A protective coating applied to wooden surfaces provides durability and aesthetic enhancement. This coating shields the wood from daily wear, including scratches, stains, and moisture damage. Polyurethane, varnish, and penetrating oils are examples of materials used for this purpose.

The implementation of a protective layer is vital for preserving the integrity and appearance of wood surfaces over time. It significantly extends the lifespan of the wood, reducing the need for frequent repairs or replacements. Historically, waxes and natural oils were utilized; modern formulations offer superior protection and longevity.

The subsequent discussion will detail various types of protective coatings, application techniques, and maintenance procedures to optimize the longevity and beauty of the underlying wood.

Preservation Strategies for Wood Surfaces

The following guidelines offer recommendations for maintaining the integrity and appearance of wood surfaces through effective surface treatments.

Tip 1: Selection of Appropriate Coating: The selection process should consider the intended use of the wood surface and the expected level of traffic. Water-based polyurethane offers durability and low VOC emissions for residential applications. Oil-based formulations provide enhanced durability for high-traffic areas.

Tip 2: Preparation is Paramount: Before application, the surface must be thoroughly cleaned and sanded to remove any existing coatings or imperfections. Proper preparation ensures optimal adhesion and a uniform appearance. Neglecting this step can lead to premature failure of the coating.

Tip 3: Apply Thin, Even Coats: Multiple thin coats are preferable to a single thick coat. This approach minimizes the risk of drips, runs, and uneven drying. Allow each coat to dry completely before applying the subsequent layer, according to the manufacturer’s instructions.

Tip 4: Controlled Environmental Conditions: Maintain consistent temperature and humidity levels during application and drying. Excessive humidity can prolong drying times and impact the coating’s curing process. Proper ventilation is also essential to remove solvent vapors.

Tip 5: Utilize Appropriate Application Tools: The choice of applicator significantly impacts the final result. Foam brushes, rollers, and specialized applicators designed for coatings can minimize brush strokes and ensure a smooth, even application.

Tip 6: Regular Maintenance is Essential: Implement a routine cleaning schedule using products specifically formulated for treated wood surfaces. Avoid harsh chemicals or abrasive cleaners, which can damage or dull the protective layer.

Adhering to these recommendations will contribute to the sustained beauty and longevity of the treated wood, preserving its aesthetic appeal and structural integrity.

The concluding sections will provide insights into troubleshooting common issues and selecting professional services.

1. Durability Enhancement

Durability enhancement is a primary objective in the selection and application of materials for protecting hardwood flooring. The inherent susceptibility of wood to wear, abrasion, and environmental factors necessitates a robust protective layer to ensure the long-term preservation of both its structural integrity and aesthetic appeal.

- Abrasion Resistance

The ability to withstand surface wear from foot traffic, furniture movement, and other physical contact is crucial. Polyurethane-based options, known for their hardness and resistance to scratching, are frequently employed in high-traffic areas. The absence of sufficient abrasion resistance results in visible surface damage, diminishing the visual appeal and requiring premature refinishing.

- Moisture Protection

Wood is inherently susceptible to moisture absorption, leading to swelling, warping, and potential decay. A properly applied coating acts as a barrier, minimizing moisture penetration. Oil-based sealers and certain water-based formulations offer superior moisture resistance compared to alternatives. Inadequate moisture protection can lead to structural damage and costly repairs.

- Chemical Resistance

Resistance to household chemicals, cleaning agents, and spills is essential for maintaining the integrity of the protected surface. Formulations with enhanced chemical resistance prevent staining, discoloration, and degradation of the coating itself. Specific epoxy-based coatings may be utilized in environments where chemical exposure is anticipated.

- UV Protection

Prolonged exposure to ultraviolet (UV) radiation can cause fading and discoloration of both the wood and the protective layer. Certain coatings incorporate UV inhibitors to mitigate these effects, preserving the original color and appearance of the surface. This is particularly relevant for areas with significant sun exposure.

The interconnectedness of these durability facets underscores the importance of selecting the appropriate protective material and applying it according to manufacturer specifications. A holistic approach to durability enhancement, addressing abrasion, moisture, chemical, and UV resistance, is essential for maximizing the lifespan and maintaining the aesthetic value of hardwood flooring.

2. Aesthetic Qualities

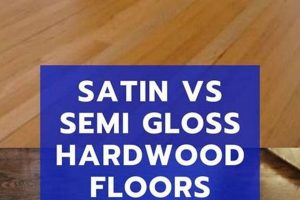

The visual characteristics of a hardwood floor are fundamentally shaped by the type of protective layer applied. The choice of coating directly influences the color, sheen, and overall appearance of the wood. A glossy coating, for instance, reflects a significant amount of light, creating a vibrant and polished look. Conversely, a matte finish absorbs more light, resulting in a more subdued and natural appearance. This choice significantly impacts the perception of the space, affecting its perceived size, warmth, and formality.

Specific surface treatments also influence the apparent color and grain of the wood. Clear coatings emphasize the natural hues and patterns, while tinted options can alter the color to achieve a desired aesthetic. The method of application also contributes to the final visual result. Uneven application or improper curing can lead to inconsistencies in sheen and texture, detracting from the intended appearance. The selection of the appropriate coating is, therefore, a crucial decision that should align with the desired aesthetic and the overall design of the space. An example illustrates this point: a modern, minimalist design might benefit from a matte, natural-looking coating, while a more traditional setting might be enhanced by a glossy, amber-toned finish.

In summary, the aesthetic qualities of a hardwood floor are inextricably linked to the selected protective layer. The choice of coating dictates the color, sheen, and overall visual impact of the floor, influencing the perception of the space and its compatibility with the surrounding decor. Understanding the interplay between these factors is essential for achieving the desired aesthetic and maximizing the visual appeal of the hardwood floor.

3. Protection Level

The protection level afforded by a surface treatment is a critical determinant of the long-term performance and aesthetic preservation of hardwood flooring. This attribute dictates the resilience of the floor against various forms of damage, thereby impacting its longevity and maintenance requirements.

- Scratch Resistance

The ability to withstand surface abrasion and scratching is paramount, particularly in high-traffic areas. The inherent hardness and composition of the protective layer dictate its scratch resistance. Polyurethane-based surface treatments generally offer superior scratch resistance compared to wax or oil-based options. For instance, a floor subjected to daily wear from pets and children necessitates a coating with high scratch resistance to maintain its aesthetic appearance. Neglecting this factor results in visible surface imperfections and necessitates premature refinishing.

- Moisture Resistance

Hardwood is susceptible to moisture damage, leading to warping, swelling, and potential fungal growth. The protective layer must provide an effective barrier against moisture penetration. Oil-based and certain specialized water-based surface treatments offer enhanced moisture resistance. An example of this is a floor in a kitchen or bathroom environment, where exposure to spills and humidity is frequent. Inadequate moisture protection can result in irreversible damage to the wood substrate.

- Chemical Resistance

Resistance to household chemicals, cleaning agents, and accidental spills is crucial for preventing staining, discoloration, and degradation of the surface. The chemical composition of the coating determines its resistance to various substances. Specialized formulations offer superior chemical resistance in environments where exposure to such agents is anticipated. For example, a spilled cleaning solution can permanently damage a surface treatment with poor chemical resistance, resulting in unsightly stains and requiring costly repairs.

- UV Protection

Prolonged exposure to ultraviolet (UV) radiation can cause fading and discoloration of the wood and the protective layer itself. Surface treatments incorporating UV inhibitors mitigate these effects, preserving the original color and appearance. This is particularly relevant in areas with significant sunlight exposure, such as near windows or skylights. Without adequate UV protection, the floor may develop an uneven or faded appearance over time.

In conclusion, the protection level conferred by a protective material is multifaceted, encompassing scratch, moisture, chemical, and UV resistance. The selection of the appropriate type and its proper application are essential for maximizing the lifespan and preserving the aesthetic value of hardwood flooring. The interplay between these factors dictates the overall performance and long-term viability of the flooring installation. The specified attributes are the minimum attributes that must be covered.

4. Application Method

The method by which a coating is applied to hardwood flooring exerts a significant influence on the final appearance, durability, and longevity of the surface treatment. Proper application is not merely a procedural step but a critical determinant of performance, directly impacting the protective qualities and aesthetic characteristics of the final product.

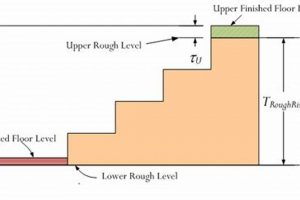

- Surface Preparation

Prior to the application of any protective layer, meticulous surface preparation is essential. This involves thorough cleaning to remove dirt, debris, and existing coatings, followed by sanding to create a smooth and even substrate. The absence of proper surface preparation impedes adhesion, resulting in uneven coverage, premature peeling, and compromised protection. Real-world examples include coatings failing due to residual wax or oil on the wood surface. The implications are significant, leading to costly rework and potential damage to the underlying wood.

- Application Technique

The specific technique employed for application directly influences the uniformity and thickness of the protective layer. Techniques such as brushing, rolling, and spraying each have distinct advantages and disadvantages. Brushing allows for precise application in detailed areas but can leave brush marks if not performed skillfully. Rolling provides efficient coverage for large areas but may result in uneven thickness. Spraying offers a smooth, even finish but requires specialized equipment and controlled environmental conditions. The selection of an inappropriate technique can lead to a subpar finish, compromising both aesthetics and protection. For instance, using an incorrect roller nap can create an orange peel effect, diminishing the visual appeal of the hardwood floor.

- Environmental Control

Environmental factors, such as temperature, humidity, and ventilation, significantly affect the curing and adhesion of the protective layer. Optimal conditions are essential for ensuring proper drying and hardening. High humidity can prolong drying times and compromise the integrity of the coating. Inadequate ventilation can lead to the accumulation of solvent vapors, posing health risks and affecting the finish quality. Real-world examples include coatings blistering or clouding due to excessive humidity during application. Maintaining a controlled environment is, therefore, crucial for achieving a durable and aesthetically pleasing result.

- Number of Coats

The number of coats applied dictates the overall thickness and protective capacity of the surface treatment. Multiple thin coats are generally preferable to a single thick coat, as they promote even drying and minimize the risk of drips, runs, and bubbling. Insufficient coating thickness compromises protection against wear, abrasion, and moisture penetration. Conversely, excessive thickness can lead to cracking and peeling. Following manufacturer recommendations regarding the number of coats is, therefore, essential for achieving optimal performance. An example of this is applying too few coats of polyurethane in a high-traffic area, resulting in premature wear and damage to the underlying wood.

In conclusion, the application method represents a critical nexus between the inherent properties of a protective material and its realized performance on hardwood flooring. Meticulous surface preparation, selection of appropriate application techniques, control of environmental conditions, and adherence to recommended coating thickness are all integral components of a successful application. Neglecting any of these factors can compromise the durability, aesthetics, and longevity of the protected surface, highlighting the importance of skilled execution and adherence to best practices in this critical process.

5. Maintenance Requirements

The longevity and aesthetic appeal of a hardwood floor are directly correlated with adherence to proper maintenance protocols. The protective material, while providing an initial barrier against wear and tear, necessitates ongoing care to preserve its integrity and effectiveness. Inadequate maintenance practices can negate the benefits of even the highest-quality protective surface, leading to premature degradation and necessitating costly repairs or replacement. For example, the accumulation of dirt and grit on the surface of a urethane-protected floor, if left unaddressed, will gradually abrade the coating, diminishing its sheen and increasing its susceptibility to scratches.

The specific maintenance procedures required are intrinsically linked to the type of protective surface employed. Waxed floors, for instance, require periodic re-waxing and buffing to maintain their luster and protective qualities. Polyurethane-coated floors, conversely, require less frequent, but consistent, cleaning with pH-neutral solutions to prevent the build-up of residue. The use of abrasive cleaners or harsh chemicals on any type of surface can strip away the protective material, leaving the wood vulnerable to damage. Understanding the specific requirements of the selected surface is, therefore, paramount to implementing an effective maintenance plan. This understanding includes being informed on how to treat certain situations and prevent damage. For instance, proper hardwood floor mat placement. A mat placement helps to eliminate or reduce damage from high-traffic flow, especially from outside elements, like rocks or pebbles.

In summary, the relationship between maintenance and the surface treatment of hardwood floors is one of interdependence. The surface provides initial protection, but diligent maintenance is essential to sustain that protection over time. Proper cleaning techniques, appropriate cleaning products, and timely repairs of any damage are all critical components of a comprehensive maintenance strategy. Ignoring these requirements can significantly shorten the lifespan of the floor and diminish its aesthetic value, underscoring the importance of proactive and informed care. A neglect to proper care, over time, degrades the structural integrity of the floor, and puts unnecessary wear and tear of the surface layer.

Frequently Asked Questions

The following section addresses common inquiries and misconceptions regarding the application, maintenance, and performance of protective materials on hardwood flooring. These answers provide guidance for homeowners and professionals seeking to optimize the longevity and aesthetic appeal of their hardwood floors.

Question 1: What factors determine the appropriate type of hardwood floor finish for a given application?

The selection depends on traffic volume, environmental conditions (moisture, UV exposure), and desired aesthetic qualities. High-traffic areas necessitate durable options like polyurethane, while moisture-prone environments benefit from oil-based sealers. The desired sheen (matte, satin, gloss) also influences the choice.

Question 2: How does surface preparation affect the performance and longevity of a hardwood floor finish?

Proper surface preparation, including thorough cleaning and sanding, is paramount. It ensures optimal adhesion, even coverage, and minimizes the risk of premature peeling or failure. Contaminants or existing coatings impede adhesion and compromise the protective qualities.

Question 3: What are the key differences between oil-based and water-based hardwood floor finishes?

Oil-based options typically offer enhanced durability and moisture resistance but emit higher levels of volatile organic compounds (VOCs). Water-based options are lower in VOCs, dry faster, but may require more coats to achieve comparable durability.

Question 4: How should hardwood floors with different types of finishes be cleaned and maintained?

Waxed floors require periodic re-waxing and buffing, while polyurethane-coated floors should be cleaned with pH-neutral solutions. Abrasive cleaners and harsh chemicals should be avoided on all types as they can damage the coating and wood.

Question 5: What are the common signs that a hardwood floor finish is failing or needs to be refinished?

Visible scratches, worn areas, discoloration, peeling, and water damage indicate that the finish is compromised and may require refinishing to prevent further damage to the underlying wood.

Question 6: What are the environmental considerations associated with different types of hardwood floor finishes?

Oil-based options typically have higher VOC emissions, contributing to air pollution. Water-based and low-VOC options are more environmentally friendly. Responsible disposal of used coatings and application materials is essential to minimize environmental impact.

These FAQs provide a foundational understanding of protective materials for hardwood floors. Careful consideration of these factors is crucial for making informed decisions and ensuring the long-term beauty and durability of hardwood flooring.

The subsequent section will delve into advanced troubleshooting techniques for addressing specific challenges encountered during the finishing process.

Conclusion

The preceding analysis has explored the multifaceted nature of hardwood floor finish. The selection, application, and maintenance of these protective layers are critical determinants of the longevity and aesthetic integrity of hardwood flooring. From abrasion resistance to UV protection, a comprehensive understanding of the available options and their respective properties is essential for informed decision-making.

Effective implementation of best practices in surface preparation, application techniques, and ongoing maintenance will safeguard the investment in hardwood flooring and ensure its enduring beauty for years to come. Further research and adherence to industry standards are encouraged to optimize the performance and sustainability of this vital component of interior design. Diligence in this area is not merely an aesthetic concern but a responsible approach to preserving a valuable resource.