These fasteners, characterized by their slender profile, are commonly employed in woodworking and carpentry for applications requiring minimal visibility of the fixing point. Their gauge, indicating diameter, provides sufficient holding power while reducing the likelihood of splitting delicate materials. Applications include attaching trim, molding, and fine woodworking components where a clean, professional appearance is paramount. An example would be securing window casings or assembling intricate cabinet details.

The significance of these fasteners lies in their ability to provide a secure bond without detracting from the aesthetic appeal of the finished product. Historically, the need for unobtrusive fastening solutions has driven the development of finer gauge options. This evolution has allowed for greater precision and control in applications where minimizing visual impact is critical. The resultant clean lines and seamless finishes contribute significantly to the perceived quality and craftsmanship of the final piece.

The following sections will delve into specific applications, best practices for usage, and considerations for selecting the appropriate length and head style for optimal performance. Further, the discussion will explore the tools used for driving these fasteners and potential challenges associated with their application.

Application Tips for Fine Gauge Fasteners

The following guidelines provide practical advice for effectively utilizing these fasteners, optimizing their performance, and minimizing potential issues during application.

Tip 1: Select the Appropriate Length: The fastener’s length should adequately penetrate the substrate to ensure a secure hold. A general rule is to penetrate at least two-thirds of the material being fastened into the underlying support. For example, when attaching 1/2-inch trim to a solid wood frame, a 1-inch fastener is generally sufficient.

Tip 2: Adjust Air Pressure on Pneumatic Tools: When using a pneumatic nailer, adjust the air pressure to prevent overdriving or underdriving. Overdriving can damage the surrounding material, while underdriving can result in a weak connection. Testing on scrap material is recommended to determine the optimal pressure setting.

Tip 3: Angle the Fastener for Enhanced Holding Power: Angling the fastener slightly during insertion can increase its resistance to pull-out forces. This technique is particularly useful when securing trim or molding to surfaces that may be subject to stress or movement.

Tip 4: Use a Nail Set to Conceal Heads: When a completely flush finish is desired, use a nail set to drive the fastener head slightly below the surface of the material. The resulting depression can then be filled with wood filler and sanded smooth.

Tip 5: Avoid Placing Fasteners Too Close to Edges: Installing these fasteners too close to the edge of the material can cause splitting or cracking. Maintain a safe distance from the edge, typically at least one-half inch, to prevent damage.

Tip 6: Consider Wood Hardness: Harder woods may require pre-drilling pilot holes to prevent bending or breaking of the fastener during insertion. Softer woods generally do not require pre-drilling.

Tip 7: Maintain Nailer Cleanliness: Regular cleaning and maintenance of the pneumatic nailer are essential for optimal performance and longevity. Follow the manufacturer’s recommendations for lubrication and cleaning procedures.

Adherence to these tips will contribute to a more professional and durable finish, reducing the likelihood of defects and ensuring a long-lasting connection.

The subsequent sections will further explore advanced techniques and troubleshooting strategies for specialized applications.

1. Gauge Diameter

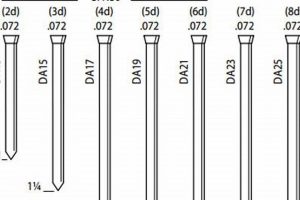

Gauge diameter is a fundamental characteristic defining the physical properties and suitability of fasteners. Within the context of these nails, the “16 gauge” designation specifies a standardized diameter critical to their intended use in fine woodworking and finishing applications. This parameter directly influences the fastener’s holding power, visibility, and the risk of splitting the workpiece.

- Definition and Measurement

Gauge refers to a standardized system for measuring wire diameter; a lower gauge number indicates a larger diameter. A 16-gauge nail possesses a precise diameter, typically around 0.0625 inches (1.6 mm). This measurement is crucial for ensuring compatibility with pneumatic nailers and achieving consistent results in application.

- Holding Power and Material Compatibility

The diameter directly correlates with the fastener’s ability to resist pull-out forces. A larger diameter generally provides greater holding power, but also increases the risk of splitting delicate materials. The 16-gauge diameter represents a balance, providing sufficient holding power for trim and molding while minimizing the likelihood of damage to the wood.

- Visibility and Aesthetic Considerations

A smaller diameter inherently results in a less conspicuous fastener head. The 16-gauge size is chosen to minimize visual intrusion, allowing the focus to remain on the craftsmanship and design of the finished piece. This is particularly important in applications where a clean, seamless appearance is desired, such as fine cabinetry or decorative molding.

- Nailer Compatibility and Performance

Pneumatic nailers designed for these nails are specifically calibrated to accommodate the precise diameter and length of 16-gauge fasteners. Using incorrect gauge nails can lead to malfunctions, misfires, and damage to the nailer. Adherence to the specified gauge ensures reliable and consistent performance during operation.

In conclusion, the gauge diameter of these nails is not merely a physical dimension but a carefully engineered parameter that dictates their functionality and suitability for a wide range of woodworking applications. The 16-gauge designation represents a deliberate compromise between holding power, visibility, and material integrity, making it a versatile choice for finish carpentry.

2. Head Styles

The head style of a fastener directly influences its performance and aesthetic impact, particularly in the context of 16 gauge finish nails. Selection of the appropriate head style is critical for achieving the desired balance between holding power, concealment, and ease of application.

- Brad Heads

Brad heads are characterized by their minimal size and nearly negligible profile. This design prioritizes concealment, making them ideal for applications where aesthetics are paramount, such as attaching delicate trim or molding. The small head size necessitates a smaller entry point, reducing the risk of splitting the wood. However, the reduced surface area also diminishes holding power, making them suitable for lighter-duty applications where the primary function is to maintain alignment rather than bear significant loads.

- Angled Heads

Angled heads, also known as chisel point heads, are designed for use in specific pneumatic nailers that drive the nails at a slight angle. This angle provides increased holding power by creating a mechanical interlock with the wood fibers. Furthermore, the angled entry point minimizes the risk of splitting, particularly in hardwoods. Angled heads are commonly used in applications where both strength and concealment are desired, such as attaching baseboards or door casings.

- Straight Finish Heads

Straight finish heads represent a compromise between concealment and holding power. They are slightly larger than brad heads, providing increased surface area for a stronger grip. These heads are typically designed to be countersunk using a nail set, allowing for the resulting depression to be filled and concealed. This option is suitable for applications where moderate holding power is required and a flush, paintable surface is desired, such as attaching window sills or chair rails.

- T-Heads

T-Heads provide the largest surface area of the finish nails. These are great for face nailing and provide the highest holding power. T-Heads are often used in industrial application.

The choice of head style for 16 gauge finish nails ultimately depends on the specific requirements of the application. Consideration must be given to the desired level of concealment, the required holding power, the type of wood being used, and the tools available for installation. Proper selection ensures a secure and aesthetically pleasing finished product.

3. Material Composition

The material composition of 16 gauge finish nails dictates their strength, durability, and resistance to corrosion. Understanding these attributes is crucial for selecting the appropriate nail for specific applications and environmental conditions. The choice of material directly impacts the longevity and structural integrity of the finished project.

- Steel Composition and Hardening Processes

Most finish nails are manufactured from steel, with variations in the specific alloy composition influencing their hardness and strength. Hardening processes, such as heat treatment, further enhance these properties, allowing the nails to penetrate dense materials without bending or breaking. Higher carbon steel, for instance, provides increased strength but may also increase brittleness. Proper hardening mitigates this risk, ensuring reliable performance.

- Surface Coatings and Corrosion Resistance

Surface coatings are frequently applied to finish nails to enhance their resistance to corrosion. Galvanization, either through electroplating or hot-dipping, is a common method that provides a protective zinc layer. This layer prevents the steel from reacting with moisture and oxygen, significantly extending the nail’s lifespan in humid or outdoor environments. Other coatings, such as phosphate, offer a lesser degree of corrosion resistance but can improve paint adhesion.

- Stainless Steel Options and Specialized Applications

For applications requiring maximum corrosion resistance, stainless steel finish nails are available. These nails are manufactured from alloys containing chromium and nickel, which form a passive oxide layer that prevents rusting. Stainless steel nails are particularly suitable for marine environments, exterior projects exposed to harsh weather, and applications involving treated lumber, where corrosive chemicals can accelerate the degradation of standard steel nails. However, stainless steel is generally softer than hardened steel, requiring careful consideration of the material being fastened.

- Adhesive Coatings and Holding Power Enhancement

Some finish nails are coated with adhesives designed to enhance their holding power. These adhesives activate upon insertion, creating a stronger bond between the nail and the surrounding wood fibers. Adhesive coatings are particularly useful in applications where vibration or stress may loosen standard nails over time. The specific type of adhesive varies depending on the manufacturer, with some offering greater resistance to moisture or temperature changes.

The diverse range of material compositions available for 16 gauge finish nails allows for tailoring the fastener selection to the specific demands of each project. Factors such as environmental conditions, load requirements, and aesthetic considerations should all be carefully evaluated to ensure optimal performance and longevity. The correct material choice contributes significantly to the overall quality and durability of the finished product, preventing premature failure and maintaining structural integrity over time.

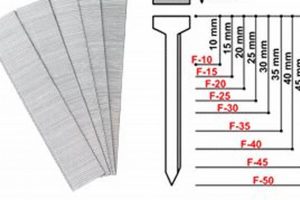

4. Length Range

The length range of 16 gauge finish nails is a critical factor directly influencing their utility across various woodworking and finishing applications. The available lengths, typically spanning from 1 inch to 2.5 inches, determine the thickness of materials that can be securely fastened. Selecting an inappropriate length can lead to either insufficient penetration, resulting in a weak hold, or excessive protrusion, compromising the aesthetic appearance and potentially creating a safety hazard. For instance, when attaching thin trim to a solid wood substrate, a shorter nail length (e.g., 1 inch) is appropriate to prevent it from piercing through the back. Conversely, securing thicker molding or baseboards requires a longer nail (e.g., 2 inches or greater) to ensure adequate engagement with the underlying framing or wall structure. The cause-and-effect relationship between nail length and the integrity of the fastening is undeniable; therefore, informed selection is paramount.

Practical applications vividly illustrate the importance of length range. Consider the task of installing crown molding. This typically involves fastening through both the molding and drywall into the wall studs. A nail length that is too short will fail to reach the stud, providing inadequate support and potentially causing the molding to detach over time. Conversely, a nail that is excessively long could protrude through the back of the stud, interfering with wiring or plumbing within the wall cavity. Similarly, in cabinet making, joining face frames to cabinet boxes demands a nail length that securely connects the components without penetrating through the interior of the cabinet. These examples highlight the need for precise length selection based on the specific materials and construction methods employed.

In summary, the available length range is an integral component of 16 gauge finish nails, enabling their versatility across a spectrum of finishing tasks. Accurate assessment of material thicknesses and structural requirements is essential for choosing the appropriate nail length, guaranteeing a secure and aesthetically pleasing outcome. Challenges often arise from misjudging material depths or selecting nails based solely on convenience. A thorough understanding of the relationship between length range and application-specific needs is crucial for achieving optimal results in woodworking and finish carpentry.

5. Application Specificity

Application specificity represents a critical consideration in the utilization of 16 gauge finish nails, significantly impacting the effectiveness and longevity of woodworking projects. The term underscores the necessity of selecting the correct fastener based on the specific demands of the task at hand, thereby ensuring optimal performance and minimizing potential failures. Inadequate appreciation of application specificity can lead to compromised structural integrity, aesthetic imperfections, and ultimately, project failure. The gauge size, coupled with factors like nail length, head style, and material, must be carefully aligned with the intended use case.

Real-life examples effectively illustrate this principle. For instance, using 16 gauge finish nails for heavy-duty structural applications, such as framing, is demonstrably inappropriate. Their slender profile and limited holding power are insufficient to withstand significant loads, potentially resulting in joint separation and structural collapse. Conversely, employing excessively robust fasteners in delicate trim work can cause unsightly splitting and damage to the material. Installing window casings, attaching intricate molding, or assembling delicate cabinet components requires a nuanced understanding of the interplay between fastener characteristics and material properties. This also demands an awareness of environmental factors, such as humidity or exposure to corrosive elements, which can further influence the selection process.

In conclusion, application specificity forms an integral component of successful woodworking and finishing. The appropriate selection of 16 gauge finish nails, informed by a thorough understanding of project requirements and material characteristics, directly contributes to enhanced structural integrity, aesthetic appeal, and overall project durability. Challenges often arise from neglecting these nuances, highlighting the need for careful evaluation and informed decision-making to ensure optimal outcomes. Ignoring application specificity can undermine the quality and longevity of finished products, emphasizing the practical significance of this understanding.

Frequently Asked Questions

The following questions address common inquiries regarding the selection, application, and performance characteristics of these fasteners, providing clarity for informed decision-making.

Question 1: What distinguishes 16 gauge finish nails from other nail gauges?

16 gauge finish nails are characterized by their relatively fine diameter, offering a balance between holding power and minimal visibility. This distinguishes them from coarser gauges, which provide greater strength but are more conspicuous, and finer gauges, which are less visible but offer reduced holding capacity.

Question 2: In what applications are 16 gauge finish nails most appropriate?

These fasteners are ideally suited for applications requiring a blend of secure fastening and aesthetic appeal, such as attaching trim, molding, cabinetry components, and other fine woodworking elements where a discreet fixing point is desired.

Question 3: What factors should be considered when selecting the appropriate length of these nails?

The length should be determined by the combined thickness of the materials being joined, ensuring adequate penetration into the substrate for a secure hold. A general guideline is to achieve penetration of at least two-thirds of the nail length into the underlying material.

Question 4: What are the advantages and disadvantages of different head styles available?

Brad heads offer maximum concealment but reduced holding power, while angled heads provide increased strength through a mechanical interlock with the wood fibers. Straight finish heads offer a compromise, allowing for countersinking and filling for a flush finish.

Question 5: How does the material composition influence the performance of 16 gauge finish nails?

Steel composition affects strength and hardness, while surface coatings, such as galvanization or stainless steel construction, enhance corrosion resistance. The choice of material should align with the environmental conditions and performance demands of the application.

Question 6: What potential challenges may arise during the application of these nails, and how can they be mitigated?

Splitting of the wood can occur, particularly near edges or in hardwoods. This can be mitigated by pre-drilling pilot holes or angling the nail during insertion. Overdriving or underdriving can also occur when using pneumatic nailers; adjusting air pressure and testing on scrap material is recommended.

The information provided clarifies key considerations for optimizing the use of 16 gauge finish nails, fostering informed decisions in diverse woodworking applications.

The next section will present a practical guide to tool selection and maintenance for working with these fasteners.

Conclusion

This exploration has illuminated the critical role of these fasteners in woodworking and finishing. From gauge diameter and head styles to material composition and application specificity, understanding these elements is paramount for achieving secure, aesthetically pleasing results. The appropriate selection and use of these nails, grounded in a clear comprehension of their properties, significantly impact the quality and longevity of finished projects.

Mastery of the principles governing 16 gauge finish nail application is essential for any woodworking professional. Continued diligence in material selection and adherence to best practices will ensure consistently superior outcomes, reinforcing the enduring value of craftsmanship and attention to detail in all endeavors.