This roofing option refers to metal panels that retain the appearance they had after initial production at the mill. It lacks any additional surface treatments like paint or coatings. The resultant bare metal surface exhibits a natural, often slightly varied, appearance that showcases the inherent characteristics of the metal itself. Aluminum, steel, and other alloys may be utilized in this form. The look can range from bright and reflective to a more subdued, matte tone, depending on the specific metal composition and the milling process.

Choosing this material offers potential cost savings, as it eliminates the expense of applied finishes. Its raw aesthetic is favored by some architectural styles, offering a unique visual appeal that evolves over time as the metal weathers and oxidizes. Historically, this material was selected primarily for its functional properties and cost-effectiveness, but it has since gained popularity for its industrial and modern aesthetic qualities. The lack of a coating also reduces concerns about chipping, peeling, or fading paint.

The following sections will delve into the specific advantages and disadvantages of this material choice, explore the different metal types commonly used, and discuss installation and maintenance considerations. Furthermore, the article will provide guidance on selecting the appropriate gauge and profile for various roofing applications, ensuring optimal performance and longevity.

Essential Considerations for Mill Finish Metal Roofs

The following guidance is offered to facilitate informed decision-making regarding this roofing option, ensuring optimal performance and aesthetic satisfaction.

Tip 1: Alloy Selection: Prioritize the metal alloy based on environmental factors. Coastal regions necessitate corrosion-resistant materials such as aluminum or certain grades of stainless steel. In drier climates, galvanized steel may prove sufficient, contingent on budgetary constraints.

Tip 2: Gauge Thickness: Specify an appropriate gauge thickness predicated on anticipated snow loads and wind conditions. Thicker gauges offer enhanced durability and resistance to deformation. Consult local building codes and structural engineers for accurate assessments.

Tip 3: Substrate Compatibility: Ensure compatibility between the metal roofing and the underlying substrate. Dissimilar metals can induce galvanic corrosion, compromising the roof’s structural integrity. Utilize appropriate underlayment materials to mitigate this risk.

Tip 4: Installation Expertise: Engage experienced and qualified roofing contractors familiar with metal roofing installation techniques. Proper installation is paramount to prevent leaks and ensure the longevity of the roof system. Verify contractor credentials and references.

Tip 5: Oil Canning Awareness: Acknowledge the potential for “oil canning,” a visual distortion common in flat metal panels. While structurally benign, oil canning can affect the aesthetic appeal. Consider textured or ribbed panels to minimize its prominence.

Tip 6: Expansion and Contraction Accommodation: Design the roofing system to accommodate thermal expansion and contraction. Utilize appropriate fasteners and allow for sufficient movement to prevent stress on the metal panels and supporting structure.

Tip 7: Regular Inspections: Implement a schedule for regular inspections to identify and address potential issues early. Examine for signs of corrosion, fastener loosening, and sealant degradation. Prompt maintenance prolongs roof lifespan.

Adhering to these recommendations promotes informed material selection, proper installation, and proactive maintenance, ultimately maximizing the lifespan and performance of this roofing solution.

The subsequent sections will explore aesthetic considerations and address frequently asked questions, providing a holistic understanding of this roofing system.

1. Raw Aesthetic

The “Raw Aesthetic” associated with metal roofing derives from the unaltered surface of the metal, directly exhibiting its intrinsic characteristics. This appeal contrasts sharply with manufactured appearances achieved through coatings or paint, finding preference in architectural designs emphasizing industrial, modern, or minimalist themes. The following facets explore this aesthetic in detail.

- Material Honesty

The unfinished surface openly displays the metal’s inherent qualities, including grain, texture, and weld marks, promoting a sense of authenticity. For example, weathering steel roofs intentionally expose rust, transforming what is normally considered a flaw into a design element. This transparency reinforces the concept of material honesty, valued in contemporary architecture.

- Industrial Character

This selection frequently evokes an industrial feel due to the association of bare metal with factories, warehouses, and functional structures. The look often complements exposed ductwork, concrete, and other raw materials, harmonizing elements within industrial-chic designs. Renovated lofts and urban dwellings often adopt this character.

- Evolution through Weathering

This roofing option undergoes a continuous visual transformation influenced by environmental exposure. Oxidation, patina formation, and subtle color changes result in a dynamic surface that reflects the roof’s history. For example, copper roofs develop a distinctive green patina, an aesthetic transformation sought after in prestigious buildings.

- Design Contrast

The starkness of the raw metal can serve as a deliberate contrast against softer, more refined materials, creating visual tension and highlighting textural differences. Pairing a steel roof with natural wood siding or glass walls enhances the visual depth of a structure, emphasizing the interplay between contrasting elements.

The “Raw Aesthetic” is not simply a matter of visual appeal; it is a design choice that expresses a commitment to material integrity, environmental responsiveness, and architectural honesty. Selecting this roofing speaks to an appreciation for inherent beauty and the dynamic processes that shape its appearance over time, making it a considered choice for projects prioritizing architectural expression alongside functional performance.

2. Cost-Effectiveness

The “Cost-Effectiveness” inherent in a metal roof installation arises primarily from the elimination of post-production finishing processes. Unlike coated or painted metal roofing, the mill finish variety forgoes the additional expenses associated with applying and curing these surface treatments. This translates to direct savings in material costs, making it an economically attractive option, particularly for large-scale projects or budget-conscious clients. The absence of coatings also reduces the potential for future maintenance expenses related to paint chipping, peeling, or fading, further contributing to the long-term affordability.

A practical example of this cost advantage can be observed in agricultural or industrial buildings where aesthetic considerations are secondary to functional requirements. The bare metal provides adequate protection from the elements without incurring the extra cost of colored or specialized finishes. Furthermore, the reduced complexity of the manufacturing process can result in shorter lead times and simplified installation procedures, indirectly decreasing labor costs. However, it’s essential to weigh these initial savings against the potential need for corrosion prevention measures, depending on the environmental conditions and the type of metal used. Galvanizing or other protective treatments might be necessary to extend the lifespan of the roof in corrosive environments, which can offset some of the initial cost advantage.

In summary, the cost-effectiveness of this roofing option hinges on the reduced manufacturing complexity and the elimination of applied finishes. This results in immediate material cost savings and potentially lower long-term maintenance expenses. However, a comprehensive cost analysis should incorporate the potential need for corrosion protection and the aesthetic implications of a bare metal surface. Understanding these trade-offs is crucial for determining whether the “Cost-Effectiveness” of this roofing system aligns with the specific requirements and priorities of a given project.

3. Corrosion Resistance

Corrosion resistance is a critical consideration when specifying roofing materials, especially in the context of metal roofing that lacks applied protective coatings. The inherent resistance of the metal itself becomes the primary defense against environmental degradation. Understanding the interplay between the metal’s composition, the surrounding environment, and potential corrosion mechanisms is paramount for ensuring the longevity and structural integrity of the roof.

- Alloy Composition and Galvanic Action

The specific alloy used in the manufacture of the metal panels significantly influences its susceptibility to corrosion. Different metals possess varying electrochemical potentials, and when dissimilar metals come into contact in the presence of an electrolyte (such as rainwater), galvanic corrosion can occur. More noble metals will corrode less, while less noble metals will corrode preferentially. For instance, using aluminum fasteners on a steel roof can lead to rapid corrosion of the steel, compromising the integrity of the fastening system and ultimately the roof’s performance.

- Environmental Factors and Atmospheric Corrosion

The surrounding environment plays a pivotal role in accelerating or mitigating corrosion processes. Coastal regions with high salinity levels, industrial areas with acidic pollutants, and locations with frequent precipitation all pose increased risks. These factors can lead to various forms of atmospheric corrosion, including uniform corrosion, pitting corrosion, and crevice corrosion. Understanding the specific environmental stressors is essential for selecting a metal alloy with adequate resistance. For example, stainless steel or aluminum alloys are often preferred in coastal environments due to their superior resistance to chloride-induced corrosion.

- Passivation and Self-Repairing Mechanisms

Some metals, like aluminum and stainless steel, exhibit self-repairing mechanisms due to the formation of a passive oxide layer on their surface. This layer acts as a barrier, preventing further corrosion. However, this passivation can be disrupted by certain chemicals or mechanical damage. For example, harsh cleaning agents can strip away the protective oxide layer on aluminum, rendering it more vulnerable to corrosion. Understanding the conditions that can compromise passivation is crucial for proper maintenance and care of the roof.

- Protective Coatings and Sacrificial Anodes

While a mill finish lacks applied coatings, certain pre-treatments, such as galvanizing (applying a layer of zinc to steel), can significantly enhance corrosion resistance. Zinc acts as a sacrificial anode, corroding preferentially to protect the underlying steel. However, the zinc coating will eventually degrade over time, necessitating periodic inspection and maintenance. Understanding the limitations and lifespan of these pre-treatments is essential for planning long-term roof maintenance strategies.

The “Corrosion Resistance” of a “mill finish metal roof” is therefore not a static property but rather a complex interplay of material selection, environmental factors, and protective mechanisms. Specifying the appropriate metal alloy and implementing appropriate mitigation strategies are essential for ensuring the long-term performance and durability of the roofing system. Proper maintenance and regular inspections further contribute to preventing corrosion and extending the lifespan of the roof, particularly in harsh environments.

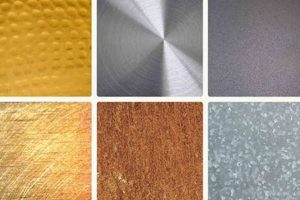

4. Material Options

The selection of appropriate materials is a paramount consideration in the specification of a metal roof with a mill finish. The absence of applied coatings necessitates a rigorous evaluation of the intrinsic properties of various metals, as these characteristics will directly dictate the roof’s durability, longevity, and aesthetic evolution. The choice of material will, therefore, profoundly influence the overall performance and lifecycle cost of the roofing system.

- Aluminum Alloys

Aluminum alloys offer excellent corrosion resistance, particularly in marine environments, due to the formation of a self-repairing oxide layer. Common alloys, such as 5052 and 3003, provide a balance of strength, formability, and weldability. However, aluminum possesses a relatively low modulus of elasticity compared to steel, which may require closer support spacing to prevent deflection under heavy snow loads. For instance, an aircraft hangar near the coast might benefit from an aluminum alloy roof due to its superior resistance to saltwater corrosion.

- Galvanized Steel

Galvanized steel provides corrosion protection through a sacrificial zinc coating. This coating corrodes preferentially, protecting the underlying steel substrate. The longevity of the galvanized coating depends on its thickness and the severity of the environmental conditions. In industrial areas with high levels of acid rain, the zinc coating may degrade relatively quickly, requiring periodic recoating or replacement. Conversely, in drier, less polluted environments, a galvanized steel roof can provide decades of reliable service. Agricultural buildings in rural areas often utilize galvanized steel roofing due to its cost-effectiveness and adequate corrosion resistance.

- Stainless Steel

Stainless steel alloys, such as 304 and 316, offer superior corrosion resistance and strength compared to aluminum and galvanized steel. The addition of chromium and nickel to the steel composition forms a passive chromium oxide layer that protects the underlying metal from corrosion. While more expensive than other options, stainless steel is often specified for high-end architectural projects and in extremely corrosive environments, such as chemical processing plants. Its durability and resistance to staining also make it a suitable choice for applications where aesthetic appeal is paramount.

- Copper

Copper is a naturally corrosion-resistant metal that develops a distinctive green patina over time due to oxidation. This patina provides a protective layer, preventing further corrosion. Copper roofing has a long lifespan, often exceeding 100 years, and requires minimal maintenance. Its aesthetic appeal and historical significance make it a popular choice for prestigious buildings and historical restorations. However, the high material cost of copper can be a significant deterrent for many projects. For example, the roofs of many historical government buildings are made of copper, showcasing its longevity and aesthetic qualities.

The choice of material for a mill finish metal roof is a multifaceted decision that requires careful consideration of environmental factors, budgetary constraints, aesthetic preferences, and structural requirements. A thorough evaluation of the properties and limitations of each material option is essential for ensuring the long-term performance and value of the roofing system. The examples provided illustrate how specific material choices can be tailored to address the unique challenges and opportunities presented by different project contexts.

5. Minimal Maintenance

The concept of “Minimal Maintenance” is a significant advantage associated with the selection of a roofing solution. The inherent properties of the materials employed and the absence of applied surface coatings contribute to a reduction in required upkeep, offering long-term benefits to building owners and facility managers.

- Elimination of Repainting

Unlike painted or coated metal roofing systems, a mill finish roof negates the need for periodic repainting. Applied coatings are susceptible to chipping, peeling, and fading due to weathering and UV exposure. The absence of these coatings removes the associated costs and labor involved in maintaining the roof’s aesthetic appearance. This is particularly beneficial for large commercial or industrial buildings where repainting can be a substantial expense.

- Reduced Risk of Coating Failure

The potential for coating failure, which can lead to corrosion and degradation of the underlying metal, is eliminated. Coating failures often require costly repairs or even complete roof replacement. By forgoing applied coatings, the risk of such failures is inherently avoided, simplifying maintenance procedures and minimizing the likelihood of extensive repairs. This aspect is especially pertinent in environments with harsh weather conditions or high levels of pollution.

- Natural Patina Development

Certain metals, such as copper and weathering steel, develop a natural patina over time. This patina acts as a protective layer, slowing down corrosion and extending the lifespan of the roof. The patina also provides an aesthetically pleasing appearance, which is often considered a desirable feature. This natural weathering process reduces the need for active maintenance interventions and contributes to the roof’s long-term durability. For example, copper roofs on historic buildings require little to no maintenance due to the protective properties of the patina.

- Simplified Cleaning Procedures

While mill finish metal roofs generally require less maintenance, periodic cleaning may still be necessary to remove debris and prevent staining. However, cleaning procedures are typically simpler and less demanding compared to coated roofs. Gentle washing with water and a mild detergent is often sufficient to remove dirt and grime. Harsh chemicals or abrasive cleaning methods should be avoided as they can damage the metal surface. The ease of cleaning contributes to the overall reduction in maintenance efforts and helps preserve the roof’s appearance.

In summary, the “Minimal Maintenance” characteristic of this material is derived from the inherent properties of the metal and the avoidance of applied coatings. This results in reduced repainting requirements, a decreased risk of coating failure, the potential for beneficial patina development, and simplified cleaning procedures. These factors collectively contribute to lower long-term maintenance costs and enhanced durability, making it an attractive option for building owners seeking a cost-effective and reliable roofing solution.

6. Weathering Process

The weathering process is an intrinsic component of metal roofing, particularly when a mill finish is selected. Mill finish roofing, lacking protective coatings, directly exposes the bare metal to environmental elements, thereby initiating and influencing the weathering progression. This process, involving oxidation, corrosion, and the accumulation of surface contaminants, results in visual and structural alterations to the roofing material. The rate and nature of weathering are contingent upon the specific metal alloy, atmospheric conditions, and geographical location. Coastal environments, characterized by high salinity, will accelerate corrosion in certain metals, while arid climates may promote a slower, more uniform oxidation. The effects of weathering are observable through changes in color, texture, and the potential formation of a patina or rust layer. For instance, copper roofing predictably develops a green patina due to oxidation, while steel may exhibit rust if not properly alloyed or treated.

The significance of understanding the weathering process lies in its impact on the roof’s long-term performance and aesthetic trajectory. Predicting and managing weathering can inform material selection and maintenance strategies. Choosing corrosion-resistant alloys, such as aluminum or stainless steel, mitigates the risk of structural degradation. Regular inspections and cleaning can remove surface contaminants that accelerate corrosion, prolonging the roof’s lifespan. Architects and building owners may also intentionally leverage the weathering process to achieve a desired aesthetic outcome. The deliberate use of weathering steel, for example, allows a controlled rust layer to form, creating a distinctive visual appearance. This approach necessitates careful consideration of the surrounding environment to ensure the rust layer remains stable and does not compromise structural integrity or leach onto adjacent surfaces.

In conclusion, the weathering process is a defining characteristic of mill finish metal roofing, influencing its visual evolution and structural performance. Recognizing the factors that govern weathering enables informed material selection, proactive maintenance, and the potential for achieving specific aesthetic goals. Challenges arise in accurately predicting the long-term effects of weathering and mitigating potential risks associated with corrosion. However, a comprehensive understanding of this process is essential for maximizing the lifespan and aesthetic value of mill finish metal roofing.

Frequently Asked Questions

The following section addresses common inquiries and misconceptions regarding mill finish metal roofing systems, providing clarity on their characteristics, applications, and limitations.

Question 1: Is a metal roof with a mill finish prone to rust?

The susceptibility to rust depends on the metal alloy. Steel alloys without a protective coating, such as galvanization, are indeed prone to rust when exposed to moisture and oxygen. Aluminum alloys, conversely, form a protective oxide layer that inhibits rust formation. Stainless steel alloys also offer excellent corrosion resistance. The appropriate metal selection is crucial for mitigating rust potential.

Question 2: Does a mill finish metal roof require more maintenance than a painted metal roof?

In general, a mill finish metal roof requires less maintenance than a painted metal roof. Painted surfaces are subject to chipping, peeling, and fading, necessitating periodic repainting. Mill finish roofs, lacking these coatings, eliminate the need for such maintenance. However, periodic cleaning may be required to remove debris and prevent staining, depending on the environment.

Question 3: How does the appearance of a mill finish metal roof change over time?

The appearance evolves due to weathering. Unprotected metals will oxidize, resulting in a patina or rust layer. The specific color and texture depend on the metal and environmental conditions. Copper develops a distinctive green patina, while steel may exhibit a reddish-brown rust. These changes are typically gradual and can enhance the aesthetic appeal for some architectural styles.

Question 4: Is a metal roof with a mill finish suitable for all climates?

Suitability depends on the metal alloy and the severity of the climate. Aluminum and stainless steel are well-suited for coastal environments due to their resistance to saltwater corrosion. Galvanized steel may be adequate for drier climates, but requires careful monitoring. Severe weather conditions, such as heavy snow or hail, may necessitate thicker gauges to ensure structural integrity.

Question 5: Does the absence of a coating affect the energy efficiency of a mill finish metal roof?

Yes, the absence of a reflective coating can impact energy efficiency. Darker, uncoated metals absorb more solar radiation, potentially increasing cooling loads in warm climates. Lighter-colored or reflective coatings can mitigate this effect by reflecting sunlight. However, factors such as roof insulation and ventilation play a significant role in overall energy performance.

Question 6: What is “oil canning” and how does it affect mill finish metal roofs?

“Oil canning” refers to the visible waviness or distortion that can occur in flat metal panels. It is a cosmetic issue and does not typically affect structural performance. Oil canning is more noticeable in mill finish roofs due to the absence of textured coatings that can mask the effect. Specifying textured or ribbed panels can minimize the prominence of oil canning.

In summary, mill finish metal roofing presents a unique blend of aesthetic characteristics, durability, and maintenance considerations. Informed decision-making requires careful evaluation of metal alloy, environmental conditions, and desired aesthetic outcomes.

The subsequent section will delve into installation best practices for mill finish metal roofing systems, ensuring optimal performance and longevity.

Conclusion

The preceding exploration has examined the multifaceted aspects of the “mill finish metal roof,” detailing its inherent characteristics, advantages, and limitations. Key considerations include alloy selection, corrosion resistance, aesthetic evolution, and maintenance requirements. The suitability of this roofing system is contingent upon careful assessment of environmental factors, budgetary constraints, and architectural objectives. The inherent “raw aesthetic” presents a distinctive visual appeal, while the potential for cost-effectiveness stems from the elimination of applied coatings. However, the absence of such coatings necessitates meticulous attention to corrosion prevention strategies and an understanding of the long-term weathering process.

Ultimately, the decision to specify a “mill finish metal roof” demands a comprehensive understanding of the trade-offs involved. Informed professionals must weigh the potential cost savings against the need for proactive maintenance and a potential shift in aesthetic expectations as the material ages. As sustainable building practices gain prominence, the inherent recyclability of metal roofing and the reduction in VOC emissions associated with the absence of coatings position the “mill finish metal roof” as a viable option for environmentally conscious designs. Future advancements in metal alloys and corrosion mitigation technologies promise to further enhance the performance and longevity of this roofing system, solidifying its place as a considered choice in contemporary construction.