The surface treatment applied to wooden cabinetry significantly impacts its appearance, durability, and overall performance. These treatments encompass a variety of materials and techniques designed to protect the wood from moisture, scratches, and fading, while also enhancing its aesthetic qualities. Common examples include varnishes, lacquers, stains, paints, and oil-based applications, each offering distinct characteristics and levels of protection.

Appropriate surface treatments are essential for extending the lifespan of wooden cabinetry and preserving its beauty. They provide a barrier against environmental factors that can cause damage, such as humidity and ultraviolet radiation. Historically, methods employed to protect and beautify wood have evolved from simple natural oils to sophisticated multi-layer coating systems, reflecting advancements in materials science and manufacturing processes. Selecting the right treatment contributes significantly to both the functional performance and the visual appeal of cabinetry within a residential or commercial space.

The following sections will delve into the various types available, explore the factors influencing their selection, and outline best practices for application and maintenance. An overview of common problems and troubleshooting tips will also be provided, offering a comprehensive guide to ensuring the longevity and aesthetic integrity of wooden cabinetry.

Tips Regarding Surface Treatments for Wood Cabinets

Properly selected and applied surface treatments can significantly enhance the lifespan and aesthetic appeal of wood cabinets. The following tips offer guidance on achieving optimal results.

Tip 1: Consider the Wood Species. The type of wood used for the cabinets will influence the choice of surface treatment. Open-grained woods, such as oak and ash, may require a filler to achieve a smooth finish, while closed-grained woods, like maple and cherry, generally do not.

Tip 2: Prepare the Surface Meticulously. A clean, smooth surface is crucial for proper adhesion. Sand the wood thoroughly, starting with a coarser grit and progressing to finer grits. Remove all dust and debris before applying any product.

Tip 3: Test the Product in an Inconspicuous Area. Before applying the chosen treatment to the entire cabinet, test it in a small, hidden area to ensure compatibility with the wood and desired aesthetic result. This minimizes the risk of unwanted outcomes on visible surfaces.

Tip 4: Apply Thin, Even Coats. Multiple thin coats are preferable to a single thick coat. Thin coats allow for proper drying and prevent runs or sags. Follow the manufacturers instructions regarding drying times between coats.

Tip 5: Ensure Adequate Ventilation. When working with solvent-based products, ensure adequate ventilation to avoid the accumulation of harmful fumes. Wear appropriate respiratory protection if necessary.

Tip 6: Use Quality Application Tools. The quality of brushes, rollers, or spray equipment can significantly impact the final result. Invest in high-quality tools appropriate for the chosen treatment.

Tip 7: Consider Environmental Factors. Exposure to sunlight, humidity, and temperature fluctuations can affect the longevity of the surface treatment. Select products formulated to withstand these environmental stressors.

Implementing these tips can help ensure that the selected enhances the cabinets’ beauty and provides lasting protection.

Further research into specific treatment types and application techniques is recommended for optimal results.

1. Protection from Moisture

The susceptibility of wood to moisture necessitates its inclusion as a primary consideration in the selection and application of surface treatments to cabinetry. Water absorption by wood leads to expansion, contraction, warping, and ultimately, decay. A properly selected and applied surface treatment acts as a barrier, inhibiting moisture penetration and preserving the structural integrity of the cabinet. Failure to adequately protect against moisture results in costly repairs or premature replacement of the cabinetry. For example, improperly sealed cabinetry in a humid bathroom is prone to swelling and delamination, significantly shortening its lifespan.

Various types of treatments offer different levels of protection. Film-forming finishes, such as varnishes and lacquers, create a continuous barrier against water. Penetrating oils, while enhancing the wood’s natural grain, typically offer less protection than film-forming options and often require more frequent reapplication. The choice of finish should align with the anticipated moisture exposure level. Kitchen cabinets near sinks or dishwashers, and bathroom vanities, demand a more robust, water-resistant finish compared to cabinetry in drier areas of the home. Furthermore, proper application techniques, including thorough surface preparation and sealing of all edges and joints, are crucial for maximizing protection.

In conclusion, protection from moisture is a fundamental aspect of wood cabinet surface treatments. Ignoring this factor leads to diminished structural integrity, aesthetic degradation, and reduced longevity of the cabinetry. The judicious selection and application of appropriate moisture-resistant finishes, coupled with meticulous attention to detail during the application process, are essential for preserving the investment and ensuring the long-term performance of wooden cabinetry.

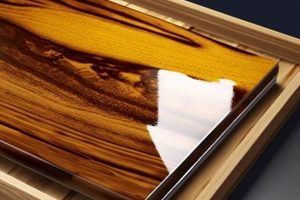

2. Enhancement of Grain

The aesthetic appeal of wood cabinetry is often directly linked to the visibility and clarity of its natural grain pattern. Surface treatments play a crucial role in either highlighting or obscuring this inherent characteristic. The selection of a particular finish directly impacts the final appearance of the wood. Transparent or translucent finishes, such as clear varnishes, oils, and some stains, are specifically chosen to accentuate the grain’s depth and texture. These finishes allow the light to penetrate the surface, revealing the wood’s unique figure. Conversely, opaque paints or heavily pigmented stains tend to conceal the grain, providing a uniform color but sacrificing the natural beauty of the wood. The cause is the inherent properties of the finish itself; transparent mediums permit light transmission, while opaque mediums block it. The effect is a visible grain or a concealed grain, respectively.

The importance of grain enhancement lies in its ability to showcase the intrinsic value and character of the wood. For instance, expensive hardwoods like cherry or walnut are frequently finished with clear coats to highlight their rich color and intricate grain patterns. This approach maximizes the aesthetic return on investment in high-quality materials. Conversely, less expensive woods may be painted to mask imperfections or to achieve a specific color scheme. Practical application of this principle is evident in custom cabinetry, where careful consideration is given to both the wood species and the chosen finish to achieve the desired aesthetic outcome. Cabinetmakers often use staining techniques to subtly alter the color of the wood while still preserving the grain’s visibility.

In conclusion, the enhancement of grain is a deliberate design choice, intricately linked to the selection of appropriate surface treatments. The decision to emphasize or conceal the grain pattern is a critical factor in achieving the desired aesthetic for wood cabinetry. Understanding this connection is essential for homeowners, designers, and cabinetmakers alike, as it directly influences the final appearance and perceived value of the finished product. Challenges arise when balancing the desire for grain enhancement with the need for durability and protection, requiring careful consideration of the specific properties of each available finish.

3. Resistance to Scratches

The susceptibility of wooden cabinetry to surface abrasions necessitates the inclusion of scratch resistance as a critical performance characteristic of any selected protective treatment. The inherent softness of wood, relative to many commonly encountered household materials, renders it vulnerable to scratches, marring the aesthetic appearance and potentially compromising the integrity of the finish. Surface treatments designed to enhance scratch resistance, therefore, function as a protective barrier, minimizing damage from daily use and prolonging the lifespan of the cabinetry. The effectiveness of a given treatment in resisting scratches is directly correlated to its hardness, elasticity, and ability to absorb or deflect impact forces. For example, a kitchen cabinet frequently used for food preparation will be more subjected to scratches and impact, and will be in need of a finish coat with greater impact.

The selection of a surface treatment with adequate scratch resistance requires careful consideration of the intended use and environment of the cabinetry. High-traffic areas, such as kitchens and bathrooms, demand more durable finishes compared to cabinets in less frequently used spaces. Polyurethane coatings, known for their hardness and abrasion resistance, are often preferred for kitchen cabinets. Conversion varnishes, offering even greater durability, are suitable for high-end applications or commercial settings. Conversely, softer finishes like waxes or oils provide minimal scratch resistance and are generally reserved for decorative pieces or low-impact areas. Furthermore, proper application techniques, including multiple thin coats and thorough curing, are essential for maximizing the scratch resistance of any selected treatment. The surface of your cabinets will wear and tear with use; a low-quality finish coat will degrade far faster than its counterpart.

In conclusion, resistance to scratches is a paramount consideration in the selection and application of surface treatments for wood cabinetry. Choosing a finish that provides adequate scratch protection not only preserves the aesthetic appeal of the cabinets but also extends their lifespan and reduces maintenance costs. The decision must be informed by the anticipated usage, environmental factors, and the inherent properties of the available treatment options. The pursuit of durable, scratch-resistant surface treatments reflects a commitment to preserving the value and longevity of wooden cabinetry, balancing aesthetics with practical performance requirements. Future development in finish products may focus on self-healing properties, further enhancing scratch resistance and reducing the visibility of surface damage over time.

4. Color and Tint Variations

The selection of colors and tints in the context of surface treatments profoundly influences the aesthetic character of wooden cabinetry. These variations extend beyond mere surface decoration; they affect the perceived depth, warmth, and style of the cabinetry, thereby shaping the overall ambiance of the space in which they are installed. Understanding the range of available options and their respective impacts is crucial for achieving the desired design aesthetic.

- Stain Application and Wood Undertones

The application of stains introduces color and tint by penetrating the wood’s porous structure. The underlying color and grain of the wood significantly affect the final appearance. For example, applying a cherry stain to pine will yield a different result than applying it to maple due to differing densities and natural undertones. Consequently, test patches are essential to preview the finished color. The type of wood in the cabinet will influence the final result.

- Paint Pigmentation and Opacity Levels

Paint offers a broader spectrum of color options but conceals the wood grain to varying degrees, dependent on the paint’s opacity. Highly pigmented paints provide complete coverage, suitable when a uniform color is desired without highlighting the woods natural features. Conversely, translucent paints allow some of the grain to show through, creating a textured effect. White or light-colored paints can brighten a room, while darker shades add depth and sophistication.

- Glazes and Antiquing Techniques

Glazes and antiquing techniques introduce subtle color variations to the surface, enhancing the cabinetry’s perceived depth and character. These techniques involve applying a thin layer of tinted material over a base coat, then selectively wiping it away to highlight recesses and contours. This method is commonly used to create a vintage or distressed look. Using a brown or black glaze over a white base can bring out the detail in the cabinets profile.

- Dyes and Color Matching

Dyes offer a method for achieving vibrant, translucent colors that highlight the wood grain without obscuring it. They penetrate deeply into the wood, providing a consistent color throughout. Dyes are particularly useful for color matching, where the goal is to precisely replicate an existing color scheme. Color matching involves careful consideration of the dye concentration, application technique, and the wood’s inherent properties. The correct combination will help cabinets tie in with the aesthetic of a room.

These color and tint variations offer a wide range of aesthetic possibilities, each with its own set of advantages and considerations. The selection of an appropriate finish is a critical step in achieving the desired visual effect for wood cabinetry, influencing not only its appearance but also its perceived value and contribution to the overall design of the space. The chosen finish will often affect lighting within the space, as well.

5. Application Method

The method by which surface treatments are applied to wood cabinetry is a critical determinant of the final appearance, durability, and longevity of the finish. Variances in technique directly influence the uniformity, thickness, and adhesion of the coating, ultimately impacting the cabinet’s resistance to wear, moisture, and aesthetic degradation.

- Spraying (Airless, HVLP)

Spraying, utilizing methods such as airless or High Volume Low Pressure (HVLP), facilitates the application of a consistent, even layer of finish across complex surfaces. This method is particularly well-suited for intricate cabinet designs and raised panel doors, minimizing the risk of brush strokes or inconsistencies. However, spraying requires controlled environments to mitigate overspray and ensure proper ventilation. The consistency of an airless spray allows for a fast and clean application.

- Brushing (Natural vs. Synthetic Bristles)

Brushing, employing either natural or synthetic bristle brushes, allows for precise control over finish application, particularly in smaller, detailed areas. Natural bristle brushes are generally preferred for oil-based finishes, while synthetic bristles are better suited for water-based products due to their resistance to swelling. Brushing requires meticulous technique to avoid brush marks and ensure a uniform coat. A benefit to brushing is the ability to get into corners and tight spaces.

- Rolling (Foam vs. Nap Rollers)

Rolling, utilizing foam or nap rollers, is an efficient method for applying finish to large, flat surfaces, such as cabinet sides and doors. Foam rollers provide a smooth, even finish, while nap rollers are better suited for textured surfaces or for applying thicker coatings. Proper rolling technique involves overlapping strokes and consistent pressure to avoid roller marks and ensure uniform coverage. Rolling is a suitable method for large, flat surfaces.

- Wiping (Cloth Application)

Wiping, involving the application of finish with a cloth, is commonly used for penetrating oils, stains, and glazes. This method allows for precise control over the color and depth of the finish, enabling the creation of custom effects and highlighting the natural grain of the wood. Wiping requires careful attention to detail to ensure even distribution and avoid streaking. The nature of the finish will ultimately determine the best application method.

The selection of an appropriate application method is integral to achieving a professional and durable finish on wood cabinetry. Consideration of the specific finish being applied, the complexity of the cabinet design, and the available resources is essential for optimizing the outcome. Skill and attention to detail are needed to ensure success.

6. Longevity of Treatment

The durability of a surface treatment applied to wood cabinetry directly impacts its long-term performance and cost-effectiveness. The lifespan of these finishes is a critical factor in evaluating their suitability, influencing maintenance schedules and replacement requirements. The extended lifespan of a finish will provide a better aesthetic and a more appealing product.

- Environmental Factors and Finish Degradation

Exposure to environmental elements, such as ultraviolet radiation, humidity fluctuations, and temperature variations, significantly affects the rate of finish degradation. Prolonged exposure can lead to fading, cracking, peeling, and delamination. Finishes formulated with UV inhibitors and moisture-resistant properties exhibit greater longevity in challenging environments. Cabinetry in areas with high humidity may need more frequent maintenance.

- Chemical Resistance and Cleaning Practices

The chemical resistance of a surface treatment determines its ability to withstand exposure to household cleaners, solvents, and other potentially damaging substances. Frequent or improper cleaning practices can accelerate finish deterioration. Finishes with superior chemical resistance maintain their integrity and appearance despite regular cleaning, reducing the need for frequent reapplication. Using harsh chemicals may strip or damage the finish.

- Abrasion Resistance and Daily Use

The level of abrasion resistance dictates a finish’s ability to withstand scratches, scuffs, and other forms of physical wear and tear resulting from daily use. High-traffic areas and surfaces subjected to frequent contact require finishes with enhanced abrasion resistance to maintain their aesthetic appeal and structural integrity. Abrasions may allow water to damage the wood beneath the finish coat.

- Maintenance Requirements and Reapplication Frequency

Different types of wood cabinet finishes have different maintenance needs. The frequency with which a finish requires maintenance or reapplication is a key indicator of its longevity. Finishes requiring minimal upkeep and less frequent reapplication offer long-term cost savings and reduced disruption to daily routines. Some finishes, like lacquer, may require more frequent maintenance than others, like varnish.

These factors underscore the importance of selecting wood cabinet finishes that prioritize longevity. A durable treatment minimizes long-term costs and ensures lasting aesthetic appeal, contributing to the overall value and satisfaction derived from the cabinetry. Understanding the interplay between finish properties, environmental conditions, and maintenance practices is essential for making informed decisions that maximize the lifespan of wood cabinet finishes. The durability will give owners the best product for their needs.

Frequently Asked Questions About Wood Cabinet Finishes

The following questions address common inquiries regarding the selection, application, and maintenance of wood cabinet finishes. Information provided aims to clarify crucial aspects for informed decision-making.

Question 1: What factors primarily influence the selection of a wood cabinet finish?

Considerations include the type of wood used, the desired aesthetic (e.g., grain visibility, color), the environment in which the cabinets will be installed (e.g., humidity, UV exposure), and the level of durability required based on usage.

Question 2: Is professional application of wood cabinet finishes always necessary?

While DIY application is possible, professional application is often recommended, particularly for complex finishes or when a flawless result is desired. Professionals possess the expertise and equipment to ensure proper surface preparation, consistent application, and optimal curing.

Question 3: How frequently should wood cabinet finishes be reapplied or maintained?

The reapplication frequency depends on the type of finish, the level of use, and the environmental conditions. High-traffic areas or cabinets exposed to moisture may require more frequent maintenance. Regular cleaning with appropriate products is crucial for extending the lifespan of any finish.

Question 4: What are the potential drawbacks of using inexpensive wood cabinet finishes?

Lower-cost finishes may offer reduced durability, chemical resistance, and UV protection. They may also be more susceptible to scratches, chipping, and fading, leading to more frequent maintenance or replacement.

Question 5: How can one assess the scratch resistance of a wood cabinet finish prior to application?

While formal testing requires specialized equipment, a simple test involves gently scratching a sample area with a fingernail or a soft object. A more robust finish will exhibit minimal or no visible scratching.

Question 6: What steps should be taken to prepare wood cabinets for refinishing?

Proper preparation includes removing existing finishes through sanding or chemical stripping, cleaning the surface thoroughly, and repairing any damages. The surface must be smooth, clean, and dry before applying any new finish.

Selecting the appropriate finish for wood cabinetry depends on balancing aesthetic preferences with practical needs. Careful consideration of the factors outlined above can assist in making informed decisions.

The following section provides an overview of common problems encountered with wood cabinet finishes and offers potential solutions.

Conclusion

The preceding discussion has explored the multifaceted aspects of wood cabinet finishes, encompassing selection criteria, application methodologies, and performance characteristics. Understanding the nuances of moisture protection, grain enhancement, scratch resistance, color variations, application techniques, and treatment longevity is paramount for informed decision-making. The selection of appropriate wood cabinet finishes significantly impacts the long-term aesthetic and functional performance of cabinetry.

Consideration of these factors facilitates a more durable and visually appealing outcome. Ongoing research and development in material science promise advancements in wood cabinet finishes, leading to enhanced performance and sustainability. Continued diligence in selection, application, and maintenance is essential to safeguard the investment in wooden cabinetry.