A pneumatic tool designed for driving small-gauge fasteners into wood trim and other delicate materials can be acquired from a prominent home improvement retailer. These tools are frequently utilized in woodworking and carpentry projects where a minimal visible fastener is desired, often found in locations offering a wide variety of tools and building supplies.

The utility of such a tool stems from its ability to provide a clean and professional finish to various projects. It avoids splitting or marring the surface of the wood, contributing to an aesthetically pleasing result. The availability of these tools through established retailers ensures accessibility and often includes associated warranties and support services, which represents a significant advantage.

The following sections will delve into specific models, considerations for selection, proper usage techniques, and maintenance guidelines applicable to this type of tool, ensuring informed purchasing decisions and optimal performance.

Tips for Selecting and Using a Finish Nailer from a Major Retailer

Maximizing the value and performance of a finish nailer requires careful consideration of various factors, ranging from model selection to proper usage and maintenance. The following provides guidance to enhance efficiency and project quality.

Tip 1: Evaluate Project Requirements: Assess the specific needs of intended projects, considering the gauge and length of nails required. Different projects may necessitate varying tool capabilities.

Tip 2: Consider Cordless Options: For increased mobility and convenience, explore cordless models. Evaluate battery life and charging time to ensure suitability for project duration.

Tip 3: Check Depth Adjustment Settings: Verify that the tool offers adjustable depth settings. This allows for precise nail placement and prevents over-driving or under-driving nails.

Tip 4: Review Safety Features: Prioritize models with safety mechanisms, such as a contact safety tip, to prevent accidental firing.

Tip 5: Maintain Consistent Air Pressure: If using a pneumatic model, maintain the air compressor at the recommended pressure level to ensure consistent performance and prevent tool damage.

Tip 6: Use Appropriate Fasteners: Utilize only the recommended type and size of fasteners for the tool. Using incorrect fasteners can compromise the tool’s performance and safety.

Tip 7: Practice on Scrap Material: Before working on the final project, practice nail placement and depth adjustment on scrap material. This minimizes errors and ensures optimal results.

Tip 8: Regularly Clean and Lubricate: Adhere to the manufacturer’s recommendations for cleaning and lubrication to prolong the tool’s lifespan and maintain optimal performance.

Adherence to these guidelines facilitates informed purchasing decisions and contributes to efficient and safe operation, leading to high-quality results.

The concluding section will provide further resources and recommendations for successful utilization of these tools.

1. Gauge

Gauge, in the context of pneumatic fastening tools and their availability at major retailers, refers to the diameter of the nails the tool is designed to drive. This specification is crucial in determining the tool’s suitability for various woodworking and carpentry applications.

- Nail Compatibility

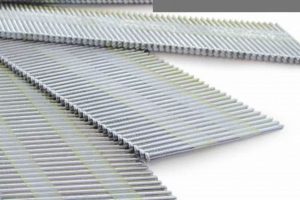

The gauge rating of a finish nailer directly dictates the range of nail gauges it can accommodate. A higher gauge number indicates a thinner nail. Selecting a tool compatible with the intended nail gauge is essential for proper operation and preventing tool damage. A retailer such as Lowe’s offers a variety of tools catering to different gauge requirements.

- Application Specificity

Different gauges are appropriate for different applications. Finer gauge nails are suitable for delicate trim work where minimal visibility is desired, while thicker gauges offer greater holding power for heavier materials. Understanding the project requirements influences the optimal gauge for the tool. The tool is capable of driving nails of varying gauges.

- Tool Selection Criteria

Gauge serves as a primary factor in selecting the appropriate tool from a retailer’s inventory. The tool must be specifically engineered to handle the chosen gauge range, ensuring consistent and reliable performance. Matching the gauge capacity to the intended use cases prevents operational inefficiencies and potential safety hazards.

- Material Considerations

The material being fastened influences gauge selection. Softer materials may require finer gauge nails to prevent splitting, while harder materials necessitate thicker gauges for adequate penetration and grip. Compatibility between material and gauge is critical for a secure and aesthetically pleasing outcome. The finish nailer’s gauge capacity must align with the material’s properties.

In summary, gauge is a critical parameter when choosing a pneumatic fastening tool from major retailers. It directly impacts nail compatibility, application suitability, tool performance, and material integrity. Careful consideration of gauge requirements ensures appropriate tool selection and optimal project outcomes.

2. Power Source

The power source of a finish nailer acquired from major retailers directly dictates its operational characteristics, portability, and suitability for various applications. Finish nailers are commonly available with two primary power source options: pneumatic and cordless (typically battery-powered). Pneumatic models necessitate connection to an air compressor, providing consistent power output for high-volume applications. However, this connection restricts mobility and requires additional equipment. Cordless models offer increased portability, eliminating the need for an air compressor and hose. The trade-off is limited runtime dependent on battery capacity and potential fluctuations in power as the battery discharges. A finish nailer’s efficacy relies on a stable and appropriate power source.

Practical examples illustrate these differences. Cabinet installers frequently favor cordless models for their ease of movement within a workspace. Conversely, trim carpenters undertaking large-scale projects may opt for pneumatic versions to avoid interruptions for battery changes. Furthermore, power source impacts maintenance requirements and overall tool longevity. Pneumatic models require attention to air compressor maintenance, while cordless tools require battery management and eventual battery replacement. These considerations must be factored into the total cost of ownership and operational planning.

In summary, the power source is an intrinsic component determining a finish nailer’s operational paradigm. Selection should be based on a careful assessment of project needs, considering the balance between power consistency, portability, and long-term maintenance. A comprehensive understanding of the power source’s implications enables informed purchasing decisions and efficient utilization of finish nailers in diverse woodworking and carpentry contexts.

3. Fastener Length

Fastener length constitutes a crucial specification in the selection and application of finish nailers acquired from retail sources. It directly influences the security and aesthetic outcome of woodworking and carpentry projects. Matching fastener length to material thickness is paramount to achieving optimal results.

- Material Thickness Compatibility

Proper fastener length ensures adequate penetration into the substrate for secure fastening, without protruding through the opposite side. Inadequate length compromises holding power, while excessive length detracts from the finished appearance and may pose a safety hazard. When working with baseboards, for instance, the fastener length must be sufficient to penetrate the wall stud behind the drywall.

- Wood Type Considerations

Different wood types exhibit varying densities and thicknesses. Harder woods necessitate longer fasteners to achieve proper grip, while softer woods may split if the fastener is too long or too thick. A tool is usually compatible with fasteners from 1/2″ to 2 1/2″.

- Tool Adjustment Capabilities

Many models offer depth-of-drive adjustment features, allowing for precise control over fastener placement and minimizing surface damage. This capability is essential for accommodating variations in material thickness and density. Depth control ensures fasteners are neither over-driven, creating unsightly dimples, nor under-driven, leaving fasteners protruding above the surface.

- Project-Specific Requirements

The nature of the project dictates the required fastener length. Fine trim work may necessitate shorter fasteners for a clean, concealed finish, whereas structural applications require longer fasteners for enhanced strength and stability. Selecting fasteners is especially important to avoid mistakes.

The interrelationship between fastener length, material properties, and tool adjustability underscores the importance of informed decision-making when selecting and utilizing these tools. Careful attention to these factors ensures secure, aesthetically pleasing, and structurally sound results across a range of woodworking and carpentry applications.

4. Application

The intended application of a finish nailer, particularly when sourced from a retailer like Lowe’s, serves as a primary determinant in selecting the appropriate tool model. The specific tasks for which the tool is intended significantly influence the required features, power, and fastener compatibility.

- Trim and Molding Installation

For installing delicate trim and molding, precision and minimal surface damage are paramount. Finish nailers designed for this application often feature adjustable depth settings to prevent over-driving nails and splitting wood. Examples include installing crown molding, baseboards, and door casings. This type of work benefits from a lightweight tool for maneuverability.

- Cabinetry and Furniture Assembly

When assembling cabinets or furniture, a balance between holding power and aesthetic finish is required. Finish nailers used in these applications must be capable of driving nails of sufficient length to provide structural integrity without leaving prominent nail holes. An example is attaching cabinet face frames or assembling drawers. The selection from Lowe’s should consider nailer gauges appropriate for hardwoods commonly used in cabinet construction.

- Staircase Construction

Finish nailers play a role in staircase construction, primarily for attaching trim and decorative elements. In this context, the tool needs to be versatile enough to handle angled surfaces and various wood densities. Examples include installing stair treads, risers, and balusters. The power source of the nailer is important when mobility is needed.

- Paneling and Wainscoting

Installing paneling and wainscoting often involves fastening thin materials to wall studs or existing surfaces. The finish nailer should offer precise control over nail depth to avoid penetrating too far and damaging the wall behind the paneling. Ensuring the fastener blends well with the finish is also a priority.

The application dictates the choice of finish nailer, considering factors like the type of material, the required level of precision, and the need for maneuverability. The diverse range of nailers available through retailers like Lowe’s caters to these varying application demands, requiring a thorough evaluation of project needs before selection.

5. Price

The price of a finish nailer available at a major retailer is a key determinant in purchasing decisions and reflects a confluence of factors including brand reputation, tool features, and intended application. Higher-priced models often incorporate advanced features such as tool-free depth adjustment, enhanced safety mechanisms, and more durable construction materials, resulting in increased longevity and performance. These features may be essential for professionals requiring consistent and reliable operation under demanding conditions. Conversely, lower-priced options may suffice for occasional users or homeowners engaged in smaller, less complex projects. The availability of a broad price range at retailers like Lowe’s allows consumers to align their purchase with their budget and anticipated usage.

The relationship between price and value is particularly relevant. A more expensive finish nailer may, in the long run, prove to be more cost-effective if it reduces downtime, requires less frequent repairs, and provides a higher quality finish, thereby minimizing material waste. For instance, a contractor using a finish nailer daily would likely benefit from investing in a higher-priced, more robust model. Alternatively, a homeowner undertaking occasional DIY projects may find that a less expensive model adequately meets their needs. Furthermore, price fluctuations may occur due to promotional offers, seasonal sales, or clearance events, providing opportunities to acquire desired models at a reduced cost. These variations necessitate careful price comparison and consideration of warranty terms and return policies to ensure a satisfactory purchase.

Ultimately, the price of a finish nailer purchased from a retailer like Lowe’s must be evaluated in conjunction with its intended use, features, and long-term ownership costs. While budgetary constraints often play a significant role, prioritizing quality and reliability can mitigate future expenses and enhance project outcomes. A comprehensive understanding of the factors influencing price empowers informed decision-making, enabling consumers to select a tool that optimally balances cost and performance.

Frequently Asked Questions

The following addresses common inquiries regarding finish nailers available from a prominent home improvement retailer, providing clarification on usage, selection, and maintenance.

Question 1: What distinguishes a finish nailer from a brad nailer?

A finish nailer typically utilizes 15- or 16-gauge nails, which are thicker than the 18-gauge nails used in brad nailers. This difference in nail size results in greater holding power in the former, making it suitable for heavier trim and molding applications. Brad nailers are generally reserved for more delicate tasks where minimal visibility of the fastener is desired.

Question 2: Is a pneumatic or cordless finish nailer preferable?

The selection of pneumatic versus cordless depends on project requirements. Pneumatic nailers offer consistent power and are well-suited for high-volume applications, but require an air compressor and hose. Cordless nailers provide greater portability but may exhibit reduced power and require battery management.

Question 3: What safety precautions should be observed when operating a finish nailer?

Eye protection is mandatory to prevent injury from flying debris. Hearing protection is recommended, especially during prolonged use. The operator should maintain a firm grip on the tool and ensure the work area is clear of obstructions. Additionally, the safety mechanism should be engaged when the tool is not in use.

Question 4: How often should a finish nailer be serviced?

Service intervals depend on usage frequency. For frequent use, cleaning and lubrication should be performed regularly, adhering to the manufacturer’s recommendations. Less frequent users may require servicing annually. Inspection for worn or damaged parts should be conducted periodically regardless of usage.

Question 5: What nail length is appropriate for various trim thicknesses?

The nail length should be sufficient to penetrate the substrate securely without protruding through the opposite side. As a general guideline, the nail should penetrate at least two-thirds of the combined thickness of the materials being fastened. Adjustments may be necessary based on the density of the wood.

Question 6: What are the common causes of finish nailer malfunctions?

Common malfunctions include nail jams, insufficient air pressure (for pneumatic models), depleted batteries (for cordless models), and worn or damaged internal components. Regular maintenance and proper tool handling can mitigate these issues.

In conclusion, careful consideration of tool specifications, safety protocols, and maintenance practices ensures optimal performance and longevity of finish nailers acquired from major retailers.

The subsequent section provides detailed guidance on troubleshooting common issues encountered during operation.

Conclusion

This exploration of finish nailer lowes has illuminated critical factors relevant to the selection, usage, and maintenance of these tools. Gauge, power source, fastener length, application, and price represent key considerations that directly impact project outcomes. Informed decision-making, coupled with adherence to safety protocols, is paramount to ensuring optimal performance and mitigating potential risks.

The judicious application of these principles fosters efficient woodworking and carpentry practices, ultimately contributing to the successful completion of diverse projects. A continued focus on tool knowledge and responsible operation remains essential for maximizing the value and utility of finish nailers across a spectrum of applications.

![Best DeWalt Finish Nailer Deals at Lowe's [Guide] Best Final Touch: Elevate Your Projects with Professional Finishing Best DeWalt Finish Nailer Deals at Lowe's [Guide] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-477-300x200.jpg)