The construction industry encompasses a broad spectrum of skills, often categorized by the level of detail and precision required. One major distinction lies between structural work and the application of aesthetic and functional enhancements. The former involves creating the framework of a building, focusing on strength and stability. For example, this includes framing walls, installing roofing, and pouring concrete foundations. The latter refers to detailed work performed to add the finishing touches and interior elements. Examples include installing trim, cabinets, doors, and flooring.

Understanding the differences between these two facets of the building process is essential for project planning, cost estimation, and ensuring the overall quality of construction. Historically, these roles might have been performed by the same individual or team. However, with increasing specialization and complexity in building design, distinct skill sets and expertise have emerged. This division of labor enhances efficiency, quality control, and safety on construction sites.

The following sections will delve into the specific tasks, tools, materials, and skills associated with each type of carpentry. A thorough examination will highlight the unique contributions each makes to the successful completion of a construction project, as well as provide insight into the career paths and training opportunities within each specialty.

Essential Considerations for Carpentry Projects

Effective project management requires a clear understanding of the skill sets and processes involved in different stages of construction. Paying close attention to the distinct demands of each phase ensures a higher quality outcome, greater efficiency, and optimized resource allocation.

Tip 1: Prioritize Structural Integrity: Ensure the underlying framework adheres to all relevant building codes and safety standards. Foundations, framing, and load-bearing walls must be inspected and verified before proceeding to subsequent steps.

Tip 2: Account for Material Properties: Understand the characteristics of lumber, plywood, and other construction materials. Factors such as moisture content, grain direction, and expansion/contraction rates influence structural performance and aesthetic results.

Tip 3: Plan for Adequate Support: Structural components require proper bracing and support during construction. Temporary supports, shoring, and scaffolding are essential for maintaining stability and preventing accidents.

Tip 4: Achieve Precise Alignment: Maintaining level, plumb, and square lines throughout the framing process is critical. Accurate measurements and careful execution ensure proper fit and alignment of subsequent finish elements.

Tip 5: Employ Appropriate Fasteners: Select fasteners (nails, screws, bolts) that are suitable for the materials being joined and the anticipated loads. Using the wrong type or size can compromise the structural integrity of the assembly.

Tip 6: Protect Exposed Framing: Implement measures to protect the structural framework from weather damage. Covering exposed lumber with tarps or applying a sealant can prevent moisture intrusion and deterioration.

Tip 7: Minimize Material Waste: Plan material usage carefully to reduce waste. Consider optimized cutting strategies and material reuse options to improve efficiency and minimize environmental impact.

Tip 8: Prepare Surfaces Properly: Ensure surfaces are clean, smooth, and properly prepared before applying finishes. Sanding, priming, and patching imperfections create a consistent base for paint, stain, and other coatings.

By adhering to these principles, construction professionals can optimize the performance, durability, and aesthetic appeal of their projects. Careful planning, attention to detail, and proper execution are essential for achieving successful outcomes.

The following sections will examine specific areas of expertise and skills.

1. Structural Framing

Structural framing, the skeletal system of any building, forms the foundational distinction within rough carpentry. This phase involves constructing the load-bearing elements, like walls, floors, and roofs, employing materials such as lumber, engineered wood products, or steel. Accuracy in this stage is paramount. Deviations from prescribed dimensions or inadequate fastening can propagate into challenges during the finish phase, potentially compromising the aesthetic and functional aspects of the project. For example, a wall that is not perfectly plumb can complicate the installation of trim or cabinetry, requiring shimming or other corrective measures that add time and cost. Conversely, a robust and precise framework simplifies subsequent stages, allowing for cleaner lines and tighter fits in interior and exterior finishes.

The connection lies in dependency: the final quality is directly proportional to the initial precision. A solid, square frame not only ensures the building’s stability but also offers a true surface for the application of finishes. Consider the installation of hardwood flooring; an uneven subfloor necessitates extensive leveling, whereas a properly framed floor system minimizes preparation and delivers a superior finished product. Similarly, door and window frames must be precisely aligned within the structural opening to ensure proper operation and weather tightness. The role of the initial framing extends beyond mere support; it sets the stage for all subsequent refinements.

In summary, structural framing represents the crucial starting point, influencing every subsequent stage in construction. Poor execution during this phase creates ripple effects, demanding costly remedies during the finish carpentry phase. Conversely, a strong, accurate frame minimizes complications, leading to a more efficient and higher-quality finished product. The understanding of this relationship is not merely academic, but a practical imperative for efficient building practices, cost control, and lasting structural integrity.

2. Detailed Trim Work

Detailed trim work represents a defining characteristic differentiating finish carpentry from its rough counterpart. This facet involves installing decorative and functional moldings, casings, baseboards, and other elements that enhance the aesthetic appeal and functionality of interior spaces. The precision and craftsmanship required in trim work stand in stark contrast to the structural focus of rough carpentry, showcasing the distinct skills and objectives of each discipline.

- Aesthetic Enhancement

Trim work introduces visual elements that define the style and character of a space. Crown molding, for example, can add elegance to a room, while baseboards protect walls from damage and create a clean transition to the flooring. The selection of trim profiles, materials, and finishes contributes significantly to the overall design aesthetic.

- Mitigation of Imperfections

Trim work serves a practical function by concealing gaps, seams, and minor imperfections that may arise during construction. Casings around doors and windows cover the joints between the framing and the finished opening, providing a seamless appearance. Skirting boards hide irregularities along the floor-wall junction.

- Material Precision

Unlike rough carpentry, where dimensional tolerances are often more forgiving, trim work demands a high degree of precision. Accurate measurements and cuts are essential for creating tight joints and smooth transitions. Mitered corners, in particular, require meticulous attention to detail to ensure a professional finish.

- Specialized Tools and Techniques

Trim work necessitates a specific set of tools and techniques. Miter saws, coping saws, and nail guns are commonly used to achieve precise cuts and secure fastenings. Skilled carpenters employ techniques such as scribing and back-cutting to address uneven surfaces and ensure a perfect fit.

The interplay between these aspects highlights trim work’s contribution to finish carpentry. While rough carpentry establishes the building’s form, trim work refines and enhances the interior. The connection lies in the dependency: well-executed trim work elevates the aesthetic appeal. The application of trim represents the refinement and decorative aspect.

3. Material Precision

Material precision forms a critical point of divergence between rough and finish carpentry. The level of accuracy demanded in material selection, cutting, and fitting directly impacts the structural integrity and aesthetic outcome of a project. While both domains necessitate careful material handling, the consequences of deviations from specified dimensions vary significantly.

- Dimensional Accuracy in Framing

In structural framing, dimensional accuracy ensures that load-bearing members meet engineering specifications. While minor variations may be permissible, gross errors can compromise the stability of the entire structure. For example, using undersized lumber for wall studs can reduce the load-bearing capacity of the wall, potentially leading to structural failure. Rough carpentry prioritizes structural integrity and code compliance, and material inaccuracies can have severe consequences.

- Fit and Tolerance in Trim Work

Finish carpentry, on the other hand, places a premium on tight fits and seamless transitions. Material precision is crucial for achieving a visually appealing and professional-looking finish. For instance, when installing crown molding, even slight discrepancies in the miter angles can create unsightly gaps. Finish carpentry demands exacting measurements and cuts, often requiring specialized tools and techniques to achieve the desired level of precision. Tolerances are much tighter, and the focus shifts from structural necessity to aesthetic perfection.

- Material Selection and Stability

The choice of materials also reflects the differing demands of rough and finish carpentry. Rough carpentry often employs construction-grade lumber that may exhibit variations in moisture content and dimensional stability. Finish carpentry typically requires higher-grade materials that are kiln-dried and less prone to warping or shrinking. The stability of the material is essential for maintaining the integrity of the finished product over time. For example, solid wood trim expands and contracts with changes in humidity, potentially causing cracks or gaps if not properly acclimated and installed.

- Impact on Cost and Efficiency

The level of material precision required affects both the cost and efficiency of a project. The high-grade materials typically used in finish carpentry are more expensive than those used in rough carpentry. The labor costs associated with finish carpentry are also higher, due to the greater skill and attention to detail required. Furthermore, correcting errors in finish carpentry can be time-consuming and costly, underscoring the importance of precision from the outset.

In summary, material precision serves as a crucial differentiator. Structural integrity and code compliance are the main goal of Material Precision for Rough Carpentry, and aesthetically perfection for finish carpentry. Understanding these differences is essential for project planning, cost estimation, and ensuring the overall quality and durability of construction projects.

4. Load-Bearing Capacity

Load-bearing capacity, a fundamental concept in structural engineering, exhibits a clear demarcation when considered within the context of structural carpentry versus finish carpentry. The capacity refers to the maximum load that a structural element can withstand before failure occurs. In structural carpentry, this aspect reigns supreme, directly influencing material selection, member sizing, and connection details. Structural elements, such as studs, joists, beams, and rafters, are explicitly designed to support anticipated loads, adhering to stringent building codes and engineering principles. Failure to adequately address this consideration in structural framing can result in catastrophic structural collapse. An illustrative example is the improper sizing of a roof beam. If the beam’s dimensions are insufficient for the anticipated snow load, the roof may deflect excessively or, in extreme cases, fail completely. Similarly, inadequate foundation design can lead to settling or cracking, compromising the building’s structural integrity. Consequently, structural carpentry mandates a thorough understanding of load calculations and material properties to ensure the building’s stability and safety.

In contrast, load-bearing capacity typically plays a less direct role in finish carpentry. Finish elements, such as trim, cabinetry, and decorative moldings, are generally non-structural and do not contribute significantly to the building’s overall load-bearing capacity. However, the connection arises in the detailing and integration of these elements with the underlying structure. For example, while a kitchen cabinet is not a load-bearing component, its attachment to a load-bearing wall requires careful consideration to prevent damage to the wall or the cabinet itself. The distribution of weight and the selection of appropriate fasteners are crucial to ensure that the finish element remains securely attached without compromising the structural integrity of the wall. Further, the placement of heavy fixtures, such as large mirrors or chandeliers, must take into account the load-bearing capacity of the ceiling or wall to which they are attached. Incorrect installation can result in the fixture detaching, posing a safety hazard. Therefore, while finish carpentry primarily focuses on aesthetics and functionality, an understanding of basic load-bearing principles remains necessary for ensuring the safe and reliable integration of finish elements with the building’s structure.

In summary, load-bearing capacity stands as a central pillar of structural carpentry, driving design decisions and dictating material choices to guarantee structural integrity. While not the primary focus of finish carpentry, it retains relevance in ensuring safe and proper integration of finish elements with the underlying structure. A comprehensive understanding of both disciplines demands acknowledging the contrasting roles and considerations surrounding load-bearing capacity, emphasizing its vital contribution to the safety and stability of the built environment.

5. Aesthetic Detailing

Aesthetic detailing distinguishes the functional precision of structural work from the visual refinement that enhances the occupant experience. In the context of rough versus finish carpentry, this element represents a divergence in priorities and skill sets, impacting the final perception and valuation of the built environment.

- Trim and Molding Profiles

The selection and installation of trim profiles exemplify aesthetic detailing. While rough carpentry establishes the structural framework, finish carpentry shapes the visual language of a space. Trim, molding, and baseboards are chosen not only for their functional properties but also for their contribution to the overall design aesthetic. For example, a Victorian-style home might feature elaborate crown molding, while a modern minimalist space might employ clean, unadorned trim. The choice of profile, material, and finish reflects the desired aesthetic and influences the perception of the space. Any errors during rough carpentry is hard to hide even with detail.

- Surface Treatments and Textures

Surface treatments, such as paint, stain, and textured finishes, play a vital role in aesthetic detailing. Finish carpentry encompasses the preparation and application of these treatments to create a visually appealing and tactile surface. The selection of color, sheen, and texture can dramatically alter the perceived size, warmth, and character of a room. For instance, a light-colored, matte finish can make a small room appear larger and brighter, while a dark, glossy finish can create a sense of drama and sophistication. Skilled finish carpenters possess the knowledge and expertise to achieve a flawless finish, enhancing the overall aesthetic impact of the space. Rough carpentry may provide surface which is hard to work with.

- Hardware and Fixture Integration

The integration of hardware and fixtures represents another facet of aesthetic detailing. Finish carpenters are responsible for installing doors, windows, cabinetry, and other fixtures, ensuring that they not only function properly but also complement the overall design aesthetic. The selection of hardware, such as doorknobs, hinges, and drawer pulls, can significantly impact the visual appeal of these elements. Similarly, the placement and alignment of fixtures, such as light fixtures and electrical outlets, must be carefully considered to maintain a cohesive and balanced design. The impact of rough work on finish work is important.

- Custom Millwork and Built-ins

Custom millwork and built-in features exemplify the highest level of aesthetic detailing. Finish carpenters with specialized skills create custom cabinetry, shelving, and other built-in elements that are tailored to the specific needs and aesthetic preferences of the client. These bespoke features add a unique and personalized touch to a space, enhancing its functionality and visual appeal. The design and execution of custom millwork require a high degree of craftsmanship and attention to detail, reflecting the expertise of skilled finish carpenters. This is extremely hard on badly built structural elements.

These aspects underscore the divergence in focus between structural and finish carpentry. A building’s structural components fulfill the requirements, while the detailing shapes the experiential elements. Through trim work, surface treatments, hardware integration, and custom millwork, finish carpentry elevates the basic structure into a refined and aesthetically pleasing environment. The interplay between these disciplines underscores the importance of both structural integrity and visual design in creating successful built environments.

6. Code Compliance

Code compliance serves as a critical intersection where structural carpentry and finish carpentry converge, although the specific regulations and their application differ significantly. In structural carpentry, adherence to building codes is paramount, impacting the fundamental safety and stability of the entire structure. Codes dictate minimum requirements for load-bearing capacity, fire resistance, and structural integrity. For example, building codes specify the permissible spans for floor joists based on the anticipated live and dead loads, influencing the size and spacing of the joists. Similarly, codes mandate fire-resistant construction techniques for walls and ceilings, impacting the materials and methods used in framing. Failure to comply with these regulations can result in structural failure, fire hazards, and legal repercussions. The role of inspection is also important at this phase.

In finish carpentry, code compliance manifests in different forms, primarily focusing on fire safety, accessibility, and egress. Codes regulate the types of materials used in interior finishes, limiting the use of flammable materials that could contribute to the spread of fire. For example, some codes restrict the use of certain types of wood paneling or carpeting in commercial buildings due to their flammability. Accessibility codes, such as the Americans with Disabilities Act (ADA), dictate requirements for door widths, clearances, and hardware to ensure that buildings are accessible to people with disabilities. Egress codes regulate the size and location of exits, ensuring that occupants can safely evacuate the building in the event of an emergency. While these regulations may not directly impact the structural integrity of the building, they play a crucial role in ensuring the safety and well-being of its occupants. The finish materials needs to be tested.

In summation, code compliance acts as an essential guide. It is imperative to comply in structure carpentry. In finish carpentry, it focuses on safety, accessibility, and egress. Understanding the differing applications of code compliance in each discipline is essential for ensuring the safety, durability, and usability of built environments. Lack of these information could cause hazards.

7. Surface Preparation

Surface preparation represents a critical stage in the construction process, bridging structural work and aesthetic finishing. The quality of surface preparation directly influences the longevity and appearance of subsequent finish applications. This stage necessitates specific skills and considerations depending on whether the surface originates from rough carpentry or requires preparation for finish carpentry.

- Framing Inspection and Correction

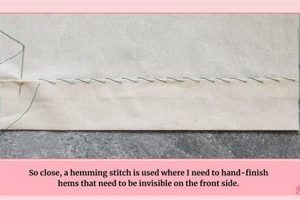

Following structural framing, surfaces require thorough inspection for imperfections that could compromise subsequent finishes. Protruding nails, splinters, and uneven surfaces must be addressed. This phase involves techniques like sanding, planing, and patching to create a uniform substrate. The degree of precision required in this correction directly affects the quality of the final aesthetic detailing. Incomplete preparation at this stage can lead to visible imperfections in the finish, such as uneven paint coverage or poorly aligned trim.

- Substrate Priming and Sealing

Priming and sealing surfaces represents a crucial step in ensuring proper adhesion and preventing moisture intrusion. Primers create a uniform surface for paint or other finishes, improving coverage and durability. Sealers protect wood from moisture damage, preventing warping, rot, and other issues that can compromise the integrity of the finish. The selection of appropriate primers and sealers depends on the type of material being used and the intended finish application. Incorrect product selection can lead to peeling, cracking, or other finish failures.

- Joint Treatment and Smoothing

For surfaces with joints or seams, such as drywall or plywood, proper treatment is essential for creating a seamless appearance. This involves applying joint compound, sanding smooth, and feathering the edges to create a uniform surface. Uneven or poorly treated joints can result in visible lines or ridges in the finished surface. The level of skill and attention to detail required in joint treatment directly impacts the overall quality of the finished product. Inadequate preparation in structural elements will cause problem during finishing.

- Material Compatibility Considerations

Surface preparation must account for the compatibility of different materials. For example, when applying paint to metal surfaces, a specialized primer is required to prevent rust and ensure proper adhesion. Similarly, when applying finish to porous materials like brick or concrete, a sealer is needed to prevent moisture absorption and ensure a uniform finish. Failure to consider material compatibility can lead to finish failures and costly repairs.

The interplay between these facets reveals that the quality of surface preparation is inextricably linked to the success of both structural and finish components. Effective surface preparation is critical for achieving durable, aesthetically pleasing results. Neglecting this crucial step can compromise the overall quality and longevity of construction projects. Proper surface preparation reduces problems.

Frequently Asked Questions

The following section addresses common inquiries regarding the distinctions between structural and finish aspects of woodwork within the construction industry. These questions clarify the roles, responsibilities, and skill sets associated with each discipline.

Question 1: What constitutes the primary difference between structural framing and finish work?

The core divergence centers on purpose. Structural framing focuses on creating the load-bearing skeletal structure of a building, prioritizing stability and adherence to building codes. Finish work concentrates on adding aesthetic and functional elements to the interior, emphasizing visual appeal and detailed craftsmanship.

Question 2: Does the selection of materials differ significantly between these specialties?

Material choices reflect the distinct demands of each domain. Structural work typically employs construction-grade lumber, prioritizing strength and cost-effectiveness. Finish work frequently utilizes higher-grade hardwoods and manufactured materials, emphasizing aesthetic qualities and dimensional stability.

Question 3: How does the required level of precision vary between the two types of carpentry?

Structural work demands accurate measurements and adherence to code specifications to ensure structural integrity. Finish work necessitates a higher degree of precision, focusing on tight joints, seamless transitions, and flawless surface finishes to achieve an aesthetically pleasing outcome.

Question 4: To what extent does building code compliance influence each type of carpentry?

Building codes exert a significant influence on structural work, dictating requirements for load-bearing capacity, fire resistance, and structural integrity. Finish work is subject to codes related to fire safety, accessibility, and egress, ensuring the safety and well-being of building occupants.

Question 5: What tools and equipment are typically associated with each specialty?

Structural work often employs heavy-duty power tools such as framing nailers, circular saws, and concrete saws. Finish work frequently utilizes precision tools like miter saws, coping saws, and sanders to achieve accurate cuts and smooth surfaces.

Question 6: Are there specific certifications or training programs recommended for each field?

While specific certifications may vary by region, structural work benefits from training in structural engineering principles and code compliance. Finish work often requires apprenticeship programs focusing on cabinet making, trim carpentry, and surface finishing techniques.

Understanding these differences is crucial for effective project planning, cost estimation, and ensuring the overall quality of construction projects. Proper execution of both structural and finish work contributes to a safe, durable, and aesthetically pleasing final product.

The next section will explore the future trends and innovations impacting the carpentry profession.

Conclusion

This exploration has delineated the core differences between structural and finish work, two distinct yet interdependent facets of the construction trade. Structural work, characterized by its emphasis on load-bearing integrity and adherence to stringent building codes, forms the foundational framework upon which all subsequent construction rests. Conversely, finish carpentry focuses on aesthetic detailing, functional enhancements, and the creation of visually appealing interior spaces. The successful integration of these two disciplines is paramount for achieving durable, safe, and aesthetically pleasing built environments.

As the construction industry continues to evolve, a comprehensive understanding of these divergent skill sets becomes increasingly crucial. Professionals involved in project planning, design, and execution must recognize the unique demands of each phase to ensure efficient resource allocation, effective quality control, and ultimately, the delivery of superior construction projects. The future of building rests on an informed appreciation of this dichotomy, fostering innovation and excellence across the spectrum of construction trades.