The process of applying a protective coating to a wooden surface designed for food preparation is a critical step in ensuring its longevity and safety. This treatment involves saturating the wood with... Read more »

A milled piece of lumber, typically of high quality, used for interior trim and decorative applications defines a key element in interior design. This material contributes significantly to the aesthetic appeal and... Read more »

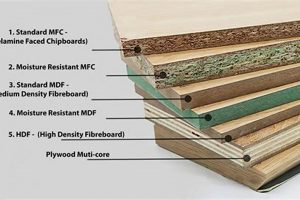

The term describes a manufactured panel, typically composed of wood or composite materials, that has undergone all necessary processing steps to render it suitable for its intended application. This includes cutting to... Read more »

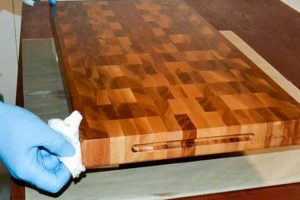

The concluding treatment of a wooden kitchen implement designed for food preparation is a critical step in its creation and maintenance. This process involves saturating the wood with a food-safe substance, typically... Read more »

This standard represents a common degree of completion for drywall surfaces prior to final decoration. It entails embedding tape in joint compound, applying multiple coats of compound over joints and fasteners, and... Read more »

A protective coating applied to wooden surfaces intended for food preparation, this sealant is formulated to prevent the absorption of liquids and bacteria while remaining non-toxic upon contact with food. An example... Read more »

The surface treatment applied to a charcuterie board serves a crucial role in both its aesthetics and functionality. This protective layer, often a food-safe oil or wax, seals the wood, preventing absorption... Read more »

The surface treatment applied to a cutting surface, commonly crafted from wood or plastic, influences its durability, hygiene, and overall performance. This treatment impacts the board’s resistance to moisture, bacteria, and staining.... Read more »

A protective coating applied to the surface of a wooden kitchen implement shields it from moisture, bacteria, and physical wear. This coating, typically food-safe, enhances durability and simplifies cleaning. For example, applying... Read more »

The outermost layer applied to a cornhole board significantly impacts both its appearance and performance. This protective coating, often a varnish, lacquer, or polyurethane, serves to shield the underlying wood from the... Read more »