Warning: Undefined array key "https://bestfinaltouch.com/contact" in /www/wwwroot/bestfinaltouch.com/wp-content/plugins/wpa-seo-auto-linker/wpa-seo-auto-linker.php on line 192

This cordless power tool is designed for driving finish nails into wood surfaces. It operates on a 20-volt battery platform, providing portability and eliminating the need for hoses and compressors. Users employ this type of nailer for tasks such as installing trim, molding, and baseboards, providing a clean, professional finish in woodworking and carpentry applications.

The freedom from cords and hoses enhances maneuverability on job sites, leading to increased efficiency and reduced setup time. The convenience of battery power has contributed to its widespread adoption, particularly in environments where access to compressed air is limited or unavailable. This type of tool represents a significant advancement over traditional pneumatic nailers, offering comparable performance with greater flexibility.

The subsequent sections will explore the specific features, operational considerations, and potential applications of this cordless nailing solution, further demonstrating its value to professional tradespeople and DIY enthusiasts alike. Detailed information regarding battery technology, nail size compatibility, and safety protocols will also be provided.

Operating Tips for Cordless Finish Nailers

This section presents critical guidelines for optimal utilization of cordless finish nailers, designed to enhance performance and ensure safe operation.

Tip 1: Battery Management: Maintain consistent battery charge levels for consistent performance. Depleted batteries can lead to incomplete nail drives. A fully charged battery is crucial for optimal functionality.

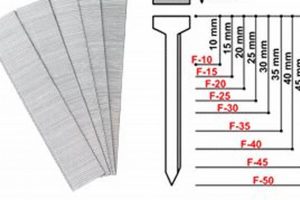

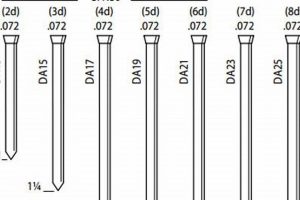

Tip 2: Nail Selection: Utilize nails of the correct gauge and length specified for the tool. Incorrect nail sizes can cause jamming or damage to the driving mechanism. Consult the manufacturer’s documentation for guidance.

Tip 3: Depth Adjustment: Adjust the nail depth setting based on the material being fastened. Driving nails too deep or not deep enough compromises the quality of the finish. Practice on scrap material to determine the appropriate setting.

Tip 4: Consistent Pressure: Apply consistent pressure to the tool during operation. Uneven pressure can result in angled nail drives or surface damage. Maintain a firm and stable grip.

Tip 5: Regular Maintenance: Regularly inspect and clean the nailer, including the nail magazine and driver blade. Remove any debris or buildup that can impede operation and reduce performance. Scheduled maintenance prolongs the tool’s lifespan.

Tip 6: Safety Precautions: Always wear appropriate eye and ear protection when operating the nailer. Consider hand protection when working for prolonged periods. Adhering to safety protocols minimizes potential injuries.

Tip 7: Storage Practices: Store the nailer in a dry and secure location when not in use. Remove the battery and nails to prevent accidental discharge. Proper storage preserves the tool’s condition.

Adhering to these guidelines ensures optimal operation, consistent results, and an extended lifespan for cordless finish nailers. Prudent application of these techniques contributes significantly to the quality and efficiency of woodworking and carpentry projects.

The concluding section will summarize the essential aspects of utilizing this type of power tool, reinforcing its advantages and overall value in professional and DIY environments.

1. Cordless Convenience

The “cordless convenience” associated with a 20V finish nailer represents a pivotal advantage over traditional pneumatic models. This advantage stems directly from the elimination of air hoses and compressors. The inherent portability allows tradespeople to operate the tool across diverse job sites, including those lacking readily available compressed air sources. The absence of cumbersome hoses reduces setup time and improves maneuverability in confined spaces, leading to enhanced productivity. For instance, installing trim in a newly constructed home without established air lines becomes significantly easier and faster with a cordless finish nailer.

Furthermore, cordless operation contributes to a safer work environment. The removal of tripping hazards associated with air hoses minimizes the risk of workplace accidents. The self-contained nature of the tool also reduces noise pollution, as compressors are no longer required for operation. Examples include working in occupied buildings or noise-sensitive environments, where minimizing disruption is crucial. The compact design and lighter weight, compared to pneumatic systems with compressors, further improve operator comfort and reduce fatigue, particularly during prolonged use.

In summary, the “cordless convenience” is not merely a supplementary feature but a core component that significantly enhances the practicality, safety, and efficiency of finish nailers. The transition to cordless technology has streamlined workflows and expanded the applicability of these tools across a wider range of construction and woodworking projects, overcoming logistical constraints associated with traditional pneumatic systems.

2. Battery Runtime

Battery runtime is a critical performance parameter for the 20V finish nailer, directly affecting its usability and productivity on a job site. It defines the period a user can operate the tool before requiring a battery recharge or replacement, influencing workflow continuity and overall project completion time. Understanding the factors impacting battery runtime is essential for optimizing tool usage.

- Battery Amp-Hour (Ah) Rating

The amp-hour rating quantifies the battery’s capacity to deliver current over time. A higher Ah rating translates directly into longer runtime between charges. For example, a 5.0Ah battery will generally power the finish nailer for a longer duration compared to a 2.0Ah battery. This difference is particularly significant on large projects where frequent battery changes would be disruptive.

- Workload Intensity

The type of material being nailed and the frequency of nail firing significantly impact battery drain. Driving nails into hardwood requires more energy per nail compared to softwood, thus reducing runtime. Similarly, continuous use at maximum nail depth settings consumes more power. Real-world scenarios include installing dense oak trim, which will necessitate more frequent battery changes than installing pine baseboards.

- Environmental Conditions

Temperature extremes can influence battery performance. Cold temperatures typically reduce battery capacity and runtime, while excessively high temperatures can accelerate battery degradation. Operating the finish nailer in sub-freezing conditions may result in a noticeable decrease in the number of nails that can be driven per charge. Conversely, prolonged exposure to direct sunlight in hot climates can shorten the battery’s lifespan.

- Battery Age and Condition

Battery performance degrades over time with repeated charge and discharge cycles. Older batteries may exhibit reduced runtime compared to new batteries, even when fully charged. Improper storage, such as leaving batteries discharged for extended periods, can also negatively impact their capacity and lifespan. Routine battery maintenance, including proper charging and storage practices, helps maximize battery performance.

The interplay between battery capacity, workload intensity, environmental factors, and battery age significantly impacts the 20V finish nailer’s overall operational effectiveness. Understanding these influences allows users to optimize their workflow, select appropriate batteries for the task at hand, and implement best practices for extending battery lifespan. Accurate estimations of runtime requirements based on these factors are crucial for efficient project planning and execution.

3. Nail Capacity

Nail capacity, a critical attribute of the 20V finish nailer, directly influences operational efficiency. This parameter quantifies the number of nails the tools magazine can hold, dictating the frequency with which the operator must reload. A higher nail capacity translates to fewer interruptions, potentially increasing productivity, especially on projects requiring extensive fastening. For example, a trim carpenter installing baseboards in a large house would benefit from a magazine holding a greater quantity of nails compared to one with a limited capacity. This reduces downtime associated with reloading, allowing for more continuous workflow. The magazine’s design, including its loading mechanism, also contributes to overall efficiency. A user-friendly loading process minimizes delays and reduces the potential for nail jams, further enhancing productivity. The relationship between nail capacity and operational speed is thus direct and significant.

The practical implications of nail capacity extend beyond mere convenience. On larger construction sites or in production environments, the cumulative effect of frequent reloads can significantly impact project timelines. Consider a scenario where multiple carpenters are simultaneously installing molding. A nailer with a reduced nail capacity would necessitate more frequent stops for each worker, potentially creating bottlenecks and delaying project completion. Furthermore, the type of nails accommodated by the magazine must align with the project’s requirements. Some magazines are designed to accept a specific range of nail lengths or collation types. Ensuring compatibility between the nailer’s capacity and the project’s nail specifications is crucial for optimal performance and to avoid operational disruptions. A mismatch can lead to unnecessary delays and increased material waste.

In summary, the nail capacity of a 20V finish nailer is more than a mere specification; it is a key determinant of operational efficiency, influencing project timelines and overall productivity. Understanding its impact, considering the project scope, and selecting a nailer with an appropriate nail capacity are crucial for achieving optimal results. Challenges associated with limited capacity can be mitigated through strategic planning and the use of high-capacity nail magazines when available. Ultimately, the nail capacity is an integral component that directly contributes to the tool’s value and effectiveness in diverse construction and woodworking applications.

4. Depth Adjustment

Depth adjustment represents a critical function integrated into the design of the 20V finish nailer. This capability allows the user to regulate the degree to which a nail is driven into the workpiece, ensuring proper fastening without damaging the surrounding material. Accurate depth adjustment is essential for achieving professional-grade results in finish carpentry applications.

- Surface Material Consistency

Variations in material density require corresponding adjustments to nail depth. Softer woods necessitate shallower nail penetration to prevent overdriving and surface marring. Conversely, harder woods require increased depth to ensure secure fastening. Without the ability to adjust depth, the user risks inconsistent results across differing material types, compromising the aesthetic quality of the finished project. Examples include transitioning from fastening pine trim to installing oak molding.

- Flush Finish Requirements

A flush finish, where the nail head is level with the surface of the material, is often a desired aesthetic outcome. Precise depth adjustment allows the user to consistently achieve this result, eliminating the need for manual nail setting and minimizing surface imperfections. Overdriving nails, leaving visible indentations, detracts from the overall appearance. Similarly, under-driven nails can protrude, creating a tactile and visual distraction. Applications such as cabinet facing and fine trim work demand precision in depth control to meet quality standards.

- Preventing Material Damage

Excessive nail penetration can cause splitting or cracking, particularly in delicate or thin materials. Adjustable depth settings allow the user to minimize this risk, preventing costly material waste and rework. Driving nails too deeply into fragile materials can result in irreversible damage, compromising the structural integrity and visual appeal of the project. Delicate applications, such as installing thin veneer or intricate decorative elements, require careful depth management.

- Fastener Security Optimization

While avoiding overdriving is important, insufficient nail penetration can compromise the security of the fastening. Adjustable depth settings enable the user to find the optimal balance, ensuring a strong and lasting connection without damaging the workpiece. Nails that are not driven deeply enough may not provide adequate holding power, leading to potential structural weaknesses. Applications such as stair rail installation and furniture construction demand sufficient fastener security for safety and longevity.

The depth adjustment function on the 20V finish nailer directly impacts the quality, durability, and aesthetic appeal of finished projects. Its integration is essential for achieving consistent, professional results across a range of materials and applications. Precise depth control reduces material waste, minimizes rework, and enhances the overall efficiency of finish carpentry tasks. The ability to fine-tune nail penetration provides the user with the flexibility needed to adapt to varying project requirements and material characteristics, solidifying the tool’s value in both professional and DIY settings.

5. Power Output

Power output is a critical determinant of the performance characteristics of a cordless finish nailer. In the context of a 20V finish nailer, power output directly influences its ability to consistently and effectively drive nails into various materials, impacting overall efficiency and suitability for diverse applications.

- Nail Driving Capability

Power output dictates the range of nail sizes and material densities the finish nailer can effectively handle. Insufficient power can result in incomplete nail drives, particularly in hardwoods or dense materials, necessitating manual nail setting or repeated attempts. For example, a higher power output enables the nailer to consistently drive 2.5-inch finish nails into oak trim without stalling or bending the nails.

- Firing Rate and Speed

The rate at which the nailer can fire nails is directly related to its power output. A higher power output generally allows for faster cycling, leading to increased productivity on large projects. Conversely, a lower power output may result in a slower firing rate, potentially creating bottlenecks and increasing overall project completion time. In production environments, a rapid firing rate is crucial for maximizing efficiency.

- Consistent Performance Under Load

A robust power output ensures consistent performance even under heavy use or demanding conditions. The ability to maintain consistent driving force, regardless of battery charge level or material resistance, is essential for reliable operation. A finish nailer with sufficient power output will exhibit minimal performance degradation as the battery discharges, providing a more predictable and consistent user experience.

- Motor Efficiency and Durability

Power output is intrinsically linked to the efficiency and longevity of the nailer’s motor. A well-designed motor with adequate power output can operate more efficiently, extending battery life and reducing the risk of overheating or premature failure. A finish nailer with a robust motor is better equipped to withstand the rigors of daily use, ensuring long-term reliability and durability.

The power output of a 20V finish nailer is a multifaceted characteristic that significantly impacts its performance, versatility, and longevity. Understanding the interplay between power output and these factors is crucial for selecting a finish nailer that meets the specific demands of the intended applications, ensuring efficient operation, consistent results, and long-term value.

6. Tool Weight

The weight of a cordless finish nailer significantly influences user experience and productivity. For the DeWalt 20V finish nailer, tool weight is a critical design consideration impacting maneuverability, fatigue reduction, and overall operational efficiency. A lighter tool reduces strain during prolonged use, enabling workers to maintain accuracy and consistency over extended periods. Conversely, an excessively heavy nailer can lead to user fatigue, diminished precision, and potential musculoskeletal issues. Therefore, manufacturers strive to optimize weight without compromising power or durability. The DeWalt 20V finish nailer’s weight is engineered to balance these competing factors, aiming to provide a tool that is both powerful and comfortable to operate. For instance, installing crown molding, a task often requiring overhead work, benefits significantly from a lighter nailer, minimizing arm fatigue and allowing for more precise nail placement. The impact on long-term job quality is substantial.

Furthermore, tool weight has implications for portability and storage. A lighter DeWalt 20V finish nailer is easier to transport between job sites, reducing physical strain during setup and takedown. The compact and relatively lightweight design also simplifies storage in toolboxes or work vehicles. This portability is particularly advantageous for contractors working on diverse projects in various locations. The weight also affects the user’s ability to work in confined spaces, where a bulky and heavy tool might be difficult to maneuver. For example, when installing trim inside a small closet, a lighter, more compact DeWalt 20V finish nailer offers a clear advantage. Therefore, understanding and appreciating the role of tool weight is paramount for maximizing the value of this type of cordless nailer.

In conclusion, tool weight is an essential attribute of the DeWalt 20V finish nailer, directly impacting user comfort, productivity, and portability. A balanced weight design contributes to reduced fatigue, improved maneuverability, and easier transportation. By optimizing weight without sacrificing power or durability, manufacturers enhance the tool’s overall value and appeal to both professional and DIY users. The practical significance of this consideration cannot be overstated, as it influences the long-term job quality and user well-being. The ongoing refinement of material science and engineering continues to drive innovation in this area, promising further enhancements in the power-to-weight ratio of cordless finish nailers.

7. Safety Features

The integration of safety features in the DeWalt 20V finish nailer is paramount, reflecting the potential hazards associated with power tools. These features are designed to mitigate risks, protect the operator, and prevent accidental injuries. Their effectiveness is critical to the safe and responsible use of the tool.

- Contact Trip Mechanism

The contact trip mechanism prevents unintended nail discharge. The nailer will only activate when the nose piece is fully depressed against the work surface. This design reduces the risk of accidental firing if the trigger is inadvertently pulled while the tool is not properly positioned. An example is preventing a nail from firing into the air or into the user’s hand during repositioning.

- Tool-Free Jam Release

Nail jams can occur during operation, necessitating a quick and safe method for clearing the obstruction. A tool-free jam release mechanism allows the user to clear jams without the need for additional tools, minimizing downtime and reducing the risk of injury associated with manual intervention. This feature prevents users from using makeshift tools or their fingers to dislodge the nail, reducing the potential for punctures or lacerations.

- Low Battery Indicator

A low battery indicator provides a visual warning when the battery charge is nearing depletion. This alert allows the user to anticipate the need for a battery change, preventing the nailer from unexpectedly shutting down mid-operation, which could lead to misfires or incomplete fastenings. It promotes safer operation by preventing interruptions that could cause a loss of control over the tool.

- Adjustable Belt Hook

An adjustable belt hook provides a convenient and secure means of temporarily storing the nailer when not in use. This feature allows the user to keep both hands free for other tasks, reducing the risk of dropping the tool or leaving it in a hazardous location. It also promotes better organization and prevents the nailer from being accidentally activated or damaged while lying on the ground.

These safety features collectively contribute to a safer operating environment for the DeWalt 20V finish nailer. By addressing potential hazards and promoting responsible tool handling, these features enhance user confidence and minimize the risk of accidents. The effectiveness of these features depends on proper usage and adherence to manufacturer’s safety guidelines.

Frequently Asked Questions

This section addresses common inquiries regarding the DeWalt 20V finish nailer, providing concise answers to enhance understanding and inform usage.

Question 1: What is the typical battery life of the DeWalt 20V finish nailer?

Battery life varies based on factors such as material density, nail size, and ambient temperature. A 4.0Ah battery typically drives between 600 and 800 nails per charge under average working conditions. Higher capacity batteries extend this runtime proportionally.

Question 2: Can the DeWalt 20V finish nailer be used for both 16-gauge and 18-gauge nails?

The DeWalt 20V finish nailer is designed for specific nail gauges. Verify the nailer’s specifications to ensure compatibility. Attempting to use incorrect gauges can damage the tool and compromise fastening performance.

Question 3: What maintenance procedures are required for the DeWalt 20V finish nailer?

Regular maintenance includes cleaning the nail magazine, inspecting the driver blade, and ensuring proper lubrication. Refer to the owner’s manual for detailed instructions and recommended service intervals. Neglecting maintenance can reduce performance and shorten the tool’s lifespan.

Question 4: Is the DeWalt 20V finish nailer suitable for driving nails into hardwood?

The DeWalt 20V finish nailer is capable of driving nails into various hardwoods, provided the nail length and depth settings are appropriately adjusted. For extremely dense hardwoods, pre-drilling pilot holes may be necessary to prevent nail bending or wood splitting.

Question 5: What safety precautions should be observed when using the DeWalt 20V finish nailer?

Always wear appropriate eye protection and hearing protection. Ensure the contact trip is properly engaged before firing. Never point the nailer at oneself or others. Disconnect the battery when performing maintenance or clearing jams. Adherence to these precautions is essential for preventing injuries.

Question 6: How should the DeWalt 20V finish nailer be stored when not in use?

Store the nailer in a dry, secure location, away from extreme temperatures and humidity. Remove the battery to prevent accidental discharge. Consider using a protective case to prevent dust and debris from entering the tool. Proper storage prolongs the tool’s lifespan and ensures reliable operation.

These FAQs provide essential information for understanding and utilizing the DeWalt 20V finish nailer effectively. Adherence to these guidelines promotes safe operation and maximizes the tool’s potential.

The subsequent section will summarize the key considerations for the optimal application of this power tool.

Conclusion

The preceding analysis has illuminated the core attributes and operational considerations of the DeWalt 20V finish nailer. Key aspects explored include its cordless convenience, battery runtime, nail capacity, depth adjustment capabilities, power output, tool weight, and integrated safety features. Understanding these elements is crucial for optimizing the tool’s performance and ensuring safe, efficient operation across diverse applications. The benefits of cordless operation, combined with adequate power and thoughtful design, position this tool as a viable alternative to traditional pneumatic systems.

The DeWalt 20V finish nailer represents a significant advancement in power tool technology, offering increased mobility, reduced setup time, and enhanced user comfort. Prospective users are encouraged to carefully evaluate their project requirements and operational constraints to determine if this type of tool aligns with their specific needs. The long-term value and performance of the DeWalt 20V finish nailer hinges on proper maintenance, adherence to safety protocols, and a thorough understanding of its capabilities. Continued innovation in battery technology and tool design promises further improvements in the efficiency and versatility of cordless finish nailers in the future.