A comparison between two types of pneumatic finish nailers, differentiated primarily by the gauge of the nails they utilize, is common among woodworking professionals and hobbyists. The gauge number indicates the thickness of the nail; a higher gauge number signifies a thinner nail. This difference in nail diameter impacts the holding power, visibility of the nail head, and potential for splitting delicate wood.

The selection of a specific nailer type is often driven by the nature of the project. A thicker nail, driven by one tool, provides a more robust hold, which is advantageous in applications demanding greater structural integrity. Conversely, the other tool, firing a thinner nail, minimizes the visibility of the fastener and reduces the risk of splitting the wood, making it suitable for detailed trim work where aesthetics are paramount. Historically, advancements in pneumatic technology have enabled finer control and precision in driving these fasteners, expanding their application across diverse woodworking tasks.

The subsequent sections will delve into a detailed examination of the strengths and weaknesses of each nailer type, considering factors such as nail size, application suitability, tool maneuverability, and the overall impact on the finished product. This comparison will provide the information necessary for making an informed decision based on specific project requirements and desired outcomes.

Effective utilization of pneumatic finish nailers hinges on understanding the nuances of each tool’s capabilities and limitations. Careful consideration of project requirements is crucial for optimal results. The following guidelines offer practical advice for selecting the appropriate tool for a given application.

Tip 1: Assess Project Demands: Prioritize structural integrity or aesthetic considerations based on the specific task. Frame construction, for instance, benefits from the greater holding power of one, while delicate trim work requires the minimal visibility offered by the other.

Tip 2: Evaluate Wood Density: Softer woods are more susceptible to splitting. In such instances, opting for one type minimizes the risk of damage and ensures a cleaner finish. Harder woods may necessitate the increased holding power provided by the other, particularly in load-bearing applications.

Tip 3: Consider Nail Head Visibility: Projects where fastener concealment is critical warrant the selection of a tool that drives nails with smaller heads. This reduces the need for extensive filling and sanding, streamlining the finishing process.

Tip 4: Match Nail Length to Material Thickness: Employing nails of appropriate length is essential for secure fastening. Insufficient nail length compromises holding power, while excessive length can protrude through the workpiece.

Tip 5: Test on Scrap Material: Before commencing a project, test the selected nailer and nail combination on scrap material. This allows for adjustments to air pressure and depth settings, preventing damage to the final product.

Tip 6: Maintain Consistent Air Pressure: Fluctuations in air pressure can lead to inconsistent nail depth. Regular monitoring and adjustment of the compressor ensure uniform results throughout the project.

Tip 7: Prioritize Safety: Always wear appropriate eye and ear protection when operating pneumatic nailers. Follow manufacturer guidelines for safe handling and maintenance procedures.

Effective decision-making regarding nailer selection demands a thorough understanding of the trade-offs between holding power, aesthetics, and material properties. Implementing these tips will contribute to higher quality results and enhanced project efficiency.

The subsequent sections will explore advanced techniques and best practices for maximizing the performance and longevity of pneumatic finish nailers, further refining the user’s understanding of these essential woodworking tools.

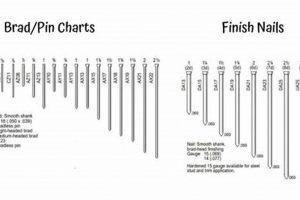

1. Nail Diameter

Nail diameter, measured by gauge, constitutes a primary differentiating factor between finish nailers. The gauge number signifies the nail’s thickness; a lower gauge, such as 15, indicates a thicker nail, whereas a higher gauge, like 16, corresponds to a thinner nail. This seemingly subtle difference significantly impacts the performance characteristics of each tool and, consequently, the suitability for particular woodworking tasks. The thicker nail of a 15-gauge system inherently provides greater shear strength and pull-out resistance, making it advantageous in applications demanding robust fastening, such as cabinet face frame construction or furniture assembly. The increased diameter results in a larger surface area for friction and mechanical interlock with the surrounding wood fibers.

Conversely, the reduced diameter of a 16-gauge nail minimizes the risk of splitting delicate wood, a critical consideration when working with intricate trim moldings or thin stock. Furthermore, the smaller nail head produced by a 16-gauge nailer is less obtrusive, reducing the amount of filling and sanding required to achieve a smooth, aesthetically pleasing finish. Examples of appropriate use cases include installing baseboards, door casings, and decorative moldings, where cosmetic considerations outweigh structural demands. The choice of nail diameter, therefore, directly influences the final appearance and structural integrity of the finished product.

In summary, understanding the inverse relationship between gauge number and nail diameter is crucial for selecting the appropriate finish nailer. The 15-gauge system prioritizes holding power, while the 16-gauge system emphasizes minimizing visible nail marks and preventing wood splitting. Ultimately, the specific application dictates the optimal choice, highlighting the importance of considering both structural and aesthetic requirements. This informed decision-making process leads to improved project outcomes and a reduction in material waste, representing a fundamental aspect of professional woodworking practices.

2. Holding Power

Holding power, the resistance of a fastener to withdrawal from a material, represents a pivotal consideration when selecting between finish nailers. The nail’s gauge, a defining characteristic in this comparison, directly influences the strength of the connection achieved. A comprehensive understanding of holding power’s facets is essential for ensuring structural integrity and longevity in woodworking projects.

- Nail Shank Diameter

The diameter of the nail shank fundamentally dictates holding power. A 15-gauge nail, possessing a larger diameter than its 16-gauge counterpart, creates a wider channel within the wood, resulting in increased friction and mechanical interlock. This enhanced contact area amplifies the nail’s resistance to pull-out forces. In applications such as furniture construction, where structural stability is paramount, the superior holding power conferred by the thicker shank is crucial for preventing joint failure over time. Conversely, in delicate trim work, the increased risk of splitting associated with the larger diameter may outweigh the benefits of enhanced holding power.

- Nail Material Composition

The composition of the nail material contributes significantly to its overall holding power. High-carbon steel nails, commonly used in both 15-gauge and 16-gauge systems, offer superior strength and resistance to bending compared to softer alloys. Furthermore, specialized coatings, such as resin or adhesive coatings, can enhance the frictional bond between the nail and the surrounding wood fibers, further increasing holding power. The selection of appropriate nail material, considering factors such as corrosion resistance and compatibility with the wood species being used, is critical for maximizing joint durability.

- Wood Density and Species

The density and species of wood profoundly influence nail holding power. Denser hardwoods, such as oak or maple, offer greater resistance to nail withdrawal than softer woods like pine or cedar. The increased density provides a tighter grip on the nail shank, enhancing its ability to withstand pull-out forces. Consequently, when working with hardwoods, the difference in holding power between 15-gauge and 16-gauge nails may be less pronounced. Conversely, in softer woods, the greater holding power of the 15-gauge nail becomes more critical for ensuring a secure and lasting connection.

- Nail Length and Penetration Depth

Nail length and penetration depth are directly proportional to holding power. A longer nail, penetrating deeper into the wood substrate, creates a larger surface area for friction and mechanical interlock. Insufficient nail length compromises holding power, increasing the risk of joint failure. Conversely, excessive nail length can protrude through the back of the workpiece, posing a safety hazard and detracting from the aesthetic appearance. Proper nail selection involves matching nail length to material thickness, ensuring adequate penetration depth while avoiding through-penetration.

The multifaceted nature of holding power underscores the importance of a comprehensive understanding of its influencing factors. The selection of nail gauge, material composition, nail length, and wood species must be carefully considered to optimize joint strength and durability. While the 15-gauge nailer generally provides superior holding power, the 16-gauge system offers advantages in terms of reduced splitting and improved cosmetic finish. Ultimately, the optimal choice depends on the specific requirements of the project, balancing structural demands with aesthetic considerations.

3. Cosmetic Finish

The aesthetic outcome of a woodworking project is significantly influenced by the selection of finish nailer, specifically when considering “15 gauge finish nailer vs 16 gauge.” The gauge of the nail directly impacts the visibility of the fastener, a critical determinant of the final appearance. A 15-gauge nail, being thicker, leaves a larger hole, necessitating more extensive filling and sanding to achieve a smooth, unblemished surface. This additional work increases labor time and material costs. Conversely, a 16-gauge nail, with its smaller diameter, creates a less conspicuous entry point, minimizing the need for extensive patching. For instance, in the installation of intricate crown molding, the reduced nail head visibility afforded by the 16-gauge nailer allows for a cleaner, more refined appearance with less post-installation processing.

The choice between these two nailer types often involves a trade-off between holding power and aesthetic appeal. While the 15-gauge nailer provides a more robust connection, particularly in structural applications, the resulting nail hole can detract from the overall visual quality if not properly addressed. The subsequent filling and sanding process, if not executed with precision, can lead to uneven surfaces and visible imperfections, diminishing the perceived quality of the finished product. In contrast, the 16-gauge nailer offers a balance between adequate holding power and minimal aesthetic disruption. This balance is particularly valuable in applications where the visual appearance is paramount, such as fine cabinetry or detailed trim work. For example, when installing pre-finished trim, the smaller nail holes of the 16-gauge system reduce the risk of damaging the surrounding finish during filling and sanding, preserving the integrity of the pre-finished surface.

Ultimately, the selection between a 15-gauge and 16-gauge finish nailer requires a careful assessment of project priorities. If structural integrity is the primary concern and cosmetic imperfections can be readily addressed, the 15-gauge nailer may be the more suitable choice. However, if aesthetic considerations take precedence, and minimizing nail hole visibility is essential for achieving a flawless finish, the 16-gauge nailer offers a compelling advantage. The practical significance of this understanding lies in the ability to make informed decisions that optimize both the structural soundness and visual appeal of woodworking projects, leading to enhanced customer satisfaction and professional reputation.

4. Wood Splitting

The propensity for wood to split during fastening represents a significant consideration when choosing between finish nailers. The gauge of the nail, differentiating the tools, directly influences the likelihood of material failure, particularly in delicate or brittle wood species. The selection process must, therefore, incorporate an understanding of wood characteristics and nail gauge implications.

- Nail Diameter and Wood Fiber Displacement

The fundamental mechanism behind splitting involves the displacement of wood fibers caused by nail insertion. A 15-gauge nail, possessing a larger diameter than a 16-gauge nail, exerts greater force on the surrounding wood, increasing the risk of separation along the grain. This is particularly relevant in hardwoods known for their tight grain structure, where lateral pressure can initiate cracks. Conversely, the reduced diameter of the 16-gauge nail minimizes fiber displacement, reducing the stress concentration and thus lowering the likelihood of splitting. Consider, for example, attaching thin strips of oak trim; the use of a 15-gauge nailer increases the probability of splitting compared to a 16-gauge nailer.

- Wood Species and Grain Orientation

The susceptibility to splitting varies significantly across wood species. Softwoods, such as pine and cedar, are generally more prone to splitting than hardwoods due to their lower density and weaker fiber bonds. Additionally, the orientation of the wood grain relative to the nail’s insertion point plays a critical role. Driving a nail parallel to the grain significantly increases the risk of splitting compared to driving it perpendicular to the grain. Consequently, when working with splitting-prone wood species, such as redwood, or when fastening near the edge of a board, the choice of a 16-gauge nailer becomes more prudent.

- Nail Point Geometry and Driving Technique

The geometry of the nail point influences the stress distribution within the wood during insertion. Chisel-point nails, commonly used in finish nailers, can wedge apart wood fibers if not driven precisely. Blunt-point nails, while requiring more force to drive, tend to crush rather than split the wood. Furthermore, the driving technique employed affects the risk of splitting. Applying excessive force or driving nails too close to knots or imperfections can exacerbate the problem. Proper technique involves maintaining a consistent driving angle and avoiding areas of weakness in the wood.

- Pre-Drilling and Pilot Holes

In situations where splitting is a significant concern, pre-drilling pilot holes can mitigate the risk. A pilot hole, slightly smaller in diameter than the nail shank, creates a pathway for the nail, reducing the amount of fiber displacement during insertion. This technique is particularly effective when working with hardwoods or when fastening near the edge of a board. While pre-drilling adds an extra step to the process, it can significantly reduce material waste and improve the quality of the finished product. For instance, when attaching delicate moldings to a hardwood substrate, pre-drilling pilot holes in conjunction with a 16-gauge nailer can provide a secure and aesthetically pleasing result.

In summation, the choice between nailers mandates an assessment of wood species, grain orientation, driving technique, and nail point geometry. While pre-drilling and careful technique may reduce splitting, a 16-gauge nailer presents a lower risk profile.

5. Application Suitability

The effective utilization of finish nailers hinges on aligning tool characteristics with project demands. The core distinction between 15-gauge and 16-gauge nailers lies in their nail size, directly impacting holding power and aesthetic finish. Consequently, application suitability emerges as a critical determinant in selecting the appropriate tool. Projects requiring robust fastening, such as furniture frame assembly or securing thick trim, benefit from the superior holding strength of a 15-gauge nailer. The thicker nail provides increased resistance to pull-out forces, ensuring structural integrity over time. Conversely, tasks demanding minimal visual disruption, like installing delicate moldings or attaching thin veneers, are better suited for a 16-gauge nailer. The smaller nail diameter reduces the likelihood of splitting and minimizes the visibility of the fastener, contributing to a cleaner, more refined aesthetic.

Real-world scenarios illustrate the practical significance of considering application suitability. In cabinet making, the 15-gauge nailer is often preferred for assembling face frames and attaching cabinet boxes, where structural stability is paramount. The robust hold provided by the thicker nail ensures long-term durability and prevents sagging or separation of components. However, when installing decorative trim on the cabinet doors, a 16-gauge nailer is favored to minimize nail holes and maintain the aesthetic appeal of the finished product. Similarly, in construction, a 15-gauge nailer may be used for attaching baseboards to wall studs, while a 16-gauge nailer is more appropriate for installing shoe molding, where visual prominence is a greater concern. Neglecting application suitability can lead to compromised structural integrity, unsightly finishes, and increased rework, ultimately affecting project quality and efficiency.

In summation, application suitability serves as a foundational principle in finish nailer selection. Understanding the trade-offs between holding power and aesthetic finish is crucial for optimizing project outcomes. While the 15-gauge nailer excels in applications requiring robust fastening, the 16-gauge nailer provides superior results in tasks demanding minimal visual disruption. A thorough assessment of project demands, material properties, and desired aesthetic outcomes is essential for making informed decisions and achieving professional-grade results. The challenges often lie in balancing competing priorities and adapting to project-specific constraints, requiring a nuanced understanding of both tool capabilities and material behaviors.

6. Tool Weight

Tool weight represents a significant ergonomic factor influencing user experience and productivity, particularly when comparing 15-gauge and 16-gauge finish nailers. The difference in weight between these tools, though seemingly minor, can impact fatigue levels, maneuverability, and overall control during extended use. This consideration is paramount for professionals and hobbyists alike, as it directly affects the quality and efficiency of woodworking projects.

- Material Composition and Construction

The materials used in the construction of finish nailers contribute substantially to their overall weight. Typically, 15-gauge nailers tend to be heavier due to the need for more robust components capable of handling the thicker nails and increased driving force. The use of heavier-gauge metals in the housing, firing mechanism, and nail magazine adds to the tool’s weight. Conversely, 16-gauge nailers often utilize lighter-weight materials, as the thinner nails require less forceful driving action. For example, a 15-gauge nailer might employ a steel housing, while a 16-gauge nailer could utilize an aluminum alloy, resulting in a noticeable weight difference.

- Internal Mechanism and Power Source

The complexity and size of the internal mechanism, including the piston, cylinder, and air delivery system, also influence tool weight. 15-gauge nailers, designed to drive larger nails, typically require a more powerful mechanism, leading to increased weight. Additionally, the presence of a battery pack in cordless models further contributes to the overall weight. A pneumatic 16-gauge nailer, relying on compressed air, may be lighter than a comparable cordless 15-gauge model. This difference is crucial for users who prioritize maneuverability and reduced strain during prolonged use.

- Ergonomic Design and Handling

Ergonomic design plays a critical role in mitigating the impact of tool weight on user fatigue. Features such as rubberized grips, balanced weight distribution, and swivel air connectors enhance comfort and control. However, even with ergonomic enhancements, a heavier tool requires more physical effort to operate, potentially leading to muscle strain and reduced precision. A lighter 16-gauge nailer, with its improved maneuverability, allows for greater control and accuracy, particularly in intricate or overhead applications. Therefore, the interplay between tool weight and ergonomic design is essential for optimizing user experience.

- Application-Specific Considerations

The suitability of a particular finish nailer is often determined by the nature of the task at hand. For heavy-duty applications, such as framing or installing thick trim, the added weight of a 15-gauge nailer may be offset by its superior holding power. However, for delicate tasks requiring precision and maneuverability, such as installing intricate moldings or attaching thin veneers, the lighter weight of a 16-gauge nailer becomes a significant advantage. A professional trim carpenter, for example, might opt for a lighter 16-gauge nailer for all-day use, while a general contractor might choose a heavier 15-gauge nailer for its versatility in various applications.

In conclusion, tool weight represents a critical ergonomic factor when comparing 15-gauge and 16-gauge finish nailers. The trade-offs between weight, power, and maneuverability necessitate a careful assessment of project requirements and user preferences. While the heavier 15-gauge nailer offers superior holding power, the lighter 16-gauge nailer provides enhanced comfort and control, particularly in delicate applications. The optimal choice ultimately depends on balancing the demands of the task with the ergonomic considerations of the user.

Frequently Asked Questions

The following addresses common inquiries regarding the selection between different gauge finish nailers, providing clear, concise answers based on established woodworking principles.

Question 1: What fundamental difference distinguishes a 15-gauge finish nailer from a 16-gauge finish nailer?

The primary distinction lies in the nail diameter. A 15-gauge nail possesses a larger diameter compared to a 16-gauge nail. This difference directly impacts holding power and aesthetic considerations.

Question 2: How does nail gauge influence holding power?

Holding power is directly proportional to nail diameter. A thicker, 15-gauge nail generally provides superior holding power compared to a thinner, 16-gauge nail.

Question 3: In what scenarios is a 15-gauge finish nailer most appropriate?

A 15-gauge finish nailer is well-suited for applications demanding robust fastening, such as furniture frame assembly or securing thick trim where structural integrity is paramount.

Question 4: When is a 16-gauge finish nailer preferable over its 15-gauge counterpart?

A 16-gauge finish nailer is advantageous in applications where minimizing nail hole visibility is critical, such as installing delicate moldings or attaching thin veneers. The smaller nail reduces the need for extensive filling and sanding.

Question 5: Does nail gauge affect the likelihood of wood splitting?

Yes. A thicker, 15-gauge nail is more likely to cause wood splitting, especially in delicate or brittle wood species. The thinner, 16-gauge nail minimizes this risk.

Question 6: How does tool weight factor into the selection process?

Tool weight affects user fatigue and maneuverability. 15-gauge nailers tend to be heavier than 16-gauge nailers, potentially impacting comfort during prolonged use. Lighter tools allow for more control.

The appropriate nailer selection should reflect both holding power and potential visual disruption. The 15-gauge is structurally stronger, but more visible; the 16-gauge minimizes visual impact at the expense of holding power.

The subsequent section will cover maintenance to prolong tool life and project quality.

Conclusion

The preceding analysis has elucidated the critical distinctions between 15 gauge finish nailers and 16 gauge finish nailers, underscoring the impact of nail diameter on holding power, cosmetic finish, wood splitting potential, and overall application suitability. The selection of one tool over the other is not arbitrary; it demands a careful evaluation of project-specific requirements, material properties, and desired aesthetic outcomes. While the 15-gauge system offers enhanced structural integrity, the 16-gauge system prioritizes minimizing visual disruption, presenting a trade-off that must be strategically navigated.

The informed application of these tools extends beyond mere preference; it reflects a commitment to professional standards and a recognition of the inherent limitations and capabilities of each system. Diligent consideration of the factors outlined herein will contribute to enhanced project quality, reduced material waste, and ultimately, a more durable and aesthetically pleasing finished product. The ongoing advancement of pneumatic technology necessitates continuous education and adaptation to ensure optimal utilization of these essential woodworking tools.

![Best Harbor Freight 16 Gauge Finish Nailer [Review] Best Final Touch: Elevate Your Projects with Professional Finishing Best Harbor Freight 16 Gauge Finish Nailer [Review] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/02/th-39-300x200.jpg)