The process under consideration relates to the enhancement of subterranean spaces affected by particulate matter common in certain geological locales. It involves specific techniques and materials designed to mitigate the challenges presented by this environment, resulting in a more habitable and functional lower level of a property. For example, a property in a coastal region prone to the ingress of fine particles into its foundation might require this type of specialized treatment prior to any standard renovation efforts.

Undertaking this specialized basement preparation offers several advantages. It addresses potential issues related to moisture management and air quality, thereby creating a healthier indoor environment. Furthermore, it can increase the value and usability of the property by transforming an otherwise problematic area into a valuable living space. Historically, mitigating such conditions was often overlooked, leading to structural damage and health concerns. Today, informed approaches prioritize preventative measures and long-term solutions.

The subsequent sections will delve into the specific methodologies employed to achieve a successful outcome in these environments, detailing the materials, techniques, and best practices utilized in the specialized preparation of such basements. These topics will include considerations for proper sealing, flooring options, and strategies to address any potential environmental concerns.

Essential Considerations for Environments Affected by Particulate Infiltration

The following guidelines address key areas of concern when adapting subterranean levels susceptible to the intrusion of granular material. Attention to these points is crucial for ensuring a durable and healthy living space.

Tip 1: Conduct Thorough Site Assessment: Prior to any construction, a comprehensive assessment of the basement’s environment is necessary. This assessment should identify the source and extent of granular material intrusion, as well as any pre-existing moisture issues. The findings of this assessment will inform the selection of appropriate mitigation strategies.

Tip 2: Implement Robust Waterproofing Measures: Effective waterproofing is paramount to prevent further ingress. This may involve exterior excavation and membrane application, interior sealant applications, or a combination of both. Selecting a system appropriate for the specific soil conditions and hydrostatic pressure is essential.

Tip 3: Install a Subfloor Drainage System: A drainage system beneath the finished floor helps manage any residual moisture. This system channels water away from the finished floor, preventing mold growth and structural damage. Consider a dimpled membrane combined with a perimeter drainage channel.

Tip 4: Employ Moisture-Resistant Materials: All materials used in the finishing process should be selected for their resistance to moisture and mold growth. This includes framing lumber, insulation, and flooring. Pressure-treated lumber and closed-cell foam insulation are recommended.

Tip 5: Seal All Cracks and Penetrations: Meticulously seal all cracks in the foundation walls and around any pipes or wires that penetrate the basement. This prevents moisture and granular material from entering the finished space. Use a flexible sealant designed for concrete.

Tip 6: Implement a Dehumidification System: A high-quality dehumidifier can help maintain a consistently low humidity level, preventing mold growth and improving air quality. The dehumidifier should be sized appropriately for the square footage of the basement.

Tip 7: Consider Air Sealing and Ventilation: Improving air sealing and ventilation will help maintain air quality in the finished basement. This may involve sealing air leaks around windows and doors, and installing a ventilation system that introduces fresh air into the space.

Adherence to these considerations promotes the creation of a safe, dry, and comfortable subterranean environment, increasing the value and usability of the property.

The subsequent section will address the selection of appropriate flooring options for such environments.

1. Assessment

The initial evaluation phase is paramount in any project focused on subterranean improvement, particularly when the existing environment is characterized by particulate matter ingress. A comprehensive assessment serves as the foundation for informed decision-making and ensures that subsequent interventions are both appropriate and effective.

- Identifying the Source and Nature of Particulate Matter

The first step involves pinpointing the origin of the granular material and determining its composition. Is it primarily sand, silt, or a combination? Understanding the source (e.g., coastal erosion, geological composition of the surrounding soil) informs the selection of appropriate mitigation strategies. For example, a basement near a beach might experience wind-blown sand infiltration, necessitating different sealing methods than a basement in an area with high silt content in the soil.

- Evaluating Existing Moisture Conditions

The presence of granular material is often associated with moisture issues. The assessment must determine the extent of dampness, the presence of standing water, and the relative humidity within the basement. This information is crucial for selecting waterproofing systems and drainage solutions. High moisture levels can exacerbate problems related to particulate matter, leading to mold growth and structural deterioration.

- Analyzing Foundation Integrity

The assessment must include a thorough inspection of the foundation walls and floor for cracks, leaks, and structural damage. The presence of cracks can facilitate the entry of both granular material and moisture. Addressing these structural issues is essential before proceeding with any finishing work. Failure to do so can compromise the long-term stability of the basement.

- Determining Air Quality and Ventilation

Basements prone to particulate matter ingress often have poor air quality and inadequate ventilation. The assessment should measure air quality parameters such as particulate matter concentration, humidity levels, and the presence of mold spores. Addressing these issues through improved ventilation and air filtration systems is crucial for creating a healthy living environment.

These assessment facets are inextricably linked to the overall success of specialized basement preparation. Accurate identification of problems enables tailored solutions, preventing future complications and creating a durable, habitable space. Neglecting this initial phase can lead to costly rework and compromised environmental quality.

2. Waterproofing Systems

Waterproofing systems are integral to the successful preparation of subterranean environments affected by granular material. The selection and implementation of appropriate waterproofing measures directly influence the durability, habitability, and long-term value of finished basements in such conditions.

- Exterior Membrane Application

Exterior waterproofing involves excavating the soil around the foundation walls and applying a waterproof membrane directly to the concrete or masonry. This method is most effective when performed during new construction but can be implemented retroactively. Examples include applying a bituminous coating or a self-adhering membrane. The primary benefit is preventing water from reaching the foundation in the first instance, thus reducing the potential for hydrostatic pressure and granular material transport into the basement.

- Interior Sealant Application

Interior waterproofing involves applying sealants and coatings to the interior walls and floor of the basement. This method is less intrusive than exterior waterproofing but may be less effective in situations with high hydrostatic pressure. Examples include applying a waterproof paint or a concrete sealant. While this approach does not prevent water from entering the foundation, it creates a barrier that can help mitigate moisture migration and granular material ingress into the finished space.

- Subfloor Drainage Systems

Subfloor drainage systems are designed to collect and redirect water that accumulates beneath the basement floor. This is typically achieved by installing a drainage mat or a network of perforated pipes that channel water to a sump pump. This system is particularly effective in mitigating hydrostatic pressure and preventing water from seeping through the concrete slab. In areas with a high water table or frequent flooding, a subfloor drainage system is essential for maintaining a dry and stable basement environment.

- Sump Pump Installation and Maintenance

A sump pump removes accumulated water from a sump pit, typically located within a subfloor drainage system. It is critical for basements prone to water intrusion. Regular maintenance and testing of the pump are essential to ensure its functionality during periods of heavy rainfall or groundwater elevation. A backup power source is advisable to prevent flooding during power outages. The absence of a functional sump pump can negate the effectiveness of other waterproofing measures.

In conclusion, the selection of a waterproofing system depends on site-specific conditions, budget constraints, and the severity of the moisture problem. A combination of exterior and interior measures is often necessary to achieve comprehensive protection in environments affected by granular material and high moisture levels. Proper installation and maintenance are crucial for ensuring the long-term effectiveness of any waterproofing system.

3. Drainage Solutions

Effective water management is critical in subterranean environments, particularly when preparing those affected by granular material accumulation. Drainage solutions serve to mitigate hydrostatic pressure and prevent water intrusion, which can exacerbate problems associated with fine particles and compromise the integrity of finished spaces.

- Perimeter Drainage Systems

Perimeter drainage systems, installed along the interior or exterior of the foundation, intercept groundwater before it reaches the basement. These systems typically consist of perforated pipes embedded in gravel, channeling water away from the foundation to a sump pit or other discharge point. For instance, a house situated on a high water table benefits from this drainage, mitigating hydrostatic pressure that can force water and granular material through foundation cracks. In the context of specialized basement preparation, this prevents moisture-related damage and ensures long-term stability.

- Sub-Slab Depressurization Systems

Sub-slab depressurization involves creating a negative pressure zone beneath the concrete slab, drawing moisture and soil gases away from the basement. This is achieved by installing a network of perforated pipes beneath the slab, connected to a fan that vents the air to the exterior. This system is particularly useful in areas with high water tables or expansive soils. An example of this benefit is found in areas prone to radon gas, a sub-slab depressurization system serves a dual purpose, mitigating both moisture and radon risks, directly contributing to improved indoor air quality.

- Sump Pump Systems

Sump pumps are essential components of many drainage strategies, responsible for removing accumulated water from sump pits. The pump activates when water reaches a predetermined level, discharging it away from the foundation. Backup power is essential to maintain functionality during power outages, which often coincide with heavy rainfall. The frequent discharge of a sump pump is clear evidence of groundwater pressure affecting the basement, highlighting its importance in the specialized preparation for environments affected by particulate accumulation.

- Grading and Surface Water Management

Proper grading around the foundation directs surface water away from the building. This includes ensuring a positive slope away from the foundation walls, as well as installing gutters and downspouts to collect and channel rainwater away from the basement. Over time, settling of the ground can diminish the benefits of this, directing water towards the house. In specialized basement preparation, meticulous attention to grading is crucial, as it minimizes the amount of water that reaches the foundation, reducing the potential for moisture-related problems and particle intrusion.

Effective drainage is fundamental in transforming subterranean environments affected by granular material into usable spaces. Proper water management reduces the risk of structural damage, mold growth, and poor air quality, enhancing the long-term value and habitability of properties. These strategies ensure a dry, healthy environment is a great benefit, creating a solid foundation for all subsequent finishing and renovation efforts.

4. Material Selection

The selection of appropriate materials is paramount in subterranean renovation, particularly when addressing environments prone to the accumulation of granular material. The inherent characteristics of chosen materials directly impact the durability, air quality, and overall longevity of the finished space.

- Moisture-Resistant Framing

Traditional wood framing is susceptible to rot and mold growth in damp conditions. In areas affected by particulate matter and potential moisture ingress, pressure-treated lumber or alternative framing materials such as steel or composite products are advisable. These materials resist moisture absorption, preventing structural degradation and the formation of mold, which can exacerbate air quality issues. Employing these materials in subterranean preparation ensures structural resilience against the challenges inherent in the environment.

- Closed-Cell Insulation

Insulation is critical for thermal regulation and moisture control. Open-cell insulation can absorb moisture, creating a breeding ground for mold and reducing its insulative properties. Closed-cell foam insulation, conversely, is water-resistant and provides a superior thermal barrier. Its resistance to moisture prevents the accumulation of water and fine particles, maintaining its effectiveness over time and contributing to a healthier indoor environment. This characteristic is crucial in mitigating the risks associated with damp subterranean settings.

- Waterproof Membrane Underlayment

Flooring systems in subterranean environments require a robust moisture barrier to prevent water vapor from penetrating the finished floor. A waterproof membrane underlayment, installed beneath the flooring material, protects against moisture migration and prevents the growth of mold and mildew. For example, in cases where a concrete slab has not been properly sealed, this becomes even more vital. The selection of a suitable waterproof membrane ensures the longevity of the flooring and contributes to a drier, more comfortable space.

- Mold-Resistant Drywall

Standard drywall is susceptible to mold growth when exposed to moisture. Mold-resistant drywall, treated with additives that inhibit mold growth, is essential for subterranean applications. This type of drywall provides an additional layer of protection against moisture-related problems, promoting better air quality and reducing the risk of health issues. Its use in specialized basement preparation significantly enhances the resistance of the finished space to the negative effects of moisture and particulate infiltration.

The selection of materials exhibiting moisture resistance and mold inhibition is not merely a precautionary measure but a fundamental requirement in subterranean spaces affected by granular material. By employing such materials, the risk of structural damage, air quality degradation, and health concerns is substantially reduced, leading to a more durable and habitable environment.

5. Air Quality

The maintenance of acceptable air quality is a critical consideration when adapting subterranean spaces, especially those impacted by particulate matter. The presence of granular substances, typical in certain geological areas, can significantly degrade indoor air quality, posing potential health risks and reducing the usability of finished basements. Effective strategies during the preparation phase are therefore essential to mitigate these risks.

- Particulate Matter Suspension

Disturbance of granular material during the finishing process can lead to the suspension of fine particles in the air. These particles, often composed of silica, dust, and other irritants, can be inhaled, potentially causing respiratory problems and exacerbating existing conditions. For example, dry sweeping during the initial cleanup can aerosolize these particles, increasing their concentration in the air. Implementing dust control measures, such as using HEPA-filtered vacuums and dampening surfaces, is crucial to minimize particulate suspension and safeguard air quality.

- Mold Spore Proliferation

The combination of moisture and organic material, often found in subterranean environments, creates conditions conducive to mold growth. Granular material can trap moisture, providing a breeding ground for mold spores, which can then be released into the air, triggering allergic reactions and respiratory issues. For instance, if granular material is found behind drywall during demolition, it may indicate pre-existing mold contamination. Thorough cleaning, disinfection, and moisture control are necessary to prevent mold spore proliferation and maintain acceptable air quality.

- Radon Gas Mitigation

Subterranean spaces are often susceptible to radon gas infiltration, a naturally occurring radioactive gas that seeps from the ground. The presence of granular material can create pathways for radon to enter the basement, increasing its concentration to dangerous levels. For example, cracks in the foundation can serve as entry points for both radon and granular substances. Radon mitigation systems, such as sub-slab depressurization, are essential to reduce radon levels and ensure the air is safe to breathe.

- Volatile Organic Compound (VOC) Emissions

Building materials and finishes used in subterranean environments can emit volatile organic compounds (VOCs), which are organic chemicals that can evaporate at room temperature and contribute to indoor air pollution. These VOCs can cause a variety of health problems, including headaches, dizziness, and respiratory irritation. For instance, certain types of adhesives and paints used in basement finishing may contain high levels of VOCs. Selecting low-VOC or VOC-free materials and providing adequate ventilation during and after construction are crucial to minimize VOC emissions and maintain acceptable air quality.

Addressing these facets during the preparation of subterranean spaces is critical for ensuring a healthy and habitable environment. Effective mitigation strategies, including dust control, moisture management, radon mitigation, and the selection of low-VOC materials, are essential to maintain acceptable air quality and protect the health of occupants. By prioritizing air quality, the long-term usability and value of finished basements can be significantly enhanced.

6. Sealing

Effective sealing is an indispensable component in the process of preparing subterranean environments affected by granular matter. It represents a proactive measure against the continued ingress of fine particles and moisture, thereby safeguarding the integrity and habitability of the finished space.

- Foundation Crack Sealing

Cracks in foundation walls and floors provide direct pathways for both granular matter and moisture to enter the basement. The thorough sealing of these cracks is paramount in preventing further intrusion. This involves employing appropriate sealant materials, such as epoxy or polyurethane-based compounds, that possess flexibility and durability to accommodate minor structural movement. For example, a hairline crack left unsealed can gradually widen over time due to freeze-thaw cycles, leading to significant water damage and particle accumulation. Sealing these vulnerabilities mitigates long-term structural issues and contributes to a drier, more stable subterranean environment.

- Penetration Sealing

Any point where pipes, wires, or other utilities pass through the foundation walls or floor represents a potential entry point for granular matter and moisture. Proper sealing around these penetrations is essential in preventing infiltration. This involves using expanding foam, caulk, or specialized sealing collars to create a watertight and airtight barrier. For instance, an unsealed pipe chase can act as a conduit for water to enter the basement during heavy rainfall, leading to dampness and mold growth. Effective sealing around these penetrations minimizes the risk of water damage and particle accumulation, enhancing the overall dryness and air quality of the finished space.

- Window and Door Sealing

Basement windows and doors, if not properly sealed, can be significant sources of air leakage and moisture intrusion. Weatherstripping, caulking, and the installation of airtight window and door systems are crucial in preventing air and water from entering the basement. For example, poorly sealed basement windows can allow cold air to enter during the winter months, increasing heating costs and creating uncomfortable drafts. Effective sealing of windows and doors improves energy efficiency and prevents moisture-related problems, contributing to a more comfortable and habitable subterranean environment.

- Wall-Floor Joint Sealing

The joint where the foundation walls meet the floor is a common area for water intrusion due to hydrostatic pressure and differential settlement. Sealing this joint with a flexible sealant or a waterproof membrane is critical in preventing water from seeping into the basement. For instance, water can wick up through the wall-floor joint due to capillary action, leading to dampness and mold growth along the base of the walls. Proper sealing of this joint minimizes the risk of water damage and particle accumulation, ensuring a drier and more stable subterranean environment.

In summary, comprehensive sealing strategies are fundamental in creating a durable and habitable subterranean space unaffected by granular matter. By addressing potential entry points through meticulous crack sealing, penetration sealing, window and door sealing, and wall-floor joint sealing, the risks associated with moisture intrusion and particle accumulation are significantly reduced, resulting in a more comfortable, healthy, and valuable finished basement.

Frequently Asked Questions About Sandy Basement Finishing

The following section addresses common inquiries concerning the specialized preparation of subterranean spaces affected by granular material infiltration. The information provided is intended to offer clarity and guidance to property owners considering such renovations.

Question 1: What distinguishes “sandy basement finishing” from standard basement finishing?

The primary distinction lies in the heightened emphasis on moisture management and particulate matter control. Standard basement finishing often overlooks the unique challenges presented by granular infiltration, whereas this specialized approach prioritizes sealing, waterproofing, and air quality considerations tailored to such environments.

Question 2: How can one determine if “sandy basement finishing” is necessary for a particular property?

Evidence of granular material accumulation, dampness, efflorescence on foundation walls, or a musty odor are indicators. A professional assessment by a qualified contractor or engineer can definitively determine the presence and extent of the issue, informing the appropriate course of action.

Question 3: What are the long-term consequences of neglecting granular material infiltration in a basement?

Failure to address granular material infiltration can lead to structural damage, mold growth, compromised air quality, and reduced property value. The accumulation of moisture can corrode building materials, weaken the foundation, and create an unhealthy living environment.

Question 4: What are the critical components of a successful “sandy basement finishing” project?

Key components include a comprehensive site assessment, robust waterproofing measures, effective drainage systems, selection of moisture-resistant materials, and proactive air quality management. Addressing each of these areas is essential for creating a durable and habitable space.

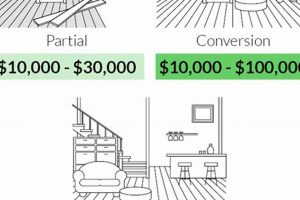

Question 5: What is the typical cost associated with “sandy basement finishing” compared to standard finishing?

The cost generally exceeds that of standard basement finishing due to the additional measures required for moisture and particulate control. The extent of the problem, the chosen waterproofing and drainage solutions, and the quality of materials all influence the overall expense.

Question 6: What ongoing maintenance is required after completing “sandy basement finishing”?

Regular inspection of the waterproofing system, sump pump functionality, and dehumidifier operation is recommended. Addressing any signs of moisture intrusion or granular material accumulation promptly can prevent long-term damage and maintain the integrity of the finished space.

In summary, addressing the unique challenges posed by granular infiltration in subterranean spaces demands a specialized approach. Prioritizing proper assessment, waterproofing, drainage, material selection, and air quality management are essential for achieving a durable, habitable, and healthy finished basement.

The subsequent section will provide resources for finding qualified professionals experienced in addressing these specific challenges.

Conclusion

The foregoing analysis has detailed the multifaceted considerations inherent in the preparation of subterranean environments subject to granular intrusion. Effective “sandy basement finishing” demands a comprehensive strategy encompassing thorough assessment, robust waterproofing, strategic drainage, appropriate material selection, diligent air quality management, and meticulous sealing techniques. Failure to address these elements comprehensively invites structural compromise, environmental degradation, and potential health hazards, diminishing the long-term value and usability of the finished space.

The complexities associated with such projects necessitate engagement with qualified professionals possessing specialized expertise. Prudent investment in these preparatory measures represents a safeguard against future complications, ensuring a durable, healthy, and valuable subterranean asset. Property owners are encouraged to approach these endeavors with diligence and foresight, recognizing the critical importance of proper execution in mitigating the inherent risks. The enduring benefits of a well-executed project will far outweigh the initial investment.