A coating that imparts a smooth, low-luster sheen, reminiscent of the fabric for which it’s named, represents a popular choice for interior applications. This type of product bridges the gap between matte and satin, offering a subtle reflective quality while minimizing imperfections on walls and other surfaces. For instance, it effectively softens the appearance of textured walls in older homes.

The advantage of using this specific coating lies in its ability to provide a warm, inviting ambiance in a room. Its subtle sheen allows for enhanced light diffusion, making spaces feel brighter and more spacious. Historically, coatings offering similar aesthetic qualities were achieved through labor-intensive techniques; however, modern formulations have made this desirable finish readily accessible to a wider range of consumers and professionals.

The following sections will delve into the specific characteristics of this coating option, including its durability, application techniques, color considerations, and ideal uses within residential and commercial settings. The intention is to offer practical guidance for selecting and utilizing this aesthetically pleasing wall finish.

Application and Maintenance Insights

Achieving optimal results with this particular wall coating requires careful attention to surface preparation and application techniques. The following guidelines are designed to maximize the aesthetic appeal and longevity of the finish.

Tip 1: Proper Surface Preparation is Critical: Ensure surfaces are clean, dry, and free from loose debris. Repair any imperfections, such as holes or cracks, and prime the surface appropriately. This foundation is crucial for uniform adhesion and a flawless appearance.

Tip 2: Employ High-Quality Application Tools: Utilize a high-quality roller with a nap appropriate for the surface texture. Synthetic brushes are recommended for cutting in edges and detail work. Inexpensive tools can compromise the final result.

Tip 3: Apply Thin, Even Coats: Multiple thin coats are preferable to a single thick coat. This technique minimizes the risk of drips, runs, and uneven sheen levels. Allow each coat to dry completely before applying the next.

Tip 4: Maintain Consistent Wet Edges: When painting large areas, maintain a wet edge to prevent lap marks. This involves overlapping each stroke slightly with the previous one while the paint is still wet. Work in manageable sections.

Tip 5: Avoid Overworking the Paint: Excessive brushing or rolling can disrupt the smooth, uniform film formation of the coating. Apply the paint with deliberate strokes and avoid repeatedly going over the same area.

Tip 6: Temperature and Humidity Control: Apply the coating within the manufacturer’s recommended temperature and humidity ranges. Extreme conditions can affect drying time, adhesion, and overall finish quality. Ventilation is also important to get rid of the smell from the paint.

Tip 7: Gentle Cleaning Practices: To maintain the finish, clean surfaces with a soft, damp cloth and mild detergent. Avoid abrasive cleaners or excessive scrubbing, as these can damage the sheen and integrity of the coating.

Adherence to these recommendations will contribute to a long-lasting and visually appealing surface treatment. Consistent application and maintenance will allow the desired subtle sheen to enhance the interior space for an extended period.

The subsequent section will address color selection and its impact on the overall aesthetic achieved with this distinctive coating.

1. Subtle sheen appearance

The term “subtle sheen appearance” is intrinsically linked to the properties of coatings imparting a finish emulating velvet. This aspect is crucial in defining the aesthetic and functional attributes of such paints, differentiating them from matte or high-gloss alternatives.

- Light Diffusion Characteristics

The degree of light reflection directly influences the perception of color and texture. A coating that falls under the “velvet finish paint” classification diffuses light more evenly than glossier paints, minimizing glare and creating a softer, more uniform visual effect. This characteristic is particularly beneficial in rooms with ample natural light, as it prevents harsh reflections.

- Hiding Imperfections

One of the key advantages of “velvet finish paint” is its ability to conceal minor surface imperfections. The low-luster sheen scatters light, thereby reducing the visibility of dents, scratches, and uneven textures on walls. This is in contrast to higher-gloss paints, which tend to accentuate such flaws due to their specular reflection.

- Color Perception

The “subtle sheen appearance” of velvet finish paints affects how colors are perceived. Colors appear richer and deeper due to the reduced light reflection, which enhances the saturation. This is important to consider when selecting colors, as the same hue may appear significantly different in a matte or glossy finish.

- Maintenance Implications

While generally more durable than matte paints, velvet finish paints with a “subtle sheen appearance” may require more careful cleaning. The slight texture can trap dirt and dust, necessitating gentle cleaning methods to avoid damaging the finish. Harsh chemicals and abrasive cleaners should be avoided to preserve the coating’s integrity and sheen level.

In essence, the “subtle sheen appearance” is a defining characteristic of coatings that provide a velvet-like finish. It influences light diffusion, the concealment of imperfections, color perception, and maintenance considerations. Selecting this type of coating involves carefully weighing these factors to achieve the desired aesthetic and functional outcomes in interior spaces.

2. Durability expectations

The anticipated lifespan and resistance to wear and tear, commonly termed “Durability expectations,” are critical considerations when selecting coatings that provide a velvet-like finish. The inherent characteristics of this finish influence its suitability for various applications and necessitate a clear understanding of its limitations.

- Abrasion Resistance

Coatings of this nature, while offering an appealing aesthetic, typically exhibit lower abrasion resistance compared to higher-gloss or specialized epoxy finishes. Frequent contact or scrubbing can gradually diminish the velvet-like sheen, resulting in noticeable variations in the surface appearance. For example, in high-traffic areas such as hallways or entryways, a more durable coating might be preferable.

- Washability and Stain Resistance

The slightly porous texture of these coatings can render them more susceptible to staining and challenging to clean. While some formulations offer enhanced washability, aggressive cleaning agents should generally be avoided, as they can compromise the finish. The selection of appropriate colors and stain-resistant additives becomes particularly important in environments prone to spills or dirt accumulation, such as kitchens or children’s rooms.

- Impact Resistance

Velvet-like finishes may exhibit vulnerability to impacts, potentially leading to chipping or cracking, especially on edges and corners. Protective measures, such as corner guards or the use of a more durable base coat, should be considered in areas susceptible to physical damage. Regular inspection and prompt repair of any damage are essential to maintaining the integrity of the coated surface.

- Environmental Factors

The durability of coatings is impacted by the external environment it is being exposed to. For example, direct exposure to sunlight may impact the pigment of the paint over time. Moreover, fluctuating conditions of humidity and temperature can cause cracks on the coating surface.

In summary, while coatings providing a velvet-like finish offer a distinct aesthetic appeal, it is imperative to carefully assess the anticipated levels of wear and tear to ensure alignment with “Durability expectations.” Selecting appropriate formulations, implementing preventive measures, and adhering to proper maintenance protocols are essential to maximizing the lifespan and preserving the appearance of these coatings in various interior applications.

3. Application complexities

Achieving a uniform and aesthetically pleasing result with coatings that provide a velvet-like finish requires careful consideration of several factors related to the application process. These “Application complexities” directly impact the final appearance and longevity of the coating.

- Surface Preparation Rigor

Unlike some coatings that can tolerate minor imperfections, paints with a velvet finish necessitate meticulously prepared surfaces. Any existing flaws, such as hairline cracks or uneven textures, will be accentuated by the subtle sheen. Thorough sanding, filling, and priming are essential to creating a smooth, uniform base for optimal adhesion and a flawless finish. Skipping these steps can result in an uneven and unprofessional appearance.

- Roller and Brush Selection

The choice of application tools significantly influences the final texture and appearance of the coating. High-quality rollers with a short nap are generally recommended to minimize stippling and ensure a smooth, even application. Synthetic brushes are often preferred for cutting in edges and detail work, as they tend to leave fewer brush marks. Using inappropriate tools can lead to an undesirable finish with visible roller or brush strokes.

- Layering Technique Precision

Achieving a uniform sheen level requires the application of thin, even coats. Overlapping strokes and consistent pressure are crucial to avoid variations in the paint film thickness, which can result in noticeable differences in the reflective properties of the surface. Multiple thin coats are preferable to a single thick coat, as they promote better adhesion and minimize the risk of runs or drips. Careful attention to layering technique is essential for a professional-looking finish.

- Environmental Condition Sensitivity

These coatings can be sensitive to environmental conditions during application. High humidity or extreme temperatures can affect the drying time and flow characteristics of the paint, potentially leading to imperfections in the final finish. Proper ventilation and adherence to the manufacturer’s recommended temperature and humidity ranges are crucial for optimal results. Failing to control these factors can compromise the appearance and durability of the coating.

The intricate interplay of surface preparation, tool selection, layering technique, and environmental conditions underscores the “Application complexities” associated with coatings that provide a velvet-like finish. Mastering these aspects is essential for achieving the desired aesthetic and ensuring the longevity of the coating in various interior applications.

4. Color reflectance properties

The inherent characteristic of a surface to reflect light, known as “Color reflectance properties,” is inextricably linked to the aesthetic impact of coatings providing a velvet-like finish. This attribute dictates how colors are perceived, influencing the overall ambiance and visual appeal of a space.

- Light Absorption and Diffusion

Coatings with a velvet finish, due to their subtle texture, tend to absorb a greater proportion of incident light compared to glossier counterparts. This increased absorption leads to enhanced light diffusion, resulting in a softer, less reflective surface. For instance, a deep blue coating will appear richer and more saturated, as the limited reflection allows the true pigment to dominate the visual experience. This property is advantageous in minimizing glare and creating a more comfortable visual environment.

- Hue Perception Modulation

The subdued reflectance of these coatings subtly alters the perceived hue of a color. Pigments appear more muted and less vibrant compared to their representation in a high-gloss finish. A vibrant red may present as a more subdued, sophisticated tone due to the reduced light reflection. This characteristic necessitates careful color selection, as the final appearance may differ significantly from that observed in a sample with a different sheen level.

- Influence on Contrast and Depth

Reduced light reflection impacts the perception of contrast and depth within a space. Darker colors absorb more light, creating a sense of intimacy and depth. Conversely, lighter colors, while still subdued compared to glossier finishes, can help to maximize the perceived brightness of a room. Strategic utilization of color and reflectance properties can effectively manipulate the spatial dimensions and create a desired atmosphere.

- Impact on Color Uniformity

The uniform light diffusion characteristic of velvet-like finishes can minimize variations in color perception across a surface. This is particularly beneficial in large areas or rooms with uneven lighting, where fluctuations in light intensity can cause colors to appear inconsistent. The coating’s ability to scatter light evenly contributes to a more cohesive and visually harmonious appearance throughout the space.

In summation, the interplay between “Color reflectance properties” and coatings designed to provide a velvet-like finish is a critical determinant of the aesthetic outcome. Understanding how these coatings absorb and diffuse light, modulate hue perception, influence contrast and depth, and promote color uniformity is essential for making informed design choices and achieving the desired visual effect in interior spaces.

5. Interior application focus

The selection of coatings with a velvet-like finish is predominantly driven by interior design considerations, establishing a strong correlation between “Interior application focus” and its utility. This is directly attributable to the aesthetic qualities the finish imparts, aligning with specific design objectives within enclosed spaces. The primary effect is the creation of a softened, diffused light reflection that minimizes glare and enhances the depth of color. For example, a living room painted with a deep gray coating of this nature will exhibit a sophisticated and inviting atmosphere due to the reduced light intensity and heightened color saturation. This focus on interior environments stems from the controlled conditions and the emphasis on visual comfort and style, where the coating’s subtle sheen can be fully appreciated without the interference of external elements or harsh weather exposure, which typically render it unsuitable for exterior use.

Further illustrating the practical significance, “Interior application focus” allows for optimized use of the coating in areas where visual appeal and tactile impressions are paramount. Bedrooms, for instance, benefit from this finish’s ability to create a calming environment due to its muted sheen and soft texture. Dining rooms and home offices also gain from this choice as it minimizes light distractions and promotes concentration or relaxation. Conversely, areas prone to high moisture or abrasion, such as bathrooms or kitchens, may require alternative, more durable coating solutions, though the velvet finish can still be employed in accent walls or low-contact surfaces. This targeted application ensures that the coating’s aesthetic benefits are maximized while mitigating potential performance drawbacks in demanding environments.

In conclusion, the preferential use of coatings with a velvet-like finish in interior spaces is a direct result of their unique aesthetic properties and the controlled environments they are typically applied within. While challenges related to durability and maintenance exist, a clear understanding of “Interior application focus” allows for strategic application of this finish, maximizing its visual impact and contributing to a cohesive and appealing interior design scheme. This nuanced approach underscores the importance of aligning coating selection with specific environmental and functional requirements within the intended space.

Frequently Asked Questions About Velvet Finish Paint

The following questions address common concerns and misconceptions regarding coatings that provide a velvet-like finish. The answers aim to provide clarity and inform decision-making.

Question 1: Is this type of paint suitable for high-traffic areas?

Coatings offering a low-luster sheen may not be the optimal choice for high-traffic zones. Their inherent texture can render them less resistant to abrasion and more susceptible to staining compared to higher-gloss alternatives.

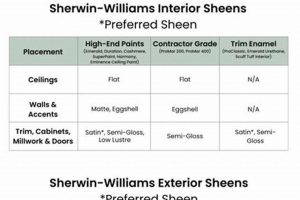

Question 2: How does this finish compare to matte and satin finishes?

This finish occupies a middle ground between matte and satin. It provides a subtle sheen that is more reflective than matte but less glossy than satin, offering a balance between hiding imperfections and providing a degree of light reflection.

Question 3: Can this coating be used in bathrooms or kitchens?

While usable, coatings that provide a velvet-like finish may not be ideal for bathrooms or kitchens due to their potential susceptibility to moisture damage and staining. Enhanced formulations with mildew-resistant properties can improve suitability.

Question 4: What is the best method for cleaning this type of paint?

Gentle cleaning practices are recommended. A soft, damp cloth and mild detergent are typically sufficient. Abrasive cleaners and excessive scrubbing should be avoided to prevent damage to the finish.

Question 5: Does this finish require special application techniques?

Meticulous surface preparation and careful application are essential for achieving a uniform and aesthetically pleasing result. Thin, even coats are recommended, and high-quality application tools are crucial.

Question 6: Will colors appear different in this type of finish compared to others?

Yes, colors will generally appear richer and deeper due to the reduced light reflection characteristic of coatings that provide a velvet-like finish. This should be considered when selecting colors for a space.

In summary, coatings offering a velvet-like finish possess unique characteristics that influence their suitability for different applications. Informed selection and proper maintenance are essential for maximizing their aesthetic appeal and longevity.

The subsequent section will explore the cost considerations associated with this particular coating option.

Conclusion

This exploration has detailed the characteristics, application, and considerations associated with “velvet finish paint”. The analysis encompassed its unique sheen, durability expectations, application complexities, color reflectance properties, and suitable interior applications. Understanding these facets is crucial for informed decision-making.

The appropriate selection and utilization of “velvet finish paint” hinges on aligning its attributes with specific project requirements. Further research and professional consultation are encouraged to ensure optimal results in achieving desired aesthetic and functional outcomes. The continued development of coating technologies may offer enhanced durability and performance characteristics in the future.