A resilient coating designed for application on various flooring types, this product provides a protective layer intended to enhance durability and maintain aesthetic appeal. Its composition focuses on creating a surface resistant to scuffs, scratches, and other common forms of wear and tear experienced in high-traffic environments. Regular application, following manufacturer guidelines, aims to extend the lifespan of the underlying floor.

The value of such a coating lies in its ability to reduce maintenance costs and improve the overall appearance of flooring. By offering enhanced protection, it minimizes the need for frequent stripping and re-waxing. This not only saves time and labor but also contributes to a more sustainable approach to floor care. Historically, the development of these types of coatings represents an evolution in floor maintenance technology, shifting from temporary solutions to more long-lasting, protective finishes.

Subsequent sections will delve into the specific application techniques, appropriate flooring types, maintenance procedures, and potential challenges associated with utilizing this type of protective floor treatment. Understanding these aspects is crucial for optimizing its performance and maximizing its benefits.

Application & Maintenance Guidance

The following recommendations are intended to optimize the performance and longevity of the protective floor coating.

Tip 1: Surface Preparation is Paramount: Prior to application, ensure the flooring is thoroughly cleaned and completely free of any existing coatings, dirt, or debris. Insufficient preparation compromises adhesion and the final finish quality.

Tip 2: Adhere to Recommended Dilution Ratios: If dilution is required, strictly follow the manufacturer’s guidelines. Incorrect dilution alters the product’s properties, affecting its ability to properly level and cure.

Tip 3: Employ Proper Application Techniques: Use a clean, lint-free mop or applicator. Apply thin, even coats, avoiding excessive build-up in any single area. Uneven application results in inconsistent gloss and wear patterns.

Tip 4: Allow Adequate Drying Time: Before allowing foot traffic, ensure each coat is completely dry. Premature traffic leads to scuffing and marring of the newly applied finish, necessitating rework.

Tip 5: Implement Regular Maintenance: Develop a routine cleaning schedule using pH-neutral cleaners specifically formulated for coated floors. Harsh chemicals damage the coating and shorten its lifespan.

Tip 6: Utilize Entrance Matting: Place mats at all entrances to minimize the amount of dirt and debris tracked onto the finished floor. This reduces abrasion and extends the intervals between recoating.

Tip 7: Consider Burnishing: Regular burnishing with appropriate pads enhances the gloss and hardness of the coating. This should be performed according to the manufacturers recommendations.

Adherence to these guidelines contributes to a durable, aesthetically pleasing, and long-lasting floor finish. Implementing a comprehensive application and maintenance plan maximizes the return on investment.

The subsequent section will address troubleshooting common issues and identifying signs requiring professional intervention.

1. High-gloss durability

High-gloss durability, as a characteristic of floor finishes, signifies the coating’s capacity to maintain a reflective sheen and resist degradation under sustained use. This attribute is a key performance indicator for the subject floor finish, influencing both its aesthetic appeal and its lifecycle cost-effectiveness.

- Abrasion Resistance

Abrasion resistance is a primary component, determining the finish’s ability to withstand the scuffing and scratching caused by foot traffic, equipment movement, and cleaning processes. A higher abrasion resistance translates to a longer-lasting gloss and reduced maintenance frequency. For example, in retail environments with high customer volume, a finish with superior abrasion resistance retains its polished appearance longer, minimizing the need for frequent recoating.

- Chemical Resistance

Chemical resistance refers to the finish’s ability to withstand exposure to cleaning agents, spills, and other substances without experiencing discoloration, softening, or other forms of degradation. A robust chemical resistance ensures that routine cleaning procedures do not compromise the gloss level or structural integrity of the coating. For instance, in healthcare facilities, the finish must withstand frequent disinfection with harsh chemicals without losing its glossy finish.

- UV Resistance

UV resistance denotes the finish’s capacity to resist fading, yellowing, or chalking when exposed to ultraviolet radiation from sunlight or artificial light sources. This property is particularly important in areas with abundant natural light, preventing the finish from becoming dull or discolored over time. In a sunlit atrium, a floor finish with high UV resistance will maintain its initial gloss and color, enhancing the overall aesthetic appeal of the space.

- Flexibility and Adhesion

Flexibility and adhesion dictate the finish’s ability to expand and contract with the underlying flooring material without cracking, peeling, or blistering. Adequate flexibility and adhesion ensure that the finish remains firmly bonded to the floor, even under fluctuating temperature and humidity conditions. In environments where the flooring material experiences significant thermal expansion, a finish with good flexibility and adhesion will provide superior long-term performance.

These interconnected facets collectively contribute to the high-gloss durability of the product. By resisting abrasion, chemicals, and UV radiation while maintaining flexibility and adhesion, the floor finish offers a long-lasting, aesthetically pleasing surface that minimizes maintenance requirements. This combination of properties directly translates to reduced lifecycle costs and enhanced overall value.

2. Superior scratch resistance

Superior scratch resistance is a crucial attribute intrinsically linked to the performance and longevity of durable floor finishes. In the context of such finishes, this characteristic refers to the coating’s inherent ability to withstand surface damage caused by abrasive forces, impact, and general wear. The relationship between this resistance and the floor finish is causal: the finish’s formulation directly dictates its capacity to resist scratching. Formulations incorporating harder polymers and cross-linking agents will inherently exhibit greater scratch resistance. The presence of superior scratch resistance is paramount; it is a key component that determines the floor’s appearance and its functional lifespan. Without it, the floor surface is susceptible to rapid degradation, requiring frequent maintenance interventions.

Real-life examples underscore the practical significance. Consider a busy retail store: floors in such environments are subject to constant abrasion from foot traffic, shopping carts, and merchandise movement. A floor finish lacking adequate scratch resistance will quickly exhibit unsightly marks and scuffs, detracting from the store’s overall aesthetic and potentially necessitating costly repairs or replacements. Conversely, a floor finish with superior scratch resistance will maintain its appearance for longer, reducing maintenance expenses and ensuring a more professional image. Similarly, in schools or healthcare facilities, where hygiene and appearance are critical, superior scratch resistance translates to easier cleaning and a lower risk of harboring bacteria in scratched surfaces. This is vital for maintaining a safe and sanitary environment.

In conclusion, superior scratch resistance is not merely a desirable feature, but an essential performance characteristic that influences the overall value and utility of floor finishes. It dictates the product’s longevity, maintenance requirements, and aesthetic appeal. Selecting a floor finish with enhanced scratch resistance represents a strategic investment that yields long-term cost savings and contributes to a more positive environment. The challenge lies in accurately assessing the scratch resistance of different products through standardized testing and real-world evaluations, ensuring that the chosen solution meets the specific demands of the intended application.

3. Low maintenance demand

The characteristic of low maintenance demand is a significant factor driving the selection and utilization of durable floor finishes. This trait directly influences long-term operational costs and the overall lifecycle value proposition of the chosen flooring solution. The inherent properties of certain floor finishes minimize the frequency and intensity of required upkeep procedures.

- Reduced Stripping and Rewaxing Cycles

The floor finish formulations are often engineered to provide extended wear resistance, which translates to less frequent stripping and re-waxing. This significantly reduces labor costs and downtime associated with traditional floor maintenance procedures. A conventional waxed floor might require stripping and re-waxing multiple times per year in high-traffic areas; a durable floor finish reduces this to annual or even less frequent interventions, leading to tangible savings.

- Simplified Cleaning Protocols

Durable finishes frequently exhibit resistance to staining and dirt penetration, enabling easier and more efficient routine cleaning. Instead of requiring harsh chemicals or specialized cleaning equipment, routine sweeping and mopping with neutral pH cleaners are often sufficient to maintain a clean and presentable surface. This not only reduces chemical usage but also minimizes the potential for damage caused by aggressive cleaning agents.

- Minimized Buffing and Burnishing Requirements

Some finishes are formulated to retain their gloss level for extended periods, reducing the need for frequent buffing or burnishing. This translates into reduced equipment usage and associated energy consumption, as well as lower labor costs. A floor that maintains its sheen with minimal intervention contributes to a more sustainable and cost-effective maintenance program.

- Enhanced Resistance to Scuffing and Scratching

Finishes designed with superior scratch and scuff resistance require less frequent repairs or touch-ups. Minor surface damage is less visible and easier to address, reducing the need for extensive restoration procedures. This characteristic contributes to a longer-lasting and more visually appealing floor, further minimizing maintenance requirements.

These intertwined attributes collectively contribute to the low maintenance demand associated with durable floor finishes. By minimizing the need for aggressive stripping, simplifying cleaning protocols, reducing buffing requirements, and enhancing scratch resistance, such finishes offer a compelling economic and operational advantage. This advantage becomes especially pronounced in large commercial or institutional settings, where minimizing maintenance demands translates to substantial cost savings and improved operational efficiency.

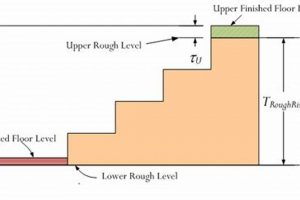

4. Prolonged floor life

The concept of prolonged floor life is intrinsically linked to the application of protective floor coatings. The coating acts as a sacrificial layer, absorbing the wear and tear that would otherwise directly impact the underlying flooring material. This protective barrier mitigates abrasion, reduces staining, and minimizes the effects of chemical exposure, all factors that contribute to premature floor degradation. The relationship is direct: effective protection extends the functional lifespan of the floor. The properties and characteristics of the coating used determine the degree of protection offered. Formulations with superior abrasion resistance, chemical resistance, and UV stability will more effectively prolong the floor’s lifespan. In the absence of such protection, flooring materials are vulnerable to damage, necessitating more frequent repairs or replacements.

In practical applications, the implementation of a durable coating system can demonstrably extend floor life. For instance, a concrete floor in a high-traffic warehouse, when uncoated, may require resurfacing within a few years due to wear from forklifts and foot traffic. Applying a suitable coating substantially reduces this wear, potentially extending the floor’s lifespan to a decade or more. Similarly, in healthcare settings, where rigorous cleaning protocols are employed, a properly selected and applied coating can protect the underlying flooring from harsh disinfectants and cleaning agents, preventing discoloration, cracking, and other forms of chemical damage. The extended lifespan achieved through this protection translates into reduced maintenance costs, minimized disruption to operations, and a more sustainable approach to building management.

In conclusion, prolonged floor life is not merely a desirable outcome but a measurable benefit achievable through the strategic application of appropriate protective coatings. Understanding the mechanisms by which these coatings protect floors is essential for making informed decisions about product selection and maintenance practices. While challenges exist in accurately predicting floor lifespan and assessing the long-term performance of different coatings, a proactive approach to floor protection offers a cost-effective means of preserving flooring assets, reducing lifecycle costs, and enhancing the overall appearance and functionality of built environments. The correlation between the application of a durable floor coating and extended floor lifespan is a significant consideration in sustainable building practices.

5. Versatile application

Versatile application, in the context of floor finishes, denotes a product’s capacity to be effectively applied across a spectrum of flooring types and environmental conditions. This characteristic is a key differentiator, influencing the scope of the product’s applicability and its overall value proposition. The product’s chemical formulation and physical properties directly dictate its ability to adhere to different surfaces, withstand varying levels of traffic, and maintain its integrity under different environmental stressors.

The ability to adapt to a diverse range of flooring materials, such as vinyl composition tile (VCT), terrazzo, concrete, and engineered wood, underscores the utility. This versatility stems from the coating’s adhesion properties, its compatibility with varying surface porosities, and its resistance to chemical interactions with the underlying material. In practice, this means that a single product can be used across an entire facility, streamlining inventory management and simplifying maintenance procedures. For example, a commercial building with a combination of VCT in hallways, terrazzo in entryways, and concrete in service areas can standardize its floor maintenance program by utilizing a finish that is suitable for all three surfaces. This eliminates the need to stock and apply multiple specialized products, reducing costs and minimizing the risk of misapplication.

Consideration must be given to the preparation techniques and the environment. Adherence to manufacturer specifications is paramount to ensuring optimal bonding and durability. A facility operating across regions with diverse humidity levels needs a coating that maintains its integrity. In conclusion, versatile application offers considerable economic and logistical advantages, making the floor finish a practical choice for organizations with diverse flooring needs. This understanding provides a basis for product selection and contributes to efficient facilities management.

Frequently Asked Questions About Durable Floor Finishes

The following section addresses common inquiries regarding the application, maintenance, and performance characteristics of durable floor finishes designed for commercial and industrial use.

Question 1: What factors influence the durability and lifespan of a floor finish?

Durability and lifespan are affected by several variables, including the type of finish, the preparation of the flooring surface prior to application, the volume and nature of foot traffic, the cleaning agents used, and adherence to recommended maintenance procedures. Proper surface preparation and consistent maintenance are crucial for maximizing longevity.

Question 2: How does the selection of a floor finish affect long-term maintenance costs?

Selecting a floor finish with superior abrasion resistance and low maintenance requirements reduces the frequency of stripping, re-coating, and intensive cleaning. This translates directly to lower labor costs, reduced chemical usage, and minimized downtime, resulting in significant long-term cost savings.

Question 3: Can a single floor finish be used on all types of flooring?

While some floor finishes offer versatile application across various flooring types, it is crucial to consult the manufacturer’s specifications to ensure compatibility. The chemical composition and physical properties of the finish must be suitable for the specific flooring material to ensure proper adhesion and prevent damage.

Question 4: How does surface preparation impact the performance of the floor finish?

Thorough surface preparation is essential for optimal adhesion and performance. The floor must be thoroughly cleaned, free of debris, and properly neutralized before applying any floor finish. Failure to adequately prepare the surface can result in poor adhesion, premature wear, and compromised appearance.

Question 5: What is the recommended cleaning procedure for floors treated with durable floor finishes?

Routine cleaning should be performed using pH-neutral cleaners specifically designed for use on coated floors. Harsh chemicals, abrasive scrubbers, and excessive water should be avoided, as they can damage the finish and shorten its lifespan. Regular sweeping or vacuuming to remove loose dirt and debris is also recommended.

Question 6: How can one identify when a floor finish requires recoating or repair?

Indications that a floor finish requires attention include visible scratches, scuffs, dullness, or areas where the finish has worn away completely. Regular inspection of high-traffic areas is recommended to identify signs of wear early, allowing for timely recoating or repair to prevent further damage to the underlying flooring.

Understanding these key aspects of floor finishes is essential for ensuring optimal performance, extending floor life, and minimizing maintenance costs. Choosing the appropriate finish and adhering to recommended maintenance procedures are critical for achieving long-term satisfaction.

Subsequent sections will explore case studies illustrating the practical application and benefits of durable floor finishes in various commercial settings.

Conclusion

This exploration has illuminated key facets of Betco Untouchable Floor Finish, underscoring its importance in maintaining flooring integrity and aesthetics. The discussion has spanned application techniques, maintenance protocols, performance characteristics, and its versatile suitability across diverse flooring types. Emphasis has been placed on its contribution to prolonged floor life and reduced maintenance demands, presenting a comprehensive understanding of its value proposition.

The information presented serves as a foundational resource for informed decision-making regarding floor maintenance strategies. Continued adherence to best practices and awareness of product advancements will ensure optimal floor performance and long-term cost effectiveness. Prioritizing durable, well-maintained flooring contributes to safety, visual appeal, and overall operational efficiency.