This pneumatic tool drives thin, headless nails into wood, typically used for delicate trim work. As an example, it affixes decorative molding to walls or secures cabinet facing without leaving a prominent mark.

Its significance lies in its ability to provide a nearly invisible fastening solution. This feature is crucial when aesthetics are paramount. The tool’s historical context situates it as a successor to hammer-and-nail methods, offering improved speed and precision in finishing applications.

The subsequent discussion will delve into specific applications, operational considerations, and maintenance procedures associated with this type of fastening device.

Operational Tips

The following recommendations enhance the performance and longevity of the equipment.

Tip 1: Regulate Air Pressure: Adhere to the manufacturer’s specified pressure range. Excessive pressure can damage the tool and the workpiece; insufficient pressure may result in incomplete nail drives.

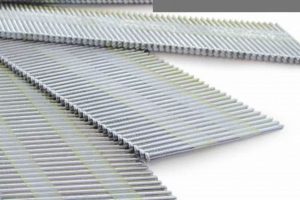

Tip 2: Utilize Appropriate Fasteners: Ensure that the nail length and gauge are suitable for the material thickness and desired holding power. Incompatible fasteners can cause jams or structural weakness.

Tip 3: Maintain a Clean Air Supply: Employ an air compressor with a functioning water separator and filter. Contaminants in the air supply can degrade internal components and reduce operational efficiency.

Tip 4: Implement Proper Tool Placement: Position the tool firmly and squarely against the work surface before actuation. Angled placement can lead to nail bending or misfires.

Tip 5: Lubricate Regularly: Apply pneumatic tool oil to the air inlet before each use. Proper lubrication minimizes friction and wear on internal moving parts.

Tip 6: Inspect the Magazine: Regularly check the nail magazine for debris or damage. Obstructions can impede nail feeding and cause malfunctions.

Tip 7: Store Appropriately: When not in use, store the tool in a clean, dry environment. Protect it from extreme temperatures and humidity to prevent corrosion.

Adherence to these guidelines optimizes performance and extends the operational lifespan of the equipment, minimizing downtime and maximizing efficiency.

The subsequent section provides guidance on common troubleshooting scenarios and maintenance procedures.

1. Fastener Gauge

The term “18 gauge” in the context of this type of finish nailer denotes the diameter of the nails it is designed to drive. An 18-gauge nail possesses a smaller diameter compared to nails of lower gauge numbers (e.g., 16 or 15 gauge). This smaller diameter is a critical factor determining the tool’s suitability for delicate trim work, where minimal visual impact from the fastener is desired. For example, installing fine molding around a window frame benefits from the use of this nailer because the resulting nail holes are less noticeable and require less filling and finishing. The choice of gauge is therefore dictated by aesthetic considerations, as well as the holding power required for the specific application.

The design and engineering of this nailer are specifically tailored to accommodate and effectively drive 18-gauge fasteners. The internal mechanisms, including the driver blade and nail magazine, are calibrated for the precise dimensions of these nails. Attempting to use nails of a different gauge would likely result in tool malfunction, damage, or ineffective fastening. For example, larger gauge nails could jam the mechanism, while smaller gauge nails may not be driven with sufficient force or accuracy. The use of the correct fastener gauge is, therefore, essential for safe and efficient operation.

In summary, the relationship between the “fastener gauge” and this tool is one of defined compatibility. The tool is expressly engineered to function with 18-gauge nails, offering a balance between holding power and minimal visibility. Deviating from this specification introduces potential risks and compromises the intended outcome of the tool’s application. Understanding this constraint is paramount for users to achieve optimal results and maintain the tool’s operational integrity.

2. Air Pressure

Air pressure serves as the motive force behind the operation of the pneumatic tool. It directly influences the velocity and depth to which an 18-gauge nail is driven into the substrate. Insufficient pressure results in nails that protrude from the material, requiring manual setting or compromising the structural integrity of the fastening. Conversely, excessive pressure can cause the nail to be driven too deeply, potentially damaging the workpiece or causing the tool to recoil excessively. The specified operating pressure range, typically found in the manufacturer’s documentation, represents a critical parameter for achieving optimal results. For example, if the recommended pressure is 70-100 PSI, deviating significantly outside this range compromises performance.

Proper air pressure regulation is further linked to the longevity and safe operation of the equipment. Consistently operating at pressures exceeding the recommended maximum accelerates wear on internal components, increasing the likelihood of malfunctions or failures. Conversely, operating below the minimum recommended pressure might cause the tool to stall, leading to inefficient operation and potential damage to the driving mechanism. Furthermore, the air pressure must be consistently maintained. Pressure fluctuations can result in inconsistent nail drives, leading to uneven or unreliable fastening. This is especially problematic in applications requiring a uniform finish, such as installing intricate trim work.

In summary, the relationship between air pressure and the tool’s functionality is direct and indispensable. Precisely regulated air pressure is essential for achieving consistent, reliable fastening, minimizing material damage, and ensuring the prolonged operational lifespan of the equipment. Accurate pressure adjustment, based on the material density and nail length, is a critical skill for any operator seeking professional-quality results and responsible tool stewardship.

3. Tool Weight

The tool weight significantly influences user fatigue and maneuverability during operation. A lighter tool reduces strain on the operator’s arm and wrist, particularly during extended use or when working in awkward positions. Heavier models, while potentially more robust, can lead to decreased precision and increased fatigue, impacting the quality of the finished work. Consider, for example, installing crown molding along a ceiling; a lighter tool facilitates easier overhead work, resulting in a more accurate and consistent installation. The weight is a primary consideration in selecting the appropriate tool for specific tasks.

Furthermore, the tool’s balance, in conjunction with its overall weight, contributes to its handling characteristics. A well-balanced tool minimizes the force required to maintain a stable position, enhancing control and reducing the likelihood of misfires or inaccurate nail placement. In contrast, a poorly balanced tool, regardless of its weight, can be unwieldy and difficult to control, especially when working with delicate materials or intricate designs. Proper weight distribution, therefore, is as crucial as the overall mass of the tool itself.

In summary, tool weight is a critical ergonomic factor affecting both operator comfort and the precision of the finished product. A balanced consideration of weight and maneuverability is essential when selecting the appropriate model, particularly for tasks requiring extended use or demanding a high degree of accuracy. The optimal weight minimizes fatigue while providing sufficient stability for consistent and professional results.

4. Nail Capacity

Nail capacity, concerning the porter cable 18 gauge finish nailer, is a crucial determinant of operational efficiency. It dictates the number of fasteners the tool can hold before requiring a reload, directly impacting workflow and project completion time.

- Magazine Size

The physical dimensions of the nail magazine define the maximum number of nails that can be loaded at one time. A larger magazine reduces the frequency of reloading, improving productivity on extensive projects. For instance, installing baseboards in multiple rooms benefits from a high-capacity magazine, minimizing interruptions.

- Nail Strip Configuration

The arrangement of nails within the magazine affects its capacity and the smoothness of the feeding mechanism. Nails are typically collated in strips or coils, and the design of these collation methods influences both the number of nails that can be accommodated and the reliability of the nail delivery system. A poorly designed strip can lead to jams and reduced capacity.

- Reloading Frequency

The inverse relationship between nail capacity and reloading frequency directly influences task completion speed. Frequent reloading introduces delays and disrupts the workflow, particularly in time-sensitive applications. A nailer with a substantial capacity minimizes these interruptions, allowing for continuous operation and enhanced efficiency.

- Project Scope Considerations

The optimal nail capacity is contingent upon the scope of the project. Smaller projects may not necessitate a high-capacity magazine, while large-scale installations demand a tool that can hold a significant number of fasteners. Selecting a nailer with appropriate capacity aligns with project requirements, maximizing productivity and minimizing downtime.

The facets of nail capacity illustrate its significance in optimizing the performance of the porter cable 18 gauge finish nailer. Magazine size, nail strip configuration, reloading frequency, and project scope all contribute to the overall efficiency and effectiveness of the tool. Understanding these aspects is critical for selecting the appropriate nailer and maximizing productivity in various finishing applications.

5. Applications

The utility of the porter cable 18 gauge finish nailer is intrinsically linked to the specific applications for which it is designed. Its design characteristicsthe gauge of the nails it uses, its power source, and its overall maneuverabilitydictate the types of tasks it can effectively perform. The following details the prominent applications.

- Trim and Molding Installation

This nailer is primarily employed for attaching trim and molding, including baseboards, crown molding, door casings, and window casings. The fine gauge of the nails minimizes visibility, allowing for a clean, professional finish. The pneumatic power ensures consistent nail depth, preventing damage to delicate trim pieces. For example, a carpenter installing intricate chair rail molding in a historical home would likely rely on this tool to preserve the aesthetic integrity of the design.

- Cabinetry Assembly

Within cabinetry, the nailer secures face frames, drawer boxes, and decorative panels. The 18-gauge nails provide sufficient holding power for these components without splitting the wood, a crucial factor in achieving durable and visually appealing cabinets. As an illustration, a cabinet maker assembling a custom kitchen island might use this tool to attach the decorative side panels, ensuring a seamless and robust construction.

- Craft Projects and Fine Woodworking

Its precision and low impact make the tool suitable for various craft projects and fine woodworking applications. It can be used to assemble small wooden boxes, picture frames, and other delicate items. For instance, an artist creating a multi-layered wooden sculpture may employ this nailer to fasten thin pieces of wood together without causing visible damage or distortion.

- Upholstery and Fabric Attachment

While not its primary purpose, this nailer can be used for light-duty upholstery tasks, such as attaching fabric to wooden frames or securing trim to upholstered furniture. The small gauge nails minimize fabric tearing and provide a secure hold. An upholsterer, for instance, might use it to tack fabric to the back of a chair or sofa frame, providing a clean and professional finish.

In summary, the scope of applications for the porter cable 18 gauge finish nailer is defined by its ability to provide a nearly invisible, yet secure, fastening solution. Its versatility across a range of tasks, from delicate trim work to cabinetry assembly, underscores its value as a specialized tool within woodworking and construction trades.

6. Maintenance

Regular maintenance is integral to the sustained performance and longevity of the porter cable 18 gauge finish nailer. Neglecting maintenance protocols precipitates a range of operational impairments, escalating from diminished efficiency to complete tool failure. For instance, insufficient lubrication results in increased friction among internal components, leading to accelerated wear and reduced driving power. Similarly, the accumulation of debris within the air intake or nail magazine obstructs proper function, potentially causing misfires or jams. Consequently, adherence to a structured maintenance regimen is paramount to preserving the tool’s intended capabilities.

Preventive maintenance, encompassing tasks such as daily lubrication with pneumatic tool oil, periodic cleaning of the nail magazine, and inspection of air hose connections, mitigates the risk of operational disruptions. Implementing these measures ensures consistent nail driving force, minimizes the incidence of jams, and prevents premature deterioration of critical components. Furthermore, periodic inspection of the safety mechanism and depth adjustment settings confirms their proper function, enhancing user safety and workpiece quality. Neglecting these checkpoints invites potential hazards and compromised results.

In conclusion, the proactive implementation of maintenance protocols is not merely an ancillary consideration but a fundamental requirement for maximizing the utility and lifespan of the porter cable 18 gauge finish nailer. Addressing potential issues through consistent lubrication, cleaning, and inspection minimizes downtime, ensures consistent performance, and safeguards the user against potential hazards. The long-term cost savings associated with proactive maintenance significantly outweigh the expenditure of time and resources, securing the tool’s ongoing effectiveness and reliability.

Frequently Asked Questions

The following addresses prevalent inquiries concerning the operation, maintenance, and application of the tool.

Question 1: What is the appropriate air pressure setting?

Air pressure should conform to the manufacturer’s specified range, typically 70-100 PSI. Deviations from this range can result in incomplete nail drives or damage to the workpiece and the tool itself.

Question 2: Can this nailer use different gauge nails?

No, this nailer is designed exclusively for 18-gauge nails. Attempting to use nails of a different gauge may cause malfunctions or damage to the internal mechanisms.

Question 3: How frequently should the tool be lubricated?

Lubrication with pneumatic tool oil is recommended before each use. This practice minimizes friction and wear on internal moving parts, prolonging the tool’s operational lifespan.

Question 4: What types of projects are suitable for this nailer?

This nailer is primarily suited for trim and molding installation, cabinetry assembly, craft projects, and light-duty upholstery tasks where minimal nail visibility is desired.

Question 5: What are the common causes of nail jams?

Nail jams can result from using incorrect nail sizes, a dirty or damaged nail magazine, or insufficient air pressure. Regular cleaning and proper nail selection mitigate these issues.

Question 6: How should the tool be stored when not in use?

The tool should be stored in a clean, dry environment, protected from extreme temperatures and humidity. This prevents corrosion and ensures optimal performance during subsequent use.

Adhering to these guidelines optimizes the tool’s performance and extends its operational lifespan.

The following section provides resources for further learning and technical support.

Conclusion

This exploration of the porter cable 18 gauge finish nailer has encompassed its operational characteristics, maintenance requirements, suitable applications, and common troubleshooting scenarios. Understanding these facets is essential for maximizing the tool’s efficiency, prolonging its lifespan, and ensuring operator safety.

Consistent adherence to recommended practices, including proper air pressure regulation, regular lubrication, and the use of appropriate fasteners, will contribute to reliable performance and professional-quality results. Continued diligence in tool maintenance and operational proficiency remains paramount for realizing the full potential of this specialized fastening device.