A specialized coating applied to leather surfaces after they have been painted or dyed, it imparts a protective layer and enhances the aesthetic quality of the treated item. This substance, often a clear acrylic or polyurethane-based formula, is designed to seal the color, prevent cracking or fading, and provide a desired sheen from matte to high gloss. As an example, consider a handcrafted leather handbag. After the application of vibrant color, a specialized coating ensures the longevity and brilliance of the design, safeguarding it against wear and tear.

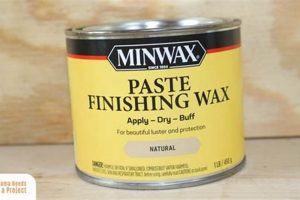

The value of this final step is found in its ability to preserve and improve the appearance and durability of leather goods. Historically, simpler methods, such as the application of natural waxes, were used to achieve similar results. Modern formulations, however, offer superior resistance to abrasion, water damage, and UV exposure, extending the lifespan of the leather and maintaining its visual appeal. This protective characteristic is especially crucial in items subject to frequent handling or exposure to the elements, such as automotive interiors, footwear, and furniture.

The following sections will delve into the various types of these protective coatings available, outlining their specific properties, application techniques, and best uses across different leather applications. Factors to consider when selecting the appropriate coating, alongside troubleshooting common issues, will also be addressed.

Tips for Optimal Application of Leather Paint Finisher

Achieving a professional and lasting result with a leather paint finisher requires careful preparation and execution. The following tips provide guidance on best practices for application, maximizing both the aesthetic appeal and protective qualities of the treatment.

Tip 1: Surface Preparation is Paramount: Prior to application, the leather surface must be thoroughly cleaned and deglazed. Residue from previous treatments or natural oils will impede adhesion and compromise the finish’s longevity. Use a dedicated leather deglazer or a mild solvent to ensure a pristine surface.

Tip 2: Thin, Even Coats are Essential: Multiple thin layers of finisher are preferable to a single heavy coat. This approach minimizes the risk of drips, runs, and cracking, resulting in a smoother, more uniform appearance. Allow each coat to dry completely before applying the subsequent one.

Tip 3: Employ Appropriate Application Techniques: The choice of application method spray, brush, or sponge depends on the size and complexity of the leather item. Spraying typically yields the most even distribution, while brushes and sponges are suitable for smaller areas or intricate details. Ensure all tools are clean and designed for use with the chosen formulation.

Tip 4: Temperature and Humidity Control Matters: Environmental conditions significantly impact drying time and finish quality. Ideal application occurs in a well-ventilated area with moderate temperature and low humidity. Extremes can lead to uneven drying, clouding, or bubbling.

Tip 5: Consistent Mixing for Uniformity: Some formulations contain settling agents. Thoroughly mix the product before and during application to ensure a consistent distribution of protective and aesthetic components. Failure to do so may result in variations in sheen or durability across the treated surface.

Tip 6: Cure Time is Critical: Adhere strictly to the manufacturer’s recommended curing time. Premature handling or use of the treated item can damage the finish and compromise its protective properties. Full curing ensures the development of optimal hardness and resilience.

Tip 7: Test Compatibility in an Inconspicuous Area: Before applying the product to the entire item, test its compatibility with the leather and underlying paint in a small, hidden area. This step allows for assessment of colorfastness, adhesion, and any potential adverse reactions.

By adhering to these guidelines, one can maximize the benefits of a leather paint finisher, achieving a durable, aesthetically pleasing result that enhances and protects the treated leather item. The key is meticulous preparation, controlled application, and adherence to manufacturer’s instructions.

The following sections will explore specific product recommendations and address frequently asked questions regarding the selection and application of leather paint finishers in various applications.

1. Adhesion Promotion

Adhesion promotion is a critical factor in the successful application of a leather paint finisher. The longevity and overall quality of the finished product hinge on the ability of the topcoat to effectively bond with the underlying paint layers. Without adequate adhesion, the finisher is prone to peeling, cracking, and premature failure, negating its protective and aesthetic benefits.

- Surface Preparation Techniques

Surface preparation plays a vital role in adhesion. Degreasing and cleaning leather prior to applying the finisher removes contaminants that inhibit bonding. Mechanical abrasion, using fine-grit sandpaper, can also create a textured surface that enhances the grip of the topcoat. In automotive leather restoration, meticulous cleaning and degreasing of worn areas are essential for ensuring the new finish adheres properly, preventing future peeling under stress.

- Primer Application for Enhanced Bonding

The use of a specialized primer designed for leather and compatible with the intended finisher is a common strategy for adhesion. These primers create an intermediary layer that chemically bonds to both the paint and the topcoat, acting as a bridge that promotes lasting adhesion. For example, when refinishing leather furniture, a primer is used to improve the bond between the existing finish and the new leather paint and protective topcoat.

- Chemical Compatibility Considerations

The chemical compatibility between the leather paint, the adhesion promoter (if used), and the finisher itself is crucial. Incompatible formulations can result in poor adhesion, discoloration, or even damage to the leather. Manufacturers often provide compatibility charts or guidelines to ensure the proper selection of products that will work harmoniously together. Choosing a finisher that is chemically compatible with the leather paint prevents issues like cracking and bubbling.

- Application Technique Influence

The application technique can significantly influence adhesion. Applying thin, even coats of the finisher allows for proper drying and bonding. Excessive thickness can lead to solvent entrapment and a weakened bond. Consistent pressure and even coverage, regardless of whether the application is done by spray, brush, or sponge, are key to maximizing adhesion. For instance, inconsistent application can cause weak spots that are vulnerable to wear in frequently touched areas like steering wheels.

In conclusion, adhesion promotion is not a singular factor but a combination of careful surface preparation, the potential use of primers, attention to chemical compatibility, and proper application techniques. Each element contributes to the overall success of the leather paint finisher, ensuring a durable and visually appealing result. The effectiveness of the finisher is only as good as its bond to the leather substrate.

2. Flexibility retention

Flexibility retention is a crucial characteristic of a successful leather paint finisher. Leather, by its nature, is a flexible material, and any coating applied to it must maintain this property to prevent cracking and ensure longevity. The primary function of a protective topcoat is to safeguard the underlying paint from abrasion, UV exposure, and general wear. However, if the topcoat lacks sufficient flexibility, it will become brittle and fail under stress, ultimately compromising the integrity of the entire finishing system. An inflexible finish will be noticeable especially on items like leather jackets, car seats or wallets as they often face stretching when used.

Formulations designed for leather frequently incorporate plasticizers or flexible polymers that allow the finisher to stretch and bend in concert with the leather substrate. The selection of appropriate additives and resin systems is essential for achieving optimal flexibility without sacrificing other desirable properties, such as abrasion resistance and UV protection. Without these additives, leather goods will appear unappealing and will likely require earlier-than-necessary repairs. For instance, when restoring leather car seats, a finisher that is flexible is critical to withstand daily wear and tear of passengers. Otherwise, cracks will appear quickly.

In summary, flexibility retention is not merely a desirable attribute but a fundamental requirement for a high-quality leather paint finisher. A properly formulated topcoat will maintain the leather’s natural pliability, ensuring that the finished product remains both aesthetically pleasing and functionally sound over time. Balancing flexibility with other performance characteristics presents a technical challenge, but the reward is a durable, long-lasting finish that enhances the value and lifespan of leather goods.

3. Abrasion Resistance

Abrasion resistance is a critical performance characteristic of any effective leather paint finisher. The daily wear and tear experienced by leather goods necessitate a protective coating capable of withstanding surface friction and preventing damage to the underlying paint layers. The ability of a finisher to resist abrasion directly impacts the longevity and aesthetic appeal of the treated leather item.

- Polymer Composition and Hardness

The inherent abrasion resistance of a leather paint finisher is largely determined by its polymer composition. Finishes formulated with durable polymers, such as polyurethanes or acrylics with crosslinking agents, exhibit superior resistance to scratching and scuffing compared to those based on softer or less resilient materials. For example, finishes used on high-wear areas like leather footwear or automotive seating typically incorporate harder polymers to prolong the coating’s lifespan and protect the underlying color layers.

- Additives for Enhanced Durability

The incorporation of specific additives can significantly enhance the abrasion resistance of a leather paint finisher. Additives such as waxes, silicas, or ceramic particles increase the surface hardness and create a protective barrier against frictional forces. These additives are often used in finishes intended for heavy-duty applications, where the leather is subjected to significant rubbing or contact. Protective coating for leather luggage must incorporate additives that provide abrasion resistance.

- Film Thickness and Layering Techniques

The thickness of the applied finish layer and the layering technique employed can also affect its abrasion resistance. Multiple thin coats of finish generally provide better protection than a single thick coat, as they allow for a more uniform distribution of the protective polymers and additives. This approach minimizes the risk of cracking or peeling, which can expose the underlying paint to abrasion. Layering techniques must also be followed, or leather paint finisher risks being damaged.

- Testing and Industry Standards

Abrasion resistance is often quantified through standardized testing methods, such as the Taber abrasion test. These tests simulate the wear and tear that a coated surface experiences in real-world conditions, providing a measurable indication of its durability. Finishes that meet or exceed industry standards for abrasion resistance are generally considered suitable for demanding applications. For example, manufacturers of leather furniture often specify finishes that have passed rigorous abrasion testing to ensure the long-term performance of their products.

In conclusion, abrasion resistance is a multifaceted property that relies on polymer selection, additive technology, application techniques, and rigorous testing. A leather paint finisher with excellent abrasion resistance will provide superior protection against daily wear and tear, preserving the appearance and extending the lifespan of the treated leather goods. It’s therefore essential that manufacturers use this trait for long lasting leather products.

4. UV Protection

Ultraviolet (UV) radiation poses a significant threat to leather goods, leading to fading, discoloration, and degradation of the material’s structural integrity. In the context of leather paint finishers, UV protection refers to the incorporation of specific additives or properties within the coating that mitigate the harmful effects of sunlight exposure.

- UV Absorbers: Chemical Defense Mechanisms

UV absorbers are chemical compounds added to leather paint finishers that selectively absorb UV radiation, converting it into less harmful forms of energy, such as heat. This process prevents UV rays from reaching and damaging the underlying paint and leather substrate. For example, benzotriazoles and hydroxyphenyl triazines are common UV absorbers used in finishes for automotive leather interiors, protecting the seats and dashboards from fading and cracking caused by prolonged sun exposure.

- UV Reflectors: Physical Barrier Against Radiation

UV reflectors, such as titanium dioxide and zinc oxide nanoparticles, function by scattering and reflecting UV radiation away from the leather surface. These materials create a physical barrier that minimizes the amount of UV light that penetrates the coating. Finishes incorporating UV reflectors are frequently employed on outdoor leather goods, such as furniture and apparel, to provide enhanced protection against sun damage.

- Polymer Stability: Enhancing Resistance Through Material Selection

The inherent UV stability of the polymers used in the leather paint finisher also plays a crucial role. Certain polymers, such as acrylics and urethanes, are more resistant to UV degradation than others. Selecting polymers with high UV stability can significantly extend the lifespan of the finish and protect the leather from sun-induced damage. For instance, a leather jacket’s finish must use polymers with high UV stability.

- Impact on Color Retention and Finish Integrity

Effective UV protection is essential for maintaining the color vibrancy and overall integrity of the leather paint finisher. UV radiation can cause pigments to fade and the finish to become brittle and crack. By incorporating UV absorbers, reflectors, and stable polymers, leather paint finishers can significantly improve color retention and extend the lifespan of the coated leather, preserving its aesthetic appeal and structural integrity. Car dashboards made of leather typically include UV protection for a longer duration and visual appeal.

In summary, UV protection is an indispensable component of high-quality leather paint finishers. By employing UV absorbers, reflectors, and stable polymers, these coatings effectively shield leather goods from the damaging effects of sunlight, ensuring long-lasting color retention, structural integrity, and aesthetic appeal. The integration of these protective measures is crucial for preserving the value and extending the lifespan of leather items subjected to outdoor or sunlit environments.

5. Sheen control

Sheen control, the ability to manipulate the surface gloss of a coating, constitutes a critical aspect of leather paint finishers. It allows manufacturers and artisans to tailor the final appearance of leather goods, aligning with aesthetic preferences and functional requirements.

- Matting Agents: Achieving a Low-Gloss Finish

Matting agents, such as silica or wax particles, are incorporated into leather paint finishers to reduce surface gloss. These agents create microscopic irregularities on the coating’s surface, scattering light and minimizing specular reflection. A matte finish may be preferred for applications where a subtle, understated appearance is desired, such as high-end leather furniture or antique restoration projects. The choice of matting agent must consider factors like particle size, dispersion, and compatibility with the finish formulation to avoid compromising other performance properties.

- Gloss Additives: Enhancing Reflectivity and Luster

Conversely, gloss additives are used to increase the reflectivity and luster of a leather paint finisher. These additives, typically consisting of specialized resins or polymers, create a smooth, uniform surface that maximizes specular reflection. High-gloss finishes are often favored for applications where a bold, eye-catching appearance is desired, such as luxury handbags or automotive interiors. The selection of gloss additives should consider factors like clarity, durability, and resistance to yellowing to ensure a long-lasting, visually appealing result.

- Formulation Variables: Balancing Aesthetics and Performance

Achieving precise sheen control requires careful manipulation of the leather paint finisher formulation. The ratio of matting agents to gloss additives, the choice of resins, and the addition of other modifiers all influence the final surface gloss. For example, increasing the concentration of matting agents will generally reduce the gloss level, while increasing the concentration of gloss additives will increase it. The formulator must also consider the potential impact of these changes on other performance properties, such as abrasion resistance, UV protection, and flexibility.

- Application Techniques: Fine-Tuning the Final Appearance

Application techniques can also play a role in sheen control. Spraying, brushing, and wiping can all yield different surface textures and gloss levels. For example, spraying typically produces a smoother, more uniform finish than brushing, resulting in a higher gloss level. The applicator must carefully control factors like spray pressure, nozzle selection, and coating thickness to achieve the desired sheen. The applicator needs to be careful of the leather material for a more accurate and visually-pleasing product.

In conclusion, sheen control is an integral aspect of leather paint finishers, enabling manufacturers and artisans to tailor the final appearance of leather goods to meet specific aesthetic and functional requirements. By carefully selecting additives, manipulating the formulation, and employing appropriate application techniques, it is possible to achieve a wide range of gloss levels, from matte to high-gloss. This manipulation enhances the value and appeal of leather products across a variety of applications.

Frequently Asked Questions about Leather Paint Finisher

This section addresses common inquiries regarding the selection, application, and performance of leather paint finisher products.

Question 1: What is the primary function of a leather paint finisher?

A leather paint finisher serves to protect the underlying paint or dye on leather goods. It provides a durable, abrasion-resistant layer that extends the lifespan of the color and enhances the overall appearance of the treated item.

Question 2: Can any type of clear coat be used as a leather paint finisher?

No. Specialized formulations designed specifically for leather are required. General-purpose clear coats often lack the flexibility and adhesion properties needed to withstand the constant flexing of leather, leading to cracking and peeling.

Question 3: How does one determine the appropriate sheen level for a leather paint finisher?

The desired sheen level is largely a matter of aesthetic preference. However, matte finishes are generally less reflective and better at concealing imperfections, while gloss finishes offer a more vibrant and eye-catching appearance. The intended use of the leather item should also be considered.

Question 4: Is surface preparation necessary before applying a leather paint finisher?

Thorough surface preparation is essential. The leather must be cleaned and deglazed to remove any contaminants that may interfere with adhesion. Failure to properly prepare the surface will compromise the durability and longevity of the finish.

Question 5: How many coats of leather paint finisher are typically required?

Multiple thin coats are generally preferable to a single thick coat. Two to three thin coats provide adequate protection and allow for proper drying and adhesion between layers. Excessive thickness can lead to cracking and reduced flexibility.

Question 6: What factors contribute to the longevity of a leather paint finish?

Longevity is influenced by several factors, including the quality of the product, the thoroughness of surface preparation, the application technique, and the environmental conditions to which the leather item is exposed. Proper maintenance, such as regular cleaning and conditioning, will also extend the life of the finish.

In conclusion, a properly selected and applied leather paint finisher can significantly enhance the durability and aesthetic appeal of leather goods. However, attention to detail and adherence to best practices are essential for achieving optimal results.

The subsequent section will offer guidance on troubleshooting common issues encountered during the application of leather paint finishers.

Conclusion

This exploration has illuminated the multifaceted nature of the leather paint finisher. Its correct application is not merely cosmetic, but a critical process in preserving and enhancing leather goods. The selection of an appropriate formulation, meticulous surface preparation, and careful application techniques dictate the ultimate success of the finishing process. Understanding the impact of factors like UV exposure, abrasion, and flexibility ensures informed decision-making in the selection and use of these protective coatings.

As materials science advances, future innovations in leather paint finisher technology promise even greater durability, enhanced aesthetic options, and improved environmental compatibility. Professionals and hobbyists alike are encouraged to remain informed about these developments to optimize their practices and achieve superior results in the ongoing effort to protect and beautify leather products.