly impacts the perceived brightness and cleanliness of the room.

- Grain Definition

The selected finish can accentuate or obscure the natural grain patterns of the wood. Some coatings enhance grain definition, emphasizing the wood’s unique character and adding visual interest. Other coatings may minimize grain definition, creating a more uniform and subdued appearance. The impact on grain visibility must align with the overall design intent.

- Color Enhancement

Certain coatings contain additives that enhance the wood’s natural color, deepening the tones and creating a richer appearance. Other coatings are formulated to maintain the wood’s original color, preventing yellowing or color shift over time. The decision to enhance or preserve the wood’s color is dictated by aesthetic preferences and the desired long-term appearance of the floor.

- Clarity and Depth

The clarity of the finish affects the perceived depth of the wood. High-clarity finishes allow the wood’s natural beauty to shine through, creating a sense of depth and dimension. Conversely, cloudy or hazy finishes can obscure the wood’s natural characteristics, resulting in a flat and lifeless appearance. Selecting a finish with optimal clarity is essential to showcase the wood’s inherent qualities.

These components collectively define the visual impact of the surface treatment. The selection of the optimal floor finishing product requires careful consideration of the desired sheen level, grain definition, color enhancement, and clarity. This informed decision-making ensures that the final result complements the architectural style and meets the specific aesthetic goals, achieving a visually pleasing and enduring floor surface.

3. Application

The successful implementation of a hardwood floor coating is intrinsically linked to proper application techniques. The characteristics of the coating, while crucial, are only fully realized through adherence to recommended procedures. Deviations from these procedures can lead to compromised performance, diminished aesthetic outcomes, and premature failure of the finish. The application stage is not merely a procedural step but a critical component influencing the coating’s long-term efficacy. For instance, insufficient surface preparation prior to application can result in adhesion failures, regardless of the product’s inherent qualities. Similarly, improper mixing of components in multi-part systems can alter the chemical properties, leading to incomplete curing and reduced durability.

Practical applications underscore the significance of this relationship. Consider a scenario where a professional floor installer, despite utilizing a high-quality, high-solids floor finish, neglects to adequately abrade the existing floor surface. The resulting finish may exhibit poor adhesion, peeling, or bubbling, necessitating costly rework. Conversely, a meticulous approach, involving thorough sanding, proper cleaning, and the application of thin, even coats, will maximize the coating’s protective properties and aesthetic qualities. Another example resides in the use of incorrect applicators; employing a low-quality brush can introduce air bubbles and inconsistencies in the finish, detracting from the overall appearance. The correct applicator, chosen based on the coating’s viscosity and recommended spread rate, facilitates a uniform and aesthetically pleasing result.

In summary, the application process is an indispensable factor in achieving optimal performance and aesthetic outcomes. A thorough understanding of manufacturer guidelines, coupled with meticulous execution, is paramount. Challenges related to application, such as environmental conditions and applicator technique, can be mitigated through rigorous training and adherence to industry best practices. Recognition of this relationship is central to maximizing the investment in hardwood floor coatings and ensuring durable, aesthetically pleasing results.

4. Protection

Wood floor coatings are fundamentally designed to provide a protective barrier against the myriad of threats that compromise the integrity of wooden surfaces. This protective functionality, specifically within the context of wood coatings, manifests as resistance to abrasion, moisture, chemical agents, and ultraviolet (UV) radiation. The efficacy of this defense directly determines the longevity and aesthetic appeal of the treated floor. Without adequate protection, wooden floors are susceptible to premature wear, staining, discoloration, and structural damage. The composition of the floor treatment dictates the level of protection afforded, with advanced formulations offering superior resistance compared to basic varnishes. For example, untreated hardwood in a high-traffic area will exhibit significant wear patterns within a short period, whereas a properly coated surface will maintain its original appearance for an extended duration.

Coatings that incorporate UV inhibitors mitigate the damaging effects of sunlight, preventing fading and discoloration. Similarly, products with hydrophobic properties minimize moisture absorption, guarding against swelling, warping, and the growth of mold and mildew. The selection of a floor finish should therefore be guided by a comprehensive assessment of the environmental stressors to which the floor will be exposed. In environments prone to spills or moisture, such as kitchens or bathrooms, coatings with enhanced water resistance are crucial. Conversely, in areas with high sun exposure, UV-resistant coatings are essential for preserving the floor’s color and integrity. The application process is also critical in maximizing the protective qualities of the finish. Improperly applied coatings may exhibit vulnerabilities, such as thin spots or areas of inadequate coverage, compromising the overall level of protection.

In summary, protection is an inherent and indispensable attribute. Its effectiveness depends on the product’s formulation, the environmental conditions, and the quality of application. The long-term performance and aesthetic preservation of wood floors are directly contingent upon the protective capabilities of the applied coating. Therefore, understanding the specific protective properties offered by a particular product and ensuring proper application are paramount to achieving a durable and visually appealing floor surface.

5. Maintenance

The long-term performance and aesthetic appeal of floors treated with floor coating are intrinsically linked to diligent maintenance practices. The finish, while providing an initial layer of protection, is subject to wear and tear from foot traffic, abrasion, and environmental factors. Inadequate maintenance accelerates the degradation of the treatment, diminishing its protective qualities and compromising the floor’s appearance. The correlation is direct: regular and appropriate maintenance extends the lifespan and preserves the intended characteristics of the coating. Failure to adhere to recommended maintenance procedures can negate the benefits of even the highest-quality application, leading to premature wear, staining, and the need for costly refinishing. Real-world examples demonstrate this connection; a high-traffic area subjected to regular sweeping and cleaning with pH-neutral solutions will exhibit far less wear compared to an identical area neglected in terms of proper maintenance. Therefore, understanding maintenance as an integral component is critical for realizing the full potential of the product.

Specific maintenance protocols vary depending on the type of coating and the environment in which it is applied. Generally, these protocols encompass routine sweeping or vacuuming to remove abrasive particles, periodic cleaning with manufacturer-recommended cleaning solutions, and the prompt removal of spills to prevent staining or damage. The selection of cleaning products is particularly important, as harsh chemicals or abrasive cleaners can degrade the treatment, diminishing its protective properties and accelerating wear. Furthermore, the use of mats or rugs in high-traffic areas can significantly reduce wear and tear, extending the lifespan of the finish. These practical applications demonstrate the importance of integrating proactive maintenance measures into the overall floor care regimen. Regular inspection for signs of wear, such as scratches or dullness, allows for timely intervention and prevents minor issues from escalating into more significant problems.

In conclusion, maintenance is not merely a post-application afterthought but an essential component of a comprehensive floor care strategy. The durability, appearance, and protective qualities of floor coatings are directly contingent upon consistent and appropriate maintenance practices. Challenges arise from a lack of awareness regarding recommended maintenance protocols and the use of inappropriate cleaning products. However, these challenges can be mitigated through education and adherence to manufacturer guidelines, ensuring the long-term preservation of the floor’s aesthetic appeal and structural integrity. Consistent application of the right maintenance routine helps to achieve a durable, long-lasting surface.

6. Composition

The composition of any wood floor coating dictates its performance characteristics, environmental impact, and suitability for specific applications. A thorough understanding of the components is therefore critical in selecting a product that meets the desired requirements for durability, aesthetics, and safety. The specific formulation, including resins, solvents, additives, and catalysts, directly influences the coating’s resistance to abrasion, chemical agents, and ultraviolet radiation, as well as its drying time, gloss level, and volatile organic compound (VOC) content.

- Resin Type

The resin constitutes the primary film-forming component. Common resin types include polyurethane, acrylic, and alkyd. Polyurethane resins generally offer superior durability and resistance to abrasion and chemicals, making them suitable for high-traffic areas. Acrylic resins tend to exhibit better UV resistance and color stability. Alkyd resins, while historically prevalent, have largely been superseded by polyurethane and acrylic due to their lower durability and higher VOC content. The choice of resin directly impacts the coating’s overall performance and longevity. For instance, a water-based polyurethane formulation designed for residential use might prioritize low VOCs and ease of application, while a solvent-based polyurethane coating intended for commercial applications may emphasize maximum durability and chemical resistance.

- Solvent System

The solvent system functions as a carrier for the resin and other components, facilitating application and film formation. Coatings are broadly classified as either solvent-based or water-based. Solvent-based coatings typically offer faster drying times, enhanced durability, and improved penetration into the wood substrate. However, they also exhibit higher VOC emissions, posing potential health and environmental concerns. Water-based coatings, on the other hand, have significantly lower VOC content, making them a more environmentally friendly choice. The selection of the solvent system involves a trade-off between performance characteristics and environmental considerations. A low-VOC, water-based polyurethane option might be selected for a school, balancing the need for a durable floor with indoor air quality concerns.

- Additives

Additives are incorporated to modify specific properties, such as flow, leveling, defoaming, UV resistance, and scratch resistance. Flow and leveling agents enhance the coating’s ability to spread evenly and eliminate brush marks or roller stipple. Defoamers prevent the formation of air bubbles during application. UV absorbers protect the finish from degradation caused by sunlight. Anti-scratch additives improve the coating’s resistance to surface scratches. These components, though present in relatively small quantities, can significantly impact the coating’s overall performance and aesthetic characteristics. For example, a coating intended for use in a sunny room would benefit from the inclusion of UV absorbers to prevent fading and discoloration of the wood.

- Catalysts and Crosslinkers

Catalysts and crosslinkers are employed in two-component systems to accelerate the curing process and enhance the coating’s physical properties. These components promote the formation of chemical bonds between the resin molecules, resulting in a more durable, chemically resistant, and abrasion-resistant film. The specific type and concentration of the catalyst or crosslinker affect the curing rate, pot life, and ultimate performance characteristics of the coating. Coatings designed for commercial applications often utilize advanced crosslinking technologies to achieve maximum durability and chemical resistance. For example, two-component polyurethane formulations are common in environments requiring exceptional abrasion resistance.

In synthesis, the composition of coating is a multifaceted aspect of its overall value. Each elementfrom the resin base and solvent carrier to the performance-enhancing additives and crosslinking agentsplays a distinct and crucial role in determining the final product’s characteristics. Informed choices, founded on a detailed comprehension of these chemical components, enable consumers and professionals alike to select coatings that optimize performance, durability, aesthetic appeal, and environmental stewardship.

Frequently Asked Questions Regarding Hardwood Floor Finishes

The following questions address common inquiries and misconceptions surrounding the selection, application, and maintenance of hardwood floor finishes, with an emphasis on providing objective and informative answers.

Question 1: What constitutes the primary determinant of a hardwood floor finish’s durability?

The composition of the resin system, particularly the type and concentration of polyurethane, acrylic, or other polymers, fundamentally influences durability. Higher concentrations of cross-linking polymers generally yield superior resistance to abrasion, chemicals, and impact.

Question 2: How does the sheen level of a hardwood floor finish impact perceived maintenance requirements?

Higher sheen levels, such as gloss or semi-gloss finishes, tend to reveal imperfections, scratches, and dust more readily than matte or satin finishes. Consequently, floors with higher sheen levels may necessitate more frequent cleaning to maintain a visually appealing appearance.

Question 3: What are the primary considerations when selecting between water-based and solvent-based hardwood floor finishes?

Water-based finishes generally exhibit lower volatile organic compound (VOC) emissions, making them a more environmentally friendly option. Solvent-based finishes, on the other hand, typically offer faster drying times, enhanced durability, and improved penetration into the wood substrate. The selection depends on balancing environmental concerns with performance requirements.

Question 4: Does the number of coats of hardwood floor finish directly correlate with increased durability?

While increasing the number of coats generally enhances the overall thickness and protective properties of the finish, the quality of the application and proper inter-coat adhesion are equally important. Applying multiple thin, even coats is preferable to applying a single thick coat, which can result in uneven drying and compromised durability.

Question 5: What measures can be implemented to minimize the risk of scratches and abrasions on hardwood floors?

Implementing preventative measures, such as using area rugs in high-traffic areas, applying felt pads to furniture legs, and implementing a regular sweeping or vacuuming routine, can significantly reduce the risk of scratches and abrasions. Additionally, selecting a finish with enhanced scratch resistance additives can provide an extra layer of protection.

Question 6: How frequently should hardwood floors be professionally refinished?

The frequency of professional refinishing depends on several factors, including the level of foot traffic, the type of finish, and the overall maintenance practices. Generally, hardwood floors in residential settings may require refinishing every 7-10 years, while floors in high-traffic commercial settings may necessitate more frequent refinishing every 3-5 years.

In summary, a comprehensive understanding of the factors influencing the selection, application, and maintenance of hardwood floor finishes is essential for achieving durable, aesthetically pleasing, and long-lasting results.

The following sections will delve into specific product lines, offering detailed insights into their respective properties and recommended applications, along with strategies for addressing common challenges.

Concluding Observations on Hardwood Floor Treatment

This exploration has underscored the critical role of appropriate hardwood floor treatment in preserving wood surfaces. The discussion encompassed factors ranging from the composition and durability of the finish to the importance of proper application and maintenance. Adherence to recommended practices is fundamental to achieving lasting aesthetic appeal and preventing premature degradation of wooden floors. Moreover, the consideration of environmental factors and specific application requirements is essential for optimal performance.

Therefore, informed decision-making regarding floor treatment selection and meticulous execution of maintenance protocols are paramount. Continued advancements in coating technology promise enhanced durability and sustainability; diligent application of current knowledge will maximize the lifespan and aesthetic value of wooden floors in diverse environments. The enduring value of wood surfaces necessitates a commitment to informed and responsible maintenance practices.