The vertical distance from the top of the toilet flange to the completed flooring surface is a critical measurement in bathroom plumbing. This dimension directly impacts the secure and leak-proof connection between the toilet and the drainage system. For example, if the flange is too high, the toilet may rock, leading to potential wax ring failure and water leakage. Conversely, if it is too low, achieving a proper seal becomes problematic, similarly resulting in leakage and potential floor damage.

Maintaining a correct dimension is essential for ensuring proper toilet function and preventing costly repairs. Ignoring this aspect during installation or remodeling can lead to significant long-term consequences, including water damage, mold growth, and structural issues. Historically, inconsistencies in plumbing practices and floor finishing materials have often resulted in variations in this measurement, highlighting the need for standardized guidelines and careful attention to detail during installation.

Subsequent sections will address recommended measurements, installation considerations, and methods for correcting deviations from the ideal dimension. This will include information on shimming techniques, flange extenders, and alternative solutions for addressing both excessively high and low flange positions in relation to the finished floor.

Essential Considerations

Proper installation of the toilet flange relative to the finished floor is paramount for a secure and watertight toilet connection. The following tips provide essential guidance for achieving optimal results and preventing future plumbing issues.

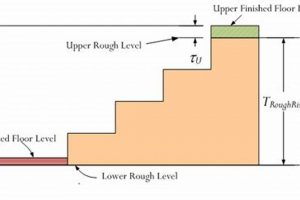

Tip 1: Prior to flange installation, accurately determine the finished floor height. This measurement should account for all flooring materials, including underlayment and the final floor covering. Ignoring this step can lead to misalignment issues.

Tip 2: The ideal position for the top of the toilet flange is flush with the finished floor. A slight variance, no more than 1/4 inch above or below, is generally acceptable. Exceeding this range necessitates corrective action.

Tip 3: When setting the flange, ensure it is securely fastened to the subfloor. Use appropriate screws or fasteners designed for the specific subfloor material. A loose flange will compromise the toilet’s stability and seal.

Tip 4: For concrete slab floors, consider using a concrete anchor system specifically designed for toilet flange installation. These anchors provide superior holding power compared to standard screws.

Tip 5: In remodel situations where the existing flange is too low, flange extenders can be used to raise the flange to the correct height. Carefully select an extender that matches the existing flange material and diameter.

Tip 6: If the flange is too high, it may be necessary to chip away some of the surrounding flooring to lower the flange. Exercise caution to avoid damaging the flange or surrounding plumbing connections.

Tip 7: Always use a new wax ring during toilet installation. A damaged or improperly seated wax ring is a primary cause of toilet leaks. Consider using a wax-free alternative for potentially longer-lasting seal.

These considerations highlight the importance of precise measurements and proper installation techniques to ensure a leak-free and structurally sound toilet installation. Adhering to these guidelines will minimize the risk of future plumbing problems and maintain the integrity of the bathroom floor.

The concluding section will delve into common problems arising from incorrect flange height and propose solutions for rectification.

1. Measurement

Precise measurement is the foundational element for a successful toilet installation. It establishes the spatial relationship between the toilet flange and the finished floor, directly influencing the system’s functionality and longevity. Deviations from recommended measurements can lead to a cascade of problems, underscoring the critical importance of accuracy.

- Establishing the Finished Floor Elevation

Accurately determining the final floor height, inclusive of all layers from subfloor to finished surface, is paramount. This measurement serves as the reference point for setting the flange. Failure to account for flooring thickness will invariably lead to an improperly positioned flange. For example, installing a flange based on the subfloor level, without considering the subsequent addition of tile and underlayment, will result in a flange set too low.

- Flange Height Tolerance

While a flush installation is ideal, a small tolerance is generally acceptable. The permissible deviation, typically within a range of -1/4 inch to +1/4 inch from the finished floor surface, allows for minor variations. Exceeding this tolerance necessitates corrective measures to avoid potential sealing issues. An instance where the flange sits more than 1/4 inch below the finished floor requires the use of flange extenders or shimming techniques to achieve proper alignment.

- Measurement Tools and Techniques

Employing appropriate tools and techniques ensures accuracy in determining the flange height. Laser levels, spirit levels, and measuring tapes are essential for precise measurement. It is crucial to verify the levelness of the surrounding floor area to avoid skewed readings. Utilizing a straight edge placed across the finished floor and measuring to the top of the flange provides a reliable method for assessing the flange height relative to the floor.

- Impact on Toilet Installation

The accuracy of the measurement directly impacts the success of the toilet installation. An improperly measured flange height can lead to an unstable toilet, a compromised wax ring seal, and potential water leakage. Conversely, a properly measured and positioned flange ensures a secure and leak-free connection between the toilet and the drainage system. A practical example includes a situation where an incorrectly measured flange height causes the toilet to rock, leading to premature failure of the wax ring and subsequent water damage to the subfloor.

These facets collectively illustrate the significance of accurate measurement in the context of the toilet flange and finished floor relationship. Precise measurement, correct tool usage, and consideration for floor elevation contribute to a robust plumbing system. Addressing measurement deficiencies proactively minimizes the risk of future plumbing issues and ensures a long-lasting, leak-free toilet installation.

2. Flushness

The efficacy of a toilet’s flushing action, often referred to as “flushness,” is significantly influenced by the position of the toilet flange relative to the finished floor. Proper flange height is a prerequisite for optimal waste removal and efficient water usage.

- Gravity and Waste Evacuation

The height of the flange directly impacts the gravitational forces acting on the waste material. A flange that is too low may impede the natural downward flow, potentially resulting in incomplete flushes and recurring clogs. In contrast, a properly positioned flange facilitates unimpeded waste evacuation, contributing to a cleaner and more efficient flush. For instance, a flange set significantly below the finished floor can create a backflow effect, reducing the momentum of the flush and hindering complete waste removal.

- Water Seal Integrity

The flange height plays a crucial role in maintaining the water seal within the toilet bowl. An incorrect height can disrupt the balance between the water level in the bowl and the siphon jet, leading to either excessive water usage or, conversely, an insufficient water seal. This can result in unpleasant odors and potential sewer gas leakage into the bathroom. Consider a scenario where an elevated flange position causes the water level in the bowl to drop excessively after each flush, diminishing the effectiveness of the water seal.

- Siphon Jet Performance

The performance of the siphon jet, which initiates the flushing action, is directly linked to the flange height. The siphon jet relies on a precise relationship between the water level and the drain opening. An improperly positioned flange can disrupt this relationship, compromising the siphon jet’s ability to create the necessary suction for efficient waste removal. For example, if the flange is too high, the siphon jet may not generate sufficient suction, resulting in a weak or incomplete flush.

- Drain Line Connection Efficiency

The flange serves as the connection point between the toilet and the drain line. An incorrect flange height can create misalignment issues, impacting the efficiency of the drain line connection. This misalignment can lead to turbulence and resistance within the drain line, hindering the smooth flow of waste material. A real-world example includes a situation where a poorly aligned flange creates a partial blockage in the drain line, leading to slow drainage and potential backups.

These interdependent elements highlight the significance of correct positioning for optimal flushness. A properly installed toilet flange, set at the appropriate height relative to the finished floor, facilitates efficient waste removal, maintains water seal integrity, ensures siphon jet performance, and promotes smooth drain line connection. Compliance with established plumbing standards is vital for maximizing toilet functionality and preventing future issues related to inefficient flushing.

3. Sealing

The integrity of the seal between a toilet and its waste drain is fundamentally dependent upon the vertical position of the toilet flange in relation to the finished floor. Insufficient or excessive vertical distance compromises the ability of the wax ring, or alternative sealing mechanism, to form a pressure-tight barrier. This connection is the primary defense against the escape of wastewater and sewer gases into the bathroom environment. When the flange is significantly lower than the floor level, the wax ring may be compressed inadequately, leaving gaps that permit leakage. Conversely, a flange positioned too high may prevent proper contact between the toilet and the ring, creating similar avenues for failure. A common manifestation of this problem is observed when a newly installed toilet exhibits a persistent odor of sewage, indicating a breach in the seal due to improper flange height.

Achieving a reliable seal requires precise adherence to recommended flange height specifications. Flange extenders provide a means to correct situations where the existing flange sits below the finished floor level. These extenders effectively raise the flange to the correct height, allowing for proper wax ring compression and a watertight connection. In situations where the flange is too high, careful removal of flooring material may be necessary to lower the relative position of the flange. Alternative sealing methods, such as wax-free gaskets, are available and can provide improved sealing performance in certain applications. However, these alternative methods are still susceptible to failure if the flange height is significantly outside of the acceptable range.

In summary, the relationship between flange height and sealing efficacy is direct and critical. Correct flange placement, coupled with the appropriate sealing method, is essential for preventing leaks, controlling odors, and ensuring a sanitary bathroom environment. Addressing discrepancies in flange height during initial installation or renovation minimizes the risk of future plumbing failures and associated property damage. Therefore, it should be an essential consideration during the planning and construction of bathroom renovations to avoid unpleasant issues.

4. Stability

The structural integrity and immobility of a toilet fixture are directly linked to the vertical position of the toilet flange relative to the finished floor. This dimensional relationship significantly influences the distribution of weight and forces, affecting the long-term stability of the installation.

- Weight Distribution and Support

A toilet’s weight is designed to be evenly distributed across the base of the fixture and transferred through the flange to the subfloor. If the flange is positioned too low, shimming may be required, creating point loads that can compromise the stability of the toilet. Conversely, if the flange sits too high, the toilet may rock, leading to uneven weight distribution and potential stress on the flange and surrounding floor. Consider a scenario where an improperly positioned flange necessitates excessive shimming, resulting in an unstable toilet that wobbles with each use.

- Secure Fastening and Anchoring

The flange provides the anchoring point for the toilet, securing it to the plumbing system and preventing movement. An incorrectly positioned flange can hinder the proper tightening of bolts, compromising the secure fastening of the toilet. This can lead to instability and potential leaks. For example, if the flange is set too high, the bolts may not reach the flange slots adequately, resulting in a loose and unstable toilet.

- Stress on Plumbing Connections

An unstable toilet places undue stress on the plumbing connections, including the water supply line and the waste drain. This stress can lead to premature wear and tear, increasing the risk of leaks and plumbing failures. A rocking toilet, caused by an improperly positioned flange, can gradually loosen the connection to the water supply, eventually resulting in a water leak.

- Long-Term Structural Integrity

The long-term stability of the toilet installation directly impacts the structural integrity of the surrounding floor and subfloor. An unstable toilet can cause repeated stress and vibration, potentially damaging the flooring materials and weakening the subfloor over time. Consider a situation where a persistently rocking toilet causes the surrounding tile to crack and the subfloor to deteriorate due to constant movement and vibration.

These facets collectively emphasize the vital link between flange positioning and the stability of the toilet. A properly installed flange, set at the correct height relative to the finished floor, ensures secure fastening, even weight distribution, reduced stress on plumbing connections, and long-term structural integrity. Neglecting the dimensional relationship between the flange and the floor can lead to instability, leaks, and costly repairs.

5. Drainage

Effective drainage is an essential function of a toilet system, directly influenced by the vertical position of the toilet flange relative to the finished floor. This height dictates the efficiency with which waste and water are evacuated from the bowl, impacting the overall performance and hygiene of the fixture.

- Gravity-Assisted Flow

Gravity plays a fundamental role in the evacuation of waste. The flange height affects the slope and trajectory of the effluent as it enters the drainage system. A flange positioned too low may create a backwater condition, impeding the natural flow and potentially leading to clogs. Conversely, a flange that is excessively high might cause splashing and inefficient waste removal. Consider a scenario where the toilet requires multiple flushes to clear solid waste due to an improperly positioned flange, resulting in inadequate gravity-assisted flow.

- Drain Line Alignment

The flange serves as the interface between the toilet and the drain line. Precise alignment is critical for unimpeded drainage. An improperly positioned flange can create an offset, causing turbulence and resistance within the drain line. This increased resistance can lead to slower drainage and a higher risk of blockages. For instance, a misaligned flange may result in a partial obstruction in the drain line, requiring frequent plunging to maintain proper flow.

- Scouring Action

Effective drainage relies on a scouring action to remove residue from the bowl and drain passageways. The flange height influences the velocity and direction of the water flow during the flush cycle. An incorrectly positioned flange can reduce the scouring action, leaving behind debris and contributing to unsanitary conditions. Imagine a situation where streaks and stains persist in the toilet bowl despite repeated flushing, indicating insufficient scouring action due to improper flange height.

- Ventilation and Airflow

Proper drainage is intrinsically linked to adequate ventilation within the plumbing system. The flange height can affect the airflow dynamics, potentially hindering the venting process and leading to negative pressure within the drain line. This negative pressure can siphon water from the toilet bowl, disrupting the water seal and allowing sewer gases to enter the bathroom. In extreme cases, a poorly positioned flange can contribute to gurgling sounds in the drain line, signaling ventilation problems.

These interconnected elements underscore the critical role of accurate flange positioning in ensuring efficient drainage. Compliance with established plumbing codes regarding flange height is paramount for optimal toilet performance. Proper installation minimizes the risk of clogs, promotes sanitary conditions, and safeguards the integrity of the plumbing system.

6. Floor Protection

The relationship between the position of the toilet flange relative to the finished floor and the preservation of the floor structure is direct and consequential. Compromised floor protection frequently arises from improper flange height, manifesting in various forms of water damage and structural deterioration. The primary mechanism through which floor damage occurs is leakage resulting from a flawed seal between the toilet and the waste drain. An incorrectly positioned flange inhibits the formation of a reliable, watertight connection, permitting water to seep beneath the toilet and saturate the surrounding flooring materials. This moisture intrusion can lead to a range of adverse effects, including the growth of mold and mildew, weakening of the subfloor, and eventual structural failure. For instance, a flange set too low may prevent adequate compression of the wax ring, creating a pathway for water to escape with each flush, slowly degrading the surrounding floor structure over time.

Furthermore, consistent exposure to moisture accelerates the decomposition of organic materials within the flooring system, fostering an environment conducive to fungal growth and pest infestation. The costs associated with remediating water damage resulting from flange-related leaks can be substantial, encompassing not only repairs to the flooring itself but also potential mold remediation and structural reinforcement. Moreover, undetected leaks can persist for extended periods, exacerbating the damage and potentially affecting adjacent rooms or levels of the building. Preventive measures, such as ensuring proper flange installation and periodic inspection of the toilet base for signs of water leakage, are crucial for mitigating the risk of floor damage and preserving the integrity of the building structure.

In summation, adherence to established plumbing standards concerning flange height is paramount for safeguarding the floor structure from moisture-related damage. Proper flange installation, coupled with routine maintenance, constitutes a proactive approach to preserving the longevity and structural soundness of the flooring system, thereby avoiding costly repairs and maintaining a healthy indoor environment. The investment in meticulous flange installation is an investment in long-term floor protection and the overall well-being of the building.

Frequently Asked Questions

This section addresses common inquiries regarding the vertical positioning of toilet flanges and its implications for plumbing system performance and building integrity.

Question 1: What is the generally accepted range for the vertical distance from the top of the toilet flange to the finished floor surface?

The ideal placement positions the top of the flange flush with the finished floor. A deviation of no more than 1/4 inch above or below this level is generally considered acceptable. Exceeding this tolerance necessitates corrective action to ensure a proper seal.

Question 2: What are the potential consequences of installing a toilet flange that is positioned too low relative to the finished floor?

An improperly positioned flange may prevent adequate compression of the wax ring, creating a pathway for water leakage. This can lead to water damage, mold growth, and eventual structural deterioration of the subfloor. Additionally, a low flange can impede proper waste evacuation and flushing efficiency.

Question 3: Conversely, what are the potential problems associated with a toilet flange installed too high above the finished floor?

A flange that is too high may not allow sufficient contact between the toilet and the wax ring, leading to a compromised seal and potential water leakage. Furthermore, it can cause the toilet to rock, resulting in instability and stress on the plumbing connections.

Question 4: What methods can be employed to correct a toilet flange that is positioned too low?

Flange extenders provide a solution for raising the flange to the correct height. These extenders are designed to fit securely onto the existing flange, effectively increasing its vertical position and allowing for proper wax ring compression.

Question 5: Is it permissible to use shims to compensate for an improperly positioned toilet flange?

While shimming can provide temporary stability, it is not a substitute for proper flange positioning. Excessive shimming can create uneven weight distribution and stress on the plumbing connections. Correcting the flange height is the preferred solution.

Question 6: What are the long-term implications of neglecting to address an improperly positioned toilet flange?

Ignoring an improperly positioned flange can lead to persistent water leakage, resulting in significant water damage, mold growth, and structural deterioration. These issues can necessitate costly repairs and potentially compromise the health and safety of the building occupants.

Ensuring correct positioning is not merely a matter of convenience; it is a crucial element in maintaining the integrity of the plumbing system and the building structure.

The following section will explore troubleshooting techniques for common issues related to toilet flange installation.

Conclusion

This exploration has underscored the critical role of the vertical distance defined by “toilet flange height above finished floor” in ensuring proper toilet function, preventing water damage, and maintaining structural integrity. Accurate measurement, adherence to recommended tolerances, and prompt correction of any deviations are paramount. Failure to address this dimensional relationship can lead to a cascade of problems, ranging from inefficient flushing to significant water damage and costly repairs.

Given the long-term consequences associated with improper installation, diligent attention to the dimensional aspects of the “toilet flange height above finished floor” is not merely a matter of code compliance, but a crucial investment in the longevity and safety of the plumbing system and the building as a whole. Strict adherence to established standards and proactive identification of potential issues are therefore essential for responsible building practices.