Superior coatings designed for vehicles represent a pinnacle in aesthetic enhancement and protective technology. These specialized applications go beyond standard paint jobs, providing a richer, more durable, and visually striking surface. For instance, a multi-layered ceramic coating, meticulously applied to a luxury sedan, exemplifies this level of refinement, offering enhanced gloss and resistance to environmental damage.

The utilization of these specialized coatings is crucial for preserving vehicle value and ensuring long-term aesthetic appeal. Beyond mere appearance, these treatments offer significant protection against scratches, UV rays, and chemical contaminants. Historically, the pursuit of ever-more durable and visually impressive auto surfaces has driven innovation in material science, leading to the advanced formulations available today.

The subsequent discussion will explore the specific types of these advanced coatings, the application processes involved, and the factors that contribute to their superior performance. Further consideration will be given to the maintenance requirements necessary to preserve the integrity and appearance of these premium treatments.

Preserving Superior Automotive Coatings

The following guidelines are designed to maintain the integrity and appearance of premium vehicle surface treatments.

Tip 1: Implement Routine Washing Procedures: Regular washing, employing pH-neutral soaps, is essential to remove surface contaminants before they bond to the coating. Avoid abrasive sponges or brushes that could induce scratching.

Tip 2: Utilize Microfiber Towels: When drying, employ high-quality microfiber towels. Their soft fibers minimize the risk of swirl marks, ensuring a flawless finish.

Tip 3: Address Contaminants Promptly: Immediately remove bird droppings, insect residue, and tree sap. These substances can etch the coating if left unattended, necessitating professional correction.

Tip 4: Consider Professional Detailing: Periodic professional detailing is recommended to rejuvenate the coating and address any imperfections that may arise over time. Experienced detailers possess the tools and expertise to maintain the surface’s optimal condition.

Tip 5: Avoid Automatic Car Washes: Automated car washes often employ harsh brushes and chemicals that can degrade the coating. Opt for hand washing or touchless car washes whenever possible.

Tip 6: Apply a Coating-Specific Sealant: Use a sealant formulated for the specific type of coating applied to the vehicle. These sealants provide an additional layer of protection against environmental elements.

Tip 7: Protect from Extreme Temperatures: Extended exposure to extreme heat or cold can compromise the coating’s integrity. Consider covered parking or a garage to mitigate these effects.

Consistently adhering to these recommendations will contribute to the longevity and aesthetic appeal of superior automotive surface treatments, protecting the investment and maintaining the vehicle’s pristine appearance.

The subsequent section will delve into the advanced technologies employed in the application and maintenance of these coatings, offering further insights into achieving optimal results.

1. Durability

Durability, in the context of superior automotive surface treatments, transcends mere resistance to scratches. It represents a comprehensive measure of a coating’s ability to withstand a range of environmental and mechanical stressors over an extended period, directly impacting the vehicle’s long-term appearance and value.

- Resistance to Environmental Degradation

Exposure to ultraviolet (UV) radiation, acid rain, and road salts are primary drivers of coating degradation. Premium coatings incorporate UV inhibitors and chemically resistant polymers to mitigate these effects. For example, a ceramic coating formulated with silane polymers forms a robust barrier against chemical etching and fading, preserving the underlying paintwork from environmental assaults.

- Abrasion Resistance

Minor abrasions from washing, road debris, and incidental contact can dull a vehicle’s finish over time. High-performance coatings are engineered to withstand these micro-scratches. This is accomplished through advanced cross-linking and surface hardness properties. This improved abrasion resistance minimizes swirl marks and maintains gloss, increasing the coating’s and the car’s longevity.

- Impact Resistance

While not designed to withstand major collisions, specialized coatings can offer a degree of impact resistance against minor chips from road hazards. The coating’s flexibility allows it to absorb some of the impact energy, reducing the likelihood of damage propagating to the underlying paint. A polyurethane-based coating, for example, offers superior flexibility compared to standard clear coats, providing a measure of chip resistance.

- Longevity and Lifespan

Durability is intrinsically linked to the lifespan of the protective layer. High-quality finishes are formulated for long-term performance, maintaining their protective properties and appearance for many years. This extended lifespan reduces the need for frequent reapplication, making them a long-term investment. The use of self-healing polymers or advanced ceramic materials are examples of technologies that enhance a coating’s long-term durability and maintain a lasting visual impact.

These multifaceted aspects of durability, inherent in superior automotive coatings, ensure the vehicle’s exterior remains pristine, resisting the detrimental effects of environmental factors and mechanical stresses. This resistance translates directly into sustained aesthetic appeal, enhanced resale value, and reduced maintenance costs over the vehicle’s lifespan.

2. Protection

The primary function of specialized vehicle surface treatments extends beyond mere aesthetics; these applications provide a critical layer of defense against environmental and physical threats. The protective characteristics inherent in these coatings represent a direct benefit, mitigating damage caused by a variety of factors and preserving the underlying vehicle structure. For instance, consider the corrosive effects of road salt on unprotected metal surfaces. A high-quality ceramic coating acts as a barrier, preventing the salt from directly contacting and degrading the vehicle’s chassis. This protective measure directly translates to a longer vehicle lifespan and reduced maintenance costs related to rust repair.

Specific examples highlight the breadth of protection afforded by these advanced finishes. UV radiation from sunlight can cause fading and oxidation of standard paint. Premium coatings incorporate UV absorbers that dissipate harmful radiation, safeguarding the vehicle’s color and gloss. Furthermore, the hydrophobic properties of certain coatings repel water and contaminants, reducing the likelihood of water spots and stains. The practical application of this protection is evident in areas with harsh weather conditions, where vehicles coated with these superior finishes maintain their appearance and structural integrity for a longer period, compared to those without such protection. Additionally, the chemical resistance offered by many elite automotive finishes guards against damage from acidic substances such as bird droppings or industrial fallout, preventing permanent etching or discoloration.

In summation, the protective properties of specialized automotive coatings constitute a significant and tangible benefit. They act as a proactive shield against environmental and physical damage, preserving the vehicle’s aesthetic appeal, structural integrity, and overall value. Understanding the mechanisms by which these coatings provide protection is crucial for making informed decisions about vehicle maintenance and ensuring the longevity of the investment. While challenges remain in developing coatings that offer complete protection against all potential threats, ongoing research and development continue to improve the effectiveness and durability of these essential protective layers.

3. Appearance

The perceived visual quality of a vehicle’s exterior is directly correlated to the application of premium automotive surface treatments. These specialized coatings elevate the aesthetic presentation beyond that achievable with standard paint systems. The enhancements encompass increased gloss, improved color depth, and a smoother surface texture. For instance, a vehicle treated with a multi-layer ceramic coating exhibits a noticeably richer and more reflective finish compared to a factory-standard clear coat. This heightened visual appeal contributes significantly to the vehicle’s perceived value and desirability.

The contribution of advanced automotive coatings to appearance extends beyond initial application. These finishes are engineered to maintain their aesthetic qualities over time, resisting fading, oxidation, and the accumulation of surface imperfections. Self-healing properties, incorporated into some coatings, mitigate minor scratches and swirl marks, preserving the smooth, reflective surface. A dark-colored vehicle, notoriously susceptible to showing swirl marks, benefits significantly from such a coating, retaining its deep, lustrous appearance for an extended period. This long-term preservation of visual appeal reduces the need for frequent detailing and contributes to the vehicle’s enduring attractiveness.

In summary, the appearance of a vehicle is materially enhanced by the selection and proper application of specialized surface treatments. These coatings not only provide an immediate improvement in gloss, color depth, and surface smoothness, but also contribute to the long-term preservation of these aesthetic qualities. The correlation between specialized surface treatments and vehicle appearance is a critical factor in maintaining a vehicle’s perceived value and overall desirability, highlighting the practical significance of investing in these advanced coatings.

4. Technology

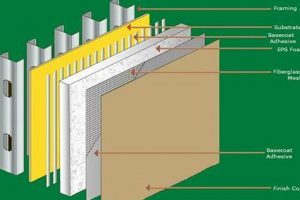

The development and application of specialized vehicle surface treatments are inextricably linked to advancements in material science, chemistry, and engineering. The sophisticated performance characteristics of these coatings, encompassing durability, protection, and appearance, are directly attributable to technological innovations. For example, the creation of ceramic coatings relies on nanotechnology to formulate particles that bond at a molecular level with the vehicle’s paint. This process generates a hard, durable layer resistant to scratches and chemical contaminants, a feat unattainable with traditional paint technologies. The technological component is, therefore, not merely an adjunct but a fundamental requirement for achieving the attributes associated with superior automotive coatings.

Further examples illustrate the practical application of technology within the field. Self-healing clear coats leverage polymer chemistry to enable minor scratches to automatically repair themselves upon exposure to heat. This technology extends the life of the coating and maintains a pristine appearance with minimal intervention. Similarly, advancements in UV inhibitors have resulted in coatings that effectively block harmful ultraviolet radiation, preventing fading and degradation of the underlying paint. The formulation and application of these coatings require specialized equipment and skilled technicians, further underscoring the technological complexity involved. Precise control over environmental conditions, application thickness, and curing processes are critical to achieving optimal performance.

In summary, the connection between technology and specialized automotive coatings is profound and multifaceted. Ongoing research and development are continuously pushing the boundaries of what is achievable in terms of durability, protection, and aesthetic enhancement. Understanding the technological underpinnings of these coatings is essential for both applicators and consumers to appreciate the value proposition and ensure proper maintenance. Challenges remain in optimizing the application process, reducing costs, and enhancing the environmental sustainability of these technologies. However, the continuing integration of technological innovation promises to further revolutionize the field of vehicle surface treatments.

5. Application

The successful implementation of superior vehicle surface treatments is fundamentally dependent on the precision and expertise involved in the application process. The quality of the materials employed is only one component; the method by which they are applied dictates the final outcome, influencing the coating’s durability, protective capabilities, and aesthetic qualities.

- Surface Preparation

Effective surface preparation is paramount. This entails a thorough cleaning and decontamination process to remove existing imperfections, contaminants, and residues. For instance, the presence of wax or silicone-based products can impede adhesion, compromising the longevity of the coating. Proper surface preparation may involve clay bar treatment, polishing, and degreasing, ensuring a clean and receptive surface for the subsequent coating layers.

- Environmental Control

The application environment significantly impacts the coating’s performance. Controlled temperature and humidity levels are essential to promote proper curing and prevent defects such as blistering or hazing. Dust-free environments are also crucial to avoid the inclusion of particulate matter within the coating. Specialized application facilities often employ climate-controlled spray booths to optimize these conditions.

- Application Technique

The method of application, including the equipment used and the technician’s skill, directly influences the uniformity and thickness of the coating. Spray application, typically employed for paints and clear coats, requires meticulous technique to achieve consistent coverage and prevent runs or orange peel. Manual application methods, such as those used for ceramic coatings, demand careful attention to detail and precise adherence to manufacturer guidelines.

- Curing Process

The curing process, whether through air drying or accelerated curing using heat lamps or infrared technology, is critical for achieving the coating’s intended properties. Improper curing can lead to incomplete cross-linking, reducing the coating’s hardness, durability, and chemical resistance. Adhering to recommended curing times and temperatures is essential for maximizing the coating’s performance characteristics.

These facets of the application process collectively determine the ultimate success of superior automotive surface treatments. A substandard application, regardless of the quality of the materials, will invariably result in diminished performance and a compromised aesthetic outcome. Therefore, engaging skilled technicians with experience and expertise in applying these specialized coatings is of paramount importance to realizing the full potential of the investment.

6. Maintenance

Maintenance is an indispensable component of realizing the full potential of superior vehicle surface treatments. The application of such finishes represents a significant investment, and diligent maintenance practices are essential to preserving their integrity and maximizing their lifespan. Neglecting maintenance protocols can negate the benefits of even the most advanced coatings, leading to premature degradation and diminished aesthetic appeal. For example, failure to promptly remove acidic contaminants, such as bird droppings, can result in etching that permanently damages the coating’s surface, necessitating costly repairs or reapplication.

Specific maintenance procedures directly impact the long-term performance of these coatings. Regular washing with pH-neutral soaps prevents the accumulation of contaminants that can compromise the finish. The use of microfiber towels minimizes the risk of swirl marks and scratches, preserving the coating’s gloss and clarity. Periodic application of coating-specific sealants provides an additional layer of protection against environmental elements. Furthermore, avoiding harsh chemicals and abrasive cleaning methods is crucial to preventing damage to the coating’s protective layer. The efficacy of these maintenance practices is evident in the comparative appearance of vehicles that receive consistent care versus those that are neglected, showcasing the tangible benefits of a dedicated maintenance regimen.

In summary, the connection between specialized automotive coatings and maintenance is inextricably linked. Proper maintenance is not merely an optional addendum but a fundamental requirement for safeguarding the investment and ensuring the long-term performance and aesthetic appeal of these advanced finishes. While challenges remain in educating consumers about the importance of maintenance and developing more durable and self-maintaining coatings, the integration of consistent and appropriate maintenance practices remains the cornerstone of preserving the value and beauty of vehicles treated with superior surface finishes.

7. Investment

The application of superior automotive coatings constitutes a financial investment. This investment transcends the initial cost of materials and labor, representing a long-term commitment to preserving the vehicle’s value and aesthetic appeal. The cause-and-effect relationship is clear: the initial financial outlay results in tangible benefits, including enhanced protection against environmental damage, prolonged preservation of the vehicle’s exterior, and, consequently, a higher resale value. The magnitude of this effect is contingent upon several factors, including the quality of the coating, the expertise of the applicator, and the diligence of ongoing maintenance.

The importance of investment as a component of superior automotive finishes is underscored by real-world examples. Consider two identical vehicles, one treated with a high-quality ceramic coating and the other left unprotected. Over a period of several years, the untreated vehicle will likely exhibit signs of wear and tear, such as scratches, fading, and water spots, diminishing its aesthetic appeal and potentially reducing its market value. In contrast, the treated vehicle, with proper maintenance, will maintain its original luster, offering a compelling advantage in terms of resale value. This discrepancy highlights the practical significance of viewing specialized automotive coatings as a strategic investment, rather than a mere expense.

In summary, the application of superior automotive coatings represents a deliberate and considered financial investment. This investment yields tangible benefits, including enhanced protection, prolonged aesthetic appeal, and improved resale value. While challenges exist in quantifying the precise return on investment due to varying market conditions and individual vehicle usage patterns, the underlying principle remains consistent: specialized automotive coatings represent a proactive approach to preserving the value and appearance of a vehicle over the long term, rendering them a financially sound decision for discerning vehicle owners.

Frequently Asked Questions

The following questions address common inquiries regarding the application, benefits, and maintenance of specialized automotive surface treatments.

Question 1: What distinguishes these surface treatments from standard automotive paint?

Specialized automotive surface treatments, such as ceramic coatings and paint protection films, offer enhanced durability, chemical resistance, and UV protection compared to standard automotive paint. These treatments bond at a molecular level, creating a robust barrier against environmental contaminants and physical abrasion.

Question 2: How long does a specialized automotive finish typically last?

The lifespan of a specialized automotive finish is contingent upon several factors, including the type of coating, environmental conditions, and maintenance practices. High-quality ceramic coatings can last several years with proper care, while paint protection films may offer up to ten years of protection against scratches and stone chips.

Question 3: Does a specialized finish eliminate the need for car washing?

While these finishes offer hydrophobic properties that repel water and contaminants, routine washing is still essential. Regular cleaning removes accumulated dirt, debris, and acidic substances that can potentially degrade the coating over time. pH-neutral soaps and microfiber towels are recommended for optimal results.

Question 4: Can these finishes be applied to any vehicle?

Specialized automotive finishes can be applied to a wide range of vehicles, including cars, trucks, motorcycles, and boats. However, proper surface preparation is critical for ensuring optimal adhesion and performance. Pre-existing paint imperfections may need to be addressed before applying the coating.

Question 5: Are specialized automotive finishes resistant to all types of scratches?

While these finishes offer enhanced scratch resistance, they are not impervious to all types of damage. Deep scratches or impacts may still penetrate the coating and affect the underlying paint. However, the coating will significantly reduce the likelihood of minor scratches and swirl marks.

Question 6: What is the recommended maintenance schedule for a vehicle with a specialized finish?

A consistent maintenance schedule is vital for preserving the integrity of the coating. This includes regular washing, prompt removal of contaminants, and periodic application of coating-specific sealants. Professional detailing services may also be beneficial for addressing any imperfections that arise over time.

The selection and proper maintenance of specialized automotive finishes contribute significantly to a vehicle’s longevity and aesthetic value.

The subsequent section will explore advanced techniques for assessing the quality and performance of elite automotive finishes.

Conclusion

The preceding exploration has detailed the multifaceted nature of elite automotive finishes. From their advanced technological underpinnings to their critical role in protection, aesthetic enhancement, and investment preservation, these specialized surface treatments represent a significant advancement over traditional automotive paint systems. The importance of proper application and meticulous maintenance has been emphasized, underscoring the necessity for skilled technicians and informed consumers.

As the automotive industry continues to evolve, so too will the technologies and techniques associated with elite automotive finishes. Continued research and development are essential to further enhance their durability, sustainability, and overall performance. The informed adoption and consistent upkeep of these superior coatings will ensure the enduring value and visual appeal of vehicles for years to come. It remains crucial to remain abreast of the latest advancements in this field to make informed decisions regarding vehicle preservation and enhancement.