These tools represent a specific type of power equipment used extensively in carpentry and woodworking. They are designed for driving fasteners into materials to create strong, aesthetically pleasing joints and finishes. A distinguishing characteristic is their portability; they operate without the constraints of an air hose or power cord. Their application is common in tasks where precision and a clean, nearly invisible hold are desired, such as installing trim, molding, or cabinetry.

The advent of these devices has provided significant advantages in terms of efficiency and maneuverability on job sites. Eliminating the need for compressors and hoses reduces setup time and minimizes tripping hazards. This enhanced freedom of movement contributes to faster completion of tasks and improved overall safety. Historically, pneumatic models were the standard, but battery-powered options have gained prominence due to advancements in battery technology, offering comparable power and runtime.

Further discussion will delve into various aspects, including factors to consider when selecting appropriate models, best practices for operation and maintenance, and a comparison of leading brands and their respective features. Understanding these nuances is crucial for professionals and serious DIY enthusiasts seeking to maximize the utility and longevity of their chosen equipment.

Operational Tips

Maximizing the effectiveness and lifespan of these tools requires careful adherence to established best practices. Consistent application of the following techniques will contribute to optimal performance and minimize potential issues.

Tip 1: Select the Appropriate Fastener Length: Choosing the correct nail length is critical to ensure a secure hold without penetrating excessively through the material. Consider the combined thickness of the materials being joined and select a fastener length that allows for adequate penetration without protruding on the opposite side.

Tip 2: Adjust Depth Settings: Most models feature adjustable depth settings that control how far the nail is driven. Experiment with these settings on scrap material to find the optimal depth that drives the nail flush with the surface without damaging the surrounding wood.

Tip 3: Maintain a Consistent Angle: Holding the tool at a consistent angle to the work surface is essential for driving nails straight and preventing them from bending or shearing. Use a firm, controlled grip and ensure the nose of the tool is flush against the material before firing.

Tip 4: Clean and Lubricate Regularly: Periodic cleaning and lubrication are vital for maintaining smooth operation. Remove any debris or sawdust from the tool’s mechanism and apply a small amount of lubricant to the appropriate moving parts as specified in the manufacturer’s instructions.

Tip 5: Inspect Battery Contacts: For cordless models, ensure the battery contacts are clean and free of corrosion. Clean the contacts with a dry cloth if necessary to maintain a reliable connection and prevent power interruptions.

Tip 6: Store Properly: When not in use, store the tool in a clean, dry environment to protect it from moisture and dust. Consider using a carrying case to prevent damage during storage and transport.

Tip 7: Use Appropriate Safety Gear: Always wear appropriate safety glasses or face shield to protect the eyes from flying debris. Ear protection is also recommended, especially during prolonged use.

Consistently following these operational tips will help to ensure precise, professional results, extend the tool’s service life, and maintain a safe working environment.

The subsequent sections will further explore common troubleshooting scenarios and offer guidance on resolving potential operational issues.

1. Gauge

Gauge, in the context of these tools, refers to the thickness of the nails they are designed to drive. This specification is critical because it directly dictates the strength of the fastener and its visibility in the finished product. Higher gauge numbers indicate thinner nails, resulting in a less conspicuous hold suitable for delicate trim work where aesthetics are paramount. Conversely, lower gauge numbers represent thicker nails, offering superior holding power for more demanding applications. Choosing the appropriate gauge is a fundamental consideration, influencing the integrity and appearance of the finished project.

For example, installing delicate crown molding typically necessitates a higher gauge nail, such as 18 gauge, to minimize the risk of splitting the wood and to reduce the visual impact of the fastener. In contrast, securing baseboards or heavier trim might require a lower gauge nail, such as 15 or 16 gauge, to ensure a robust and durable connection. Incorrect gauge selection can lead to either inadequate holding strength, resulting in loose or unstable trim, or excessive visibility, detracting from the overall aesthetic appeal. Furthermore, using the wrong gauge can potentially damage the tool itself if it is not designed to handle the specified nail size.

In summary, gauge represents a vital component specification that directly impacts the functionality and appearance of work performed with these tools. Understanding the relationship between gauge, material thickness, and desired finish is essential for achieving optimal results and preventing potential complications. Careful consideration of gauge, alongside other factors like nail length and material type, contributes to the overall quality and longevity of the finished product. Further exploration into other performance characteristics will reveal a more holistic understanding of optimal tool selection and application.

2. Battery Voltage

Battery voltage represents a crucial specification in cordless finish nailers, directly influencing the power and performance capabilities of these tools. A higher voltage generally translates to increased driving force and the ability to handle more demanding fastening tasks. Understanding the implications of different voltage levels is essential for selecting a tool appropriate for the intended applications.

- Driving Power and Nail Size

Higher voltage batteries provide the necessary energy to drive nails of larger sizes and into denser materials. For example, a 20V model may be capable of consistently sinking 2 1/2-inch finish nails into hardwood trim, whereas a lower voltage model might struggle or require multiple attempts. Selecting a tool with adequate voltage ensures reliable performance and minimizes the risk of bent or improperly set nails.

- Runtime and Efficiency

While higher voltage often implies greater power, it does not always directly correlate to longer runtime. Runtime is also influenced by battery capacity (measured in amp-hours) and the efficiency of the tool’s motor. However, a higher voltage system can sometimes deliver more work per battery charge by optimizing energy delivery. Efficient energy use is critical in cordless models where battery life is a significant factor in overall productivity.

- Tool Weight and Ergonomics

Generally, higher voltage systems require larger and heavier batteries, which can impact the tool’s overall weight and ergonomics. A heavier tool can lead to increased user fatigue during prolonged use, especially when working overhead or in awkward positions. Manufacturers strive to balance voltage, battery size, and tool weight to provide optimal performance without compromising user comfort and maneuverability.

- Cost and Compatibility

Cordless tools and their corresponding batteries are often part of a specific brand’s ecosystem. Opting for a particular voltage platform commits the user to that brand’s battery system. Higher voltage tools typically command a higher price point due to the increased power and performance they offer. Considering budget constraints and the potential for future tool purchases within the same battery platform is essential for making a cost-effective decision.

In conclusion, battery voltage is a pivotal factor influencing driving power, runtime, ergonomics, and cost in cordless finish nailers. Selecting the appropriate voltage requires careful consideration of the intended applications, desired level of performance, and budget. A well-informed decision regarding battery voltage contributes significantly to the overall effectiveness and satisfaction derived from using these tools. Other factors, such as nail capacity and firing modes, also contribute to the final result.

3. Nail Capacity

Nail capacity is a critical performance attribute of cordless finish nailers, directly influencing workflow efficiency and project completion speed. This specification denotes the maximum number of nails the tool’s magazine can hold, impacting the frequency of reloading and the overall continuity of the work process. Understanding nail capacity is paramount for optimizing productivity in various finishing applications.

- Magazine Size and Reload Frequency

A larger magazine capacity reduces the need for frequent reloading, allowing users to work for extended periods without interruption. This is particularly beneficial in large-scale projects or when working in locations where accessing nail supplies is inconvenient. Conversely, a smaller magazine may be sufficient for smaller, less demanding tasks where reloading is not a significant impediment.

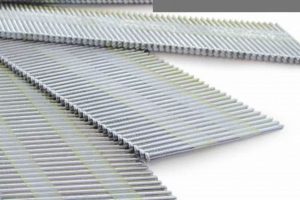

- Nail Strip Configuration and Compatibility

Nail capacity is intrinsically linked to the nail strip configuration used by the tool. Some models accept full strips of nails, maximizing capacity, while others use partial strips or coils. Ensuring compatibility between the nail strip type and the tool’s magazine is essential for preventing jams and ensuring smooth operation. Mismatched nail strips can lead to malfunctions and decreased efficiency.

- Tool Weight and Balance Considerations

A higher nail capacity can potentially increase the tool’s weight, particularly when the magazine is fully loaded. Manufacturers often balance nail capacity with weight distribution to maintain comfortable ergonomics and minimize user fatigue. A well-balanced tool, even with a larger nail capacity, reduces strain and enhances maneuverability, contributing to improved accuracy and control.

- Impact on Job Site Efficiency and Productivity

Nail capacity directly influences job site efficiency and overall productivity. The time saved by reducing reload frequency can accumulate significantly over the course of a project, resulting in faster completion times and increased profitability. Selecting a tool with an appropriate nail capacity optimizes workflow and minimizes downtime, contributing to a more streamlined and efficient work process.

In summary, nail capacity represents a key factor influencing the operational efficiency and productivity of cordless finish nailers. By understanding the relationship between magazine size, nail strip configuration, tool weight, and overall job site requirements, users can select a tool that maximizes performance and minimizes disruptions. The appropriate nail capacity, combined with other factors such as battery voltage and firing mode, contributes to the overall effectiveness and value of these tools in various finishing applications.

4. Firing Modes

Firing modes in cordless finish nailers directly influence application speed and precision. The selection of firing mode significantly affects the tool’s suitability for different tasks. Two primary modes exist: sequential actuation and contact actuation, each offering distinct advantages and disadvantages in specific contexts. Sequential actuation requires the user to depress the safety contact tip fully against the work surface before pulling the trigger, preventing accidental nail discharge. Conversely, contact actuation allows for rapid nail placement by keeping the trigger depressed and “bumping” the safety contact tip against the work surface. This mode prioritizes speed but demands greater user control to avoid misfires or unintended nail placement.

The appropriate firing mode selection depends heavily on the nature of the finishing task. For intricate trim work or applications requiring precise nail placement, sequential actuation is generally preferred. This mode minimizes the risk of errors and allows for careful alignment before each nail is driven. In contrast, contact actuation excels in high-volume applications, such as installing sheathing or fencing, where speed is paramount and minor variations in nail placement are less critical. For instance, installing baseboards in a large room might benefit from contact actuation to expedite the process, while attaching delicate crown molding typically necessitates the control offered by sequential actuation. Incorrect firing mode selection can result in damaged materials, increased rework, and reduced overall efficiency.

Ultimately, understanding firing modes is crucial for maximizing the utility and safety of cordless finish nailers. Each mode presents a trade-off between speed and precision, requiring users to carefully assess the demands of the task at hand. The choice of firing mode, coupled with appropriate safety precautions, contributes significantly to the quality and efficiency of finishing work. As technology advances, manufacturers may introduce additional firing modes or hybrid systems that offer greater versatility and control, further emphasizing the importance of understanding these fundamental operational parameters.

5. Weight

Weight, a significant ergonomic factor, directly influences the user experience and productivity associated with cordless finish nailers. The tool’s weight impacts maneuverability, fatigue levels, and overall control during operation. A careful balance between power and weight is crucial for optimizing performance across various applications.

- Maneuverability and Accessibility

A lighter tool enhances maneuverability, allowing for easier access to tight spaces and overhead work areas. Reduced weight translates to greater flexibility when positioning the nailer, particularly in intricate trim installations or awkward angles. This enhanced accessibility improves accuracy and reduces the likelihood of errors in challenging environments. For example, installing crown molding near a ceiling often demands a lightweight tool for precise nail placement.

- User Fatigue and Sustained Operation

The weight of a cordless finish nailer directly contributes to user fatigue, especially during prolonged use. Heavier tools require more physical exertion to hold and operate, leading to increased muscle strain and reduced endurance. This fatigue can compromise accuracy and potentially increase the risk of accidents. Lighter models enable sustained operation with less physical strain, enhancing productivity over extended periods. Consider a professional carpenter installing trim throughout an entire house; a lighter nailer significantly reduces fatigue and improves overall efficiency.

- Balance and Control

Weight distribution plays a critical role in the overall balance and control of the tool. A well-balanced nailer feels more natural and easier to handle, reducing the effort required to maintain a steady hand. Proper balance minimizes wobble and improves accuracy, especially when driving nails into delicate materials. This stability is particularly important when working with hardwood or brittle trim where precision is paramount. A balanced tool ensures consistent results and minimizes the risk of material damage.

- Material Composition and Component Density

The weight of a cordless finish nailer is influenced by its material composition and the density of its internal components. Manufacturers often employ lightweight materials, such as high-strength polymers or aluminum alloys, to minimize overall weight without compromising durability. The size and weight of the battery also contribute significantly to the tool’s overall mass. Balancing robust construction with lightweight materials is a key consideration in the design and engineering of these tools.

In conclusion, the weight of a cordless finish nailer represents a critical ergonomic factor that impacts maneuverability, fatigue, balance, and material selection. Choosing a tool with an appropriate weight profile optimizes user comfort, enhances productivity, and improves the overall quality of finishing work. Careful consideration of weight, alongside other factors such as power, nail capacity, and firing mode, contributes to the selection of a tool that best meets the demands of the specific application.

6. Depth Adjustment

Depth adjustment is a critical feature in cordless finish nailers, significantly impacting the quality and precision of finishing work. Its primary function is to control the depth to which a fastener is driven into the material. This precise control is essential to ensure the nail head is flush with the surface without either protruding or being driven too deep, which can compromise the aesthetic appeal and structural integrity of the finished piece. Depth adjustment mechanisms typically involve a dial or knob that allows the user to fine-tune the driving force, accommodating variations in material density and nail length.

The importance of depth adjustment is evident in various finishing applications. For instance, when installing delicate trim made of softwoods like pine, a shallow depth setting is required to prevent the nailer from sinking the fastener too deep, causing unsightly dents or splitting the wood. Conversely, when working with hardwoods like oak or maple, a deeper setting may be necessary to ensure the nail is driven fully and securely. Without proper depth adjustment, achieving a consistent and professional finish becomes challenging, potentially leading to rework and material waste. Consider the installation of a wainscoting panel: if the depth is not correctly adjusted, some nails may protrude, requiring manual hammering and filling, while others may be set too deep, creating noticeable depressions in the wood surface. Accurate depth adjustment, therefore, is essential for achieving the desired aesthetic and functional outcome.

In summary, depth adjustment is an indispensable component of cordless finish nailers, providing the necessary control for achieving professional-quality results across a range of finishing applications. It allows users to adapt to varying material densities and fastener lengths, ensuring nails are driven flush with the surface without causing damage or compromising structural integrity. Mastering depth adjustment is crucial for maximizing the effectiveness and versatility of these tools, enabling users to produce consistently high-quality finished products. Furthermore, attention to depth adjustment also increases the longevity of the material.

7. Ergonomics

Ergonomics plays a pivotal role in the design and usability of cordless finish nailers. The tool’s ergonomic features directly influence user comfort, reduce fatigue, and enhance precision during extended operation. These considerations are not merely aesthetic; they directly impact productivity and the potential for musculoskeletal strain. A well-designed tool minimizes stress on the user’s joints, muscles, and tendons, promoting a safer and more efficient work environment. Factors such as handle design, weight distribution, and vibration dampening contribute significantly to the overall ergonomic profile of a cordless finish nailer. For instance, a handle contoured to fit the natural curve of the hand reduces grip force and minimizes the risk of carpal tunnel syndrome. Furthermore, strategically positioning the tool’s center of gravity can improve balance and reduce strain on the wrist and forearm.

The practical implications of ergonomics are readily apparent in real-world applications. Consider a professional carpenter installing trim in a large home. Using a nailer with poor ergonomics could lead to rapid fatigue, reduced accuracy, and an increased risk of repetitive strain injuries. Conversely, a tool designed with ergonomic principles in mind allows the carpenter to work for extended periods with greater comfort and control, resulting in higher quality workmanship and reduced downtime. Features such as adjustable belt hooks and integrated LED lights also contribute to ergonomic benefits by improving accessibility and visibility in challenging work environments. Proper ergonomic design extends beyond the physical tool itself to include the user’s posture and work habits. Maintaining a comfortable stance and avoiding prolonged periods of repetitive motion are essential for minimizing the risk of injury.

In summary, ergonomics is an essential component of cordless finish nailer design, directly impacting user comfort, safety, and productivity. Manufacturers that prioritize ergonomic considerations create tools that are more user-friendly, reduce fatigue, and minimize the risk of musculoskeletal disorders. While challenges remain in balancing ergonomic design with power and performance, the benefits of investing in well-designed tools are clear. By understanding the importance of ergonomics and adopting proper work practices, users can maximize the efficiency and longevity of these tools while promoting a safer and more comfortable work environment.

Frequently Asked Questions

The following addresses prevalent inquiries regarding cordless finish nailers, providing detailed explanations to enhance user understanding and facilitate informed decision-making.

Question 1: What distinguishes a cordless finish nailer from other types of nailers?

These devices are specifically engineered for precision finishing work, such as installing trim, molding, and cabinetry. The primary distinction lies in the smaller gauge nails they utilize, which minimize visibility and reduce the risk of splitting delicate materials. Furthermore, their cordless operation provides enhanced maneuverability and eliminates the need for cumbersome air hoses or power cords.

Question 2: What factors should be considered when selecting a cordless finish nailer?

Critical considerations include battery voltage (which affects power), nail capacity (influencing reload frequency), firing mode (sequential or contact actuation), tool weight (impacting user fatigue), depth adjustment (for precise nail placement), and ergonomics (for comfortable handling). Assessing these factors based on the intended applications is essential for optimal performance.

Question 3: How does battery voltage affect the performance of a cordless finish nailer?

Higher battery voltage generally translates to increased driving force, enabling the tool to drive nails into denser materials more effectively. While higher voltage doesn’t directly correlate to longer runtime, it can improve overall efficiency by optimizing energy delivery. The selected voltage should align with the demands of the anticipated tasks.

Question 4: What are the advantages and disadvantages of sequential versus contact actuation firing modes?

Sequential actuation prioritizes precision and prevents accidental nail discharge by requiring the safety contact tip to be fully depressed before firing. Contact actuation emphasizes speed, allowing for rapid nail placement by “bumping” the safety contact tip while holding the trigger. The choice depends on whether precision or speed is the primary concern.

Question 5: How is proper depth adjustment achieved and why is it important?

Depth adjustment mechanisms typically involve a dial or knob that allows for fine-tuning the driving force. Accurate depth adjustment ensures that the nail head is flush with the material surface without protruding or being driven too deep. This is crucial for achieving a professional finish and preventing damage to the work piece.

Question 6: What maintenance practices are recommended for cordless finish nailers?

Regular maintenance should include cleaning the tool’s mechanism to remove debris, lubricating moving parts as specified by the manufacturer, inspecting battery contacts for corrosion, and storing the tool in a clean, dry environment. Adhering to these practices extends the tool’s lifespan and ensures reliable operation.

These FAQs provide a foundational understanding of cordless finish nailers, empowering users to make informed choices and optimize their use of these tools.

The subsequent section will explore common troubleshooting scenarios and offer guidance on resolving potential operational issues.

Concluding Remarks

This exposition has elucidated the multifaceted characteristics of cordless nailers finish nailer, encompassing operational principles, critical performance metrics, and essential maintenance protocols. A thorough understanding of gauge, battery voltage, nail capacity, firing modes, weight, depth adjustment, and ergonomic design is paramount for selecting and utilizing these tools effectively. Proper application of the outlined operational tips will contribute to optimal performance and extended tool longevity.

Mastery of the nuances presented herein will empower users to maximize the potential of cordless nailers finish nailer, ensuring consistent, professional-grade results in various finishing applications. Continued adherence to safety guidelines and proactive maintenance practices will further enhance user experience and contribute to a safer, more productive work environment.

![Best DeWalt Finish Nailer Deals at Lowe's [Guide] Best Final Touch: Elevate Your Projects with Professional Finishing Best DeWalt Finish Nailer Deals at Lowe's [Guide] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-477-300x200.jpg)