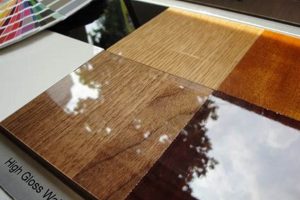

A lustrous coating, creating a reflective and smooth surface on wooden materials, is often desired for its aesthetic qualities. This type of treatment enhances the wood’s natural beauty by providing a protective layer and deepening the richness of the grain. As an example, applying several coats to a tabletop can transform a simple piece into a visually striking focal point.

Such a surface offers significant advantages, including increased durability and resistance to scratches, moisture, and stains. Historically, achieving this level of sheen was a time-consuming process, involving multiple applications of natural oils and waxes, followed by extensive polishing. This treatment has been favored throughout various design movements for its capacity to convey elegance and sophistication.

This article will delve into the application techniques, optimal wood selection, and maintenance strategies for creating and preserving this elegant surface treatment. Further sections will also address safety considerations and environmentally responsible alternatives.

Achieving Optimal Results

The following guidelines are designed to maximize the visual impact and longevity of the surface treatment. Proper preparation and application are crucial for a professional-looking result.

Tip 1: Wood Selection. The inherent characteristics of the chosen wood species significantly impact the final appearance. Close-grained hardwoods, such as maple or cherry, typically provide a smoother and more consistent surface than open-grained woods. Consider the wood’s natural color and grain pattern in relation to the desired aesthetic.

Tip 2: Surface Preparation. Thorough sanding is essential. Begin with a coarse grit sandpaper and gradually progress to finer grits, ensuring a uniformly smooth surface. Remove all dust particles with a tack cloth prior to application.

Tip 3: Application Technique. Apply thin, even coats, allowing each coat to dry completely before applying the next. Avoid drips, runs, and pooling of the finish. Multiple thin coats are preferable to a single thick coat.

Tip 4: Product Selection. Choose a product specifically formulated for achieving the desired level of sheen. Consider factors such as drying time, durability, and VOC content. Always follow the manufacturer’s instructions carefully.

Tip 5: Environmental Conditions. Application should occur in a dust-free environment with adequate ventilation and stable temperature and humidity levels. Extreme temperatures or high humidity can negatively affect the drying and curing process.

Tip 6: Sanding Between Coats. Lightly sand between coats with very fine-grit sandpaper (e.g., 400 grit or higher) to remove any imperfections or dust particles. This ensures a smooth and flawless final surface.

Tip 7: Consider a Sealant. Applying a sanding sealer prior to the top coats can help fill the wood pores and create a more uniform base for the subsequent finish layers.

Implementing these practices helps to create a resilient and visually striking surface, enhancing the wood’s natural beauty and providing lasting protection.

The following section will address potential challenges and troubleshooting tips for achieving consistent results.

1. Durability

The longevity of a surface treatment is intrinsically linked to its durability, a critical factor in assessing its long-term value. A high gloss surface, while visually appealing, must withstand the rigors of daily use to maintain its aesthetic qualities. Inadequate durability results in scratching, chipping, and eventual degradation of the reflective surface, negating the initial investment. This is particularly evident in high-traffic areas or on surfaces subjected to frequent cleaning.

The composition of the finish and the application process directly influence its durability. For instance, a multi-layer system, consisting of a primer, several coats of finish, and a protective topcoat, offers superior resistance to wear and tear compared to a single-coat application. Similarly, formulations with higher solids content tend to create a more robust and resilient surface. Consider a bar top; a durable coating is essential to withstand spills, impacts, and constant use. Another example could be wooden flooring, which must withstand foot traffic and furniture movement. Each case clearly showcases the practical significance of understanding the connection between “Durability” and “high gloss wood finish”.

Ultimately, the selection of a high gloss treatment requires a careful evaluation of its inherent durability. Factors such as the intended use of the wooden item, the anticipated level of wear and tear, and the environmental conditions must be considered. Prioritizing durable coatings is essential to ensure the long-term preservation of the finish and to minimize the need for frequent repairs or replacements. By emphasizing durability, the aesthetic qualities of the finish can be enjoyed for years to come. Addressing the challenge to find the suitable materials ensures successful and long-term coating.

2. Reflectivity

Reflectivity is a defining characteristic of high gloss wood finishes, directly influencing the visual impact and aesthetic appeal of treated surfaces. It is the property that allows light to bounce off the surface, creating a mirror-like sheen. This attribute is often the primary reason for choosing a high gloss treatment, as it enhances the perception of depth, brightness, and overall elegance.

- Specular Reflection

Specular reflection occurs when light rays strike the surface and bounce off at an equal angle. This creates a clear, undistorted image of the surroundings on the surface of the wood. High gloss finishes are formulated to maximize specular reflection, resulting in a highly polished and mirror-like appearance. For example, a grand piano finished with a high gloss coating exhibits specular reflection, allowing the viewer to see a clear reflection of the room and its contents.

- Refractive Index

The refractive index of the finish material plays a crucial role in determining the degree of reflectivity. Materials with a higher refractive index bend light more effectively, resulting in a greater amount of light being reflected back to the observer. Finishes with high refractive indices, such as certain acrylics and polyurethanes, are often preferred for achieving a high gloss effect. Example: A clear high refractive index coating, that is very transparent, applied to wood.

- Surface Smoothness

The smoothness of the finished surface is paramount for achieving optimal reflectivity. Any imperfections or irregularities, such as scratches or orange peel texture, will scatter light, reducing the clarity and intensity of the reflected image. Therefore, meticulous sanding and application techniques are essential to create a perfectly smooth surface that maximizes light reflection. Example: After several coats, polishing with fine compound makes the surface much smoother.

- Color and Light Interaction

The color of the finish and the underlying wood influence the perceived reflectivity. Darker colors tend to absorb more light, resulting in a less intense reflection compared to lighter colors. Additionally, the interaction of light with the wood grain can create subtle variations in reflectivity, adding depth and character to the finished surface. Example: A dark ebony high gloss finish will reflect less light than a light maple high gloss finish.

These aspects of reflectivity directly contribute to the overall aesthetic impression of high gloss wood finishes. By manipulating the refractive index, surface smoothness, and color, skilled finishers can achieve a range of reflective effects, enhancing the natural beauty of the wood and creating visually stunning surfaces. The careful control and optimization of these factors are essential for achieving the desired high gloss appearance.

3. Smoothness

A direct relationship exists between surface smoothness and the visual quality of a high gloss wood finish. The degree of smoothness directly dictates the reflectivity and clarity achievable. A rough or uneven surface diffuses light, scattering it in multiple directions and reducing the intensity of specular reflection. Consequently, the finish appears dull and lacks the characteristic mirror-like sheen associated with a high gloss appearance. Conversely, a perfectly smooth surface allows for uniform reflection, maximizing the visual impact. In practice, achieving this level of smoothness requires meticulous surface preparation, involving multiple stages of sanding with progressively finer grits of sandpaper. The objective is to eliminate all surface imperfections, such as scratches, grain irregularities, and imperfections from previous finish coats.

The impact of smoothness extends beyond aesthetics. An uneven surface provides more surface area for dirt and contaminants to adhere to, making cleaning more difficult and potentially damaging the finish over time. A smooth surface, on the other hand, is easier to clean and maintain, preserving the finish’s clarity and reflectivity for a longer duration. The choice of application method also plays a significant role in achieving smoothness. Spraying techniques often produce smoother results compared to brushing or wiping, as they minimize the introduction of surface imperfections. Leveling agents within the finish formulation can further enhance smoothness by reducing surface tension and promoting even distribution during application. For example, applying a self-leveling clear coat to a sanded surface is often the final step in achieving “smoothness.”

In summary, surface smoothness is not merely a cosmetic attribute but rather a fundamental requirement for a high gloss wood finish. Its influence extends to reflectivity, clarity, maintainability, and overall durability. The time and effort invested in achieving a perfectly smooth surface during preparation and application are critical to realizing the full potential of the finish and ensuring its long-term performance. Improper surface finishing prevents ideal light transfer for final coating. Therefore, emphasis on meticulous technique leads to a better final product. Understanding and prioritizing smoothness allows for a deeper understanding of the relationship between wood finishes and woodworking goals.

4. Clarity

Clarity, in the context of wood finishing, refers to the transparency and lack of visual distortion within the applied coating. It is a crucial determinant of the final aesthetic quality, particularly in high gloss finishes, where the intent is to enhance the inherent beauty of the underlying wood grain. Reduced clarity diminishes the visual depth and richness of the wood, obscuring the natural patterns and colors. In essence, a lack of clarity negates the purpose of a transparent finish, making the choice of wood species less relevant. For example, if one invests in an expensive piece of figured maple, a finish lacking in clarity will hide the figure, wasting the aesthetic potential of the material.

The factors affecting clarity include the quality of the finishing product itself, the presence of contaminants during application, and the degree of surface preparation. Finishes containing low-quality solvents or excessive additives can exhibit haziness or cloudiness, reducing transparency. Dust particles, air bubbles, or other impurities trapped within the finish layer can also scatter light, diminishing clarity. Proper sanding and cleaning of the wood surface prior to application are essential to remove any substances that may interfere with the finish’s optical properties. Another key practical application of this is understanding the cause and remedy of “orange peel”. Orange peel finish prevents an ideal visual transfer.

In conclusion, clarity is an indispensable attribute of a high gloss wood finish. It ensures that the natural beauty of the wood is fully revealed, enhancing the depth, richness, and overall aesthetic appeal. By carefully selecting high-quality finishing products, maintaining a clean working environment, and employing proper surface preparation techniques, it is possible to achieve exceptional clarity, resulting in a finish that showcases the wood’s inherent characteristics in their best light. Emphasizing clarity allows the value and work invested in the underlying wood surface to shine through.

5. Protection

The protective function of a high gloss wood finish is paramount, safeguarding the underlying wood from environmental damage and physical wear. The finish forms a barrier, mitigating the effects of moisture, ultraviolet radiation, and abrasion. Absent this protection, wood is susceptible to warping, cracking, discoloration, and staining, thereby compromising its structural integrity and aesthetic appeal. The protective qualities directly contribute to the longevity of the treated item; an untreated wooden table, for instance, will quickly show signs of water damage and scratches, while a properly finished one can withstand years of use.

The degree of protection offered varies based on the type and formulation of the finish. Polyurethane finishes, known for their durability, provide excellent resistance to abrasion and chemical spills, making them suitable for high-traffic surfaces. Varnishes offer good protection against moisture and UV radiation, rendering them appropriate for outdoor applications. Lacquers, while offering a high gloss sheen, may require more frequent maintenance due to their lower resistance to scratching. Consider museum artifacts; a protective finish is critical to preserving the artifact for generations. Another example is the finish on a musical instrument, such as a guitar; the finish protects the wood from humidity and handling, while also contributing to the instrument’s tonal qualities. Proper implementation helps provide a better visual transfer to create a surface with an ideal aesthetic.

Ultimately, selecting a high gloss finish necessitates a careful assessment of the required level of protection. Factors such as the intended use of the item, the environmental conditions to which it will be exposed, and the desired lifespan must be considered. Prioritizing finishes that offer adequate protection ensures that the wood remains structurally sound and aesthetically pleasing for an extended period. Thus, “protection” is not merely an ancillary benefit, but rather an intrinsic component of the finish’s value and utility. Ensuring suitable materials and techniques are applied leads to a more robust coating.

6. Application

The achievement of a high gloss wood finish is inextricably linked to the application process. Even the highest quality finishing products will yield substandard results if improperly applied. Application encompasses a series of steps, each crucial for achieving the desired aesthetic and protective qualities. These steps typically include surface preparation, finish selection, the application method itself, and subsequent curing and polishing. Errors at any stage can manifest as imperfections, such as orange peel texture, runs, drips, or inconsistent sheen levels. For example, inadequate sanding before applying the finish creates a rough surface that diffuses light, reducing the perceived gloss. Similarly, applying too much finish at once can lead to runs and sags, compromising the surface’s smoothness and clarity. This reveals its practical significance: meticulous application directly impacts the outcome.

The application method itself significantly influences the final result. Spraying, for instance, generally produces a smoother, more even finish than brushing or wiping, as it minimizes the introduction of brush strokes or lint particles. However, spraying requires specialized equipment and a controlled environment to prevent overspray and contamination. Brushing, while more accessible, demands considerable skill to avoid brush marks and ensure a uniform coat. The choice of applicator, such as the type of brush or spray nozzle, also plays a critical role. Furthermore, environmental conditions, such as temperature and humidity, can affect the finish’s drying and curing characteristics, impacting the final gloss level and durability. A real-world example would be a professional furniture restorer employing a multi-step spraying process in a climate-controlled booth to achieve a flawless, high gloss finish on an antique piece.

In summary, the application process is not merely a procedural step but an integral component of a high gloss wood finish. Understanding and mastering the various techniques, coupled with careful attention to detail and environmental factors, are essential for achieving optimal results. The challenges associated with application underscore the need for skilled craftsmanship and a thorough understanding of the materials and processes involved. Therefore, quality application of a “high gloss wood finish” ensures a valuable piece. Proper application reveals light and value.

Frequently Asked Questions About High Gloss Wood Finish

The following questions address common inquiries and concerns regarding high gloss wood finishes. Each answer provides concise, factual information to enhance understanding and inform decision-making.

Question 1: What distinguishes a high gloss finish from other sheen levels?

A high gloss finish reflects a significant amount of light, typically exceeding 70% on a gloss meter. This level of reflectivity creates a mirror-like appearance, contrasting with matte, satin, and semi-gloss finishes that diffuse more light.

Question 2: What wood species are best suited for a high gloss application?

Close-grained hardwoods, such as maple, cherry, and birch, are generally preferred due to their smooth surfaces and minimal pore structure. These characteristics facilitate the creation of a uniform and reflective finish. Open-grained woods, such as oak and ash, can be used, but require pore filling for optimal results.

Question 3: Is special surface preparation necessary for high gloss finishes?

Meticulous surface preparation is critical. This involves thorough sanding with progressively finer grits of sandpaper to eliminate all imperfections. Dust removal is essential to prevent contamination during the finishing process. A sanding sealer may be applied to create a uniform base for the topcoat.

Question 4: What types of finishes can achieve a high gloss sheen?

Several types of finishes, including polyurethane, lacquer, and varnish, can achieve a high gloss sheen. The selection depends on the desired level of durability, chemical resistance, and application requirements. Polyurethane is often favored for its durability, while lacquer is known for its fast drying time.

Question 5: How is a high gloss finish maintained and cleaned?

Regular cleaning with a soft, damp cloth is recommended to remove dust and debris. Avoid abrasive cleaners or harsh chemicals that can scratch or dull the surface. Periodic waxing or polishing can help maintain the sheen and protect the finish.

Question 6: What are the safety precautions to consider when applying high gloss finishes?

Many finishing products contain volatile organic compounds (VOCs) that can be harmful. Application should occur in a well-ventilated area, and appropriate personal protective equipment, such as a respirator and gloves, should be worn. Consult the manufacturer’s safety data sheet (SDS) for specific handling and disposal instructions.

In summary, achieving and maintaining a high gloss finish requires careful attention to detail, proper material selection, and adherence to safety guidelines. Understanding these aspects is essential for successful outcomes.

The following section will address potential challenges and troubleshooting tips for achieving consistent results.

High Gloss Wood Finish

This exploration has elucidated the multifaceted nature of achieving and maintaining a durable and aesthetically pleasing high gloss wood finish. Key determinants include meticulous surface preparation, the selection of appropriate wood species and finishing products, skillful application techniques, and diligent ongoing maintenance. Each of these elements is interdependent, contributing to the overall quality and longevity of the finished surface. The absence of any one element can compromise the final outcome, diminishing the visual impact and potentially reducing the protective capabilities of the treatment.

As demonstrated, a high gloss wood finish represents more than a mere cosmetic enhancement; it constitutes a significant investment in the preservation and elevation of the inherent qualities of wood. The informed application of these principles ensures a lasting legacy of craftsmanship, enhancing both the functional and aesthetic value of treated surfaces for generations to come. Continued research and development in finishing technologies offer the prospect of even more durable, sustainable, and visually striking options in the future, further solidifying the enduring appeal of wood as a timeless material.