This pneumatic tool, utilizing narrow-diameter fasteners, is designed for precise woodworking applications. It excels in tasks such as installing trim, molding, cabinetry, and other fine detailing where minimal visibility of the fastener is desired. The gauge refers to the diameter of the nails it uses, influencing the holding power and the size of the entry point on the workpiece. As an example, it can efficiently secure baseboards to walls, leaving a nearly invisible mark once filled.

The adoption of this type of nailer significantly increases efficiency and accuracy in finish carpentry. Prior to its widespread use, these tasks were primarily completed by hand, requiring more time and potentially leading to inconsistencies. The tool’s controlled depth setting prevents over-driving or under-driving nails, resulting in a cleaner, more professional finish. Its powered operation reduces user fatigue and improves overall project turnaround time.

The following sections will delve into the specific features of this particular model, explore its optimal usage scenarios, discuss maintenance best practices, and compare it against alternative fastening methods commonly employed in woodworking and construction.

Essential Usage Guidelines

The following guidelines are provided to maximize the performance and lifespan of the tool, as well as ensure user safety and optimal results in woodworking applications.

Tip 1: Select Appropriate Fasteners: Use only 16-gauge finish nails that are compatible with the specific model. Verify the nail length is appropriate for the material thickness to ensure adequate holding power without protruding through the back of the workpiece.

Tip 2: Adjust Depth Settings: Fine-tune the depth-of-drive setting to consistently set nails flush with the surface. Test the setting on a scrap piece of the same material before commencing work on the final piece.

Tip 3: Maintain Proper Air Pressure: Operate the tool within the manufacturer’s recommended air pressure range. Insufficient pressure may result in incomplete nail driving, while excessive pressure can damage the tool or the workpiece.

Tip 4: Utilize Safety Equipment: Always wear appropriate eye protection when operating the nailer. Consider using hearing protection in environments with prolonged exposure to pneumatic tool noise.

Tip 5: Regular Lubrication: Apply a few drops of pneumatic tool oil to the air inlet before each use. This practice ensures smooth operation and prolongs the lifespan of the internal components.

Tip 6: Clean the Tool Periodically: Regularly inspect and clean the nailer to remove debris and prevent jams. Disconnect the air supply before performing any maintenance.

Tip 7: Store Properly: When not in use, disconnect the air hose and store the nailer in a clean, dry environment, away from extreme temperatures and humidity.

Adhering to these guidelines will help ensure consistent, professional results, while minimizing the risk of accidents or tool malfunction.

The subsequent sections will address advanced techniques, troubleshooting common issues, and comparisons with other types of nailers, providing a comprehensive overview of optimal tool utilization.

1. Fastener Gauge

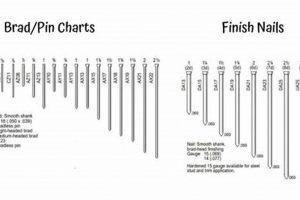

The fastener gauge is a defining characteristic of a finish nailer, directly dictating the tool’s applications and the resulting finish quality. In the context of a “16 gauge dewalt finish nailer”, the 16-gauge designation represents a specific nail diameter, impacting the tool’s suitability for various woodworking projects.

- Nail Diameter and Holding Power

A 16-gauge nail has a smaller diameter than a 15-gauge nail but is larger than an 18-gauge brad nail. This intermediate size provides a balance between holding power and minimal visibility on the finished surface. The smaller the gauge number, the larger the nail diameter. Therefore, a 16-gauge fastener offers more substantial holding capabilities compared to higher-gauge fasteners, making it appropriate for trim applications requiring secure attachment.

- Cosmetic Impact

Due to its relatively small diameter, a 16-gauge nail leaves a less conspicuous hole than larger nails. This feature is crucial in finish carpentry where aesthetic considerations are paramount. The small entry point typically requires minimal filling and sanding to achieve a smooth, professional finish. This is in contrast to larger gauge nails that necessitate more extensive hole filling and surface preparation.

- Tool Compatibility and Availability

A 16 gauge dewalt finish nailer is specifically designed to accept 16-gauge nails. Attempting to use a different gauge nail will result in tool malfunction or damage. The availability of 16-gauge nails is widespread, ensuring a readily accessible supply for users of these nailers. Nails are available in various lengths, coatings, and head styles to suit diverse project requirements.

- Application Specificity

The 16-gauge fastener is generally employed for interior trim, baseboards, crown molding, cabinetry, and furniture assembly. Its balance of holding strength and minimal surface impact makes it a versatile choice for these applications. While it is suitable for some exterior trim applications, it is not recommended for structural framing or projects requiring high shear strength.

The 16-gauge specification of this dewalt tool is a critical factor in determining its suitability for a given woodworking task. Its balanced characteristics make it a popular choice for professionals and DIYers seeking a blend of holding power and aesthetic appeal in their finished projects. Understanding the implications of the fastener gauge is essential for making informed decisions about tool selection and application.

2. Depth Adjustment

The depth adjustment feature on a 16-gauge finish nailer is integral to achieving consistent and professional results in finish carpentry. This mechanism allows the user to control the degree to which the nail is driven into the workpiece, preventing both superficial placement (where the nail head protrudes) and over-driving (where the nail sinks too deeply, potentially damaging the surrounding material). The effectiveness of the fastener is contingent upon precise setting, and improper depth can compromise the structural integrity of the join and detract from the aesthetic quality of the finished product. For example, when installing delicate trim around a window frame, an inappropriately set nail can split the wood or leave an unsightly, difficult-to-conceal depression.

Different materials exhibit varying densities, necessitating adjustments to the driving depth. Softer woods like pine require less force, while hardwoods such as oak demand a greater setting. The depth adjustment mechanism on this dewalt tool is usually a dial or similar control that modifies the tool’s power output. Accurate calibration of this setting is crucial to ensure nails are consistently set flush or slightly countersunk, facilitating easy filling and a smooth surface. Furthermore, the appropriate depth setting mitigates the risk of nail “walk-out”, where vibrations or material movement cause the fastener to gradually emerge from the wood over time. Failing to adjust the depth when switching between materials can result in inconsistent results, increased rework, and compromised project quality.

In summary, the depth adjustment feature on a 16-gauge dewalt finish nailer is not merely an ancillary function but a fundamental control element essential for achieving optimal fastening and a high-quality finish. Understanding and utilizing this feature correctly allows the user to adapt to material variations, minimize cosmetic imperfections, and ensure secure and lasting joinery. Improper depth adjustment leads to substandard results and compromises the overall integrity of the project. Therefore, mastering this aspect of the tool is paramount for anyone engaged in finish carpentry.

3. Air Pressure

Air pressure serves as the driving force behind the operation of a 16 gauge dewalt finish nailer. Precise regulation of air pressure is paramount for achieving consistent and accurate fastening results.

- Optimal Operating Range

Each pneumatic tool, including this nailer, is designed to function within a specific air pressure range, typically measured in pounds per square inch (PSI). Operating outside this range can lead to performance degradation or tool damage. For instance, if the recommended range is 70-100 PSI, exceeding 100 PSI may cause excessive wear on internal components, while operating below 70 PSI may result in incomplete nail driving.

- Impact on Nail Depth and Consistency

Consistent air pressure directly affects the depth at which the nail is driven. Fluctuations in air pressure result in variations in nail depth, leading to inconsistent fastening. This is particularly critical in finish carpentry where uniform nail placement is essential for a professional appearance. A drop in pressure mid-operation can cause nails to protrude, requiring manual correction and increasing labor time.

- Compressor Selection and Maintenance

The choice of air compressor is crucial. The compressor must provide sufficient air volume (measured in cubic feet per minute, CFM) at the required pressure to power the nailer effectively. Regular maintenance of the compressor, including draining moisture and inspecting hoses for leaks, is vital for maintaining consistent air pressure and preventing operational issues. Water in the air lines can lead to corrosion and erratic tool performance.

- Influence on Tool Longevity

Maintaining the correct air pressure not only affects immediate performance but also influences the tool’s lifespan. Operating consistently within the recommended pressure range reduces stress on internal components, minimizing wear and tear. Conversely, excessive pressure accelerates component failure, reducing the nailer’s operational life.

The interplay between air pressure and the 16 gauge dewalt finish nailer is thus a critical element in ensuring efficient, consistent, and long-lasting performance. Proper management of air pressure, through careful compressor selection, diligent maintenance, and adherence to the recommended operating range, is essential for realizing the full potential of this tool.

4. Safety Mechanisms

The integration of safety mechanisms within a 16 gauge dewalt finish nailer is paramount to mitigate risks associated with pneumatic tool operation. These mechanisms are engineered to prevent unintended nail discharge, safeguard the user and bystanders from potential injury, and promote responsible tool handling. Without functional safety features, the risk of accidental nail firing increases significantly, potentially leading to severe puncture wounds. The importance of these mechanisms is underscored by the high-velocity projection of nails, which can cause serious harm even at moderate distances. For example, a contact-actuation trigger, a common safety feature, requires the tool’s nose to be fully depressed against the work surface before the trigger can be activated, preventing firing into open air or against unintended targets.

Specific safety mechanisms commonly incorporated into this tool include the aforementioned contact-actuation (or sequential-actuation) trigger, which necessitates a specific sequence of actions to fire a nail. Another crucial element is the adjustable depth-of-drive, which, beyond influencing finish quality, can also prevent over-driving and ricochet of nails. Proper maintenance of these mechanisms is essential; damaged or malfunctioning safety features render the tool hazardous. Furthermore, strict adherence to manufacturer guidelines regarding personal protective equipment (PPE), such as safety glasses, is crucial in conjunction with the tool’s built-in safety features. A practical application of these safety features is evident in large-scale construction sites, where mandatory PPE and tool safety inspections are enforced to minimize workplace accidents.

In conclusion, safety mechanisms are not merely add-ons but integral components of a 16 gauge dewalt finish nailer, directly impacting user safety and operational responsibility. Understanding and respecting these mechanisms, coupled with proper maintenance and adherence to safety protocols, is essential for minimizing the risk of injury. The challenge lies in consistently reinforcing the importance of these safety features and ensuring that users prioritize safety over expediency, thereby fostering a safer working environment. This emphasis on safety aligns with broader efforts to promote responsible tool usage and prevent avoidable accidents in construction and woodworking industries.

5. Maintenance Schedule

A consistent maintenance schedule is critical for preserving the functionality, extending the lifespan, and ensuring the safe operation of a 16 gauge dewalt finish nailer. Neglecting routine maintenance can lead to performance degradation, increased risk of malfunction, and potential safety hazards. The following schedule outlines key maintenance tasks essential for optimizing the tool’s performance.

- Daily Lubrication

Before each use, the tool requires lubrication with pneumatic tool oil. Introduce a few drops of oil into the air inlet to ensure smooth operation of internal components. This lubrication reduces friction, minimizes wear, and prevents corrosion, thereby extending the life of seals and O-rings. For instance, failing to lubricate can cause seals to dry out and crack, leading to air leaks and reduced power.

- Regular Cleaning

The nailer should be cleaned periodically to remove debris, sawdust, and accumulated grime. Disconnect the air supply and use compressed air to blow out any obstructions from the nail magazine, nosepiece, and other moving parts. A build-up of debris can cause jams, misfires, and inconsistent nail driving. In woodworking environments, sawdust is particularly problematic, as it can compact within the tool’s mechanisms.

- Inspection of Air Hoses and Fittings

Regularly inspect air hoses and fittings for leaks, cracks, or damage. Leaks reduce air pressure, compromising the tool’s performance. Replace any damaged hoses or fittings immediately. Ensure that all connections are secure and airtight. The use of thread sealant on fittings can help prevent leaks and maintain consistent air pressure. Diminished air pressure can lead to nails not being fully driven, increasing the risk of injury.

- Fastener Magazine Maintenance

The fastener magazine, which holds the nails, requires periodic inspection and cleaning. Ensure that the spring mechanism is functioning correctly and that the magazine is free from obstructions. A malfunctioning magazine can cause nail feeding problems, resulting in jams and inconsistent firing. A misaligned magazine can contribute to bent or damaged nails, leading to reduced holding power.

Adhering to this maintenance schedule is essential for preserving the efficiency and safety of a 16 gauge dewalt finish nailer. By proactively addressing these maintenance points, users can minimize downtime, extend the tool’s operational life, and ensure consistent, reliable performance in various woodworking and construction applications. Consistent maintenance not only protects the investment in the tool but also contributes to a safer and more productive work environment.

Frequently Asked Questions

The following addresses common inquiries regarding the operation, maintenance, and application of the specified pneumatic tool.

Question 1: What is the appropriate air pressure for optimal performance?

The recommended operating air pressure is typically between 70 and 100 PSI (pounds per square inch). Consult the tool’s manual for the precise range specific to the model. Exceeding the maximum pressure can damage internal components, while insufficient pressure results in incomplete nail driving.

Question 2: How frequently should the tool be lubricated?

Lubrication is essential before each use. Introduce a few drops of pneumatic tool oil into the air inlet to ensure smooth operation and prevent premature wear of internal components.

Question 3: What type of nails are compatible with this tool?

The tool is designed exclusively for 16-gauge finish nails. Using nails of a different gauge will cause malfunctions and potentially damage the tool. Verify nail length compatibility with the thickness of the material being fastened.

Question 4: How is nail depth adjusted?

Nail depth is adjusted via a dial or similar control, typically located near the tool’s nose. Adjust the setting to ensure nails are driven flush with the surface or slightly countersunk, depending on the material. Test adjustments on scrap material before working on the final piece.

Question 5: What safety precautions should be observed during operation?

Always wear appropriate eye protection. Ensure the tool’s contact-actuation mechanism is functioning correctly. Disconnect the air supply before performing maintenance or clearing jams. Never point the tool at oneself or others.

Question 6: How should the tool be stored when not in use?

Disconnect the air hose and store the tool in a clean, dry environment, away from extreme temperatures and humidity. This prevents corrosion and protects internal components from damage.

Adherence to these guidelines ensures safe, efficient, and reliable operation.

The subsequent section will explore troubleshooting common issues encountered during use.

Conclusion

Throughout this discussion, the capabilities and characteristics of the 16 gauge dewalt finish nailer have been examined. From its core function of driving narrow-diameter fasteners to its nuanced features such as depth adjustment and safety mechanisms, the tool’s inherent design and operation have been thoroughly explored. The importance of proper maintenance, fastener selection, and adherence to safety guidelines has been emphasized to optimize both performance and user safety. Its application in various woodworking tasks, particularly those requiring a balance between holding power and minimal surface impact, has been highlighted.

The utility of the 16 gauge dewalt finish nailer is contingent upon a comprehensive understanding of its operational parameters and responsible handling. Continued adherence to best practices in usage and maintenance will ensure its longevity and consistent performance, contributing to the successful completion of numerous woodworking projects. Investing in such knowledge translates directly into a more efficient, safer, and ultimately more rewarding woodworking experience.

![Best Harbor Freight 16 Gauge Finish Nailer [Review] Best Final Touch: Elevate Your Projects with Professional Finishing Best Harbor Freight 16 Gauge Finish Nailer [Review] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/02/th-39-300x200.jpg)