A business provides specialized surface treatments for metallic components and products. These processes enhance the appearance, durability, and functionality of metal items through the application of various coatings and finishes. An example involves a company applying a protective layer to automotive parts to prevent corrosion and improve aesthetics.

Such services are vital across numerous industries, including aerospace, automotive, construction, and manufacturing. They offer protection against wear, corrosion, and extreme temperatures, thereby extending the lifespan of metal components. Historically, these treatments have evolved from simple protective coatings to advanced techniques utilizing specialized materials and equipment.

The following sections will delve into specific aspects of this specialized field, examining the technologies employed, the types of finishes available, and the considerations for selecting the appropriate treatment for various applications.

Tips for Optimal Metal Surface Treatment

Achieving the desired outcome in metal finishing necessitates careful planning and execution. The following tips provide guidance to ensure optimal results.

Tip 1: Material Assessment is Paramount. Identifying the specific alloy and its existing condition is crucial. Different metals react differently to various treatments; therefore, understanding the base material ensures compatibility and prevents adverse reactions.

Tip 2: Define Performance Requirements Precisely. Clearly outlining the intended use of the finished product is essential. Performance requirements such as corrosion resistance, hardness, or aesthetic appeal directly influence the selection of the most appropriate finishing process.

Tip 3: Surface Preparation Significantly Impacts Adhesion. Proper cleaning and pre-treatment are fundamental for achieving a durable and uniform finish. Removing contaminants, oxides, and imperfections ensures optimal adhesion of the applied coating.

Tip 4: Controlled Application Environments Enhance Quality. Maintaining precise control over environmental factors, such as temperature and humidity, during the application process is vital. These variables directly influence the consistency and quality of the final finish.

Tip 5: Material Selection Should Align with Environmental Regulations. Careful consideration must be given to the environmental impact of the chosen finishing process. Selecting environmentally friendly alternatives and adhering to relevant regulations minimizes ecological footprint.

Tip 6: Post-Treatment Inspection is Necessary for Quality Assurance. Thorough inspection after the finishing process is critical to identify any defects or inconsistencies. Implementing quality control measures ensures that the finished product meets the specified requirements.

Tip 7: Consult with Finishing Professionals for Expertise. Seeking expert advice from experienced professionals is highly recommended. Their knowledge and expertise can help navigate the complexities of metal finishing and ensure optimal results.

Adhering to these guidelines optimizes the effectiveness of metal surface treatments, maximizing the lifespan and performance of finished products.

The subsequent sections will explore advanced techniques and innovative solutions in the realm of specialized metal finishing.

1. Surface Preparation

Surface preparation is foundational to the success of specialized metal finishing processes. Its effectiveness directly influences the adherence, durability, and overall performance of subsequently applied coatings. The intricacies of this stage demand a thorough understanding of material properties and the intended application environment.

- Contaminant Removal

The removal of oils, grease, dirt, and oxides from the metal surface is paramount. These contaminants impede proper coating adhesion, leading to premature failure. Processes such as degreasing, chemical etching, and abrasive blasting are employed based on the type and severity of contamination. For instance, removing mill scale from steel prior to powder coating is crucial for corrosion resistance.

- Surface Roughening

Creating a controlled surface profile enhances mechanical interlocking between the metal substrate and the applied coating. Techniques like abrasive blasting introduce microscopic irregularities that increase the surface area for bonding. The degree of roughening must be carefully calibrated to optimize adhesion without compromising the integrity of the metal.

- Chemical Activation

Specific chemical treatments can alter the surface chemistry of the metal, promoting the formation of a strong bond with the coating material. These treatments often involve the creation of a conversion coating, such as phosphate or chromate, which provides a chemically active layer for subsequent coating adhesion. Aluminum anodizing, for example, creates a porous oxide layer that enhances paint adhesion.

- Passivation

Passivation treatments create a thin, inert layer on the metal surface, preventing corrosion and improving coating adhesion. These processes are particularly important for stainless steel and other corrosion-resistant alloys. Passivation typically involves the application of nitric acid or other oxidizing agents to form a protective oxide film.

The selection and implementation of appropriate surface preparation techniques are critical determinants of the final product quality. Inadequate preparation will inevitably lead to coating failure, increased maintenance costs, and reduced component lifespan. The investment in proper surface preparation yields significant returns in terms of enhanced performance and extended service life.

2. Coating Application

Coating application constitutes a critical process within specialized metal surface treatment. The efficacy of this stage directly influences the protective and aesthetic qualities imparted to metallic components. Proper coating application necessitates a comprehensive understanding of various techniques, materials, and their interactions with the underlying metal substrate.

Different coating methods cater to specific performance requirements. Electroplating, for example, utilizes an electrolytic process to deposit a thin layer of metal onto a substrate, enhancing corrosion resistance and wear properties. Powder coating involves the application of a dry, free-flowing powder electrostatically, followed by curing under heat to create a durable finish. In contrast, specialized techniques like Physical Vapor Deposition (PVD) are employed to create extremely thin and hard coatings for demanding applications, such as aerospace components or cutting tools. The selection of the appropriate coating and application method is contingent upon factors like the type of metal, intended use, and desired finish characteristics.

Errors in coating application can lead to premature failure of the finished product. Inadequate surface preparation, improper coating thickness, or inconsistent curing can compromise the protective properties of the coating. Quality control measures, including thickness testing, adhesion testing, and visual inspection, are essential to ensure that the coating meets specified standards. The careful integration of coating application techniques with surface preparation and material compatibility considerations is paramount for achieving durable and aesthetically pleasing results.

3. Material Compatibility

Material compatibility is a critical determinant in the success of any metal surface treatment operation. When incompatible materials are combined, the results can range from ineffective finishes to catastrophic failures of the treated components. In the context of specialized metal finishing, this consideration extends beyond merely the base metal and the coating material; it encompasses all chemicals, cleaning agents, and preparatory treatments employed in the process. For instance, applying an acidic etchant to a metal that is highly susceptible to acid corrosion will compromise the structural integrity of the component before any coating can even be applied.

The consequences of ignoring material compatibility are manifold. Galvanic corrosion, where one metal corrodes preferentially to another when in electrical contact in the presence of an electrolyte, is a prime example. In specialized surface treatment, this could manifest as the premature degradation of a fastener electroplated with a dissimilar metal. Moreover, the coefficient of thermal expansion differences between the base metal and the coating can lead to cracking or delamination under varying temperature conditions. Aircraft components subjected to wide temperature swings during flight are particularly vulnerable if material compatibility is not thoroughly assessed during the finishing process. A careful selection process, informed by material science principles and industry best practices, is essential to mitigate these risks.

In summary, material compatibility serves as a cornerstone of specialized metal finishing. The selection of appropriate treatments and coatings must be predicated on a comprehensive understanding of the chemical and physical interactions between all involved materials. Failure to prioritize material compatibility can result in compromised performance, reduced lifespan, and potentially hazardous outcomes. Therefore, thorough material assessment and rigorous testing protocols are indispensable for ensuring the long-term integrity and reliability of finished metal components.

4. Corrosion Resistance

Corrosion resistance is an indispensable attribute of specialized metal finishing. The primary function of many surface treatments is to protect the underlying metal substrate from environmental degradation. Corrosion, a natural process that deteriorates materials through chemical reactions with their surroundings, can significantly compromise the structural integrity and functionality of metal components. Therefore, the ability of a specific finishing process to impart robust corrosion resistance is a crucial performance criterion. For instance, in marine environments, metal parts are constantly exposed to saltwater, a highly corrosive medium. Effective surface treatments, such as galvanizing or specialized coatings, are essential to prevent rust and extend the lifespan of these parts.

The effectiveness of corrosion-resistant finishes depends on several factors, including the type of metal being treated, the specific environment in which the finished component will operate, and the characteristics of the coating itself. Techniques like electroplating can deposit a sacrificial layer of metal (e.g., zinc) that corrodes preferentially to the base metal, providing cathodic protection. Other coatings, such as powder coatings and specialized paints, act as a physical barrier, preventing corrosive agents from reaching the metal surface. The selection of the appropriate finishing technique requires careful consideration of these factors. For example, in the automotive industry, undercarriage components are often treated with multiple layers of protective coatings to withstand constant exposure to road salt and moisture.

In conclusion, corrosion resistance is not merely a desirable feature but a fundamental requirement of specialized metal finishing. The implementation of appropriate surface treatments is critical for preserving the structural integrity, extending the service life, and ensuring the reliable performance of metal components across diverse applications. Ongoing research and development continue to improve the effectiveness of corrosion-resistant finishes, addressing the challenges posed by increasingly demanding operating environments and stringent performance standards.

5. Quality Control

Quality control is integral to specialized metal finishing, ensuring that surface treatments meet specified requirements and function as intended. Rigorous quality control protocols mitigate risks, improve efficiency, and enhance the longevity of finished metal components.

- Dimensional Verification

Dimensional verification involves precise measurement of finished components to confirm adherence to design specifications. Deviations from specified dimensions can compromise functionality and fit. In metal finishing, this includes verifying coating thicknesses, flatness, and overall dimensions of treated parts. For example, aerospace components require strict adherence to dimensional tolerances to ensure proper assembly and performance.

- Adhesion Testing

Adhesion testing assesses the strength of the bond between the coating and the underlying metal substrate. Inadequate adhesion can lead to premature coating failure and corrosion. Various methods, such as pull-off tests and scratch tests, are used to quantify adhesion strength. Automotive coatings, for instance, must withstand exposure to harsh environmental conditions, necessitating robust adhesion properties.

- Corrosion Testing

Corrosion testing evaluates the ability of finished components to withstand corrosive environments. Salt spray testing, humidity testing, and immersion testing are common methods used to accelerate corrosion and assess the effectiveness of protective coatings. Metal parts used in marine applications require exceptional corrosion resistance to prevent degradation and ensure long-term performance.

- Visual Inspection

Visual inspection involves a thorough examination of finished components for defects such as scratches, blemishes, and inconsistencies in coating appearance. While subjective, visual inspection can identify gross imperfections that may compromise functionality or aesthetics. High-end consumer products, for example, demand flawless finishes to meet customer expectations.

These facets of quality control, when meticulously implemented, contribute significantly to the overall value proposition of specialized metal finishing. Ensuring that coatings meet stringent standards for adhesion, corrosion resistance, and dimensional accuracy results in durable, reliable, and aesthetically pleasing metal components that meet the demands of diverse industries.

6. Environmental Compliance

Specialized metal finishing operations, including those providing surface treatments, are inherently linked to stringent environmental compliance regulations. The processes involved frequently utilize chemicals and generate byproducts that can pose significant environmental risks if not properly managed. Cause and effect are evident: the failure to adhere to environmental regulations can lead to soil and water contamination, air pollution, and harm to ecosystems. Therefore, compliance is not merely a legal obligation but an ethical imperative.

Environmental compliance is a critical component of responsible metal finishing practices. It dictates the implementation of pollution control technologies, waste management protocols, and safe handling procedures for hazardous materials. For example, metal finishing facilities are required to treat wastewater to remove heavy metals and other pollutants before discharge. Air emissions from processes like spray painting and coating application must be controlled through the use of scrubbers and filters. Furthermore, many facilities are transitioning to more environmentally friendly alternatives, such as water-based coatings and non-toxic cleaning agents. The practical significance of this understanding is substantial; proactive environmental management not only minimizes environmental impact but also enhances the long-term sustainability and reputation of businesses.

The interconnectedness of environmental compliance and metal finishing extends beyond regulatory requirements. It encompasses a commitment to continuous improvement and the adoption of sustainable practices. Challenges persist in balancing environmental protection with economic viability, but the increasing availability of innovative technologies and the growing demand for environmentally responsible products are driving positive change. Ultimately, the integration of environmental compliance into the core values of businesses operating in this sector is essential for safeguarding the environment and ensuring a sustainable future.

7. Adhesion Strength

Adhesion strength is a critical parameter in surface treatment, directly impacting the durability and longevity of applied coatings. It represents the force required to separate a coating from its substrate, indicating the robustness of the bond between the two. Ineffective adhesion results in premature coating failure, leading to corrosion, wear, and compromised structural integrity. For specialized metal finishing, achieving high adhesion strength is paramount to ensuring the protective and functional properties of the finish are maintained under various operating conditions. An illustrative example is the application of powder coatings on automotive components. If adhesion is insufficient, the coating will chip or peel, exposing the underlying metal to corrosive elements, ultimately diminishing the part’s service life. Cause and effect are undeniably linked: inadequate adhesion leads to premature deterioration and increased maintenance costs.

The performance and aesthetic appeal of metal products are affected significantly by the strength of the adhesive bond between the coating and the underlying metal. Consider the example of aerospace components: coatings that fail to adhere properly can lead to delamination and subsequent damage, potentially jeopardizing flight safety. The practical significance extends to numerous other industries, from construction to electronics, where the durability of the finish is essential for product performance and customer satisfaction. Proper surface preparation techniques, such as cleaning, etching, and application of primers, play a vital role in optimizing adhesion strength. Similarly, the selection of compatible coating materials and appropriate curing processes is crucial. Failure to carefully control these variables can result in significantly reduced adhesion, rendering the finishing process ineffective.

In conclusion, adhesion strength serves as a cornerstone of specialized metal finishing. The process involves a complex interplay of surface chemistry, material properties, and application techniques. The pursuit of enhanced adhesion is a continuous effort, driving innovation in coating materials, surface preparation methods, and quality control protocols. Challenges remain in developing coatings that can withstand increasingly demanding environmental conditions and mechanical stresses. Nevertheless, prioritizing adhesion strength in metal finishing operations is essential for ensuring the long-term performance and reliability of finished metal products. Ultimately, robust adhesion translates into enhanced product lifespan, reduced maintenance costs, and increased customer satisfaction.

Frequently Asked Questions

The following addresses common inquiries regarding specialized metal finishing services. The information is intended to provide clarity and guidance on key aspects of these processes.

Question 1: What factors determine the selection of a specific metal finishing process?

The selection hinges on several critical factors, including the base metal composition, the intended application environment, desired performance characteristics (e.g., corrosion resistance, hardness), and budgetary constraints. A comprehensive evaluation of these elements is necessary to determine the most appropriate finishing technique.

Question 2: How does surface preparation influence the outcome of metal finishing?

Surface preparation is paramount. Proper cleaning, degreasing, and etching remove contaminants that impede coating adhesion. A suitably prepared surface ensures a strong, durable bond between the metal substrate and the applied finish, maximizing performance and longevity.

Question 3: What are the environmental considerations associated with metal finishing processes?

Metal finishing can involve hazardous chemicals and generate environmentally damaging waste. Compliance with environmental regulations is crucial. Responsible practices include proper waste disposal, pollution control, and the utilization of environmentally friendly alternatives whenever feasible.

Question 4: How is the quality of a metal finish assessed?

Quality assessment involves various testing methods, including visual inspection, adhesion testing, corrosion testing, and dimensional measurements. These tests ensure that the finished product meets specified requirements and performs as intended.

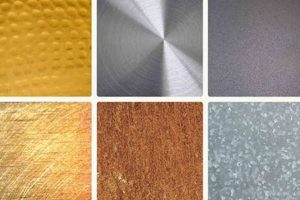

Question 5: What are the common types of metal finishes available?

A wide range of finishes exists, including electroplating, powder coating, anodizing, and painting. Each technique offers distinct advantages in terms of corrosion resistance, wear resistance, aesthetic appeal, and cost. The optimal choice depends on the specific application requirements.

Question 6: How can the lifespan of a metal finish be extended?

Lifespan extension involves proper maintenance and care. Regular cleaning, avoidance of harsh chemicals, and prompt repair of any damage can significantly prolong the life of a metal finish. Selecting a durable finish appropriate for the operating environment is also critical.

In summary, effective metal finishing requires careful planning, meticulous execution, and ongoing maintenance. Adhering to best practices ensures optimal performance and long-term value.

The subsequent section will delve into advanced technologies and future trends in specialized metal finishing.

Concluding Remarks on Windsor Metal Finishing

This exposition has clarified the nuances involved in processes used by facilities like Windsor Metal Finishing, underlining the importance of surface preparation, material compatibility, coating application, and stringent quality control measures. The imperative of environmental compliance, alongside the significance of adhesion strength in ensuring durability, has been thoroughly examined. These elements collectively contribute to the effectiveness and longevity of finished metal components.

The information presented underscores the critical role that specialized surface treatments play in safeguarding metal assets across diverse industries. As technological advancements continue to reshape the metal finishing landscape, stakeholders are encouraged to prioritize informed decision-making and embrace innovation to optimize performance and ensure the sustained integrity of finished products. Further research and diligent application of established best practices are essential for advancing the field and maximizing the value derived from these essential services.

![Top Asheville Metal Finishing: [Your Brand] Quality Best Final Touch: Elevate Your Projects with Professional Finishing Top Asheville Metal Finishing: [Your Brand] Quality | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-666-300x200.jpg)