This pneumatic tool is designed for driving 16-gauge finish nails into wood. It is often used in woodworking and carpentry applications, providing a method for fastening trim, molding, cabinetry, and other delicate wood pieces without the visibility of larger nails or screws. Its gauge refers to the thickness of the nails it uses; 16-gauge nails are thicker than 18-gauge but thinner than 15-gauge. An example application is attaching baseboards to walls, where minimizing visible nail holes is desired.

The utilization of such a tool enhances the speed and efficiency of woodworking projects compared to manual nailing. It provides a consistent depth and countersinking of the nails, leading to a cleaner, more professional finish. The history of pneumatic nailers reflects advancements in power tool technology, allowing for greater precision and reduced user fatigue compared to traditional hammer-and-nail methods. Benefits encompass increased productivity, a more refined final product, and reduced risk of wood splitting during fastening.

The subsequent discussion will delve into the specific features, operation, maintenance, and potential applications of this type of fastening equipment, providing a comprehensive understanding of its role in construction and woodworking.

Operational Tips

The following guidelines provide recommendations for optimal performance and longevity of pneumatic fastening equipment.

Tip 1: Regulate Air Pressure. Maintain consistent air pressure within the manufacturer’s specified range. Excessive pressure can drive nails too deep, damaging the workpiece, while insufficient pressure may result in incomplete nail insertion.

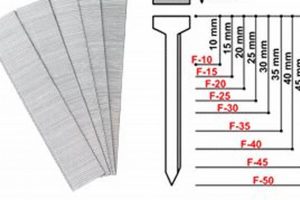

Tip 2: Select Appropriate Nail Length. The nail length should correspond to the combined thickness of the materials being joined. Insufficient nail length compromises holding power, while excessive length can protrude from the back of the workpiece.

Tip 3: Maintain Proper Tool Angle. Ensure the tool is held perpendicular to the work surface during operation. Angled driving can result in bent nails or inconsistent fastening.

Tip 4: Use Safety Glasses. Eye protection is crucial during operation. Debris or errant fasteners can cause serious eye injury.

Tip 5: Regularly Lubricate the Tool. Pneumatic tools require periodic lubrication with pneumatic tool oil. This reduces friction and wear on internal components, extending tool life.

Tip 6: Clear Jammed Nails Promptly. Attempting to force a jammed nail can damage the tool. Follow the manufacturer’s instructions for clearing nail jams.

Tip 7: Store the Tool Properly. When not in use, store the equipment in a clean, dry environment to prevent corrosion and damage. Disconnect the air hose before storage.

Adherence to these guidelines will promote safe and efficient operation, minimizing potential damage to the tool and ensuring consistent fastening results.

The subsequent sections will address specific maintenance procedures and troubleshooting techniques for this type of equipment.

1. Fastening Applications

The utility of a pneumatic finish nailer is directly tied to the types of fastening applications it can effectively address. The specific design and nail gauge capacity dictates the range of suitable tasks. A 16-gauge finish nailer, for example, excels in applications where a balance between holding strength and minimal visibility is required. The cause-and-effect relationship is clear: the desire for a nearly invisible fastener, coupled with the need for adequate holding power, leads to the selection of a 16-gauge tool. This type of equipment is, therefore, a component of projects requiring a refined finish. Examples include installing door and window casings, attaching baseboards and crown molding, assembling cabinet face frames, and securing decorative trim. The selection of this tool for these purposes is based on the understanding that it provides sufficient strength to hold these elements in place while leaving a small, easily concealable nail hole.

The practical significance of this understanding lies in the efficiency and quality of the final product. Incorrect selection of fastening applications may lead to a compromised outcome. Using a nailer with insufficient power for a particular task may result in nails not being fully driven, requiring manual completion and increasing labor. Conversely, using a tool with excessive power can cause damage to the workpiece. For instance, attempting to fasten delicate trim with a framing nailer would likely split the wood. Therefore, selecting the appropriate tool for the task directly affects the time required for completion and the overall quality of the finished product.

In summary, the choice of a 16-gauge finish nailer is directly influenced by the intended fastening applications. These include trim work, molding installation, and cabinet assembly where a balance of holding strength and minimal surface damage is paramount. Challenges arise when materials require greater holding power, necessitating larger gauge fasteners and potentially compromising the desired finish. A thorough understanding of the relationship between these factors is crucial for achieving optimal results in woodworking and finishing projects.

2. Nail Gauge Specificity

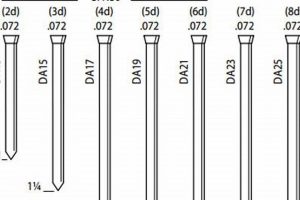

Nail gauge specificity is a defining characteristic of any nailer, including a 16-gauge model. The gauge number indicates the thickness of the nail; a lower gauge number denotes a thicker nail. A 16-gauge tool is engineered to accept and drive nails of this specific thickness. The cause-and-effect relationship is straightforward: the design of the nailer’s magazine, driver, and firing mechanism are calibrated to accommodate 16-gauge nails exclusively. Attempting to use nails of a different gauge will either result in the tool malfunctioning or damaging the internal components. Therefore, nail gauge specificity is a component feature of the tool, precluding interchangeability with other nail sizes. For example, using 15-gauge nails in a 16-gauge finish nailer will likely jam the tool and potentially damage the firing mechanism, while 18-gauge nails would be too thin to be properly driven.

The practical significance of understanding nail gauge specificity lies in ensuring proper tool operation and preventing damage. Users must consistently use the correct gauge of nails specified by the manufacturer. Failure to do so can void the warranty and necessitate costly repairs. Furthermore, the choice of nail gauge directly affects the holding power and aesthetic finish of the work. For instance, a carpenter installing delicate trim will select a 16-gauge nailer because it provides sufficient holding strength while minimizing visible nail holes. A thicker nail, while offering greater holding power, would leave a more prominent mark that would require filling and finishing, increasing labor and potentially detracting from the overall appearance.

In summary, nail gauge specificity is an intrinsic element of nailer design, determining its functional capabilities. This principle dictates the compatible nail size and influences the tool’s suitability for specific applications. Challenges arise when users attempt to deviate from the specified nail gauge, leading to operational issues and potential damage. Therefore, adherence to nail gauge specifications is crucial for safe, efficient, and effective utilization, aligning with the broader goals of professional woodworking and construction practices.

3. Pneumatic Power Source

The operation of a 16-gauge finish nailer relies on a pneumatic power source. This mechanism utilizes compressed air to drive the nail into the workpiece. The cause-and-effect relationship is direct: the application of compressed air activates the internal piston, which, in turn, propels the nail. Without a sufficient supply of compressed air within the specified pressure range, the tool will not function correctly. This relationship is an inextricable component of the equipment’s operational design. For instance, connecting the tool to an air compressor with a pressure setting below the nailers minimum requirement will result in incomplete nail insertion, while exceeding the maximum pressure could damage the tool’s internal seals and mechanisms.

The practical significance of understanding the tool’s reliance on a pneumatic power source resides in ensuring its proper functionality and longevity. A user must possess a compatible air compressor capable of delivering the required pressure and volume of air. The proper setup involves connecting the nailer to the compressor using an air hose equipped with the appropriate fittings. Moreover, routine maintenance of the air compressor, including draining moisture from the tank and maintaining proper oil levels, is crucial for preventing damage to the nailer and ensuring consistent performance. In construction and woodworking environments, this translates to selecting a compressor with adequate capacity for the tasks at hand and implementing regular maintenance schedules to minimize downtime.

In summary, the pneumatic power source forms the foundation for the 16-gauge finish nailer’s operation. Its presence is a necessary element for the tool to drive nails, and its proper maintenance is essential for ensuring reliable and effective performance. Challenges arise when there are inconsistencies in the air supply, such as pressure fluctuations or inadequate air volume, leading to operational malfunctions. Adherence to recommended maintenance procedures and understanding the tool’s air pressure requirements are critical for optimizing its functionality and extending its lifespan.

4. Depth Adjustment Feature

The depth adjustment feature is an integral component of the 16-gauge finish nailer. Its function is to regulate the extent to which the nail is driven into the material. This control allows for countersinking the nail, ensuring the nail head sits flush with or slightly below the surface of the workpiece, and optimizing the quality of the finished project. The cause-and-effect relationship is direct: rotating the depth adjustment mechanism alters the driving depth of the nail. For example, turning the adjustment knob clockwise may decrease the depth, while counter-clockwise rotation increases it. This allows for adaptation to materials of varying densities. This is essential for ensuring a clean finish without damaging the surface.

The practical significance of this feature lies in its ability to adapt to diverse applications. Consider installing trim made of soft pine versus installing trim made of harder oak. The softer pine would require a shallower nail depth to prevent the nail from passing through the material or creating an unsightly indentation. Conversely, harder oak necessitates a greater nail depth to ensure secure fastening. The depth adjustment feature enables the operator to achieve this adaptability, resulting in a professional and consistent finish across varying material types. Therefore, by adjusting the depth, damage to the surrounding material is minimized, and time spent filling and sanding is reduced.

In summary, the depth adjustment feature is a critical element of the 16-gauge finish nailer, enabling precise control over nail penetration. The absence of this control would limit the tool’s versatility and lead to inconsistent results. Challenges arise when the operator fails to properly adjust the depth, leading to either protruding nail heads or surface damage. A thorough understanding of this function and its effect on different materials is crucial for maximizing the tool’s potential and achieving optimal results in woodworking and carpentry tasks. It serves to reduce waste, improve efficiency, and ensure higher quality outcomes in a variety of projects.

5. Maintenance Requirements

The longevity and performance of a 16-gauge finish nailer are directly dependent on adherence to stipulated maintenance requirements. The intricate mechanics of this pneumatic tool necessitate regular upkeep to ensure proper functioning and prevent premature failure. A direct cause-and-effect relationship exists between neglecting maintenance and experiencing operational issues. For example, a failure to regularly lubricate internal components can lead to increased friction, overheating, and ultimately, damage to the tool’s piston and firing mechanism. This aspect of upkeep is not merely an optional consideration; it is a critical component of responsible tool ownership.

Consider the scenario of a professional carpenter who consistently uses a 16-gauge finish nailer for daily trim work. If this individual neglects to regularly oil the tool, clean the air filter, and drain the air compressor tank, the nailer’s performance will degrade over time. The tool may begin to misfire, experience reduced power, or even cease to function altogether. The costs associated with repairing or replacing the damaged tool, coupled with the downtime incurred, can significantly impact productivity and profitability. Conversely, a consistent maintenance schedule, including periodic disassembly and cleaning, can extend the tool’s lifespan and maintain its optimal performance. This is particularly relevant in demanding work environments where the tool is subjected to frequent use and exposure to dust and debris.

In summary, regular maintenance is not merely a recommendation but a fundamental prerequisite for the sustained performance and reliability of a 16-gauge finish nailer. Neglecting these requirements introduces operational challenges and increases the likelihood of costly repairs or replacements. A proactive approach to maintenance, encompassing lubrication, cleaning, and inspection, mitigates risks and ensures consistent, efficient operation, underscoring the interconnectedness between tool upkeep and professional standards in woodworking and construction trades.

Frequently Asked Questions

This section addresses common inquiries regarding the application and maintenance of pneumatic finish nailers.

Question 1: What is the appropriate air pressure for operating a 16-gauge finish nailer?

The optimal air pressure typically falls within the range specified by the manufacturer, generally between 70 and 100 PSI (pounds per square inch). Exceeding the maximum pressure can damage the tool, while insufficient pressure may result in incomplete nail driving. Consult the tool’s manual for precise recommendations.

Question 2: Can different brands of 16-gauge finish nails be used interchangeably?

While 16-gauge nails adhere to a standardized size, variations in collation (the method of holding the nails together) and slight dimensional differences may exist between brands. It is advisable to use nails recommended by the tool manufacturer to ensure proper feeding and prevent jamming.

Question 3: How frequently should a pneumatic finish nailer be lubricated?

Daily lubrication is generally recommended for tools in frequent use. A few drops of pneumatic tool oil should be applied to the air inlet before each use. Refer to the manufacturer’s instructions for specific lubrication guidelines.

Question 4: What causes a pneumatic finish nailer to misfire or jam?

Common causes include insufficient air pressure, incorrect nail gauge, a dirty or damaged driver blade, or a buildup of debris within the tool’s mechanism. Regularly cleaning and maintaining the tool can minimize these issues.

Question 5: Is it necessary to use safety glasses when operating a pneumatic finish nailer?

The consistent utilization of eye protection is imperative. The potential for flying debris or ricocheting fasteners poses a significant risk of eye injury.

Question 6: How should a pneumatic finish nailer be stored when not in use?

The equipment must be disconnected from the air supply, and the magazine should be emptied. Store in a clean, dry environment to prevent corrosion and damage. Consider using the carrying case provided by the manufacturer for protection.

Adhering to these guidelines promotes safe operation and extends the lifespan of the equipment.

The subsequent section will explore troubleshooting techniques for the equipment.

Conclusion

The preceding exploration of the Ryobi 16 gauge finish nailer has detailed its operational principles, maintenance requirements, and application-specific considerations. Essential facets, encompassing gauge specificity, pneumatic power requirements, and depth adjustment functionality, each contribute to the tool’s performance profile. Proper adherence to maintenance protocols and an understanding of its intended applications are necessary for maximizing the tool’s utility and extending its operational lifespan.

Ultimately, the informed and judicious use of this equipment remains the responsibility of the operator. Proficiency in its operation, coupled with diligent maintenance practices, will dictate its effectiveness in contributing to quality workmanship. As technology advances, future iterations may offer enhanced features; however, the fundamental principles of operation and maintenance will remain paramount for any pneumatic fastening system. Prioritizing safety and adherence to established guidelines remains crucial for optimizing results and minimizing potential hazards in any woodworking or construction environment.