Post-press operations in the Austin metropolitan area transform printed materials from raw sheets into refined, usable products. These specialized services encompass a range of techniques applied after the printing process, including cutting, folding, binding, and other treatments that enhance the final product’s functionality and aesthetic appeal. Examples include producing perfect-bound books, saddle-stitched magazines, and intricately folded brochures.

The availability of comprehensive post-press solutions is critical for businesses and organizations requiring professionally finished printed materials. These services ensure documents are not only visually appealing but also durable and easy to use. Historically, these processes were manual and labor-intensive, but advancements in technology have led to increased efficiency and precision, allowing for larger production runs and more complex designs. This contributes to a thriving local print industry and supports diverse communication needs.

This article will delve into the specific services offered by local providers, explore the technologies utilized, and examine the factors businesses should consider when selecting a post-press partner to meet their unique project requirements. Considerations such as turnaround time, budget, and the complexity of the finishing process will be addressed.

Optimizing Post-Press Projects

Achieving optimal results in post-press requires careful planning and consideration of several key factors. The following tips can assist in maximizing the impact and cost-effectiveness of your projects.

Tip 1: Project Planning and Communication: Clearly define project specifications upfront, including desired finish, quantity, and budget. Open communication with the post-press provider ensures a shared understanding of requirements and minimizes potential errors.

Tip 2: Material Selection: Consider the paper stocks compatibility with chosen finishing techniques. Certain coatings or textures may impact folding, binding, or lamination processes. Consulting with the provider on material suitability is essential.

Tip 3: Accurate File Preparation: Ensure print-ready files adhere to the providers specifications. This includes proper bleed, crop marks, and color management to guarantee accurate reproduction and minimize delays.

Tip 4: Proofing and Review: Request and thoroughly review physical or digital proofs before production. This allows for the identification and correction of any errors in layout, color, or finishing details.

Tip 5: Turnaround Time Considerations: Factor in sufficient lead time for post-press services, especially for complex projects. Rushing the process may compromise quality and increase costs.

Tip 6: Budget Allocation: Allocate a realistic budget for post-press, recognizing that specialized finishes and intricate designs can impact overall project expenses. Obtain quotes from multiple providers to compare pricing and services.

Tip 7: Sustainability Considerations: Explore eco-friendly finishing options, such as water-based coatings or recycled paper stocks, to minimize the projects environmental impact.

Careful attention to detail and proactive communication with post-press providers are vital for successful outcomes. By implementing these strategies, businesses can ensure their printed materials are not only visually appealing but also accurately represent their brand and message.

The next section will explore specific case studies illustrating successful post-press applications and their impact on overall project effectiveness.

1. Local Service Availability

The proximity of post-press services directly influences project timelines, logistical costs, and the capacity for direct collaboration. The availability of “bindery finishing austin” is not just a matter of convenience but a critical factor in optimizing the entire print production workflow.

- Reduced Turnaround Times

Having local access to post-press operations significantly shortens the time required to complete print projects. Instead of shipping materials to distant facilities, businesses can benefit from faster processing and delivery. This is particularly important for time-sensitive projects, such as marketing campaigns with strict deadlines or urgent document production.

- Lower Transportation Costs

Engaging local service providers minimizes shipping expenses associated with transporting printed materials. Reduced transportation distances also contribute to a lower carbon footprint, aligning with sustainability goals. The cost savings can be substantial, especially for large-volume projects.

- Enhanced Communication and Collaboration

Working with a local partner facilitates face-to-face meetings and direct communication throughout the post-press process. This enables better understanding of project requirements, quicker problem resolution, and greater flexibility in accommodating changes or adjustments. This collaborative environment can lead to higher-quality outcomes.

- Support for the Local Economy

Choosing local “bindery finishing austin” services strengthens the regional economy by supporting local businesses and creating job opportunities. This contributes to a more vibrant and sustainable business ecosystem within the Austin metropolitan area. A thriving local industry also fosters innovation and competition, leading to better services and competitive pricing.

Ultimately, the benefits of local service availability extend beyond mere convenience. It directly impacts the efficiency, cost-effectiveness, and quality of print projects. By prioritizing local partnerships, businesses can optimize their post-press operations and contribute to the growth of the Austin community.

2. Cutting and Folding

Cutting and folding are fundamental operations within “bindery finishing austin,” directly influencing the final presentation and functionality of printed materials. Precise cutting ensures accurate dimensions and clean edges, critical for a professional appearance. Folding techniques create brochures, leaflets, and other multi-page documents. Deviations in either process compromise the overall quality and usability of the finished product.

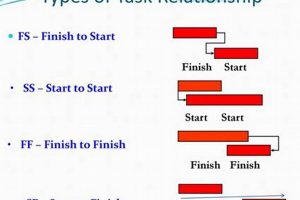

The connection between cutting and folding is a sequential one. First, printed sheets undergo cutting to achieve the desired size. Subsequently, these cut sheets are folded according to specific requirements, such as a tri-fold for brochures or a gate-fold for marketing materials. The accuracy of the cutting process is paramount for proper alignment during folding. Inaccurate cutting leads to uneven folds, misaligned text, and a diminished visual impact. For instance, a business relying on promotional flyers that are not correctly cut and folded risks conveying an unprofessional image, potentially deterring customers. Another example are instruction manual needs accurate cutting and folding for proper use.

Mastery of cutting and folding techniques is therefore essential for providers. The selection of appropriate cutting and folding equipment, coupled with skilled operators, ensures consistent quality and efficiency. Furthermore, an understanding of paper grain and its effect on folding is crucial for preventing cracking and achieving crisp, clean folds. The precision in these steps significantly impacts the final deliverable.

3. Binding Techniques Variety

The breadth of binding options within “bindery finishing austin” directly influences the functionality, durability, and aesthetic appeal of finished documents. A diverse array of techniques allows for tailored solutions that meet the specific needs of diverse projects.

- Saddle Stitching

A cost-effective method involving folding sheets and securing them through the fold line with staples or wire. Commonly used for magazines, booklets, and brochures with a low page count. Improper execution can lead to crooked staples or buckling, affecting visual presentation. Successful “bindery finishing austin” relies on precise machinery and skilled operators to ensure consistent, professional results.

- Perfect Binding

Involves gluing the edges of pages together to create a smooth spine, characteristic of paperback books and thicker magazines. Proper adhesion and squaring of the spine are critical for durability and readability. Failures in adhesion lead to page separation, and a poorly squared spine detracts from the professional appearance. Experienced “bindery finishing austin” professionals understand the importance of proper adhesive selection and application techniques.

- Case Binding

A premium binding method employing rigid covers and sewn or glued signatures, used for hardcover books and high-value documents. This technique demands precision and specialized equipment for creating a durable and aesthetically pleasing product. Issues include loose signatures, uneven board edges, or subpar cover materials. Skilled “bindery finishing austin” services offer meticulous attention to detail, resulting in a long-lasting, high-quality finished product.

- Spiral Binding (Coil Binding)

Uses a plastic or metal coil to hold pages together, allowing the document to lay flat. Ideal for calendars, notebooks, and reference manuals. Coil damage or incorrect hole placement compromises functionality and appearance. Competent “bindery finishing austin” facilities utilize accurate punching and coil insertion machinery to ensure smooth page turning and a secure binding.

The strategic selection and flawless execution of binding techniques are pivotal to the success of print projects. By offering a diverse range of binding options and adhering to stringent quality standards, “bindery finishing austin” professionals can transform printed sheets into valuable, functional, and visually appealing products.

4. Lamination and Coating

Lamination and coating represent crucial surface treatment processes within “bindery finishing austin,” impacting both the aesthetic appeal and functional longevity of printed materials. Lamination involves applying a thin plastic film to the printed surface, providing protection against moisture, abrasion, and UV damage. Coating, conversely, refers to the application of a liquid varnish or sealant that dries to form a protective or decorative layer. The selection of appropriate lamination or coating techniques is a direct consequence of the intended use and desired visual characteristics of the final product. For example, a children’s book might benefit from a durable, glossy lamination to withstand handling, whereas a high-end brochure could employ a soft-touch coating for a luxurious tactile experience. The absence of these treatments can lead to premature wear, fading, or a less impactful presentation, particularly in frequently handled or environmentally exposed items.

The practical applications of lamination and coating within “bindery finishing austin” are widespread. Business cards, for example, frequently undergo lamination to enhance durability and impart a professional feel. Marketing materials, such as brochures and postcards, often receive UV coating to increase vibrancy and attract attention. Packaging materials utilize various coatings to protect against scuffing, moisture, and chemical exposure during shipping and handling. Incorrect application, such as uneven coating or bubbling in lamination, undermines these intended benefits, resulting in a subpar finished product. Selecting the correct process and ensuring precise application is essential for achieving the desired outcome.

In summary, lamination and coating are indispensable components of “bindery finishing austin,” offering both protective and aesthetic enhancements to printed materials. Understanding the properties and applications of different lamination films and coating formulations is paramount for achieving optimal results. Failure to properly implement these techniques can diminish the value and longevity of the printed product, highlighting the practical significance of expertise in this area. The careful selection and execution of these processes contribute significantly to the overall quality and impact of the final deliverable.

5. Quality Control Standards

The consistent application of rigorous quality control standards is paramount to the success of any “bindery finishing austin” operation. These standards serve as a framework for ensuring that every project meets predetermined specifications and consistently delivers high-quality results. Without adherence to such standards, inconsistencies, errors, and defects can compromise the functional integrity and aesthetic appeal of finished products, ultimately undermining their value and impact. The relationship between quality control and post-press services is causal; the presence of robust quality control directly leads to improved product outcomes and enhanced customer satisfaction. Conversely, a lack of quality control results in increased waste, rework, and dissatisfied clients.

The practical application of quality control within “bindery finishing austin” manifests in several critical areas. Pre-production checks verify the accuracy of incoming materials and ensure that all necessary components are present. In-process inspections monitor the performance of machinery and the adherence to specifications during each stage of production, from cutting and folding to binding and lamination. Post-production inspections assess the finished product against established criteria, identifying and correcting any deviations from the required standards. For example, a perfect-bound book undergoes scrutiny to ensure proper spine adhesion, accurate page alignment, and a clean, professional finish. Defective items are rejected, and corrective actions are implemented to prevent recurrence. Similarly, saddle-stitched booklets are inspected for correctly placed staples, even page distribution, and a flush trim. A real-world example might involve a print run of marketing brochures where strict quality control identifies and corrects color inconsistencies before the entire batch is completed, saving time, money, and resources.

In summary, quality control standards are not merely an optional add-on but an integral and indispensable component of “bindery finishing austin.” They provide a systematic approach to minimizing errors, maximizing efficiency, and ensuring consistent product quality. While implementing and maintaining stringent quality control processes may present challenges, the benefits in terms of reduced waste, enhanced customer satisfaction, and a strengthened reputation far outweigh the costs. Furthermore, adherence to these standards is increasingly important in a competitive market, where customers demand high-quality products and reliable service.

Frequently Asked Questions Regarding Bindery Finishing in Austin

The following provides answers to commonly asked questions concerning post-press operations within the Austin metropolitan area. It is intended to clarify common misconceptions and provide a clear understanding of available services.

Question 1: What is the typical turnaround time for bindery finishing projects in Austin?

Turnaround time varies depending on project complexity, volume, and current workload. Simple cutting and folding operations may be completed within 24-48 hours. More intricate processes, such as perfect binding or case binding, can require several days to a week. Accurate estimates are provided upon project evaluation.

Question 2: What file formats are preferred for submitting projects to Austin bindery finishing services?

Print-ready PDF files are the industry standard. All fonts must be embedded or outlined, and images should be at a resolution of at least 300 DPI. Properly prepared files minimize potential delays and ensure accurate reproduction.

Question 3: What is the minimum order quantity for bindery finishing services in Austin?

Minimum order quantities vary depending on the specific service and provider. Some facilities specialize in large-volume runs, while others accommodate smaller, custom projects. It is advisable to contact individual providers to inquire about their minimum order requirements.

Question 4: Can Austin bindery finishing services handle projects with specialized paper stocks or unique finishing requirements?

Most reputable providers possess the capabilities and expertise to work with a wide range of paper stocks, including coated, uncoated, textured, and specialty materials. Unique finishing requirements, such as die-cutting, embossing, or foil stamping, can often be accommodated. Consultation is recommended to confirm compatibility and feasibility.

Question 5: How does bindery finishing contribute to the overall cost of a print project in Austin?

Bindery finishing represents a significant portion of the total project cost, particularly for complex or specialized processes. Factors influencing cost include the type of binding, lamination, or coating, as well as the project volume and turnaround time. Obtaining multiple quotes allows for accurate cost comparison and informed decision-making.

Question 6: Are eco-friendly bindery finishing options available in Austin?

Yes, many providers offer environmentally responsible options, such as recycled paper stocks, water-based coatings, and vegetable-based inks. Inquiring about sustainable practices and certifications demonstrates a commitment to environmental stewardship.

In summary, understanding these key aspects of post-press services is crucial for planning and executing successful print projects. Proactive communication and careful consideration of project requirements are essential.

The following article section will explore case studies illustrating the impact of effective post-press strategies on overall project outcomes.

Conclusion

This exploration of bindery finishing austin has illuminated the crucial role of post-press operations in transforming raw printed materials into refined, functional products. From meticulous cutting and folding to diverse binding techniques and protective surface treatments, each stage significantly impacts the final quality, durability, and aesthetic appeal. The availability of local services, adherence to rigorous quality control standards, and adaptability to specialized project requirements are essential considerations for achieving optimal outcomes.

The strategic selection and precise execution of bindery finishing processes contribute directly to the success of print projects, enhancing brand communication, ensuring product longevity, and ultimately maximizing return on investment. Therefore, a thorough understanding of available techniques and a collaborative partnership with experienced service providers are paramount for businesses seeking to leverage the full potential of printed materials.

![Do *Assholes* Really Finish First? [Truth & Tactics] Best Final Touch: Elevate Your Projects with Professional Finishing Do *Assholes* Really Finish First? [Truth & Tactics] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-214-300x200.jpg)