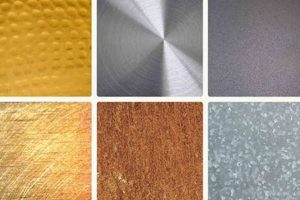

A surface treatment designed to replicate the appearance of aged or patinated metal is frequently applied to newly manufactured items. This process typically involves chemical treatments, layering of paints, or mechanical abrasion to create a visual effect reminiscent of naturally occurring oxidation and wear seen on older metal objects. For example, brass hardware on cabinetry may undergo this treatment to give it a vintage aesthetic.

The practice of artificially aging metal surfaces offers several advantages. It allows manufacturers to imbue products with character and historical appeal without the lengthy natural aging process. Furthermore, this method can enhance the perceived value and uniqueness of items, catering to consumer preferences for classic and timeless designs. Historically, simulating age has been employed to connect new products to established traditions of craftsmanship and design.

The subsequent sections will delve into specific techniques for achieving simulated metal aging, examining the materials and processes involved in creating these distinctive surface effects. We will also explore the applications across various industries and provide guidance on the proper maintenance of these treated surfaces.

Achieving Desired Results

The application of simulated aging requires careful consideration of several key factors to ensure a consistent and aesthetically pleasing outcome.

Tip 1: Surface Preparation is Paramount. Prior to any chemical or mechanical treatment, ensure the metal surface is thoroughly cleaned and free of any contaminants, such as oils, grease, or existing coatings. Inadequate preparation can lead to uneven results and poor adhesion of subsequent layers.

Tip 2: Understand the Metal Substrate. Different metals react differently to various treatments. Brass, copper, and steel will exhibit distinct aging patterns. Research the appropriate techniques and chemicals specific to the metal being treated to achieve the desired patina.

Tip 3: Control Chemical Exposure. When using chemical patination solutions, carefully monitor the exposure time. Overexposure can result in an unnatural or excessively corroded appearance. Regular inspection during the process is essential.

Tip 4: Employ Layering Techniques. A multi-layered approach, involving the application of different tones and textures, can create a more nuanced and realistic aged effect. Experiment with various paints, washes, and glazes to build depth.

Tip 5: Consider Mechanical Abrasion. Strategic use of abrasive tools, such as sandpaper or steel wool, can simulate wear and tear. Focus on areas that would naturally experience friction or handling for a believable outcome.

Tip 6: Sealing for Protection and Longevity. After achieving the desired effect, apply a sealant or clear coat to protect the finish from further degradation and maintain its appearance. Choose a sealant appropriate for the metal and intended environment.

Tip 7: Experimentation is Key. Before applying any treatment to the final piece, conduct tests on scrap metal to refine your technique and determine the optimal combination of processes and materials.

By adhering to these guidelines, individuals can enhance their ability to produce convincing and enduring simulations of metal aging, thus augmenting the visual appeal and value of their projects.

The following sections will elaborate on the specific chemical and mechanical techniques used to achieve these effects, providing a more detailed understanding of the processes involved.

1. Authenticity of Appearance

The perceived value and success of a surface treatment designed to mimic aged metal are intrinsically linked to the authenticity of its appearance. The desired effect necessitates a faithful replication of the characteristics observed in naturally aged metal, which include specific color variations, textural irregularities, and patterns of wear. The absence of such authenticity diminishes the credibility of the simulated age, rendering the surface treatment artificial and unconvincing. For instance, a bronze sculpture intended to evoke antiquity will fail to resonate with viewers if the applied patina lacks the subtle gradations and nuanced coloring characteristic of genuine oxidation over time. Authenticity functions as a primary determinant in the overall effectiveness of the surface treatment.

Achieving such authenticity requires a multifaceted approach. Detailed observation of genuine aged metal surfaces is crucial for accurately capturing the intricate details of natural aging processes. This includes careful study of the types of corrosion products formed on specific metals, the influence of environmental factors on the rate and pattern of oxidation, and the subtle variations in color and texture that arise from prolonged exposure. Furthermore, the selection of appropriate materials and techniques is paramount. Chemical patination processes, for example, must be carefully controlled to avoid producing an unnatural or overly uniform appearance. Mechanical abrasion techniques should be employed strategically to simulate realistic patterns of wear and handling.

Ultimately, the pursuit of authenticity in metal finishing is not merely an aesthetic concern but a matter of functional relevance. A surface treatment that successfully replicates the appearance of aged metal enhances the perceived value and desirability of the object, creating a connection to history and tradition. In the restoration of antique artifacts, authenticity is essential for preserving the integrity and cultural significance of the original piece. The challenge lies in balancing the desire for visual fidelity with the practical considerations of durability and cost-effectiveness. The successful integration of these factors defines the quality and impact of metal finishing.

2. Chemical Patination Control

Chemical patination control is a fundamental component in the creation of simulated aged metal surfaces, influencing the resulting appearance and durability of the treatment. The process involves the application of chemical solutions to induce controlled corrosion or oxidation, replicating the visual characteristics of naturally aged metal. Without precise control over chemical exposure, temperature, and solution concentration, the resulting finish may exhibit an unnatural or inconsistent appearance, detracting from the intended aesthetic. For example, when replicating an aging effect on copper, excessive exposure to ammonia-based solutions can lead to an overly aggressive and uniform verdigris, lacking the nuanced color variations observed in authentic patina.

The practical application of chemical patination control extends across various industries, including architectural hardware, decorative arts, and automotive restoration. In the production of antique-style door handles, controlled chemical treatments are employed to replicate the surface texture and coloration of aged brass or bronze. Conversely, in automotive restoration, careful patination techniques are used to create a “barn find” aesthetic, where specific areas of the vehicle’s exterior display controlled amounts of rust and oxidation. Furthermore, understanding the chemical reactions involved enables the selection of appropriate protective coatings to halt further corrosion and preserve the desired finish. These coatings, if not applied properly, can also alter the finished surface.

In summary, precise control over chemical patination is essential for achieving a convincing and enduring simulated aged metal surface. Inadequate control compromises the authenticity and aesthetic appeal of the treatment. Successfully replicating the look of naturally aged metal requires not only a thorough understanding of chemical processes but also meticulous attention to detail in application and post-treatment protection. Challenges remain in adapting these techniques to diverse metal alloys and environmental conditions, emphasizing the need for ongoing research and refinement of chemical patination methods.

3. Mechanical Abrasion Technique

Mechanical abrasion technique, as it relates to simulated aged metal surfaces, plays a critical role in replicating the characteristic wear patterns and surface irregularities found on authentic antique items. The process involves the controlled removal of material from the metal surface using various abrasive tools, such as sandpaper, steel wool, or abrasive pads, to simulate the effects of handling, environmental exposure, and general wear over time. The selection of appropriate abrasive materials and the application of specific techniques are vital in achieving a convincing and aesthetically pleasing result. In the context of replicating an antique finish, mechanical abrasion complements chemical patination processes, adding a textural dimension that enhances the perception of age and authenticity.

The application of mechanical abrasion techniques can significantly impact the final appearance of a metal surface. For instance, when creating a simulated aged bronze finish on architectural hardware, careful abrasion with fine-grit sandpaper can remove highlights from raised areas, revealing the underlying metal and accentuating the subtle variations in color and texture produced by chemical patination. This controlled removal of material mimics the gradual erosion of the surface that occurs over decades of use. In the restoration of antique firearms, mechanical abrasion techniques are employed to carefully remove rust and corrosion while preserving the original finish and markings. The skill and precision of the technician are paramount in achieving a balance between removing unwanted damage and maintaining the historical integrity of the artifact. Different techniques include dry brushing or wet sanding. Abrasive tools can leave scratch and swirl marks for a unique finish.

In summary, mechanical abrasion is an indispensable component in the creation of authentic and convincing simulated aged metal surfaces. It serves to complement chemical patination processes, adding a crucial textural element that enhances the perception of age and authenticity. The selection of appropriate abrasive materials, the mastery of specific techniques, and the careful control of the abrasion process are essential in achieving a desired outcome. The challenges in its use relate to the need for precision and control. The method creates wear marks to mimic its use. This process is fundamental in replicating the unique characteristics of antique metal, with an understanding that proper execution directly contributes to the overall success and visual appeal of the simulated finish.

4. Protective Sealing Application

The protective sealing application represents a critical final step in achieving and maintaining a simulated metal age. Its primary function is to mitigate the effects of environmental factors, such as moisture, oxygen, and pollutants, which contribute to the degradation of the underlying metal and the alteration of the applied aging effect. Without an effective protective sealant, the carefully created patina or surface treatment is susceptible to premature wear, discoloration, or even complete removal, negating the intended aesthetic. For instance, architectural bronze hardware, treated to replicate an antique finish, will likely corrode rapidly in coastal environments without a suitable sealant, undermining the desired appearance.

The selection of an appropriate sealant is contingent upon the type of metal, the specific aging process employed, and the intended environment. Acrylic lacquers, polyurethane coatings, and specialized waxes are commonly used, each offering varying degrees of protection and aesthetic impact. For example, the application of a matte acrylic lacquer on artificially aged steel can provide a durable barrier against rust while preserving the surface’s textured appearance. The improper selection or application of a sealant, however, can introduce unintended consequences, such as glossiness that detracts from the aged effect or chemical reactions that further alter the patina. Therefore, expertise in material compatibility and application techniques is essential for ensuring optimal protection without compromising the desired aesthetic qualities.

In conclusion, protective sealing application is integral to the longevity and visual integrity of a simulated metal age. The careful selection and application of an appropriate sealant safeguard the underlying metal and preserve the intended aesthetic qualities. This understanding ensures the long-term success of any project aimed at creating a lasting and visually compelling antique finish. Continued advancements in sealant technologies are essential for addressing the challenges posed by diverse metal substrates and increasingly demanding environmental conditions.

5. Substrate Metal Compatibility

The selection of a base metal and its compatibility with aging treatments are foundational to achieving a realistic and durable replicated antique finish. Incompatibility between the substrate metal and applied chemicals or techniques can lead to undesirable results, including accelerated corrosion, uneven patination, and compromised structural integrity. Understanding these interactions is essential for successful execution.

- Electrochemical Potential and Corrosion

Different metals possess varying electrochemical potentials. When dissimilar metals are in contact in the presence of an electrolyte (e.g., moisture), galvanic corrosion can occur. Applying an aging treatment that introduces an electrolyte or etches the surface can exacerbate this effect. For instance, using an acidic patination solution on a steel item with brass accents may cause the steel to corrode preferentially, undermining the structural integrity and aesthetic of the piece.

- Reactivity with Patination Solutions

Patination solutions react differently with various metals. A solution designed for copper will not produce the same effect on steel or aluminum. The chemical composition of the metal determines the type and rate of oxidation. Applying a copper-specific patina to brass might yield an uneven or unpredictable color, as brass is an alloy of copper and zinc, each reacting differently. Similarly, the zinc content in galvanized steel can hinder the development of a desired patina.

- Surface Preparation Requirements

Each metal necessitates unique surface preparation before aging treatments. Some metals require degreasing, etching, or mechanical abrasion to ensure proper adhesion and uniform reaction with patination solutions. Applying a chemical treatment to an unprepared aluminum surface may result in inconsistent color absorption, leading to a mottled or patchy appearance. Similarly, failing to remove existing coatings on steel can prevent the patination solution from interacting directly with the metal surface.

- Durability and Longevity Considerations

The inherent properties of the base metal affect the durability of the simulated antique finish. Some metals are more resistant to corrosion and wear than others. Applying an aging treatment to a less durable metal, such as zinc, without proper sealing can result in rapid deterioration of the finish, especially in harsh environments. Conversely, using a more durable metal, such as stainless steel, may require more aggressive treatments to achieve the desired effect.

The consideration of substrate metal compatibility extends beyond aesthetics, impacting the long-term stability and value of items treated with an aged finish. Recognizing the distinct properties of metals ensures both an authentic aesthetic and the preservation of the underlying material. A detailed understanding guides responsible material selection and treatment methodologies.

6. Environmental Considerations

The interaction between applied aged metal finishes and the environment constitutes a crucial consideration for longevity and aesthetic stability. Environmental factors, including atmospheric pollutants, humidity, temperature fluctuations, and exposure to ultraviolet radiation, exert significant influence on the rate and nature of corrosion processes affecting the treated metal surface. The application of simulated aging, while often intended to replicate naturally occurring patina, can inadvertently create a surface more susceptible to accelerated degradation in certain environments. For instance, an aged brass finish applied to exterior architectural hardware in a coastal region with high salinity will experience more rapid and aggressive corrosion compared to a similar application in a dry, inland climate. Failure to account for these environmental variables during the selection and application of finishing techniques can result in premature failure of the finish and compromise the intended aesthetic qualities.

Furthermore, the chemical processes involved in creating aged metal finishes can introduce environmental challenges. The patination solutions often contain corrosive chemicals, such as acids or ammonia-based compounds, that require careful handling and disposal to minimize environmental impact. Improper disposal of these chemicals can contaminate soil and water resources, posing risks to ecosystems and human health. Similarly, the mechanical abrasion techniques used to simulate wear patterns can generate dust and airborne particles that require appropriate ventilation and filtration to prevent respiratory hazards. As a practical example, the restoration of antique automotive components utilizing chemical aging techniques necessitates strict adherence to environmental regulations regarding waste disposal and worker safety to mitigate the risks associated with hazardous materials. A balance is achieved between authentic reconstruction and environmental stewardship.

In conclusion, environmental considerations are inextricably linked to the success and sustainability of simulated aged metal finishes. Understanding the potential impacts of environmental factors on finish durability, as well as the environmental consequences of the processes used to create these finishes, is paramount. Employing environmentally responsible practices, such as utilizing less toxic chemicals, implementing effective waste management strategies, and selecting durable protective coatings, contributes to preserving both the aesthetic qualities of the aged metal finish and the integrity of the surrounding environment. Ignoring these elements leads to a short term aesthetic gain with potential long term environmental implications.

7. Durability and Longevity

Durability and longevity are intrinsic components of a successful simulated aged metal finish, directly impacting its practical value and aesthetic appeal over time. The purpose of replicating the appearance of age often necessitates preserving that appearance against further, uncontrolled degradation. A finish prone to rapid wear or corrosion negates the initial intent of simulating antiquity, rendering the process economically and aesthetically unsound. For instance, architectural bronze hardware treated to appear aged requires robust protective measures to withstand environmental exposure and daily use; otherwise, the simulated patina degrades unevenly, creating an unsightly and inauthentic appearance. The balance between achieving an aged aesthetic and ensuring lasting protection defines the success of such applications.

The selection of appropriate materials and techniques significantly influences the durability and longevity of the finish. Chemically induced patinas must be stabilized with protective coatings to prevent further corrosion. Mechanical abrasion techniques must be carefully controlled to avoid weakening the underlying metal structure. The application of clear coats, waxes, or other sealants provides a barrier against moisture, pollutants, and ultraviolet radiation, thus extending the lifespan of the finish. Consider antique automotive restoration, where replicating the original patina involves sealing the surface to prevent further rusting while maintaining the visual character of aged metal. This careful equilibrium ensures the vehicle retains its vintage aesthetic without succumbing to uncontrolled decay. Similar logic applies to preserving aged firearms finishes.

In conclusion, the pursuit of an aged metal appearance necessitates a concurrent focus on durability and longevity. The selection of compatible materials, precise execution of aging techniques, and application of protective measures are critical for preserving the intended aesthetic over time. A failure to prioritize durability undermines the effort and value invested in replicating antiquity, resulting in a finish that deteriorates prematurely. Proper attention to these facets ensures that the simulated age remains a visual asset rather than a liability, contributing to the item’s enduring aesthetic and practical utility. The long-term success depends on a holistic approach which balances aesthetic goals with conservation necessities.

Frequently Asked Questions

This section addresses common inquiries regarding the creation, maintenance, and characteristics of surfaces replicating aged metal, offering insights into techniques and considerations.

Question 1: What are the primary methods for creating a simulated antique metal finish?

Common methods include chemical patination, which employs solutions to induce controlled corrosion; mechanical abrasion, utilizing tools to simulate wear; and layering techniques, involving paints and glazes for depth. Combinations of these methods are often employed to achieve desired results.

Question 2: How can the authenticity of a replicated aged metal surface be assessed?

Authenticity is judged by the accurate replication of natural aging characteristics, including color variations, textural irregularities, and patterns of wear. Careful observation of genuine antique metal surfaces serves as a reference.

Question 3: What role does the substrate metal play in the aging process?

The substrate metal significantly influences the aging process. Different metals react differently to chemical treatments and environmental factors, necessitating tailored techniques to achieve a desired effect.

Question 4: How can the durability of an antique metal finish be enhanced?

Durability is enhanced through the application of protective sealants, such as lacquers or waxes, which create a barrier against moisture, pollutants, and ultraviolet radiation. Proper surface preparation and controlled application of aging techniques are also crucial.

Question 5: What environmental considerations are relevant to antique metal finishing?

Environmental considerations include the safe handling and disposal of chemicals used in patination processes, as well as the selection of durable and environmentally friendly protective coatings. Proper ventilation and filtration are also necessary when performing mechanical abrasion.

Question 6: Can an antique metal finish be applied to any metal surface?

While various techniques exist, not all methods are suitable for every metal. Compatibility between the aging process and the substrate metal is critical. Some metals may require specialized treatments or be unsuitable for certain techniques due to their chemical properties.

Understanding these key aspects facilitates informed decision-making regarding the application and maintenance of simulated aged metal surfaces.

The subsequent section will delve into case studies, illustrating successful applications of these techniques in various industries and environments.

In Summary

The preceding exploration has illuminated the multifaceted aspects of creating and maintaining an “antique metal finish”. The effectiveness of this treatment hinges upon a comprehensive understanding of chemical processes, mechanical techniques, substrate material properties, and environmental influences. Each of these elements contributes to the authenticity, durability, and long-term stability of the final product.

As design trends continue to value historical aesthetics, the demand for convincingly aged metal surfaces will persist. Continued research into environmentally responsible materials and techniques, alongside a commitment to meticulous application, will ensure that the “antique metal finish” remains a viable and aesthetically compelling option. The pursuit of enduring beauty demands a synthesis of artistry and scientific rigor.

![Top Asheville Metal Finishing: [Your Brand] Quality Best Final Touch: Elevate Your Projects with Professional Finishing Top Asheville Metal Finishing: [Your Brand] Quality | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-666-300x200.jpg)