A battery-powered tool utilized for driving finish nails into wood, primarily employed in trim work and other delicate woodworking applications. This type of power tool offers freedom of movement due to the absence of a compressed air hose or electrical cord. An example of its usage would be attaching baseboards to a wall or assembling decorative molding.

The significance of such a device lies in its portability and convenience, allowing users to perform tasks in locations where traditional pneumatic or corded nailers are impractical. The lack of a hose eliminates setup time and reduces the risk of tripping hazards. The evolution of battery technology has made these tools a viable alternative, offering sufficient power and runtime for most finish carpentry jobs. This has led to increased efficiency and flexibility on job sites.

The subsequent sections will detail specific features, operation, maintenance, and safety considerations relevant to this category of tool. Furthermore, a comparative analysis of different models and their suitability for various tasks will be provided, alongside troubleshooting common issues that may arise during operation.

Operational Tips

The following guidelines are intended to maximize the effectiveness and longevity of the specified fastening device. Adherence to these recommendations will contribute to safer and more efficient project completion.

Tip 1: Battery Maintenance: Ensure batteries are fully charged before each use. Store batteries in a cool, dry environment to prevent degradation. Regular charging and discharging cycles are crucial for optimal battery performance.

Tip 2: Depth Adjustment: Precisely adjust the depth setting to match the material being fastened. Driving nails too deep can damage the workpiece, while insufficient depth compromises holding power. Test the setting on scrap material before proceeding with the final assembly.

Tip 3: Nail Selection: Employ the correct gauge and length of finish nails for the specific application. Using nails that are too large can split delicate wood, while undersized nails may not provide adequate support. Consult fastening charts for guidance.

Tip 4: Proper Stance and Grip: Maintain a stable stance and a firm, balanced grip on the tool during operation. This ensures accuracy and reduces the risk of misfires or accidental injury. Use both hands for optimal control.

Tip 5: Regular Cleaning: Periodically clean the nailer’s nose and driver blade area to remove debris and prevent jamming. Accumulated sawdust and resin can impede the tool’s functionality. Consult the manufacturer’s instructions for proper cleaning procedures.

Tip 6: Air Pressure Management: (If applicable, to models with pneumatic assist) Monitor and maintain consistent air pressure as specified by the manufacturer. Fluctuations in pressure can affect the tool’s performance and lead to inconsistent nail driving.

Tip 7: Storage Practices: Store the tool in a dry, secure location when not in use. This protects it from environmental damage and prevents unauthorized access. Consider using the original packaging or a dedicated tool case for storage.

Tip 8: Safety Precautions: Always wear appropriate eye and ear protection during operation. Furthermore, be aware of the tool’s firing mechanism and take precautions to prevent accidental actuation. Remove the battery when performing maintenance or changing nails.

Following these practices not only enhances the tool’s performance and extends its lifespan but also promotes a safer working environment and yields more professional results. Consistent adherence to these tips ensures the tool operates as intended and maximizes its value.

The subsequent section will delve into troubleshooting common malfunctions, providing practical solutions for resolving issues encountered during operation. This knowledge will further equip the user to maintain the tool’s operational efficiency.

1. Cordless Convenience

Cordless convenience, in the context of a Ryobi cordless finish nailer, refers to the operational freedom and mobility afforded by eliminating the need for a compressed air hose or electrical cord. This characteristic fundamentally alters the user’s workflow and expands the tool’s potential applications.

- Enhanced Mobility and Accessibility

The absence of restrictive tethers allows for unencumbered movement around a workspace. Tasks in remote locations, such as attics or rooftops, become more manageable. Confined spaces, where maneuvering with a hose or cord is cumbersome, are more easily accessible.

- Reduced Setup and Breakdown Time

Eliminating the need to set up and dismantle air compressors or extension cords saves considerable time. This is particularly beneficial in scenarios requiring frequent relocation or short bursts of work. The tool is readily available for immediate use, promoting efficiency.

- Decreased Risk of Tripping Hazards

The removal of hoses and cords from the work area significantly reduces the potential for tripping hazards. This contributes to a safer working environment, minimizing the risk of accidents and injuries. Workplace safety is paramount, and cordless tools mitigate this risk.

- Increased Versatility Across Job Sites

The ability to operate independently of external power sources expands the range of job sites where the tool can be effectively utilized. From residential renovations to outdoor construction projects, the Ryobi cordless finish nailer adapts to diverse environments, maximizing its utility.

These facets of cordless convenience collectively contribute to a more efficient, safer, and versatile tool. The Ryobi cordless finish nailer capitalizes on these advantages, offering a practical solution for a wide array of finishing applications. This design philosophy enhances productivity and overall user experience, making it a valuable asset in both professional and DIY settings.

2. Battery Performance

Battery performance is a critical determinant of a Ryobi cordless finish nailer’s functionality and overall value. The nailer’s ability to consistently drive nails effectively, and for an extended period, hinges directly on the battery’s capacity, discharge rate, and overall health. A battery with insufficient power results in inconsistent nail depth, misfires, or premature cessation of operation, hindering project completion and potentially damaging materials. Consider a scenario where a trim carpenter is installing crown molding in a large room. A battery that quickly depletes forces frequent interruptions for recharging, significantly increasing project duration and labor costs. The practical significance lies in understanding that inadequate battery performance negates the advantages of cordless operation, rendering the tool less efficient than its corded or pneumatic counterparts.

Further analysis reveals that battery technology, specifically the type of battery employed (e.g., lithium-ion), influences the nailer’s performance across various environmental conditions. Lithium-ion batteries, commonly used in these tools, generally exhibit superior energy density and reduced self-discharge compared to older battery chemistries. However, extreme temperatures can still impact their performance. For instance, working in cold weather can reduce battery capacity and power output, potentially affecting the nailer’s ability to drive nails flush. Similarly, overheating can shorten battery lifespan and pose safety risks. Practical applications, therefore, necessitate awareness of these environmental constraints and adherence to manufacturer-recommended operating temperatures and storage guidelines.

In conclusion, battery performance directly dictates the practical utility of a Ryobi cordless finish nailer. Insufficient capacity, poor discharge rates, or vulnerability to environmental factors compromise the tool’s effectiveness and reduce overall user satisfaction. Optimizing battery usage through proper charging, storage, and operating practices is essential to realizing the full potential of the tool. The ongoing challenge involves balancing the demands for increased battery capacity with considerations for tool weight, size, and cost, thereby ensuring a practical and user-friendly design that meets the diverse needs of professionals and DIY enthusiasts alike.

3. Depth Adjustment

Depth adjustment, in the context of a Ryobi cordless finish nailer, constitutes a fundamental feature influencing the quality and precision of fastening operations. It directly governs the degree to which a finish nail penetrates the workpiece, dictating both the aesthetic outcome and structural integrity of the assembled materials.

- Flush Fastening and Surface Preservation

The primary function of depth adjustment is to enable flush fastening, whereby the nail head sits level with the surface of the material. In applications such as installing trim or molding, this is essential for achieving a seamless and visually appealing finish. Overdriving the nail results in unsightly dents or damage to the workpiece, while insufficient depth leaves the nail protruding, creating an uneven surface and compromising the hold. The ability to finely tune the nail depth minimizes these risks.

- Material Compatibility and Nail Size Accommodation

Different materials, such as hardwoods and softwoods, exhibit varying degrees of resistance to nail penetration. Depth adjustment allows the user to compensate for these differences, ensuring consistent and appropriate nail placement regardless of the material’s density. Furthermore, it accommodates variations in nail length, preventing “blow-through” on thinner stock or inadequate fastening with shorter nails in thicker materials.

- Mechanism and Calibration

The depth adjustment mechanism on a Ryobi cordless finish nailer typically involves a dial or knob that regulates the force applied to the nail. This mechanism is often calibrated with markings indicating relative depth settings. Accurate calibration is crucial for consistent performance; a miscalibrated tool can lead to unpredictable nail depths, undermining the benefits of the adjustment feature. Regular inspection and, if necessary, recalibration of the mechanism are therefore essential.

- Impact on Project Outcome and Efficiency

Precise depth adjustment contributes significantly to the overall quality of woodworking and finishing projects. It reduces the need for manual correction, such as using a nail set to countersink protruding nails or filling overdriven holes. This not only saves time and effort but also minimizes the risk of further damage to the workpiece. Consequently, effective depth adjustment enhances both project efficiency and the final aesthetic result.

The interplay between depth adjustment and the capabilities of the Ryobi cordless finish nailer extends beyond mere convenience; it represents a critical factor in achieving professional-grade results. Masterful utilization of this feature empowers the user to adapt to varying materials, nail sizes, and project requirements, ultimately enhancing the tool’s versatility and value.

4. Nail Capacity

Nail capacity, pertaining to a Ryobi cordless finish nailer, is a pivotal specification determining the number of nails the tool’s magazine can accommodate. This attribute directly influences operational efficiency and the frequency of reloading, impacting project workflow.

- Operational Efficiency

A higher nail capacity reduces the need for frequent interruptions to reload the magazine. This directly translates to increased operational efficiency, particularly on larger projects involving extensive trim work or repetitive fastening tasks. Conversely, a lower capacity necessitates more frequent reloading, potentially extending project completion time and disrupting workflow.

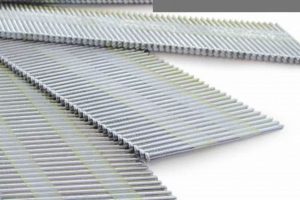

- Magazine Design and Nail Strip Configuration

Nail capacity is intrinsically linked to the design of the nailer’s magazine and the configuration of the nail strips it accepts. Some models feature angled magazines to maximize capacity within a compact form factor, while others utilize straight magazines for simplicity. The type of nail strip (e.g., collated with glue, wire, or plastic) also influences capacity and the ease of loading and unloading.

- Impact on Tool Weight and Balance

Increased nail capacity can potentially impact the tool’s overall weight and balance. A larger magazine designed to hold more nails may add to the tool’s bulk, affecting maneuverability and potentially increasing user fatigue, especially during prolonged use. Manufacturers often strive to balance capacity with ergonomics to optimize user comfort and control.

- Project Suitability

The ideal nail capacity depends largely on the type and scale of projects being undertaken. For small, occasional tasks, a lower capacity may suffice. However, for professional carpenters or contractors engaged in large-scale projects, a higher capacity is generally preferable to minimize downtime and maximize productivity.

Nail capacity, therefore, is a critical consideration when evaluating the suitability of a Ryobi cordless finish nailer for specific applications. Balancing capacity with factors such as magazine design, tool weight, and project requirements is essential to optimizing performance and user satisfaction. The selection should align with the anticipated demands of the tasks at hand to ensure efficient and effective operation.

5. Ergonomic Design

Ergonomic design, in the context of a Ryobi cordless finish nailer, represents a critical consideration that significantly impacts user comfort, reduces fatigue, and enhances overall productivity. The tool’s design must facilitate natural movements, minimize strain on joints, and accommodate a range of hand sizes to ensure optimal usability.

- Grip Design and Material

The grip’s design and material composition directly influence the user’s ability to maintain a secure and comfortable hold. Ergonomic grips often incorporate textured surfaces and contoured shapes to conform to the hand, reducing slippage and minimizing the force required to maintain control. Materials such as overmolded rubber or thermoplastic elastomers provide cushioning and absorb vibration, further reducing fatigue during prolonged use. A poorly designed grip can lead to hand strain, reduced accuracy, and increased risk of repetitive stress injuries.

- Weight Distribution and Balance

The distribution of weight and the tool’s overall balance are essential factors in minimizing user fatigue. A well-balanced nailer allows for more controlled and precise operation, reducing the need for excessive force to maintain its position. An unbalanced tool, particularly one that is top-heavy, can strain the wrist and arm muscles, leading to discomfort and reduced productivity. Ergonomic designs strive for a balanced distribution of weight to minimize these effects.

- Trigger Mechanism and Activation Force

The design of the trigger mechanism and the amount of force required to activate it can significantly impact user comfort and control. A trigger that is too stiff or requires excessive force to pull can lead to finger fatigue and reduced accuracy. Ergonomic designs prioritize triggers that are easily accessible, require minimal force to activate, and provide tactile feedback to indicate actuation. A smooth and responsive trigger mechanism enhances user control and minimizes the risk of accidental misfires.

- Overall Tool Shape and Maneuverability

The overall shape and size of the nailer should facilitate easy maneuverability in a variety of working conditions. Compact designs allow access to tight spaces, while streamlined profiles minimize the risk of snagging on obstacles. Ergonomic designs consider the tool’s dimensions and shape to optimize its handling characteristics, ensuring that it can be comfortably used in a range of orientations and positions. This improves user efficiency and reduces the physical strain associated with awkward or difficult-to-reach fastening locations.

The interplay of these ergonomic facets directly affects the user experience with a Ryobi cordless finish nailer. Designs that prioritize user comfort, reduce fatigue, and enhance control ultimately contribute to improved productivity, increased safety, and reduced risk of injury. The ergonomic design is thus a crucial element in assessing the overall value and suitability of the tool for both professional and DIY applications.

6. Safety Mechanisms

Safety mechanisms integrated within a Ryobi cordless finish nailer are paramount in mitigating the inherent risks associated with power tools. These features are designed to prevent accidental discharge, reduce the potential for user injury, and enhance overall operational safety.

- Contact Actuation Systems

A prevalent safety feature involves contact actuation, requiring the nailer’s nose to be pressed firmly against the workpiece before the trigger can be engaged. This prevents accidental firing if the trigger is inadvertently pulled while the tool is not in the intended operating position. A scenario where this mechanism proves crucial is when the user is repositioning the nailer or navigating around obstacles; the contact actuation prevents unintentional nail discharge.

- Sequential Actuation Mode

Sequential actuation enhances safety by mandating a specific sequence of operations: first, the nose is pressed against the workpiece, and then the trigger is pulled. This mode significantly reduces the risk of “bump firing,” where nails are unintentionally discharged by bouncing the nailer’s nose against the work surface while the trigger is continuously depressed. This mode is particularly beneficial for novice users or in applications where precision and controlled nail placement are paramount.

- Lockout Mechanisms

Lockout mechanisms serve to disable the nailer when not in use, preventing unauthorized or accidental activation. These may take the form of a physical switch or button that must be engaged to permit operation. This feature is particularly important during storage, transportation, or maintenance, minimizing the potential for unintended discharge. A practical example is a lockout switch preventing a child from accidentally operating the tool.

- Depth Adjustment Safeguards

While primarily intended for controlling nail depth, the depth adjustment mechanism can also contribute to safety. By ensuring the nail is consistently driven to the correct depth, it reduces the likelihood of nails protruding from the surface, creating a potential hazard. Furthermore, proper depth setting minimizes the risk of the nailer recoiling excessively, which could lead to loss of control and potential injury.

These safety mechanisms, when functioning correctly, significantly reduce the risk associated with operating a Ryobi cordless finish nailer. However, reliance on these features should not supersede the necessity for adherence to established safety protocols, including the use of personal protective equipment and a thorough understanding of the tool’s operating instructions. Proper training and responsible tool handling remain fundamental to safe operation.

7. Maintenance Needs

The operational lifespan and consistent performance of a Ryobi cordless finish nailer are directly contingent upon adherence to a regular maintenance schedule. Neglecting maintenance protocols can lead to diminished efficiency, premature component failure, and potentially hazardous operating conditions. Consistent attention to these needs ensures the tool remains a reliable and safe asset.

- Cleaning of the Firing Chamber and Nozzle

Accumulation of debris, such as sawdust, nail fragments, and resin, within the firing chamber and nozzle can impede the smooth operation of the driver blade and obstruct the proper seating of nails. Regular cleaning, using compressed air and appropriate solvents, is essential to prevent jamming and ensure consistent nail depth. For example, failure to remove hardened resin can cause the driver blade to stick, resulting in misfires and potential damage to the tool’s internal mechanisms. Neglecting this component will degrade performance over time.

- Battery Maintenance and Storage

The battery pack is a critical component of a cordless finish nailer. Improper charging, storage in extreme temperatures, or allowing the battery to fully discharge can significantly reduce its lifespan and performance. It is imperative to follow the manufacturer’s recommendations for charging and storing the battery. Storing the battery in a cool, dry place when not in use helps preserve its capacity. Furthermore, avoiding deep discharge cycles extends the battery’s overall lifespan, thus preserving the tool’s usability.

- Inspection and Lubrication of Moving Parts

Moving parts, such as the driver blade, piston, and linkages, require periodic inspection for wear and lubrication to ensure smooth operation and prevent premature failure. Applying a light lubricant, as recommended by the manufacturer, reduces friction and minimizes wear on these components. An example of neglect would be a dry piston causing excessive friction within the cylinder, leading to reduced power and eventual seizure. The lubrication ensures the tool can maintain optimal performance.

- Nail Magazine Maintenance

The nail magazine should be inspected regularly for damage or deformation that could impede the smooth feeding of nail strips. Bent or damaged magazine components can cause jams and misfeeds, disrupting the tool’s operation. Cleaning the magazine track to remove debris is also important. Additionally, ensuring the spring mechanism that advances the nail strip is functioning correctly is essential for reliable nail feeding. A malfunctioning magazine renders the nailer useless.

These maintenance facets, although distinct, are interconnected in their influence on the Ryobi cordless finish nailer’s performance and longevity. Diligent adherence to a maintenance routine mitigates the risk of malfunctions and ensures the tool remains a reliable asset for diverse woodworking and finishing applications. The practical benefits of this proactive approach far outweigh the time and effort invested in regular maintenance procedures.

Frequently Asked Questions

The following addresses common inquiries regarding the Ryobi cordless finish nailer, providing objective information to aid understanding and proper usage.

Question 1: What is the expected battery runtime for a Ryobi cordless finish nailer under typical operating conditions?

Battery runtime varies depending on the specific battery amp-hour rating, nail size, wood density, and frequency of use. Under moderate usage, a 4.0 Ah battery can typically drive several hundred nails before requiring a recharge. Observe the battery indicator and refer to the manufacturer’s specifications for precise estimates.

Question 2: Can a Ryobi cordless finish nailer effectively drive nails into hardwoods such as oak or maple?

Yes, but optimal results require selecting the appropriate nail size and adjusting the depth setting accordingly. Hardwoods necessitate a higher depth setting compared to softwoods. Pre-drilling pilot holes may also be beneficial to prevent wood splitting, especially near edges.

Question 3: What is the recommended procedure for clearing a jammed nail from a Ryobi cordless finish nailer?

First, disconnect the battery. Then, consult the tool’s manual for the specific jam clearing procedure, typically involving opening the magazine, removing any obstructions, and resetting the driver mechanism. Avoid using excessive force, which can damage internal components.

Question 4: Is it necessary to use exclusively Ryobi-branded nails with a Ryobi cordless finish nailer?

No, the nailer is generally compatible with any standard finish nails that meet the specified gauge, length, and collation type indicated in the tool’s manual. However, using nails that deviate from these specifications may result in jamming or inconsistent performance.

Question 5: How frequently should a Ryobi cordless finish nailer be cleaned and lubricated?

Cleaning the firing chamber and nozzle should be performed after each use or after driving several hundred nails. Lubrication of moving parts is typically recommended every few months or as needed, depending on usage intensity. Refer to the manufacturer’s guidelines for specific lubrication points and recommended lubricants.

Question 6: What safety precautions should be observed when operating a Ryobi cordless finish nailer?

Always wear appropriate eye and ear protection. Ensure the work area is clear of obstructions. Maintain a firm grip on the tool and keep hands away from the firing zone. Disconnect the battery when performing maintenance or changing nails. Never point the nailer at oneself or others.

Understanding these points promotes safe and efficient operation of the Ryobi cordless finish nailer. Adherence to these guidelines maximizes the tool’s performance and extends its operational lifespan.

The subsequent section provides a comparative analysis of different models available in the market, offering insight into their respective features and suitability for various applications.

Conclusion

The preceding analysis has examined critical aspects of the Ryobi cordless finish nailer, encompassing operational tips, maintenance needs, safety mechanisms, and performance factors such as battery runtime and depth adjustment. Understanding these facets is crucial for maximizing the tool’s utility and ensuring safe operation. Proper application of the discussed techniques and adherence to manufacturer guidelines will yield optimal results across diverse projects.

The information presented aims to empower users with the knowledge necessary to make informed decisions regarding the selection, operation, and maintenance of this class of power tool. Continued awareness of evolving battery technologies and adherence to recommended safety protocols will further enhance the tool’s longevity and contribute to a safer working environment. Future advancements may address improvements in battery capacity and ergonomic design, further increasing the practical utility of this versatile tool.

![Best DeWalt Finish Nailer Deals at Lowe's [Guide] Best Final Touch: Elevate Your Projects with Professional Finishing Best DeWalt Finish Nailer Deals at Lowe's [Guide] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-477-300x200.jpg)