A coating that provides a durable, glossy surface is often desired for wood, metal, and other materials. This type of product typically dries quickly, forming a hard and smooth film. For example, it’s often used on furniture to enhance its appearance and protect it from wear.

This protective and decorative layer offers several advantages. Its resistance to scratches and chemicals ensures longevity, making it suitable for high-use items. Historically, it has been prized for its ability to impart a lustrous sheen, enhancing the aesthetic value of various objects and surfaces.

The following sections will delve deeper into the application techniques, safety considerations, and various types of materials available, offering a comprehensive understanding of achieving a professional-quality result.

Application Guidelines

These guidelines provide key considerations for achieving optimal results with this type of coating.

Tip 1: Surface Preparation: Ensure the substrate is clean, dry, and free of any contaminants. Sanding the surface prior to application enhances adhesion. Any imperfections should be addressed before proceeding.

Tip 2: Thinning the Material: Proper thinning is crucial for a smooth application. Refer to the manufacturer’s instructions for the appropriate thinner and mixing ratios. Insufficient thinning can lead to orange peel texture, while excessive thinning can result in runs.

Tip 3: Application Method: Spray application generally yields the most even finish. Use a consistent spray pattern, overlapping each pass by approximately 50%. Multiple thin coats are preferable to a single thick coat.

Tip 4: Environmental Conditions: Temperature and humidity play a significant role in the drying process. Avoid applying in excessively humid or cold environments. Optimal conditions typically range from 65F to 75F with moderate humidity.

Tip 5: Sanding Between Coats: Lightly sand between coats with fine-grit sandpaper (e.g., 400-grit or higher) to remove any imperfections and improve adhesion of subsequent coats. Clean the surface thoroughly after sanding.

Tip 6: Safety Precautions: Always wear appropriate personal protective equipment, including a respirator, gloves, and eye protection. Ensure adequate ventilation in the work area to prevent the buildup of harmful vapors.

Tip 7: Curing Time: Allow sufficient curing time for the coating to fully harden. Consult the manufacturer’s specifications for recommended curing times. Premature handling can damage the finish.

Adherence to these guidelines will contribute to a durable and aesthetically pleasing outcome. Careful preparation, proper application techniques, and attention to safety protocols are essential for achieving professional-quality results.

The following sections will cover common issues, troubleshooting steps, and maintenance procedures.

1. Durability

The lifespan of any surface treatment is paramount, and the correlation between a robust outer layer and its longevity is undeniable. This class of coating is valued for its capacity to create a hard, protective film, which directly impacts the resistance to scratches, abrasion, and chemical exposure. Consequently, its implementation often extends the functional lifespan of the underlying material. For example, wooden furniture treated with this substance exhibits superior resistance to daily wear compared to untreated or less resilient finishes.

Consider musical instruments, where the coating is not only for aesthetic enhancement but also acts as a barrier against environmental factors such as humidity and temperature fluctuations. A durable finish prevents warping, cracking, and other damage that can compromise the instrument’s sound quality and structural integrity. Furthermore, in automotive applications, its durability ensures protection against road debris, UV radiation, and corrosive substances, preserving the vehicle’s appearance and structural components.

Ultimately, the durability conferred by this type of coating is a critical factor in its selection across diverse applications. By providing a resilient barrier against external stressors, it offers long-term protection and aesthetic preservation, contributing significantly to the overall value and lifespan of the coated object. The selection of appropriate application methods and maintenance procedures are crucial to maximizing its durability potential.

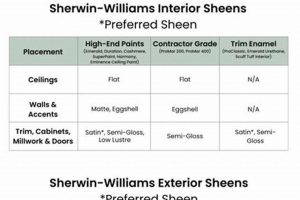

2. Gloss Level

Gloss level, a critical attribute of a coating, significantly influences the visual characteristics of surfaces treated with this type of coating. It pertains to the degree of light reflection from the surface, impacting the aesthetic appeal and perceived quality of the finished product. Different applications call for different levels of sheen, dictating the specific type of coating used.

- Measurement and Types

Gloss levels are typically measured using a gloss meter, which quantifies the amount of light reflected at specific angles. These measurements are categorized into distinct types: matte, satin, semi-gloss, and high-gloss. Matte surfaces diffuse light, resulting in a low sheen, while high-gloss surfaces reflect light almost specularly, creating a mirror-like appearance. The selection of the appropriate type depends on the intended visual effect and the functional requirements of the coated object.

- Aesthetic Impact

The chosen gloss level dramatically affects the perceived look and feel of the coated item. High-gloss finishes often convey a sense of luxury and modernity, making them popular for furniture, automotive coatings, and musical instruments. Matte finishes, conversely, offer a more subdued, contemporary aesthetic, often favored in interior design applications where glare reduction is desirable. Satin and semi-gloss finishes provide a balance between reflectivity and subtlety, suitable for a wide range of applications.

- Durability and Maintenance

Gloss level can also influence the durability and maintenance requirements of the coated surface. High-gloss finishes, while visually appealing, tend to show scratches and imperfections more readily than matte finishes. Therefore, they may require more frequent cleaning and maintenance to preserve their pristine appearance. Matte finishes, with their diffused light reflection, are better at concealing minor blemishes, making them a more practical choice for high-traffic areas or surfaces prone to wear and tear.

- Application Specifics

Achieving the desired gloss level depends on various factors, including the product formulation, application technique, and environmental conditions. Proper surface preparation, thinning ratios, and spray gun settings are essential for ensuring uniform gloss distribution. Multiple thin coats are generally preferable to a single thick coat, as they allow for better leveling and minimize the risk of imperfections. Post-application polishing may also be necessary to achieve the desired level of sheen.

In summation, gloss level is a pivotal consideration when selecting this coating. Its effect extends beyond mere aesthetics, influencing the perceived quality, durability, and maintenance requirements of the coated item. A thorough understanding of gloss levels and their implications is essential for achieving the desired outcome and ensuring long-term satisfaction.

3. Application Method

The process by which this coating is applied significantly influences the final quality and performance. Selecting an appropriate application method is critical to achieving a smooth, durable, and aesthetically pleasing finish.

- Spray Application

Spray application, typically utilizing compressed air or airless spray systems, is widely regarded as the superior method for applying this type of coating. This technique ensures an even, uniform film thickness, minimizing the risk of brush strokes or roller marks. Proper equipment calibration and technique are crucial to avoid issues such as runs, sags, or orange peel texture. Examples include automotive refinishing and high-end furniture manufacturing, where a flawless appearance is paramount. The consistency and control afforded by spray application contribute to maximizing the coating’s protective and aesthetic properties.

- Brush Application

Brush application, while less common for large-scale projects, can be suitable for smaller, intricate areas or touch-up work. Selecting a high-quality brush with fine bristles is essential to minimize brush marks. Multiple thin coats, applied with even pressure, are preferable to a single thick coat. This method requires greater skill and attention to detail to achieve a satisfactory result. An example would be detailed trim work on cabinetry or furniture restoration, where precision is more important than speed. However, brush application typically results in a less uniform finish compared to spraying.

- Roller Application

Roller application is generally not recommended due to the propensity for creating an uneven finish and introducing air bubbles. The textured surface of a roller can leave visible marks, detracting from the smoothness that this finish is prized for. While certain specialized rollers designed for smooth surfaces exist, they still do not typically achieve the same level of quality as spray application. In specific cases, a foam roller might be used for applying a base coat or sealer before subsequent spray applications, but it is rarely used for applying the topcoat itself.

- Electrostatic Application

Electrostatic application is a specialized technique used in industrial settings. It involves charging the coating particles and the object being coated with opposite electrical charges. This creates a strong attraction between the particles and the object, resulting in high transfer efficiency and minimal overspray. This method is often used in mass production environments, such as coating metal components, where uniformity and efficiency are critical. The even coating and reduced waste make electrostatic application an efficient and environmentally conscious choice for large-scale operations.

The selection of an appropriate application method for this coating hinges on factors such as the size and complexity of the project, the desired finish quality, and the available equipment and skill level. While spray application generally yields the best results, alternative methods may be suitable for specific applications or circumstances. Understanding the strengths and limitations of each technique is crucial for achieving a satisfactory outcome.

4. Drying time

The period required for a coating to fully cure is a critical factor influencing project timelines, handling procedures, and overall finish quality. This is particularly relevant when utilizing this type of finish due to its unique chemical composition and fast-drying characteristics.

- Solvent Evaporation Rate

The fast drying time associated with this type of coating is primarily due to the rapid evaporation of solvents. This characteristic distinguishes it from other coatings that cure through oxidation or polymerization. For instance, a typical application may become touch-dry within minutes, allowing for subsequent coats to be applied relatively quickly. This rapid evaporation, however, necessitates careful control of environmental factors, such as temperature and humidity, which can significantly affect the solvent release rate and, consequently, the uniformity of the finish. Lower temperatures and high humidity can retard evaporation, leading to prolonged drying times and potential for defects.

- Film Build and Thickness

The thickness of each applied coat directly impacts drying time. Thicker coats require a longer period for complete solvent evaporation. Application of excessive material in a single coat can lead to solvent entrapment, resulting in a soft, uncured finish beneath a seemingly dry surface. This can compromise the durability and adhesion of the coating. Multiple thin coats are generally recommended to facilitate proper drying and achieve optimal film build without extending the overall drying time excessively. Control of the application process is thus crucial.

- Environmental Factors

As previously mentioned, ambient temperature and humidity play a significant role in determining the overall drying time. High humidity levels impede solvent evaporation, while low temperatures slow down the process. Adequate ventilation is also essential to facilitate the removal of solvent vapors. In industrial settings, controlled drying environments are often employed to maintain consistent and predictable drying times. For instance, heated spray booths are commonly used to accelerate drying and ensure proper curing, regardless of external environmental conditions. Maintaining optimal conditions is critical for achieving the desired finish properties.

- Recoat Windows and Cure Times

The term “recoat window” refers to the period during which subsequent coats can be applied without requiring additional surface preparation, such as sanding. This is a critical consideration, as exceeding the recoat window necessitates additional steps, adding time and complexity to the project. Full cure time refers to the period required for the coating to reach its maximum hardness and chemical resistance. Premature handling or use of the coated object before full cure can damage the finish and compromise its protective properties. Understanding both recoat windows and full cure times is essential for planning and executing projects effectively.

Understanding the interplay between solvent evaporation, film thickness, environmental conditions, and the associated recoat windows and cure times is paramount when working with this finish. Careful attention to these factors enables efficient application, minimizes the risk of defects, and ensures the long-term durability and aesthetic appeal of the finished product.

5. Chemical resistance

The ability to withstand exposure to various chemical substances is a critical attribute for any surface coating, directly influencing its longevity and applicability in diverse environments. The degree to which this type of coating resists degradation or alteration upon contact with chemicals determines its suitability for specific applications. A lack of resistance can lead to discoloration, softening, blistering, or complete failure of the finish, rendering it ineffective as a protective barrier. For example, a surface coated with a chemically vulnerable material may become permanently damaged if exposed to common household cleaners or industrial solvents.

The inherent chemical resistance is determined by the specific formulation of the product, including the resins, solvents, and additives employed. Certain formulations exhibit high resistance to acids, alkalis, and solvents, making them suitable for use in laboratories, manufacturing facilities, or areas prone to spills and chemical exposure. Conversely, other types may be more susceptible to degradation from even mild chemicals, limiting their use to less demanding environments. The selection of an appropriate product, therefore, requires a thorough understanding of the anticipated chemical exposure and the corresponding resistance characteristics. For instance, coatings used on laboratory benchtops must withstand exposure to a broad range of chemicals, whereas coatings used on furniture may only require resistance to common household substances.

Ultimately, the significance of chemical resistance lies in its direct impact on the functional lifespan and aesthetic integrity of the coated surface. Proper selection of a product with adequate resistance ensures long-term protection, reduces maintenance costs, and preserves the appearance of the treated object or area. Furthermore, understanding the limitations of a given coating in terms of chemical exposure is crucial for preventing premature failure and ensuring a safe and functional environment. The long-term cost-effectiveness of a surface treatment is inextricably linked to its ability to withstand chemical challenges, making it a critical consideration in material selection and application.

6. Surface preparation

The adherence and final appearance of this finish are critically dependent on the quality of surface preparation. Inadequate surface preparation directly compromises adhesion, leading to premature chipping, peeling, and overall failure of the coating. The presence of contaminants, such as dirt, grease, or existing coatings, prevents a proper bond between the surface and the applied product, resulting in a weak and unreliable finish. For instance, applying this coating over a greasy surface will inevitably lead to poor adhesion and eventual delamination. Proper surface preparation ensures a stable and receptive substrate, maximizing the lifespan and aesthetic quality of the coating.

Specific methods of surface preparation vary depending on the substrate material and the presence of existing coatings or contaminants. Sanding is a common technique used to create a mechanical key for the coating to adhere to. This process involves abrading the surface to create microscopic irregularities that increase the surface area available for bonding. The grit of sandpaper used should be appropriate for the material being prepared, with coarser grits used for removing existing finishes and finer grits used for creating a smooth, uniform surface. For example, preparing wood for finishing typically involves sanding with progressively finer grits, followed by thorough cleaning to remove dust and debris. Metal surfaces may require degreasing and etching to remove contaminants and promote adhesion.

Ultimately, the success of any project involving this finish hinges on meticulous surface preparation. By removing contaminants, creating a receptive surface profile, and ensuring proper cleaning, the likelihood of achieving a durable, aesthetically pleasing, and long-lasting finish is significantly enhanced. Neglecting this critical step inevitably leads to compromised results and potential rework, underscoring the importance of thorough and professional surface preparation techniques.

7. Thinning ratio

The thinning ratio is a critical parameter directly affecting the performance and application of this coating. It defines the proportion of thinner added to the coating to achieve the desired viscosity for spraying or brushing. An incorrect ratio can result in a range of application and finish defects, compromising the coating’s protective and aesthetic properties. For example, if a manufacturer recommends a 2:1 coating-to-thinner ratio, deviating significantly from this recommendation will likely lead to problems. Exceeding the recommended thinner volume can lead to runs, sags, and reduced film build. Conversely, insufficient thinning can result in poor atomization, orange peel texture, and difficulty in achieving a smooth, even finish. Therefore, precise adherence to the manufacturer’s specifications is essential for optimal results.

The appropriate thinning ratio depends on several factors, including the application method, the ambient temperature, and the desired film thickness. Spray application typically requires a greater degree of thinning than brush application to ensure proper atomization and flow. Higher temperatures can also necessitate increased thinning to compensate for the coating’s increased viscosity. Furthermore, the desired film thickness influences the thinning ratio; thinner coats generally require a more diluted mixture. In practical terms, a furniture refinisher might adjust the thinning ratio based on the specific spray equipment used and the prevailing environmental conditions in the workshop. Adjustments should be made cautiously and incrementally, with test sprays or brushouts performed to verify the suitability of the modified ratio before applying the coating to the entire project.

In conclusion, the thinning ratio is an indispensable component of successful application and achieving the desired properties of this coating. Maintaining precise adherence to the manufacturer’s recommendations, while accounting for application method and environmental factors, is crucial. Deviations from the recommended ratio can lead to various problems, impacting the coating’s performance, durability, and aesthetic qualities. Mastering the art of appropriate thinning requires both theoretical knowledge and practical experience, and the consequences of ignoring it can be significant and costly.

Frequently Asked Questions About Lacquer Finish Paint

This section addresses common inquiries regarding the properties, application, and performance characteristics of this coating. Careful review of these points can aid in informed decision-making and optimal utilization of this finish.

Question 1: Is this type of coating suitable for outdoor applications?

Generally, this type of coating is not recommended for prolonged outdoor use due to its limited UV resistance and potential for cracking or discoloration under direct sunlight. Specific formulations may offer improved UV resistance, but alternatives designed explicitly for outdoor environments are often preferable.

Question 2: What is the expected lifespan of this finish on a high-use surface?

The lifespan depends on factors such as surface preparation, application quality, and the level of wear and tear. Under typical indoor conditions, a properly applied coating can last for several years. However, high-use surfaces may require periodic maintenance or recoating to maintain their appearance and protective properties.

Question 3: How does one properly dispose of excess coating materials?

Proper disposal involves adhering to local regulations for hazardous waste. Excess coating materials should never be poured down drains or disposed of in regular trash. Contacting a local waste management facility or hazardous waste disposal service ensures compliance with environmental regulations and prevents potential contamination.

Question 4: What are the potential health hazards associated with its application?

This type of coating typically contains volatile organic compounds (VOCs) that can pose health hazards if inhaled or absorbed through the skin. Proper ventilation, the use of respirators, and protective clothing are essential to minimize exposure. Refer to the safety data sheet (SDS) for detailed information on potential health risks and safety precautions.

Question 5: Can this coating be applied over existing finishes?

Applying it over existing finishes requires careful surface preparation and compatibility testing. Incompatible coatings can lead to adhesion problems or undesirable reactions. Sanding the existing finish to create a mechanical key and applying a primer can improve adhesion, but a test area is recommended to verify compatibility.

Question 6: How does one achieve a high-gloss finish with this type of product?

Achieving a high-gloss finish involves meticulous surface preparation, proper thinning, and a controlled application technique. Multiple thin coats, followed by sanding with progressively finer grits and buffing, are often required. Proper spray equipment and environmental conditions are also essential for achieving a flawless, high-gloss surface.

In summary, a thorough understanding of its limitations and proper application techniques is crucial for maximizing the benefits of this coating.

The following section will address safety measures for applying this type of coating.

Lacquer Finish Paint

This exploration has presented various aspects of lacquer finish paint, encompassing its definition, application methodologies, and critical considerations such as durability, gloss level, thinning ratios, and safety protocols. The materials efficacy is contingent on adherence to established best practices and a thorough understanding of its inherent limitations. Proper application and maintenance are paramount to achieving optimal results and maximizing the lifespan of treated surfaces.

The information provided serves to underscore the importance of informed decision-making when utilizing lacquer finish paint. Its inherent properties and application complexities necessitate a conscientious approach to ensure both performance and safety. Further research and adherence to manufacturer specifications are strongly encouraged to fully leverage the potential of this surface treatment.