This refers to a specific high-grit sharpening stone used to refine the edge of blades. The “Shapton” designation indicates the manufacturer, known for producing quality sharpening stones. “K0710” is the product code. “Melon” is the color name of the stone. “8000” denotes the grit size, signifying a very fine abrasive used for achieving a polished, keen edge. It is typically employed after coarser stones have established the primary bevel. As an example, a woodworker or chef might use this to put a final, razor-sharp edge on a plane iron or kitchen knife.

Utilizing a stone of this fineness is crucial for achieving optimal sharpness, extending the life of the blade, and improving the efficiency of cutting tasks. A highly polished edge reduces friction and allows for cleaner, more precise cuts with less effort. Historically, achieving such fine edges required considerable skill and a progression through numerous natural stones. Modern synthetic stones, such as this, provide a more consistent and predictable method for attaining and maintaining a superior edge.

The subsequent sections will delve deeper into the specific applications, best practices for usage, and comparisons with alternative sharpening methods.

Essential Usage Considerations

Proper utilization is paramount to realizing the full potential of this finishing stone. Adherence to the following guidelines will ensure optimal results and prolong the life of the stone.

Tip 1: Stone Preparation: Before use, the stone should be lapped flat to ensure even sharpening. A dedicated lapping plate or coarse diamond stone is recommended for this purpose. A flat surface is critical for consistent edge geometry.

Tip 2: Lubrication: This stone is designed to be used with water. Maintain a thin layer of water on the surface during sharpening to facilitate swarf removal and prevent clogging. Distilled water is preferred to minimize mineral deposits.

Tip 3: Pressure Application: Apply light, consistent pressure during the sharpening process. Excessive pressure can lead to uneven wear and damage the blade’s edge. The weight of the blade itself is often sufficient.

Tip 4: Angle Consistency: Maintaining a consistent sharpening angle is crucial for achieving a uniform bevel. Consider using a sharpening guide or jig to assist in maintaining the desired angle. Precise angle control yields a sharper and more durable edge.

Tip 5: Stroke Technique: Employ a consistent stroke technique, either pushing or pulling the blade across the stone. Overlapping strokes are recommended to ensure the entire edge is sharpened evenly. A controlled stroke promotes even abrasion.

Tip 6: Swarf Removal: Regularly clean the stone’s surface with a nagura stone or a dedicated cleaning stone to remove accumulated swarf. A clean stone cuts more effectively and prevents scratches.

Tip 7: Storage: After use, thoroughly clean and dry the stone before storing it in a safe place. Avoid exposing the stone to extreme temperatures or humidity. Proper storage prevents damage and prolongs the stone’s lifespan.

Effective implementation of these techniques will yield a highly refined and durable edge on various blades.

The ensuing sections will provide insights into troubleshooting common issues and advanced sharpening techniques.

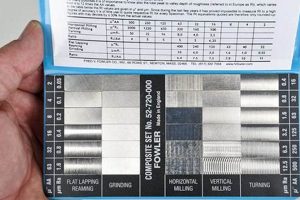

1. Abrasive Particle Size

Abrasive particle size is a defining characteristic in the context of “shapton k0710 melon 8000 blade finishing.” This parameter determines the stone’s capability to refine and polish a blade’s edge, influencing the resulting sharpness and smoothness.

- Refinement vs. Material Removal

The 8000 grit designation signifies an extremely fine abrasive particle size. Stones of this grit are primarily intended for refinement and polishing, rather than aggressive material removal. This fine grit allows the stone to smooth microscopic imperfections on the blade’s edge, creating a highly polished surface that enhances cutting performance. For instance, in sharpening a high-end chef’s knife, the 8000 grit stone is used after coarser stones have established the primary bevel, resulting in a razor-sharp edge suitable for precise culinary tasks. This refinement process is crucial for achieving a superior cutting performance.

- Surface Finish and Friction Reduction

A finer abrasive particle size directly correlates with a smoother surface finish on the blade. This smoothness translates into reduced friction during cutting, requiring less force and producing cleaner cuts. Consider the application of this principle to woodworking tools such as plane irons or chisels. A highly polished edge, achieved with an 8000 grit stone, allows the tool to glide through wood with minimal resistance, resulting in a smoother surface and reduced effort. The connection between abrasive particle size and surface finish directly impacts the efficiency and quality of cutting operations.

- Edge Stability and Durability

While a very fine edge is desirable for sharpness, extreme thinness can compromise its stability and durability. The 8000 grit stone, when used appropriately, can create a refined edge that is both sharp and relatively durable. By polishing the edge and removing any microscopic burrs or imperfections, the stone strengthens the edge, making it less prone to chipping or rolling over during use. In the context of straight razors, for example, the final honing on an 8000 grit stone ensures that the edge is sharp enough for a close shave while also being durable enough to withstand repeated use. This equilibrium between sharpness and durability is a critical consideration.

- Visual Inspection and Microscopic Evaluation

The impact of abrasive particle size on the blade’s edge can be visually assessed and microscopically evaluated. Under magnification, the surface finished by an 8000 grit stone will exhibit a highly polished appearance, with minimal scratches or imperfections. This visual and microscopic evaluation confirms the effectiveness of the sharpening process and provides insights into the quality of the resulting edge. For example, metallographic analysis of a blade sharpened with an 8000 grit stone will reveal a highly refined microstructure at the edge, indicating the degree of refinement achieved by the abrasive particle size. This analytical approach provides objective evidence of the stone’s performance.

These facets collectively illustrate that abrasive particle size is not merely a numerical designation but rather a critical factor influencing the sharpness, smoothness, durability, and visual characteristics of the blade’s edge. Each of these concepts contribute to the overall performance and efficacy of “shapton k0710 melon 8000 blade finishing.”

2. Surface Flatness

Surface flatness is a critical factor in achieving optimal results when employing the “shapton k0710 melon 8000 blade finishing” process. A deviation from a perfectly flat surface compromises the stone’s ability to uniformly refine the blade’s edge, leading to inconsistent sharpness and potential damage.

- Uniform Abrasive Contact

A flat stone surface ensures that the abrasive particles make consistent contact with the entire length of the blade’s edge. This uniform contact is essential for even sharpening and polishing. Conversely, a warped or uneven stone will concentrate pressure on certain areas of the blade, resulting in an inconsistent bevel and uneven wear. As an example, consider sharpening a long chef’s knife on a stone that is significantly dished. The center of the blade may not make contact with the stone at all, while the tip and heel receive excessive abrasion. This results in an unevenly sharpened blade that performs poorly.

- Angle Consistency and Bevel Geometry

Maintaining a consistent sharpening angle is paramount to achieving a sharp and durable edge. A flat stone surface provides a stable platform for maintaining the desired angle throughout the sharpening process. An uneven stone makes it difficult to control the angle, potentially leading to a rounded or convex bevel. This alters the blade’s geometry and reduces its cutting efficiency. A woodworker sharpening a chisel on a non-flat stone may inadvertently create a rounded bevel, making it difficult to achieve precise cuts and ultimately compromising the tool’s performance.

- Effective Lapping and Maintenance

The ability to effectively lap or flatten the sharpening stone is directly dependent on its inherent flatness. A stone that is significantly warped or uneven requires more aggressive lapping to restore a flat surface. This aggressive lapping removes more material and shortens the lifespan of the stone. Regular lapping is necessary to maintain optimal performance, but the process is only effective if the underlying stone is reasonably flat. Imagine attempting to flatten a potato chip; the unevenness prevents any sort of uniform abrasion, rendering the flattening attempt futile. This is analogous to a severely warped sharpening stone.

- Prevention of Localized Wear and Damage

An uneven stone surface can create localized areas of high pressure during sharpening. These areas of high pressure can lead to accelerated wear on the stone and potential damage to the blade. Excessive pressure on specific points can cause the abrasive particles to break down prematurely, reducing the stone’s effectiveness. Furthermore, it can cause microscopic chipping or rolling of the blade’s edge, compromising its sharpness. The impact of localized wear highlights the importance of surface flatness in ensuring both the stone’s longevity and the blade’s integrity.

In summary, maintaining surface flatness is not merely a procedural step but a fundamental requirement for achieving optimal results with the “shapton k0710 melon 8000 blade finishing” process. Its impact on uniform abrasive contact, angle consistency, lapping effectiveness, and wear prevention underscores its importance in achieving and maintaining a superior blade edge. Without a flat stone surface, the inherent potential of the sharpening process is significantly diminished.

3. Lubrication Requirements

Lubrication is integral to the proper utilization of the “shapton k0710 melon 8000 blade finishing” process. The Shapton K0710, specifically, is designed to be used with water. Water serves as a coolant, preventing heat buildup during sharpening which could alter the blade’s temper. Furthermore, the water suspends abraded metal particles (swarf), preventing them from clogging the stone’s surface. This swarf, if allowed to accumulate, hinders the stone’s cutting action and can lead to scratches on the blade. For example, sharpening a plane iron without adequate lubrication will result in a build-up of steel particles on the stone, causing it to glaze over and reducing its ability to effectively refine the edge. Distilled water is preferable to minimize mineral deposits that could contaminate the stone’s surface over time. The absence of proper lubrication negates the benefits of using a high-grit stone, rendering the “finishing” aspect ineffective.

The correct application of water also influences the sharpening stroke. A thin, consistent layer of water reduces friction between the blade and the stone, allowing for smoother and more controlled movements. This enhanced control is particularly crucial when working with a fine grit stone, where precise manipulation is necessary to achieve the desired level of sharpness. Excessive water, however, can dilute the swarf suspension, requiring more frequent cleaning of the stone. Conversely, insufficient water results in increased friction and potential heat damage. The optimal amount of water is a thin film that continuously carries away swarf without causing excessive splashing or dilution. Observing a slight slurry formation on the stone’s surface is a positive indication of proper lubrication. Maintaining the water film, therefore, becomes a crucial aspect of the “shapton k0710 melon 8000 blade finishing” process.

In conclusion, adherence to the lubrication requirements is not merely a supplemental step, but a fundamental necessity for achieving the intended results with this sharpening stone. The lack of appropriate lubrication significantly compromises the stone’s performance, potentially damaging the blade and preventing the attainment of a refined, sharp edge. By understanding and implementing proper lubrication techniques, the user can maximize the effectiveness of the “shapton k0710 melon 8000 blade finishing” process and ensure the longevity of both the blade and the stone.

4. Pressure Sensitivity

Pressure sensitivity is a paramount consideration when utilizing the “shapton k0710 melon 8000 blade finishing” process. This sharpening stone, due to its high grit and fine abrasive particles, requires a delicate touch to achieve optimal results without damaging the blade or the stone itself. Applying excessive force can negate the benefits of this finishing stone, leading to undesirable outcomes.

- Deformation of the Blade Edge

Excessive pressure during sharpening, particularly with a fine-grit stone, can cause microscopic deformation of the blade’s edge. Instead of polishing and refining, excessive force can cause the edge to roll over or even chip, negating the sharpening process. For instance, applying significant downward pressure when honing a straight razor on the Shapton 8000 can deform the delicate edge, rendering the razor dull and uncomfortable to use. Controlled, light pressure is essential to maintain the integrity of the blade’s geometry.

- Uneven Stone Wear

Applying inconsistent or excessive pressure concentrates wear on specific areas of the stone’s surface. This leads to unevenness and reduces the stone’s ability to uniformly sharpen the blade. Over time, this uneven wear can render the stone unusable, requiring frequent lapping or replacement. A common example is applying more pressure to the heel of a knife during sharpening. This localized pressure will cause the stone to dish out more rapidly in that area, resulting in inconsistent sharpening across the blade’s length.

- Premature Abrasive Breakdown

The abrasive particles in the Shapton 8000 are designed to gently polish and refine the blade’s edge. Excessive pressure can cause these particles to fracture prematurely, reducing the stone’s cutting efficiency. This results in a less refined edge and shortens the lifespan of the stone. Consider applying heavy pressure while sharpening a chisel. The abrasive particles on the Shapton 8000 will break down more rapidly, reducing the stone’s ability to polish the edge and potentially leaving behind larger scratches.

- Heat Generation

Increased pressure generates more friction between the blade and the stone, leading to heat buildup. This heat can alter the temper of the steel, potentially softening the blade and making it more prone to dulling. In extreme cases, excessive heat can cause the blade to warp or even crack. Sharpening a high-speed steel tool with excessive pressure on the Shapton 8000 will generate significant heat, potentially compromising the tool’s hardness and cutting ability. Light pressure and frequent water application are crucial to minimize heat generation.

The facets above show that pressure sensitivity is a crucial skill that needs to be mastered to effectively use this type of whetstone to enhance the edge of any blades.

5. Final Edge Refinement

Final edge refinement represents the culmination of the sharpening process, specifically when utilizing the shapton k0710 melon 8000 blade finishing stone. This stage is critical for achieving peak sharpness and optimizing cutting performance. It addresses the microscopic imperfections remaining after coarser sharpening stages and establishes the final geometry of the cutting edge.

- Micro-Bevel Formation

The shapton k0710 melon 8000 allows for the creation of a subtle micro-bevel on the blade’s edge. This micro-bevel, while often imperceptible to the naked eye, significantly enhances the edge’s durability and reduces the likelihood of chipping or rolling. For example, when sharpening a straight razor, the 8000 grit stone is used to create a micro-bevel that balances sharpness and edge retention, enabling a comfortable and effective shave. The micro-bevel acts as a reinforcement, preventing the extremely fine edge from prematurely degrading under use.

- Polishing of the Cutting Surface

The 8000 grit abrasive polishes the cutting surface to an exceptionally smooth finish. This polishing action reduces friction during cutting, allowing the blade to glide through materials with minimal resistance. In the context of culinary knives, a polished edge created with the shapton k0710 melon 8000 allows for cleaner and more precise cuts, improving both efficiency and presentation. Reduced friction translates to less effort required from the user and enhanced control over the cutting process.

- Removal of Residual Burr

Even after careful sharpening with coarser stones, a microscopic burr may remain on the blade’s edge. The shapton k0710 melon 8000 is effective at removing this residual burr, leaving a clean and consistent cutting edge. Failure to remove the burr can result in a “toothy” edge that catches on materials and performs inconsistently. For instance, removing the burr from a wood carving tool ensures a smooth and controlled cutting action, preventing tear-out and improving the quality of the finished piece.

- Optimization of Edge Geometry

The final edge refinement stage allows for the precise optimization of the blade’s geometry. This involves subtly adjusting the angle and shape of the edge to achieve the desired balance of sharpness, durability, and cutting performance. Using the shapton k0710 melon 8000 provides the control and precision necessary to fine-tune the edge to meet the specific requirements of the intended task. A surgeon, for example, would require a scalpel edge with an extremely acute angle for precise incisions, while a butcher might prefer a slightly more obtuse angle for enhanced durability.

These facets of final edge refinement emphasize the essential role of the shapton k0710 melon 8000 blade finishing stone in achieving the highest level of sharpness and performance. This stage bridges the gap between a sharpened blade and a truly exceptional cutting tool, illustrating the importance of meticulous attention to detail in the sharpening process.

Frequently Asked Questions

This section addresses common inquiries regarding the use and maintenance of the Shapton K0710 Melon 8000 sharpening stone, providing detailed information to optimize its performance and lifespan.

Question 1: What types of blades are best suited for the Shapton K0710 Melon 8000?

This stone excels at refining edges on high-quality, hardened steel blades. It is particularly effective for tools requiring extreme sharpness, such as straight razors, surgical instruments, and precision woodworking tools. While suitable for most steel types, softer steels may not fully benefit from the stone’s fine grit.

Question 2: How often should the Shapton K0710 Melon 8000 be lapped?

Lapping frequency depends on usage intensity. Inspect the stone regularly for signs of uneven wear or dishing. As a general guideline, lapping is recommended after every few uses, or whenever the stone’s surface no longer feels consistently flat. Consistent lapping ensures uniform sharpening.

Question 3: What type of lapping plate is recommended for the Shapton K0710 Melon 8000?

A coarse diamond lapping plate or a silicon carbide flattening stone is recommended. These materials are abrasive enough to effectively remove material from the Shapton stone and restore its flatness. Avoid using softer materials that may not be aggressive enough to flatten the stone efficiently.

Question 4: Can the Shapton K0710 Melon 8000 be used with oil instead of water?

No, the Shapton K0710 Melon 8000 is designed specifically for use with water. Oil will clog the pores of the stone and prevent it from sharpening effectively. Using oil will also make the stone difficult to clean and may permanently damage its surface.

Question 5: How should the Shapton K0710 Melon 8000 be stored when not in use?

After use, thoroughly clean and dry the stone to prevent rust or mildew. Store the stone in a dry, stable environment, away from direct sunlight and extreme temperatures. Consider using a protective case or box to prevent damage during storage and transportation.

Question 6: How can one determine if the Shapton K0710 Melon 8000 is no longer effective?

A loss of cutting speed, difficulty achieving a sharp edge, and excessive loading of the stone are indicators of reduced effectiveness. If lapping no longer restores the stone’s performance, or if the stone exhibits significant cracking or crumbling, replacement may be necessary. Proper maintenance can significantly extend the stone’s lifespan.

In summary, proper usage and maintenance are critical for maximizing the performance and longevity of the Shapton K0710 Melon 8000. Adhering to the guidelines outlined in this FAQ section will ensure consistent and reliable sharpening results.

The following section will explore advanced sharpening techniques utilizing the Shapton K0710 Melon 8000.

Conclusion

The preceding discussion has comprehensively explored the attributes, utilization, and maintenance of the shapton k0710 melon 8000 blade finishing stone. Key aspects, including abrasive particle size, surface flatness, lubrication requirements, pressure sensitivity, and final edge refinement, have been detailed to provide a thorough understanding of its role in achieving optimal blade sharpness. The importance of each element in the sharpening process has been highlighted, emphasizing the need for meticulous technique and adherence to established guidelines.

Mastery of the shapton k0710 melon 8000 blade finishing process requires diligent practice and a commitment to understanding the nuances of blade sharpening. By applying the principles outlined, users can achieve exceptional sharpness and extend the lifespan of their valuable cutting tools, thereby contributing to precision and efficiency in various applications. Continuous refinement of sharpening skills and a critical evaluation of results remain essential for sustained excellence.