The average peak-to-valley height of a surface within a sampling length is a key metric in surface texture assessment. This parameter quantifies the mean vertical distance between the highest and lowest points... Read more »

A metallic or organic coating applied to the exposed copper pads on a printed circuit board serves as a protective layer and provides a solderable surface for component assembly. This treatment prevents... Read more »

The external texture and appearance of stainless steel, achieved through various manufacturing processes, significantly impacts its functional and aesthetic properties. These processes range from simple mechanical polishing to complex chemical treatments, each... Read more »

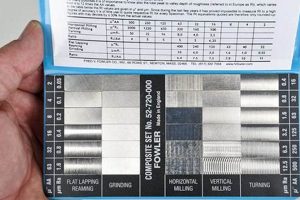

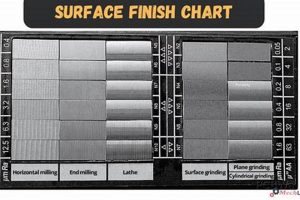

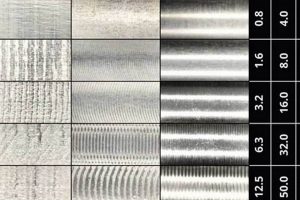

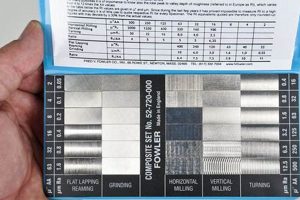

A specific degree of smoothness or texture on a manufactured part, achieved through controlled material removal or surface treatment processes, is often designated by a numerical value. One such designation represents a... Read more »

A surface roughness measurement, quantified in microinches Arithmetic Average (Ra), describes the average deviation of the surface from a mean line. A designation of 32 Ra indicates a surface finish where the... Read more »

Root Mean Square (RMS) surface roughness quantifies the average deviation of a surface from its ideal flatness. It is calculated by mathematically averaging the squares of the vertical distances of the surface... Read more »

Treatments applied to aluminum alloys to modify their surface properties are essential for enhancing performance and aesthetics. These processes include, but are not limited to, anodizing, powder coating, painting, and specialized textures.... Read more »

A measure of the arithmetic average of the absolute values of the surface height deviations, measured from the mean line, provides a common method for quantifying texture. This value, typically expressed in... Read more »