The application of treatments to metallic surfaces to enhance their properties and appearance is a crucial process in various industries. These treatments aim to improve characteristics such as corrosion resistance, wear resistance, and aesthetic appeal. Common methods include plating, coating, and other surface modification techniques. For example, components used in aerospace require specialized treatments to withstand harsh environmental conditions and extreme temperatures.

This type of surface enhancement contributes significantly to the longevity and performance of metal products. By preventing degradation and improving functionality, these processes reduce maintenance costs, extend the lifespan of equipment, and enhance overall product quality. The history of such techniques can be traced back centuries, evolving from simple methods to sophisticated, high-precision operations. This evolution reflects advancements in material science and manufacturing technology.

The following sections will delve into specific aspects of this industry, including the different types of treatments available, the industries that benefit most, and the latest innovations driving advancements in the field. We will also explore considerations for selecting appropriate surface treatments based on application requirements and performance goals.

Surface Enhancement Best Practices

Adhering to established protocols is essential for achieving optimal outcomes in surface treatment processes. The following guidelines represent key considerations for ensuring quality and durability of finished metal components.

Tip 1: Material Compatibility Assessment. Prior to commencing any surface treatment, conduct a thorough assessment of the base metal’s composition and properties. Incompatibility can lead to adhesion failures, compromised corrosion resistance, or undesirable aesthetic results.

Tip 2: Rigorous Surface Preparation. Proper surface preparation is paramount. This includes degreasing, cleaning, and potentially etching or blasting to create a suitable profile for coating adhesion. Failure to prepare the surface adequately will lead to premature coating failure.

Tip 3: Controlled Application Parameters. Precisely control application parameters such as temperature, pressure, and dwell time during coating or plating processes. Deviations from specified parameters can impact coating thickness, uniformity, and ultimately, performance.

Tip 4: Adherence to Industry Standards. Comply with relevant industry standards and specifications (e.g., ASTM, ISO) for surface treatment processes and testing. These standards provide benchmarks for quality and performance.

Tip 5: Implement Quality Control Measures. Integrate rigorous quality control measures at each stage of the process, including visual inspection, thickness testing, adhesion testing, and corrosion testing. Early detection of defects minimizes waste and ensures consistent quality.

Tip 6: Environmental Compliance. Implement environmentally responsible practices throughout the surface treatment process. This includes proper waste disposal, emissions control, and the use of environmentally friendly materials when possible.

Tip 7: Documentation and Traceability. Maintain detailed records of all process parameters, material specifications, and test results. This documentation ensures traceability and facilitates troubleshooting in the event of issues.

Implementing these best practices will contribute to enhanced product performance, extended service life, and reduced costs associated with rework and premature failure. A proactive and meticulous approach to surface enhancement is essential for maximizing the value of metal components.

The subsequent sections will provide a more in-depth examination of specific surface treatment technologies and their applications across diverse industries.

1. Adhesion

Adhesion represents a critical parameter in surface finishing processes. It refers to the strength of the bond between the applied coating or plating and the substrate metal. Insufficient adhesion can lead to premature coating failure, resulting in corrosion, wear, and compromised functionality of the treated component. The effectiveness of various surface treatments depends significantly on achieving a robust and durable bond. Consequently, surface preparation techniques play a vital role in optimizing adhesion, involving cleaning, etching, or mechanical abrasion to create a suitable surface profile.

Poor adhesion in the surface finishing of metals can manifest in numerous detrimental ways. Examples include blistering or peeling of protective coatings on automotive components, leading to accelerated corrosion in road salt environments. In aerospace applications, inadequate adhesion of specialized coatings on turbine blades can result in thermal barrier coating spallation, causing engine inefficiency and potential catastrophic failure. Similarly, in electronics manufacturing, poor adhesion of conductive plating on circuit boards can lead to circuit malfunctions and device failures. Each situation highlights the practical consequences of insufficient bond strength.

Therefore, understanding and controlling the factors that influence adhesion is crucial for ensuring the long-term performance and reliability of surface-treated metal components. Overcoming challenges related to material incompatibility, surface contamination, and inappropriate application techniques remains essential. Through proper material selection, rigorous process control, and adherence to industry standards, robust adhesion is achievable, contributing significantly to the overall success of surface finishing applications.

2. Corrosion Resistance

Corrosion resistance is a pivotal characteristic imparted by metal finishing processes, protecting metallic substrates from degradation caused by environmental factors. The primary cause of corrosion is the electrochemical reaction between the metal and its surroundings, leading to material loss and structural weakening. Metal finishing techniques mitigate this by creating a barrier between the metal and the corrosive environment. The importance of corrosion resistance as a component is evident across diverse sectors. In marine engineering, the application of specialized coatings to ship hulls prevents saltwater-induced corrosion, extending the vessel’s lifespan and reducing maintenance costs. In the automotive industry, similar treatments protect vehicle bodies from rust, contributing to improved safety and aesthetic appeal.

The effect of these protective measures are significant. For example, components used in oil and gas pipelines are subject to extremely corrosive conditions. The application of specific metal finishing treatments, such as cathodic protection in conjunction with specialized coatings, becomes essential. Such measures can significantly extend the lifespan of these pipelines. Proper surface preparation, precise application of coatings, and adherence to industry standards are paramount. These will ensure the long-term performance and reliability of the protective layer. Factors such as the composition of the metal substrate, the corrosivity of the environment, and the specific treatment applied influence the final outcome.

The understanding of the relationship between corrosion resistance and metal finishing is vital for engineers and designers. It enables informed decisions regarding material selection and surface treatment strategies. The selection of inappropriate surface finishing can result in catastrophic failures and significant financial losses. Conversely, effective implementation of corrosion-resistant treatments can dramatically extend the service life of metal components, reduce maintenance requirements, and enhance overall product quality. Continued research and development are driving advancements in metal finishing technologies, offering increasingly effective and sustainable solutions for combating corrosion in various applications.

3. Aesthetics

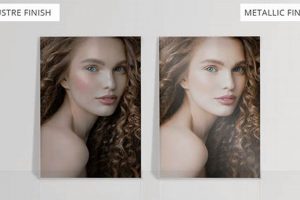

Aesthetics plays a significant, although sometimes understated, role in surface treatment processes. Beyond functional enhancements such as corrosion resistance and improved wear characteristics, the visual appeal imparted by surface treatments can be a critical factor in product acceptance and market success. The following points detail some key facets of aesthetics in relation to surface treatments.

- Color and Finish Uniformity

Consistent color and finish across all treated components are essential, particularly for visible parts in consumer products or architectural applications. Variations in color or gloss can detract from perceived quality and create inconsistencies in the overall product presentation. For example, anodized aluminum components used in building facades must exhibit uniform color to maintain the desired aesthetic design.

- Surface Smoothness and Texture

The smoothness and texture of a treated surface significantly impact its aesthetic appeal. Coatings can be applied to create glossy, matte, or textured finishes. The choice of finish can influence the perceived quality and tactile experience of the product. Polished metal surfaces, often achieved through processes like buffing or electropolishing, enhance the reflective properties of the metal, conveying a sense of luxury and refinement.

- Absence of Defects

Aesthetically pleasing surface treatments are characterized by the absence of defects such as scratches, blemishes, or inconsistent coating thickness. These imperfections can detract from the product’s visual appeal and create the perception of poor workmanship. Stringent quality control measures are essential to ensure the consistent application and flawless appearance of surface treatments.

- Customization and Branding

Surface treatments can be utilized to incorporate custom designs, logos, or branding elements onto metal components. Techniques such as powder coating, screen printing, or laser engraving allow for the integration of visual identifiers, enhancing brand recognition and adding a unique aesthetic dimension to the product. This capability is particularly valuable in industries such as automotive, where personalized styling is often a key differentiator.

These aesthetic considerations underscore the comprehensive nature of surface treatment processes. While functional performance remains paramount, the visual appeal conferred by these techniques contributes significantly to the overall value and marketability of finished metal products. A well-executed surface treatment balances both functional and aesthetic requirements, resulting in a product that is not only durable and reliable but also visually appealing and commercially successful.

4. Wear Resistance

Wear resistance, a critical performance characteristic of metal components, is significantly enhanced through various surface treatments. These treatments alter the surface properties of the metal, increasing its ability to withstand friction, abrasion, erosion, and other forms of mechanical degradation. The relationship between these processes and the enhanced durability of treated parts is crucial for extending service life and reducing maintenance costs in a wide range of applications. Effective implementation of these techniques minimizes material loss and preserves the functional integrity of the component.

- Hardfacing Techniques and Overlay Coatings

Hardfacing involves depositing a wear-resistant material onto the surface of a base metal. These materials, often alloys containing carbides or hard particles, provide a sacrificial layer that protects the underlying substrate from wear. Examples include tungsten carbide coatings applied to cutting tools to increase their lifespan and resistance to abrasive wear, and Stellite alloys used in valve seats to combat wear caused by high-temperature and high-pressure fluids. Hardfacing extends the operational lifespan of high-wear components in heavy machinery and manufacturing equipment.

- Diffusion Hardening Processes

Diffusion hardening modifies the surface chemistry of a metal by introducing elements such as carbon, nitrogen, or boron. These elements diffuse into the surface, forming hard compounds that increase wear resistance. Carburizing, nitriding, and boriding are common examples of diffusion hardening processes. Gears and crankshafts in automotive engines often undergo nitriding to enhance their surface hardness and resistance to wear, minimizing friction and extending their operational life. These treatments are particularly effective in components subjected to high contact stresses and sliding wear.

- Thin Film Coatings and Surface Modification

Thin film coatings, such as titanium nitride (TiN) or diamond-like carbon (DLC), provide a thin, hard, and wear-resistant layer on the metal surface. These coatings reduce friction and protect against abrasive wear. They are frequently used on cutting tools, medical implants, and precision components to improve their performance and durability. The application of DLC coatings on automotive engine components reduces friction, leading to improved fuel efficiency and reduced emissions. Surface modification techniques, such as ion implantation, can also enhance wear resistance by altering the microstructure of the metal surface.

- Role of Lubrication and Surface Finish

The effectiveness of wear-resistant surface treatments is often enhanced by proper lubrication and surface finish. Lubrication reduces friction and prevents direct contact between surfaces, minimizing wear. A smooth surface finish reduces the contact area and promotes the formation of a stable lubricant film. Combining wear-resistant surface treatments with optimized lubrication and surface finish leads to synergistic improvements in wear performance. For example, a hard chrome plated surface combined with a suitable lubricant can significantly reduce wear in hydraulic cylinders.

The discussed surface treatments contribute to enhanced wear resistance in diverse applications. By employing appropriate hardfacing, diffusion hardening, thin film coating, and surface modification techniques, the service life of metal components is extended, thereby reducing the frequency of replacement and maintenance. Understanding these components is crucial for engineers. Informed decision-making in material selection and surface treatment strategies is ensured. Such awareness contributes to improved product quality and durability.

5. Surface Hardness

Surface hardness, as it relates to metal finishing, directly influences the durability and performance of treated components. Metal finishing techniques, including those employed to improve hardness, serve to modify the outermost layer of a metal object, enhancing its resistance to indentation, scratching, and abrasion. This characteristic is particularly vital in applications where components are subjected to high wear or contact stresses. For instance, in the automotive industry, gears and bearings undergo hardening processes to extend their lifespan and maintain dimensional integrity under demanding operating conditions. These components represent cause and effect relationship between surface hardness and norco metal finishing where one of our main topic is.

The achievement of a specific surface hardness is often a primary objective in metal finishing. Processes such as case hardening, nitriding, and the application of hard coatings (e.g., chromium plating, titanium nitride deposition) are specifically chosen to increase the hardness of the metal surface. The selection of a particular technique depends on factors such as the type of metal, the desired hardness level, and the operating environment. In aerospace applications, turbine blades are often coated with hard, wear-resistant materials to withstand the extreme temperatures and abrasive conditions within jet engines. These components are an example for the importance of surface hardness.

Understanding the connection between surface hardness and metal finishing is significant for engineers and designers. Informed decisions concerning material selection and surface treatment strategies will prolong the service life, ensure reliable operation, and reduce the risk of premature failure, by understanding norco metal finishing better. Improper selection of surface treatments can lead to inadequate hardness, resulting in accelerated wear and reduced component lifespan. In conclusion, surface hardness is a critical consideration in metal finishing and a vital aspect for various industries.

6. Preparation Methods

Preparation methods form the foundational stage in any surface finishing operation. The effectiveness and longevity of subsequent treatments are inextricably linked to the quality of the preparation phase. Inadequate preparation will inevitably lead to compromised performance and premature failure of the finished product. Thus, understanding the various facets of preparation is crucial in achieving desired outcomes.

- Cleaning and Degreasing

The removal of contaminants such as oil, grease, dirt, and scale is essential prior to any surface treatment. These contaminants can interfere with coating adhesion, resulting in inconsistent coverage and reduced corrosion resistance. Methods such as solvent cleaning, alkaline cleaning, and vapor degreasing are commonly employed, each tailored to specific types of contaminants and substrate materials. For example, intricate parts with complex geometries may require ultrasonic cleaning to ensure thorough removal of contaminants from hard-to-reach areas.

- Surface Activation

Surface activation processes enhance the reactivity of the metal surface, promoting strong bonding with subsequent coatings or platings. Techniques such as etching, pickling, and chemical conversion treatments are used to create a micro-roughened surface that increases the surface area available for adhesion. An example is the use of phosphoric acid etching on aluminum alloys to improve the adhesion of paints and adhesives, enhancing the overall durability of the finished component.

- Mechanical Preparation

Mechanical preparation methods, including abrasive blasting, grinding, and polishing, are used to remove surface imperfections, create a desired surface texture, or improve the dimensional accuracy of the component. Abrasive blasting, for instance, employs compressed air to propel abrasive media against the metal surface, removing rust, scale, and old coatings while simultaneously creating a roughened surface that promotes coating adhesion. Grinding and polishing, on the other hand, are used to achieve a smooth, uniform surface finish, often required for decorative applications or to reduce friction.

- Masking and Fixturing

Selective surface treatment often requires masking specific areas of the component to prevent unwanted coating or plating. Masking materials include tapes, lacquers, and custom-designed fixtures that conform to the geometry of the part. Proper masking techniques ensure that only the intended areas receive the surface treatment, maintaining dimensional tolerances and preventing interference with functional features. Careful attention to detail is essential to prevent bleed-through or undercutting of the coating at the masked edges.

These preparation methods, while varied in their specific applications, share the common goal of creating a clean, reactive, and appropriately textured surface that facilitates the successful application of subsequent surface treatments. The selection of appropriate preparation methods is dictated by the type of metal, the nature of the surface contaminants, and the desired properties of the finished product. The integration of robust preparation protocols into surface finishing operations is crucial for achieving optimal performance and long-term reliability of metal components.

7. Material Compatibility

Material compatibility is a cornerstone of successful surface treatment applications. The interactions between the substrate metal and the applied finishing material dictate the ultimate performance, durability, and longevity of the treated component. Incompatibility can lead to a spectrum of adverse outcomes, ranging from adhesion failures and accelerated corrosion to compromised mechanical properties and reduced service life. Understanding these interactions is crucial for selecting appropriate surface treatments and achieving desired outcomes.

- Electrochemical Compatibility and Galvanic Corrosion

When dissimilar metals are in contact in an electrolyte, a galvanic cell can form, leading to accelerated corrosion of the more active metal. Surface treatments involving plating or coating dissimilar metals require careful consideration of their electrochemical potentials to prevent galvanic corrosion. For example, plating steel with a less noble metal like zinc provides sacrificial protection, while plating steel with a more noble metal like copper can accelerate corrosion if the coating is breached. Proper alloy selection and the use of barrier coatings are essential for mitigating galvanic corrosion risks.

- Coefficient of Thermal Expansion (CTE) Mismatch

Significant differences in the CTE between the substrate metal and the applied coating can lead to stress buildup during temperature cycling. This stress can cause cracking, delamination, or spalling of the coating, compromising its protective function. Applications involving exposure to wide temperature ranges, such as aerospace components or automotive exhaust systems, require careful matching of CTE values or the use of compliant interlayer coatings to accommodate thermal expansion mismatches. Coating failure due to CTE mismatch often presents as a network of fine cracks on the surface.

- Chemical Reactivity and Interdiffusion

Certain metal combinations can exhibit chemical reactivity or interdiffusion at elevated temperatures, leading to the formation of intermetallic compounds or the depletion of alloying elements from the substrate. This can alter the mechanical properties of the metal and compromise the integrity of the surface treatment. For example, applying aluminum coatings to titanium alloys at high temperatures can result in the formation of brittle intermetallic compounds at the interface. Barrier layers or diffusion-resistant coatings are used to prevent or minimize interdiffusion between dissimilar metals.

- Adhesion Mechanisms and Interfacial Bonding

Achieving strong and durable adhesion between the surface treatment and the substrate metal depends on the formation of chemical bonds or mechanical interlocking at the interface. The chemical reactivity of the metals, the surface preparation techniques, and the application parameters all influence the strength and stability of the interfacial bond. Some surface treatments, such as anodizing, rely on the formation of a chemical bond between the oxide layer and the base metal. Other treatments, such as plasma spraying, rely on mechanical interlocking of the coating with a roughened substrate surface. Proper surface cleaning and activation are essential for promoting strong interfacial bonding.

These facets highlight the critical importance of material compatibility considerations in surface finishing operations. Proper material selection, rigorous process control, and adherence to industry standards are essential for achieving durable, reliable, and high-performance surface treatments. A comprehensive understanding of the interactions between the substrate metal and the applied finishing material is crucial for maximizing the value and extending the service life of metal components.

Frequently Asked Questions about Metal Finishing

The following section addresses common inquiries regarding metal finishing processes and their implications. The aim is to provide clear and concise information based on established practices and industry standards.

Question 1: What defines metal finishing as a distinct industrial process?

Metal finishing encompasses a range of surface treatments applied to metallic workpieces to alter their properties. These treatments, whether chemical or mechanical, aim to enhance corrosion resistance, improve aesthetic appeal, increase wear resistance, or modify electrical conductivity. It is a distinct process from initial metal fabrication or shaping.

Question 2: What factors influence the selection of a specific metal finishing technique?

The selection depends on several considerations, including the type of base metal, the intended application of the finished component, environmental conditions, and performance requirements. Cost-effectiveness and regulatory compliance also play a role in the decision-making process.

Question 3: What are the environmental considerations associated with metal finishing?

Metal finishing processes can generate hazardous waste materials, including heavy metals and volatile organic compounds. Adherence to environmental regulations and the implementation of waste minimization strategies are essential. Developing environmentally friendly alternatives continues to be an area of ongoing research and development.

Question 4: How is the quality of metal finishing assessed and verified?

Quality control measures encompass a range of testing methods. These include visual inspection, coating thickness measurements, adhesion testing, corrosion testing, and chemical analysis. Compliance with industry standards, such as those established by ASTM International and ISO, ensures consistent quality and performance.

Question 5: What are the long-term cost implications of metal finishing?

While metal finishing involves an initial investment, it can yield long-term cost savings. Reduced maintenance, extended component lifespan, and improved product reliability contribute to a lower total cost of ownership. The benefits generally outweigh the initial expense.

Question 6: How do emerging technologies impact metal finishing?

Advancements in nanotechnology, plasma treatments, and additive manufacturing are revolutionizing metal finishing. These technologies enable the creation of coatings with enhanced properties, improved precision, and reduced environmental impact. Continued innovation is expected to further transform the industry.

In summary, metal finishing is a multifaceted field. A comprehensive understanding of the technical, economic, and environmental considerations is critical for effective implementation.

The following sections will explore case studies illustrating the application of metal finishing techniques in various industries.

Conclusion

This article has presented an overview of metal finishing, examining essential aspects such as adhesion, corrosion resistance, aesthetics, wear resistance, surface hardness, preparation methods, and material compatibility. Each element plays a critical role in determining the overall effectiveness and longevity of surface-treated metal components. The selection and application of appropriate techniques directly impact product performance, durability, and cost-effectiveness across diverse industrial sectors. This overview provides a necessary foundation for making informed decisions.

The continued advancement in metal finishing technologies promises further improvements in material properties and environmental sustainability. Understanding these factors is crucial for organizations seeking to optimize their processes and maintain a competitive edge. Further investigation and adherence to best practices will ensure effective implementation and optimal results in metal finishing applications.