The features encompassing a provider’s capacity to alter the surface properties of metallic materials represent a critical aspect of manufacturing. This involves a range of processes, both chemical and mechanical, intended to enhance a material’s aesthetics, durability, corrosion resistance, and other functional attributes. As an example, consider the application of a coating to protect a metal component from environmental degradation, or the smoothing of a surface to reduce friction.

The availability of these specialized services provides significant value across diverse industries. Improved product longevity, enhanced performance characteristics, and aesthetic appeal translate to increased market competitiveness. Historically, advancements in these techniques have paralleled industrial growth, driving innovation in material science and manufacturing methodologies. Their accessibility enables businesses to produce higher-quality, more reliable goods.

The subsequent sections will delve into specific methods employed, the types of materials commonly treated, quality control measures, and considerations for selecting a suitable provider. A detailed exploration of these elements is essential for informed decision-making regarding surface treatment solutions.

Selecting the appropriate method for modifying metallic surfaces requires careful consideration. The following guidelines offer a framework for optimizing outcomes and ensuring compatibility with project objectives.

Tip 1: Material Compatibility Assessment: Rigorously evaluate the interaction between the base metal and the selected process. Incompatible combinations can lead to reduced adhesion, accelerated corrosion, or compromised structural integrity. Consult material compatibility charts and conduct preliminary testing when uncertain.

Tip 2: Performance Requirement Specification: Define the precise performance enhancements sought. Increased wear resistance, improved corrosion protection, or specific aesthetic attributes dictate process selection. A vague understanding of performance needs can result in suboptimal solutions.

Tip 3: Pre-Treatment Standardization: Implement consistent pre-treatment procedures. Proper cleaning, degreasing, and surface preparation are critical for uniform adhesion and performance. Variations in pre-treatment quality directly affect the longevity and effectiveness of the final finish.

Tip 4: Process Parameter Control: Maintain strict control over process parameters. Temperature, dwell time, current density, and chemical concentrations must be precisely regulated. Deviation from established parameters can lead to inconsistencies in finish quality and performance.

Tip 5: Vendor Qualification: Conduct thorough vendor due diligence. Evaluate a provider’s experience, certifications, equipment capabilities, and quality control procedures. A reputable vendor offers demonstrable expertise and consistent results.

Tip 6: Post-Treatment Evaluation: Implement robust post-treatment inspection procedures. Verify coating thickness, adhesion strength, and corrosion resistance through standardized testing methods. Early detection of defects minimizes potential failures in the field.

Tip 7: Environmental Regulation Compliance: Ensure adherence to all applicable environmental regulations. Waste disposal, emissions control, and material handling practices must align with local, regional, and national standards. Compliance protects both the environment and the long-term viability of operations.

Effective implementation of these guidelines can lead to significant improvements in product performance, durability, and overall quality. A proactive approach to surface modification decisions minimizes risks and maximizes the return on investment.

The subsequent section will focus on evaluating the costs associated with various techniques, along with strategies for optimizing budgets while maintaining high standards.

1. Corrosion Resistance

Corrosion resistance, a crucial attribute in metallic materials, is significantly enhanced through various surface treatment processes. These processes, integral to this broad field, mitigate degradation caused by environmental factors, extending the lifespan and reliability of metal components.

- Protective Coatings

Coatings, such as paints, powder coatings, and specialized films, act as a physical barrier, preventing direct contact between the metal substrate and corrosive agents. For instance, epoxy coatings are commonly applied to steel structures in marine environments to resist saltwater corrosion. The effectiveness of these coatings depends on their adhesion, impermeability, and resistance to chemical breakdown.

- Galvanic Protection

Galvanizing, a method of applying a zinc coating to steel, provides sacrificial protection. Zinc, being more electrochemically active than steel, corrodes preferentially, safeguarding the underlying metal. Galvanized steel is widely used in construction and automotive applications, providing long-term protection against rust. This process leverages the electrochemical properties of different metals to inhibit corrosion.

- Passivation

Passivation involves creating a thin, inert oxide layer on the metal surface, hindering further oxidation. Stainless steel, for example, forms a chromium oxide layer that protects the underlying metal from corrosion. The formation and maintenance of this passive layer are crucial for the material’s resistance to corrosive environments. This technique is commonly employed in medical implants and food processing equipment.

- Chemical Conversion Coatings

Chemical conversion coatings, such as phosphate and chromate coatings, chemically react with the metal surface to form a protective layer. These coatings improve paint adhesion and provide a degree of corrosion resistance. Phosphate coatings are often used on automotive components, while chromate coatings are applied to aluminum alloys for corrosion protection and improved paint adhesion.

The effective implementation of these methods is paramount for ensuring the longevity and performance of metal components in diverse environments. The selection of the appropriate technique depends on the specific application, the type of metal, and the severity of the corrosive environment. These applications represent a crucial aspect, directly influencing the durability and reliability of manufactured goods.

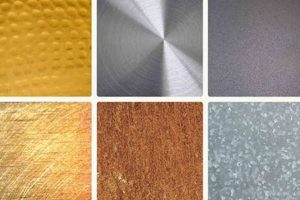

2. Aesthetic Enhancement

Aesthetic enhancement constitutes a significant facet within the broader realm of metal surface treatments. The application of specialized techniques directly influences the visual appeal of metallic components and products. The strategic manipulation of surface characteristics, such as texture, color, and reflectivity, allows manufacturers to align products with specific market demands and brand identities. The processes employed range from simple polishing to complex multi-layered coatings, each designed to achieve a desired aesthetic outcome. For example, the application of a brushed finish to stainless steel appliances imparts a sense of sophistication and minimizes the visibility of fingerprints, thereby increasing consumer appeal.

The relationship between surface modification processes and perceived aesthetic value is demonstrably strong. Techniques like powder coating provide a durable, uniform finish in a wide array of colors, enhancing both the product’s visual attractiveness and its resistance to environmental factors. Similarly, anodizing aluminum creates a protective oxide layer that can be dyed to produce vibrant and long-lasting colors. In the automotive industry, chrome plating is often used on trim and wheels to create a bright, reflective surface that is associated with luxury and high performance. These treatments represent crucial variables in determining the market success of many products.

Ultimately, the integration of aesthetic considerations within metal surface modification processes is critical for competitive differentiation. While functionality remains paramount, visual appeal significantly influences consumer purchasing decisions. Challenges in achieving optimal aesthetic results include maintaining consistency across large production runs and ensuring the durability of the applied finishes under various operating conditions. Successful integration necessitates a thorough understanding of material properties, process parameters, and the desired aesthetic outcome, further solidifying the importance of comprehensive treatment strategies in contemporary manufacturing.

3. Wear Reduction

Wear reduction, as a critical function, is inextricably linked to surface treatment methodologies. The degradation of metallic components through friction, abrasion, erosion, and other wear mechanisms is a pervasive concern across numerous industrial applications. The strategic application of particular surface treatments directly mitigates these effects, extending the operational lifespan and enhancing the reliability of critical parts. Surface treatments modify the surface properties of the metal, creating a barrier against wear forces. For instance, the application of hard coatings, such as titanium nitride (TiN), significantly increases surface hardness, thereby reducing abrasive wear in cutting tools and forming dies. Similarly, processes such as carburizing and nitriding introduce a hardened surface layer that resists wear in gears and bearings.

The importance of wear reduction is evident in the performance of components under high stress or demanding conditions. In the aerospace industry, turbine blades are subject to extreme temperatures and high rotational speeds, making them susceptible to wear. Coatings, such as thermal barrier coatings and wear-resistant overlays, are applied to protect these blades from both thermal degradation and wear, ensuring the safe and efficient operation of jet engines. In the automotive sector, engine components, such as piston rings and cylinder liners, benefit from surface treatments that reduce friction and wear, leading to improved fuel efficiency and reduced emissions. The selection of an appropriate treatment method depends on the specific application, the nature of the wear mechanism, and the desired performance characteristics.

In conclusion, wear reduction is a crucial element, directly contributing to the longevity, efficiency, and reliability of metallic components. The strategic application of surface treatments is an essential engineering practice for industries where component wear is a significant concern. Further research and development in surface engineering continue to improve the effectiveness of treatments, addressing increasingly demanding applications and enhancing overall system performance. Understanding the connection between treatment options and wear behavior is vital for optimizing the design and manufacturing of durable and reliable products.

4. Surface Hardness

Surface hardness, a critical mechanical property, is directly influenced by metal surface treatments. It defines a material’s resistance to localized plastic deformation, typically assessed through indentation testing. Enhancing this characteristic is a primary objective in numerous industrial applications, directly correlating with improved wear resistance, prolonged component lifespan, and enhanced performance under demanding operational conditions. The selection and application of appropriate metal finishing capabilities are crucial for achieving targeted surface hardness levels.

- Case Hardening

Case hardening involves altering the chemical composition of the surface layer of a metal component, typically steel, to increase its hardness while maintaining a ductile core. Techniques such as carburizing, nitriding, and carbonitriding introduce elements like carbon or nitrogen into the surface, forming a hardened case that resists wear and fatigue. Automotive gears, for instance, undergo case hardening to withstand high loads and repetitive stress, ensuring reliable performance and extended service life. The depth and hardness of the case layer are carefully controlled to optimize the balance between surface hardness and core ductility. This precise control exemplifies the importance of refined metal finishing capabilities.

- Hard Coating Deposition

Hard coating deposition processes, including physical vapor deposition (PVD) and chemical vapor deposition (CVD), deposit thin films of hard materials onto the metal surface. Materials such as titanium nitride (TiN), chromium nitride (CrN), and diamond-like carbon (DLC) offer exceptional hardness and wear resistance. Cutting tools, forming dies, and aerospace components benefit from these coatings, enhancing their performance and extending their operational lifespan. PVD and CVD processes enable precise control over coating thickness, composition, and microstructure, allowing for tailored solutions to meet specific application requirements. The capabilities in this domain are essential for achieving desired hardness and durability.

- Surface Cold Working

Surface cold working techniques, such as shot peening and roller burnishing, induce compressive residual stresses in the surface layer of a metal component, increasing its hardness and fatigue resistance. Shot peening involves bombarding the surface with small spherical media, while roller burnishing uses hardened rollers to plastically deform the surface. These processes are commonly used in the aerospace and automotive industries to enhance the fatigue life of critical components such as crankshafts and suspension springs. The introduction of compressive stresses inhibits crack initiation and propagation, thereby improving the component’s resistance to fatigue failure. This method demonstrates how mechanical metal finishing capabilities can enhance surface properties.

- Electroless Deposition

Electroless deposition is a chemical plating process that deposits a uniform coating of metal onto a substrate without the use of external electric current. Electroless nickel plating, for example, produces a hard, wear-resistant coating with excellent corrosion protection. This process is widely used in the electronics, automotive, and aerospace industries to enhance the surface properties of components with complex geometries. The hardness of the electroless nickel coating can be further increased through heat treatment, resulting in superior wear resistance and extended service life. The precision and versatility of electroless deposition highlight the importance of chemical-based metal finishing capabilities.

In summary, the enhancement of surface hardness through targeted metal finishing capabilities is critical for improving the performance, durability, and lifespan of metallic components. The selection of the appropriate method depends on the specific application, the type of metal, and the desired performance characteristics. The examples presented demonstrate the diverse range of techniques available and their significance in various industries. Metal finishing capabilities that address surface hardness are therefore essential for achieving desired material properties and ensuring the reliability of manufactured goods.

5. Adhesion Improvement

Adhesion improvement is an intrinsic aspect of metal surface technology, referring to the enhancement of the bond strength between a metallic substrate and a subsequently applied coating, film, or adhesive. Deficient adhesion can lead to premature coating failure, corrosion, and compromised component performance. Effective enhancement strategies, facilitated by metal finishing capabilities, are critical for ensuring the longevity and reliability of finished products. The underlying cause of adhesion problems often lies in surface contamination, inadequate surface energy, or the formation of weak interfacial layers. The selection of appropriate treatment methodologies directly addresses these causes.

A primary example is surface roughening, commonly achieved through mechanical or chemical etching. The increased surface area provides more contact points for the coating material, resulting in a stronger mechanical interlock. Chemical conversion coatings, such as chromate conversion on aluminum, not only improve corrosion resistance but also create a more receptive surface for paint adhesion. Furthermore, plasma treatments modify the surface chemistry of the metal, increasing its surface energy and promoting stronger chemical bonding with the applied coating. In the aerospace industry, where stringent performance requirements are paramount, meticulous surface preparation is essential to ensure the structural integrity and environmental protection of coated components. For instance, titanium alloys undergo complex surface treatments to enhance the adhesion of protective coatings used in aircraft engines.

In conclusion, adhesion improvement is not merely an isolated process but an integrated element of broader metal finishing capabilities. Proper surface preparation, encompassing cleaning, roughening, and chemical modification, is fundamental for achieving robust and durable coatings. By understanding and implementing effective adhesion improvement strategies, manufacturers can significantly enhance the performance, longevity, and overall value of their products. The ongoing development of advanced treatment technologies promises to further refine adhesion performance, addressing the challenges associated with increasingly demanding applications and materials.

6. Dimensional Accuracy

Dimensional accuracy, representing the degree to which a finished part conforms to its specified dimensions, is intrinsically linked to metal finishing capabilities. Surface treatments, while primarily focused on modifying surface properties, inevitably impact overall part dimensions. The material added or removed during processes such as plating, coating, or grinding directly influences the final size and shape. Maintaining dimensional accuracy, therefore, necessitates precise control over these processes. For example, in the manufacturing of precision gears, even a micron-level deviation from the intended dimensions can significantly affect gear meshing and performance. Metal finishing capabilities, when properly implemented, mitigate these risks through controlled material deposition or removal, ensuring the final product meets stringent dimensional tolerances.

The connection between surface treatments and dimensional changes is further exemplified in industries requiring tight clearances and fits. Aerospace components, for instance, often demand extremely precise dimensions to ensure proper functionality within complex assemblies. Metal finishing processes, such as thin-film coating deposition, must be carefully calibrated to avoid exceeding permissible dimensional variations. Advanced techniques, like precision grinding or controlled etching, are employed to fine-tune dimensions after initial surface treatments. The selection of appropriate metal finishing capabilities is contingent on the required level of dimensional accuracy and the specific characteristics of the material being treated. Ignoring the dimensional impact of surface treatments can lead to costly rework or component rejection.

In conclusion, dimensional accuracy is not merely a separate consideration but rather an integral aspect of metal finishing capabilities. Achieving desired surface properties without compromising dimensional integrity demands a comprehensive understanding of the processes involved and meticulous control over their parameters. The ability to predict and manage dimensional changes is crucial for producing high-quality, reliable components across diverse industries. A failure to address this link can undermine the benefits of surface treatments, emphasizing the need for integrated approaches to metal finishing. The effectiveness of these techniques is defined by their dimensional impact.

7. Electrical Conductivity

Metal finishing capabilities profoundly influence the electrical conductivity of metallic surfaces. While the inherent conductivity of a metal is a fundamental property, surface treatments can either enhance or degrade its ability to conduct electricity. The presence of oxides, contaminants, or insulating layers on the surface impedes electron flow, thereby reducing conductivity. Conversely, certain treatments can remove these impediments or introduce conductive materials, improving overall performance. This relationship necessitates careful selection and control of finishing processes when electrical conductivity is a critical design parameter. Understanding this relationship is paramount in applications ranging from electronics manufacturing to power distribution.

The effect of surface treatments on conductivity is evident in several practical examples. Gold plating, often employed on electrical connectors and circuit board components, serves to improve conductivity and prevent corrosion. The gold layer provides a highly conductive and corrosion-resistant interface, ensuring reliable electrical contact. Conversely, anodizing, a process commonly applied to aluminum, creates an insulating oxide layer, intentionally reducing conductivity to prevent electrical shorts and corrosion. The choice between these processes depends directly on the desired electrical characteristics of the finished part. Furthermore, surface roughness, induced by certain finishing techniques, can increase the effective resistance of a conductor, highlighting the importance of surface smoothness in high-frequency applications.

In conclusion, electrical conductivity is not merely an intrinsic property of a metal but a characteristic that can be significantly modified through metal finishing processes. Whether the goal is to enhance conductivity for improved performance or to reduce it for insulation purposes, a clear understanding of the relationship between surface treatments and electrical properties is essential. Careful process selection, precise control of process parameters, and thorough testing are crucial for achieving the desired electrical performance. Neglecting this aspect can lead to significant performance limitations or even failure in critical applications.

Frequently Asked Questions Regarding Metal Finishing Capabilities

The following section addresses common inquiries concerning metal finishing processes. These questions aim to provide clarity on the various aspects involved in altering the surface properties of metallic materials.

Question 1: What constitutes a comprehensive assessment of a vendor’s metal finishing capabilities?

A thorough evaluation should include a review of the vendor’s certifications, equipment inventory, quality control procedures, experience with specific materials, and compliance with relevant environmental regulations. A physical audit of the facility is often recommended to verify claims.

Question 2: How does the choice of metal finishing process impact the overall cost of a project?

The selection of the finishing method directly influences material costs, processing time, energy consumption, and waste disposal expenses. Processes requiring specialized equipment or hazardous chemicals will generally be more expensive. Life-cycle cost analysis should be considered.

Question 3: What are the primary considerations when selecting a metal finishing process for corrosion protection?

The severity of the corrosive environment, the base metal’s susceptibility to corrosion, the desired lifespan of the component, and any aesthetic requirements must be carefully considered. Salt spray testing and electrochemical measurements are often employed to assess corrosion resistance.

Question 4: How do surface treatments affect the mechanical properties of a metal component?

Certain surface treatments, such as case hardening, can significantly increase surface hardness and wear resistance. However, other processes, like excessive etching, may weaken the component. A comprehensive understanding of the interaction between the treatment and the base metal is crucial.

Question 5: What role does surface preparation play in the success of a metal finishing process?

Proper surface preparation, including cleaning, degreasing, and etching, is essential for ensuring adequate adhesion and uniform coating coverage. Contamination on the surface can lead to coating defects and premature failure. Standardized preparation procedures are crucial.

Question 6: How are environmental regulations impacting the metal finishing industry?

Stringent regulations regarding waste disposal, emissions control, and the use of hazardous substances are driving the adoption of more environmentally friendly finishing processes. Compliance with these regulations is essential for maintaining operational viability.

Metal finishing capabilities encompass a wide range of considerations, from process selection to environmental impact. Informed decision-making requires a thorough understanding of the various factors involved.

The following segment will explore future trends and innovations in metal finishing technologies.

Conclusion

This exposition has detailed the comprehensive nature of metal finishing capabilities, underlining their crucial role in enhancing material properties and extending product lifecycles. The discussion spanned a range of processes, their impact on material characteristics, and the importance of vendor selection and regulatory compliance. Emphasis was placed on the direct influence of surface treatments on corrosion resistance, aesthetic appeal, wear reduction, surface hardness, adhesion, dimensional accuracy, and electrical conductivity, demonstrating the multifaceted benefits derived from specialized surface modification.

The continued advancement of metal finishing capabilities is essential for progress across numerous industries. As materials science evolves and performance demands increase, a dedication to research, innovation, and responsible application of these technologies will be critical for maintaining competitiveness and achieving sustainable manufacturing practices. Stakeholders are encouraged to prioritize comprehensive understanding and strategic implementation of these techniques to maximize the value and longevity of their products.

![Top Asheville Metal Finishing: [Your Brand] Quality Best Final Touch: Elevate Your Projects with Professional Finishing Top Asheville Metal Finishing: [Your Brand] Quality | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-666-300x200.jpg)