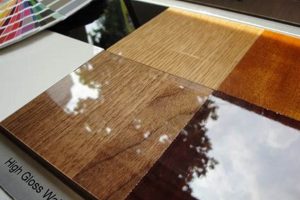

A lustrous coating applied to timber surfaces, resulting in a reflective and smooth appearance, enhances the natural beauty and durability of the wood. It serves as a protective layer, safeguarding the substrate from moisture, scratches, and ultraviolet radiation. An example includes a clear, high-sheen lacquer applied to a mahogany dining table, yielding a deep, rich, and mirror-like surface.

This treatment is frequently employed to elevate the aesthetic appeal and longevity of wooden furniture, flooring, and architectural elements. Its use dates back centuries, with variations in materials and techniques evolving over time. The advantages of this surface application include heightened resistance to wear and tear, ease of cleaning, and an improved visual presentation, adding value to the finished product.

The remainder of this article will delve into the different types of materials utilized to achieve this specific aesthetic. It will also examine application methods, surface preparation techniques, and considerations for maintenance and repair, providing a thorough understanding of achieving and preserving such a surface treatment.

Achieving a Superior Sheen

The attainment of a flawless surface necessitates careful planning and execution. These guidelines provide crucial insights for optimal results.

Tip 1: Select the Appropriate Product. The market offers a wide array of formulations, each possessing distinct properties. Evaluate factors such as intended use, environmental conditions, and desired sheen level to determine the optimal coating for the specific project. Consider a polyurethane-based coating for high-traffic surfaces requiring exceptional durability.

Tip 2: Surface Preparation is Paramount. Prior to application, the wood must be meticulously cleaned, sanded, and free from any imperfections. Improper preparation can compromise adhesion and result in an uneven final appearance. Sanding with progressively finer grits ensures a smooth foundation for the coating.

Tip 3: Thin Coats are Essential. Applying multiple thin coats is preferable to a single thick coat. This technique minimizes the risk of runs, drips, and air bubbles, while also promoting proper curing and adhesion. Allow each coat to dry completely before applying the next.

Tip 4: Control Environmental Conditions. Temperature and humidity can significantly impact the drying and curing process. Maintaining a stable and controlled environment within the recommended range is crucial for achieving optimal results. Avoid application in direct sunlight or during periods of high humidity.

Tip 5: Employ Proper Application Techniques. The method of application, whether brushing, spraying, or wiping, should be tailored to the specific product and the nature of the project. When brushing, use a high-quality brush and apply long, even strokes, working in the direction of the wood grain. When spraying, maintain a consistent distance and overlap each pass by approximately 50%.

Tip 6: Sand Between Coats. Lightly sanding between coats with fine-grit sandpaper helps to remove any imperfections and create a smoother surface for subsequent coats. Ensure that all sanding dust is removed before proceeding.

Tip 7: Allow Adequate Curing Time. Full curing can take several days or even weeks, depending on the specific product and environmental conditions. Avoid placing heavy objects on the surface until the coating has fully cured to prevent damage and ensure long-term durability.

Adherence to these recommendations will significantly enhance the likelihood of achieving a durable, aesthetically pleasing outcome, characterized by exceptional clarity and depth.

The subsequent sections will provide detailed information on product selection and maintenance.

1. Durability

The endurance of a timber surface, particularly when enhanced with a high-sheen coating, is directly proportional to the inherent qualities of both the wood and the applied material. A resilient topcoat safeguards the underlying substrate from physical abrasion, chemical exposure, and environmental stressors that would otherwise degrade the wood. For instance, a kitchen countertop finished with a robust, catalyzed lacquer demonstrates superior resistance to water damage and scratching from utensils, thereby extending its service life compared to an untreated surface. The selection of a coating designed for heavy use is, therefore, essential for maximizing the longevity of the object.

Furthermore, the application technique substantially affects the protective qualities. Multiple, properly cured layers of a polyurethane varnish, for example, form a dense barrier against moisture penetration, minimizing swelling and warping in humid environments. Conversely, a thinly applied or improperly cured finish provides inadequate defense, leaving the wood vulnerable to damage. Regular maintenance, such as gentle cleaning and the occasional re-application of a protective wax, can further enhance the longevity of the treated surface by preventing the accumulation of abrasive particles and replenishing the protective layer.

In summary, durability in a high-luster wood treatment is a multifaceted attribute determined by material selection, application methodology, and routine upkeep. The investment in high-quality products and meticulous execution yields a substantial return in the form of increased resistance to wear and tear, preserving the aesthetic appeal and structural integrity of the wood over extended periods. Understanding this interrelationship is critical for making informed decisions about wood finishing and ensuring its sustained performance.

2. Reflectivity

Reflectivity is an inherent attribute of a high-luster coating, directly dictating its visual characteristics. The ability of a surface to reflect light in a specular manner determines the level of perceived gloss and contributes significantly to the overall aesthetic appeal. A coating exhibiting high reflectivity creates a mirror-like effect, enhancing the natural grain and depth of the wood. Conversely, a coating with low reflectivity appears matte or satin, diffusing light and obscuring the wood’s inherent features. The selection of a product with the appropriate reflectivity level is, therefore, paramount to achieving the desired aesthetic outcome. For example, a grand piano frequently employs a high-reflectivity coating to project an image of elegance and sophistication, showcasing the meticulous craftsmanship.

The degree of reflectivity is influenced by several factors, including the smoothness of the surface, the refractive index of the coating material, and the presence of additives or pigments. A perfectly smooth, defect-free surface maximizes specular reflection, while imperfections such as scratches or air bubbles scatter light and reduce reflectivity. The use of clear, high-refractive-index coatings, such as certain acrylic or polyurethane formulations, enhances the surface’s capacity to reflect light, resulting in a brighter, more vibrant appearance. Moreover, the incorporation of matting agents or pigments can intentionally reduce reflectivity, creating a more subdued or textured surface. The precise control of these variables enables the customization of surface reflectivity to suit specific design preferences and functional requirements. Furniture design often reflects these choices, with different levels of reflectivity chosen for diverse styles, from contemporary minimalism to traditional opulence.

In conclusion, reflectivity is not merely an aesthetic quality of high-luster wood surfaces; it is a measurable and controllable parameter that directly impacts the visual experience and perceived value. Understanding the factors that influence reflectivity, from surface preparation to material selection, is crucial for achieving optimal results. While challenges may arise in maintaining a consistent level of reflectivity across large surfaces or over extended periods, the benefits of a well-executed, highly reflective finish in terms of visual impact and perceived quality remain substantial. This understanding underpins the successful application of high-luster coatings in a wide range of applications, from fine art to architectural design.

3. Application

The successful attainment of a high-luster wood surface is intrinsically linked to the application process. This stage directly determines the uniformity, smoothness, and overall integrity of the protective and decorative layer. Improper techniques invariably lead to visual defects, compromised durability, and a diminished aesthetic outcome. For instance, the presence of brush strokes, uneven spray patterns, or contaminants trapped within the coating significantly detracts from the desired reflective quality. Similarly, inadequate surface preparation, such as failing to properly sand or clean the wood, can result in poor adhesion, premature failure, and a lackluster appearance. Therefore, the meticulous execution of each step in the application sequence is essential for achieving the desired result.

Various application methods, including brushing, spraying, and wiping, each possess inherent advantages and disadvantages. Brushing, while often cost-effective for smaller projects, requires considerable skill to avoid visible brush marks and ensure even coverage. Spraying, on the other hand, provides a more uniform application, especially on intricate surfaces, but necessitates specialized equipment and careful control of environmental factors to minimize overspray and solvent evaporation issues. Wiping techniques, commonly employed for applying oil-based finishes, offer a balance between control and efficiency, allowing for the gradual build-up of thin, even layers. Regardless of the chosen method, adherence to the manufacturer’s recommendations regarding product viscosity, application rate, and drying times is crucial. A practical example is the application of multiple thin coats of polyurethane using a high-volume, low-pressure (HVLP) sprayer to achieve a durable, glass-like surface on a custom-built guitar.

In summation, the application process represents a critical juncture in the creation of a lustrous wood finish. It bridges the gap between material selection and the final aesthetic outcome. Challenges such as maintaining a dust-free environment, managing application variables, and ensuring proper curing require careful planning and execution. The pursuit of a superior finish necessitates a thorough understanding of application techniques, material properties, and environmental considerations. Mastery of this process translates directly into the creation of a durable, visually stunning surface that enhances the inherent beauty of the wood.

4. Preparation

The attainment of a superior high-luster surface is predicated upon meticulous preparation. This initial phase establishes the foundation upon which the final aesthetic and functional properties depend. Inadequate preparation invariably results in surface imperfections, compromised adhesion, and a diminished sheen. The removal of existing coatings, contaminants, and surface irregularities is paramount. Sanding, a fundamental aspect of preparation, creates a smooth and uniform substrate, facilitating optimal adhesion of the applied material. For instance, the refinishing of an antique cabinet necessitates the careful removal of aged varnish and the meticulous sanding of the underlying wood to ensure a flawless and enduring outcome. The practical significance of this phase lies in its ability to prevent future failures and ensure the long-term performance of the finished piece. Improper preparation is a direct cause of peeling, cracking, and uneven luster, negating the benefits of even the highest-quality topcoats.

The preparation process extends beyond mere surface leveling. It encompasses the proper sealing of porous woods to prevent excessive absorption of the coating material. It also involves the application of appropriate primers or sealers to enhance adhesion and prevent bleed-through of tannins or dyes present in the wood. For instance, certain hardwoods, such as cherry or mahogany, require a specialized sealer to prevent the discoloration of the final coating. A failure to address these issues during preparation invariably leads to aesthetic defects and compromises the protective properties of the finish. Furthermore, environmental control plays a crucial role in the preparation process. Maintaining a dust-free environment minimizes the risk of contamination, while ensuring adequate ventilation promotes proper drying of preparatory materials. The selection of appropriate cleaning agents and the meticulous removal of residue are equally critical to achieving optimal results.

In conclusion, preparation constitutes a foundational element in the creation of a high-luster surface. It is not merely a preliminary step, but rather an integral component that directly influences the final outcome. Overcoming challenges such as identifying hidden imperfections and implementing appropriate corrective measures requires expertise and attention to detail. This understanding is essential for any craftsman seeking to achieve a durable, aesthetically pleasing, and long-lasting application. Success is directly proportional to the effort and precision invested in the preparation stage, ensuring a seamless transition to the subsequent application and finishing processes.

5. Protection

A high-luster surface provides a crucial barrier against environmental factors and physical damage, significantly extending the lifespan of the underlying wood. This protective layer shields the substrate from moisture penetration, which can lead to warping, swelling, and fungal growth. For instance, exterior doors coated with a robust, high-sheen marine varnish exhibit exceptional resistance to rain, snow, and humidity, preventing the degradation that would otherwise occur over time. Furthermore, the coating acts as a shield against ultraviolet (UV) radiation, mitigating the discoloration and weakening of the wood caused by prolonged sun exposure. The protective qualities of a high-luster surface are also evident in its resistance to scratches, abrasions, and chemical spills, safeguarding against daily wear and tear. Countertops finished with a durable, high-sheen polyurethane demonstrate resistance to staining from food and beverages, maintaining their aesthetic appeal for extended periods. Protection, therefore, is not merely a superficial benefit; it is a fundamental attribute of a high-luster surface, ensuring its longevity and structural integrity.

The effectiveness of protection is directly correlated to the quality of the coating and the application process. Multi-layered application of marine varnish ensures the maximum protection to the wooden boat in the sea, thus protects wood from moisture and UV rays. Proper surface preparation is also paramount, as it promotes adhesion and prevents the penetration of moisture or contaminants. Moreover, maintenance plays a vital role in sustaining the protective qualities of the finish. Regular cleaning removes dirt and grime that can abrade the surface, while periodic re-application of a protective wax replenishes the barrier against moisture and scratches. By diligently attending to these factors, it is possible to maximize the protective benefits of a high-luster surface and ensure its continued performance over time.

In summary, protection is an indispensable element of high-luster wood surfaces, acting as a shield against environmental stressors and physical damage. The long-term preservation of the wood is fundamentally dependent on the protective qualities of the coating. By understanding the factors that influence protection, and by implementing appropriate application and maintenance practices, the lifespan of the wood can be substantially prolonged, ensuring its continued aesthetic appeal and structural soundness. This understanding is particularly critical in applications where the wood is exposed to harsh conditions or high levels of wear and tear.

6. Maintenance

The longevity and aesthetic appeal of a high-luster wood surface are inextricably linked to diligent maintenance practices. While the initial application of a protective coating provides a robust barrier against environmental factors and physical wear, its effectiveness diminishes over time without proper upkeep. Maintenance serves to replenish the protective layer, remove abrasive contaminants, and mitigate the effects of everyday use. A neglected surface will inevitably exhibit signs of wear, including scratches, dullness, and eventual degradation of the coating itself, necessitating costly repairs or complete refinishing. The consistent application of appropriate cleaning methods and protective products is therefore essential for preserving the integrity and visual characteristics of a high-luster surface. For instance, a dining table meticulously finished with multiple coats of lacquer requires regular cleaning with a non-abrasive cleaner and periodic polishing with a furniture wax to maintain its reflective sheen and prevent the accumulation of grime that can dull the surface.

Specific maintenance procedures vary depending on the type of coating and the intended use of the surface. Surfaces subjected to heavy use, such as flooring or countertops, necessitate more frequent cleaning and the application of more robust protective measures. The use of appropriate cleaning agents is also critical. Harsh chemicals or abrasive cleaners can damage the coating, leading to discoloration, scratching, or even delamination. Instead, gentle, pH-neutral cleaners specifically formulated for wood surfaces are recommended. Regular dusting or vacuuming helps to remove abrasive particles that can scratch the finish. Additionally, the strategic placement of mats and rugs in high-traffic areas can minimize wear and tear on flooring. Preventative measures such as using coasters under beverages and placemats under dishes further contribute to the preservation of the surface.

In conclusion, maintenance is not merely an optional addendum to a high-luster wood surface, but rather an integral component of its long-term viability. The investment in appropriate cleaning methods, protective products, and preventative measures translates directly into a prolonged lifespan, sustained aesthetic appeal, and reduced need for costly repairs. While challenges may arise in consistently adhering to a rigorous maintenance schedule, the benefits of doing so far outweigh the effort involved. Understanding the direct correlation between maintenance and the preservation of a high-luster finish empowers owners to make informed decisions and implement proactive measures, thereby safeguarding their investment and ensuring the enduring beauty of the wood.

Frequently Asked Questions

This section addresses common inquiries regarding high-luster treatments on wood, providing clear and concise information to assist in decision-making and maintenance.

Question 1: What distinguishes a high-luster coating from other wood finishes?

High-luster coatings possess a significantly higher degree of reflectivity compared to matte, satin, or semi-gloss finishes. This results in a mirror-like sheen that enhances the wood’s natural grain and depth.

Question 2: Is a high-luster treatment suitable for all types of wood?

While generally applicable, certain wood species with inherently open grains may require additional preparation, such as pore-filling, to achieve a perfectly smooth surface for optimal reflectivity.

Question 3: How durable are high-luster surfaces compared to other finishes?

Durability is primarily dependent on the type of coating material used, rather than the sheen level. However, high-luster finishes often require greater care to prevent scratches and abrasions, which are more visible on highly reflective surfaces.

Question 4: What cleaning products are recommended for maintaining a high-luster surface?

Gentle, pH-neutral cleaners specifically formulated for wood surfaces are recommended. Abrasive cleaners and harsh chemicals should be avoided, as they can damage the coating and diminish the sheen.

Question 5: Can a damaged high-luster surface be repaired?

Minor scratches and blemishes can often be repaired with specialized polishing compounds. However, more significant damage may necessitate professional refinishing to restore the surface to its original condition.

Question 6: What are the primary advantages of choosing a high-luster treatment for wood?

The primary advantages include enhanced aesthetic appeal, increased light reflection, and a perceived sense of luxury and sophistication. A properly maintained high-luster surface can significantly elevate the visual impact of wooden furniture and architectural elements.

In summary, while high-luster surfaces offer significant aesthetic advantages, they also require careful consideration regarding material selection, application techniques, and ongoing maintenance.

The subsequent section will delve into case studies and real-world applications of high-luster treatments on wood.

Conclusion

This article has comprehensively explored the attributes, application, and maintenance considerations surrounding glossy wood finish. The examination encompassed durability, reflectivity, surface preparation, protection, and the critical role of ongoing maintenance. It is evident that achieving and preserving such a surface demands meticulous attention to detail, informed material selection, and a thorough understanding of application techniques.

The successful implementation of glossy wood finish represents a significant investment in the long-term aesthetic and functional value of wooden objects. While challenges may arise, the transformative potential of this treatment, when executed with precision and diligence, warrants careful consideration for those seeking to elevate the visual impact and longevity of their wood surfaces. Further research and continuous refinement of application methods will undoubtedly contribute to even greater advancements in this field.