The outer coating applied to the body of a Fender Stratocaster guitar serves both aesthetic and protective purposes. This layer, typically lacquer or polyurethane, defines the instrument’s visual appeal and safeguards the wood from environmental factors like moisture and impact. Examples include solid colors like Olympic White and Black, as well as sunburst patterns and metallic hues.

A durable and visually appealing surface is crucial for maintaining the instrument’s value and longevity. It contributes significantly to the overall playing experience and can influence a player’s perception of the instrument’s quality. Historically, the materials and application techniques have evolved, reflecting advancements in paint technology and shifting aesthetic preferences.

The following discussion will delve into the various types of materials employed, the application processes involved, and the impact of different options on the instrument’s sound and collectibility.

Guidance on Maintaining Fender Stratocaster Exterior Coatings

Proper care ensures the longevity and appearance of the instrument. Understanding the composition and vulnerabilities of the coating is essential for preserving its integrity.

Tip 1: Regularly wipe down the instrument after each use with a clean, lint-free cloth. This removes fingerprints, sweat, and other contaminants that can degrade the surface over time.

Tip 2: Use cleaning products specifically formulated for musical instruments. Avoid household cleaners, as they may contain harsh chemicals that can damage the coating.

Tip 3: Store the instrument in a case when not in use. This protects it from dust, scratches, and extreme temperature or humidity fluctuations.

Tip 4: Avoid prolonged exposure to direct sunlight. Ultraviolet (UV) radiation can cause fading and discoloration, particularly in nitrocellulose lacquer.

Tip 5: When polishing, use a gentle, circular motion and apply minimal pressure. Excessive polishing can wear down the coating over time.

Tip 6: Be cautious when using guitar stands. Some materials in guitar stands can react with certain types of coating, causing damage. Use stands with inert padding.

Tip 7: Address minor scratches and blemishes promptly. Specialized scratch removers can often restore the surface to its original condition, preventing further degradation.

Consistent application of these preventative measures significantly prolongs the aesthetic appeal and structural integrity of the instrument’s exterior, preserving its value and enjoyment.

This guidance offers practical measures for maintaining the appearance. The subsequent discussion will delve into repair techniques for more significant damage.

1. Color Palette

The selection of colors available for Fender Stratocaster bodies is a critical element influencing both aesthetic appeal and historical accuracy, directly impacting the instrument’s desirability and market value.

- Historical Accuracy and Era-Specific Colors

Certain colors are associated with specific eras in Fender’s history. For example, Fiesta Red and Daphne Blue are characteristic of the 1960s. A Stratocaster finished in a historically accurate color for its year of manufacture is generally more desirable to collectors. Deviations from established palettes can significantly affect value and perceived authenticity.

- Custom Color Availability and Rarity

Beyond standard offerings, Fender has, at times, offered custom color options. These were often based on automotive paint colors of the period. Guitars with factory-applied custom colors are generally rarer than those with standard colors, increasing their collectibility and market value. Documented examples with original documentation substantiating the custom finish command a premium.

- Color Fading and Aging Characteristics

The specific type of finish used, whether nitrocellulose lacquer or polyurethane, affects how the color ages over time. Nitrocellulose lacquers tend to yellow and exhibit checking patterns, while polyurethane finishes are more resistant to fading and cracking. The aging process contributes to the instrument’s vintage character and can influence its perceived authenticity.

- Impact on Resale Value and Collectibility

The combination of color choice, historical accuracy, and aging characteristics directly impacts the resale value and collectibility of a Stratocaster. Certain colors, particularly those associated with famous players or specific production runs, are highly sought after by collectors. A well-preserved instrument in a rare or desirable color will command a higher price than a similar instrument in a common color.

In conclusion, the color palette of Fender Stratocaster exterior coatings is not merely an aesthetic consideration but a crucial factor affecting its historical significance, collectibility, and ultimate value. Careful consideration of color accuracy, rarity, and aging characteristics is essential when assessing and preserving these instruments.

2. Lacquer Type

The type of lacquer employed in Fender Stratocaster coatings significantly influences the instrument’s tonal characteristics, durability, and long-term aesthetic aging. The selection of lacquer directly affects how the wood resonates and how the coating withstands environmental factors and wear over time.

- Nitrocellulose Lacquer: Composition and Characteristics

Nitrocellulose lacquer, a common finish on vintage Stratocasters, is known for its thin application and ability to allow the wood to “breathe.” Its composition results in a softer, more flexible finish that tends to check and yellow over time, contributing to a vintage aesthetic. This type of lacquer is more susceptible to damage from solvents and temperature changes. Examples include the finishes found on pre-CBS Stratocasters, which exhibit characteristic aging patterns.

- Polyurethane Lacquer: Composition and Characteristics

Polyurethane lacquer offers a more durable and resilient coating compared to nitrocellulose. Its chemical composition results in a harder, thicker finish that is less prone to cracking and yellowing. While providing enhanced protection against wear and environmental factors, polyurethane can dampen the wood’s natural resonance due to its increased density. Modern Stratocasters often utilize polyurethane for its protective qualities.

- Impact on Tonal Properties

The type of lacquer applied impacts the instrument’s tonal properties. Nitrocellulose, due to its thinner application, allows the wood to vibrate more freely, potentially resulting in a more resonant and open sound. Polyurethane, with its thicker composition, can restrict the wood’s vibration, leading to a slightly more focused and less airy tone. The degree to which lacquer affects tone is a subject of ongoing debate, but experienced players often perceive a difference.

- Effect on Aging and Aesthetics

Nitrocellulose lacquer ages and wears differently than polyurethane. Nitrocellulose is prone to cracking (checking) and yellowing due to UV exposure and oxidation. This aging process is often sought after for its vintage appeal. Polyurethane, being more resistant to environmental factors, tends to maintain its original appearance for a longer period. The choice of lacquer significantly determines the long-term aesthetic trajectory of a Stratocaster.

In summary, the choice between nitrocellulose and polyurethane lacquer for Fender Stratocaster coatings represents a trade-off between tonal characteristics, durability, and aesthetic aging. The decision often reflects the desired balance between vintage authenticity and modern resilience, significantly impacting the instrument’s overall character and long-term value.

3. Application Method

The manner in which a finish is applied to a Fender Stratocaster body is a critical determinant of its appearance, durability, and ultimately, its value. The skill and technique employed during application directly influence the coating’s thickness, uniformity, and adherence to the wood, impacting both the instrument’s aesthetic qualities and its protective capabilities.

- Spraying Techniques and Equipment

The use of various spraying techniques, such as electrostatic spraying or traditional airbrushing, significantly affects finish quality. Electrostatic spraying can provide a more uniform and efficient application, minimizing waste and ensuring consistent coverage. The type of spray gun, nozzle, and air pressure settings also play crucial roles in achieving the desired thickness and texture. Variations in these parameters can result in uneven coats, orange peel texture, or other imperfections visible on the surface.

- Number of Coats and Layering Process

The number of coats applied and the layering process employed are essential for building up the desired finish thickness and achieving optimal color saturation. Multiple thin coats are generally preferred over a single thick coat, as they allow for better adhesion and reduce the risk of runs or sags. Each coat must be properly cured before applying the next to prevent solvent entrapment and ensure proper bonding between layers. The specific number of coats and curing times vary depending on the type of coating and environmental conditions.

- Surface Preparation and Sanding

Proper surface preparation is paramount for ensuring a smooth and durable finish. This involves sanding the wood to a consistent grit level to remove imperfections and create a uniform surface for the coating to adhere to. The use of appropriate sanding techniques and materials is critical for avoiding scratches or swirl marks that may be visible through the finish. Sealer coats are often applied to fill the wood pores and prevent the finish from sinking into the grain, resulting in a smoother and more even appearance.

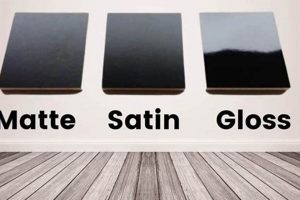

- Buffing and Polishing Procedures

The final buffing and polishing stages are essential for achieving a high-gloss, mirror-like finish. These procedures involve using progressively finer abrasive compounds to remove any remaining imperfections and enhance the smoothness and clarity of the surface. Proper buffing techniques and equipment are crucial for avoiding swirl marks or burn-through, which can damage the finish and detract from its overall appearance. The quality of the buffing and polishing directly impacts the perceived value and collectibility of the instrument.

In conclusion, the application method represents a complex interplay of techniques, equipment, and materials that directly shapes the visual and protective characteristics of Fender Stratocaster finishes. From surface preparation to final polishing, each step in the process contributes to the overall quality and long-term durability of the coating, influencing the instrument’s aesthetic appeal and market value.

4. Durability Factors

The longevity and resilience of Fender Stratocaster coatings are determined by a confluence of interconnected factors. These elements dictate the finish’s resistance to environmental stressors, physical impacts, and the inevitable wear that accompanies regular use, directly affecting the instrument’s long-term appearance and value.

- Coating Material Composition

The chemical composition of the coating itself plays a pivotal role. Polyurethane coatings, for instance, are inherently more resistant to solvents and abrasion than nitrocellulose lacquer. This translates to a greater capacity to withstand cleaning agents, accidental spills, and the friction of picks or clothing. For example, a Stratocaster finished with a thick polyurethane layer is less likely to exhibit buckle rash (wear on the back of the body) than one with a thin nitrocellulose coating subjected to the same conditions.

- Application Thickness and Uniformity

The thickness and uniformity of the coating are crucial for providing adequate protection. A thicker, consistently applied finish offers a more robust barrier against moisture ingress, preventing swelling or warping of the wood beneath. Conversely, a thin or unevenly applied finish is more susceptible to chipping, cracking, and localized wear. This is particularly relevant in areas prone to high contact, such as the edges of the body and the neck pocket.

- Environmental Conditions and Storage Practices

Environmental factors, such as temperature fluctuations and humidity levels, exert a significant influence on the durability of the coating. Exposure to extreme heat or cold can cause expansion and contraction, leading to cracking or checking (fine lines in the finish). High humidity can promote moisture absorption, potentially causing the wood to swell and distort the finish. Proper storage in a controlled environment, such as a case with humidity control, is essential for mitigating these effects.

- UV Exposure and Chemical Interactions

Prolonged exposure to ultraviolet (UV) radiation can cause fading and discoloration, particularly in nitrocellulose lacquer. Additionally, contact with certain chemicals, such as those found in some guitar straps or polishes, can react with the coating, causing softening, blistering, or other forms of degradation. Selecting UV-resistant coatings and using compatible cleaning and maintenance products are important for preserving the finish’s integrity.

The interplay of these durability factors determines the long-term viability of Fender Stratocaster exterior coatings. A comprehensive understanding of these elements enables informed decisions regarding finish selection, maintenance practices, and storage conditions, ultimately safeguarding the instrument’s aesthetic appeal and structural integrity.

5. Aging Process

The aging process significantly transforms Fender Stratocaster finishes, altering their appearance, texture, and ultimately, their perceived value. This transformation is a complex interaction of environmental factors and material properties, resulting in unique characteristics that distinguish vintage instruments.

- Lacquer Checking and Crazing

Nitrocellulose lacquer, commonly used on vintage Stratocasters, is susceptible to checking and crazing. These fine cracks appear due to temperature and humidity fluctuations, causing the lacquer to expand and contract at different rates than the wood beneath. The resulting network of hairline fractures is a hallmark of aged nitrocellulose finishes, contributing to a vintage aesthetic and often increasing the instrument’s value among collectors. Polyurethane finishes are generally more resistant to checking, leading to a different aging trajectory.

- Color Fading and Yellowing

Exposure to ultraviolet (UV) light causes many Fender Stratocaster finishes to fade and yellow over time. This is particularly noticeable in lighter colors and clear coats, where the pigments break down and the lacquer itself discolors. For example, Olympic White finishes can turn a creamy yellow, while Sunburst finishes may lose their vibrancy. The extent of fading depends on the type of pigment used, the degree of UV exposure, and the type of lacquer. This alteration in color is considered desirable by many vintage guitar enthusiasts.

- Wear Patterns and Relic’ing

The aging process also manifests in the form of wear patterns, such as scratches, dents, and worn spots on the finish. These imperfections are the result of regular use and contact with the player’s body, clothing, and accessories. The specific wear patterns are unique to each instrument, reflecting its history and playing style. Intentional relic’ing, where new instruments are artificially aged to replicate these wear patterns, has become a popular trend, attempting to capture the aesthetic of vintage instruments.

- Finish Softening and Texture Changes

Over time, certain finishes can soften and become more pliable due to the gradual degradation of the lacquer or polyurethane. This softening can result in a slight tackiness or stickiness to the touch. Additionally, the surface texture may change, becoming smoother or more textured depending on the specific finish type and environmental conditions. These changes in texture contribute to the overall feel of the instrument and can be a subtle indicator of its age and authenticity.

The aging process is a fundamental aspect of Fender Stratocaster finishes, transforming their appearance and contributing to their unique character. These changes, whether natural or artificially induced, play a significant role in the perceived value and desirability of these instruments.

6. Custom Options

Custom options significantly influence the aesthetic and functional characteristics of Fender Stratocaster finishes. The availability of tailored exterior treatments directly impacts the instrument’s desirability and potential market value. These modifications extend beyond standard color choices to encompass specific material compositions, application techniques, and personalized wear patterns, allowing for individualized expression and optimized performance.

The interplay between custom options and the final appearance is evident in the selection of non-standard colors. For instance, a player might request a finish matched to a vintage automobile paint code, creating a unique and visually striking instrument. The choice of lacquer type, such as thin-skin nitrocellulose for enhanced resonance or a durable polyurethane for greater protection, represents another critical customization. Moreover, the application process can be tailored to achieve specific effects, including relic’ing techniques that simulate the wear and tear of a vintage instrument. The Fender Custom Shop exemplifies the practical application of these principles, offering a vast array of individualized exterior options that cater to discerning players and collectors.

The selection of custom options during the finishing process directly affects the Stratocasters perceived value and long-term appeal. Challenges arise in accurately replicating vintage finishes or achieving consistent results with custom aging techniques. The understanding of these challenges allows for more informed decisions, optimizing both the instrument’s aesthetic value and functional lifespan. This knowledge is crucial for both players seeking personalized instruments and collectors seeking valuable, unique examples.

7. Historical Accuracy

Historical accuracy serves as a pivotal benchmark in assessing the authenticity and value of Fender Stratocaster instruments, particularly concerning the exterior coatings applied during specific production periods. Deviation from established finishing practices can significantly impact an instrument’s collectibility and perceived originality.

- Color Palette Concordance

The color palette employed on a Stratocaster must align with the colors documented as available during its purported year of manufacture. For example, a 1957 Stratocaster finished in a color exclusively offered in the 1960s would be considered historically inaccurate. Verification against documented Fender color charts and expert authentication is essential. This concordance directly affects valuation and collectibility.

- Lacquer Type Authentication

The type of lacquer used on a Stratocaster must correspond to the materials utilized during its designated era. Pre-CBS Stratocasters typically feature nitrocellulose lacquer, while later models transitioned to polyurethane. The presence of polyurethane on an instrument purported to be from the nitrocellulose era raises questions regarding its historical accuracy. Analytical testing, such as spectroscopic analysis, can aid in determining the lacquer composition.

- Application Technique Verification

The application methods employed on Stratocaster finishes provide insights into their historical accuracy. The presence of overspray in areas inconsistent with factory practices or the absence of expected tooling marks can indicate refinishing or alteration. Microscopic examination of the finish can reveal details about the original application process, confirming or refuting its adherence to historical norms.

- Aging Pattern Consistency

The aging patterns exhibited by a Stratocaster finish must align with the expected wear and degradation characteristics of its age and lacquer type. Unnatural or inconsistent aging patterns, such as excessive checking on a polyurethane finish, may suggest artificial relic’ing or alterations. Expert analysis of the finish’s wear patterns can help determine its authenticity and historical accuracy.

These facets underscore the critical role of historical accuracy in evaluating the authenticity and value of Fender Stratocaster finishes. Scrutiny of color palette, lacquer type, application technique, and aging patterns provides a comprehensive framework for assessing an instrument’s adherence to historical norms, impacting its collectibility and perceived originality.

Frequently Asked Questions

This section addresses common inquiries and clarifies prevalent misconceptions regarding the exterior coatings applied to Fender Stratocaster guitars.

Question 1: Does the finish on a Stratocaster significantly impact its sound?

The extent to which a finish affects a Stratocaster’s tone remains a subject of debate. Thinner finishes, such as nitrocellulose lacquer, are often purported to allow the wood to resonate more freely, resulting in a more open sound. Conversely, thicker finishes, like polyurethane, may dampen the wood’s vibrations, potentially leading to a slightly more focused tone. However, the audible difference can be subtle and highly subjective.

Question 2: What is the difference between nitrocellulose and polyurethane finishes?

Nitrocellulose lacquer is a thinner, more pliable finish that is prone to checking and yellowing over time. It is often associated with vintage instruments. Polyurethane is a more durable and resilient finish that is resistant to cracking and fading. It provides greater protection against environmental factors but may not age in the same way as nitrocellulose.

Question 3: How should a Stratocaster finish be properly maintained?

Regular cleaning with a soft, lint-free cloth is essential for removing fingerprints, dust, and other contaminants. Specialized guitar cleaning products formulated for instrument finishes are recommended. Avoid harsh chemicals or abrasive cleaners, as they can damage the coating. Storing the instrument in a case when not in use provides protection from dust, scratches, and extreme temperature fluctuations.

Question 4: What causes finish checking on vintage Stratocasters?

Finish checking, also known as crazing, is caused by the expansion and contraction of nitrocellulose lacquer due to temperature and humidity fluctuations. These fluctuations create stress within the finish, resulting in a network of hairline cracks. Checking is a common characteristic of aged nitrocellulose finishes and is often considered desirable by vintage guitar enthusiasts.

Question 5: Can a damaged Stratocaster finish be repaired?

Minor scratches and blemishes can often be repaired using specialized scratch removers and polishing compounds. More significant damage, such as deep scratches or cracks, may require professional refinishing. Refinishing can restore the instrument’s appearance, but it may also affect its value, particularly if historical accuracy is a concern.

Question 6: Does the color of a Stratocaster finish affect its value?

Yes, the color of a Stratocaster finish can significantly impact its value, particularly for vintage instruments. Rare or historically accurate colors, especially those associated with specific production runs or famous players, are often highly sought after by collectors. Custom color finishes, if documented and original, can also command a premium.

These frequently asked questions highlight the key aspects of Stratocaster coatings, providing valuable insight into the materials, maintenance, and historical significance that contribute to the instrument’s overall value and appeal.

The subsequent discussion will explore the relationship between Stratocaster exterior options and collectibility.

Conclusion

This exploration of Fender Stratocaster finishes has illuminated the multifaceted role these coatings play. Beyond mere aesthetics, these serve as protective barriers, influencing tonal properties, and contributing to an instrument’s historical narrative and market value. The composition of materials, application techniques, and aging characteristics are all critical factors.

A thorough understanding of exterior treatments is essential for collectors, players, and luthiers alike. Continued research and meticulous preservation efforts are necessary to safeguard the legacy and inherent value of these iconic instruments. Further investigation into the long-term impact of modern coating technologies is warranted to ensure the continued evolution and appreciation of the Stratocaster.