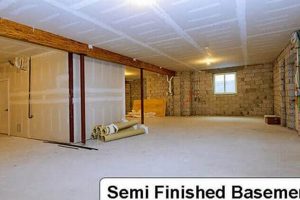

The process of transforming an unfinished lower level into a functional and aesthetically pleasing living space within the Indianapolis metropolitan area requires specialized expertise. Such projects often involve framing, insulation, drywall installation, electrical wiring, plumbing, and flooring to create rooms suitable for various purposes, such as recreation, entertainment, or additional living quarters. These renovations increase usable square footage and can significantly enhance property value.

Completing such home improvement projects offers numerous advantages. Beyond expanding living space, it can improve energy efficiency by properly insulating the foundation. Furthermore, a professionally executed lower-level transformation can address moisture issues, prevent mold growth, and increase a home’s resale value. Historically, homeowners have sought these renovations to adapt their homes to changing family needs and lifestyle preferences.

This article will delve into crucial considerations for planning and executing a successful project, including selecting qualified contractors, understanding local building codes, and optimizing design choices for both functionality and aesthetic appeal. The following sections will explore these topics in detail to provide homeowners with the information needed to make informed decisions regarding their home renovation endeavors.

Essential Considerations for Lower-Level Transformation in Indianapolis

The successful completion of a lower-level project requires careful planning and diligent execution. The following recommendations provide guidance for property owners embarking on such an undertaking.

Tip 1: Secure Multiple Bids. Procuring quotes from several qualified contractors ensures competitive pricing and allows for a comprehensive comparison of services offered. Evaluate bids based on scope of work, materials specified, and projected timelines.

Tip 2: Verify Contractor Credentials. Confirm that the chosen contractor possesses the necessary licenses and insurance required by the State of Indiana and the City of Indianapolis. Request references from previous clients to assess the contractor’s reputation and workmanship.

Tip 3: Obtain Required Permits. Adherence to local building codes is paramount. Acquire all necessary permits from the Department of Metropolitan Development before commencing any work. Failure to do so may result in fines and delays.

Tip 4: Address Moisture Concerns. Indianapolis’ climate can contribute to basement dampness. Conduct a thorough inspection for existing leaks or potential sources of moisture. Implement waterproofing measures, such as interior or exterior sealing, to prevent future problems.

Tip 5: Optimize Insulation. Proper insulation is crucial for energy efficiency and comfort. Utilize closed-cell spray foam or rigid foam board insulation to minimize heat loss and maintain a consistent temperature.

Tip 6: Plan for Egress. Ensure compliance with egress requirements by incorporating an emergency exit, such as an egress window or walkout, to meet safety regulations.

Tip 7: Consider Soundproofing. Minimize noise transmission to upper floors by incorporating soundproofing materials in walls and ceilings. Options include resilient channels, soundproof drywall, and acoustic insulation.

These considerations will contribute to a well-executed and compliant lower-level renovation, enhancing the value and usability of the property. The subsequent section will outline the common pitfalls associated with these projects and strategies to avoid them.

1. Design Optimization

Design optimization, in the context of Indianapolis lower-level renovations, is the strategic process of maximizing space utilization, functionality, and aesthetic appeal within the constraints of the existing structure and budget. It represents a critical phase that directly impacts the long-term value and usability of the renovated space.

- Spatial Configuration

Optimal spatial configuration involves careful consideration of room placement, flow, and proportion. For example, a design might prioritize an open-concept layout for a recreational area, while designating separate, enclosed spaces for bedrooms or home offices. Improper spatial planning can result in cramped, unusable areas and diminished overall value. Careful consideration should be given to natural light sources and incorporating designs that maximize available light.

- Material Selection

Material selection is paramount for both aesthetics and durability. The selection of flooring, wall coverings, and lighting fixtures must align with the intended use of the space and the homeowner’s aesthetic preferences. Furthermore, materials chosen must be suitable for the unique environmental conditions of a lower level, with moisture resistance being a key consideration. For instance, engineered wood or tile are preferable to solid hardwood in areas prone to dampness.

- Functional Integration

Functional integration refers to the seamless incorporation of essential utilities and amenities. This includes carefully planning the placement of electrical outlets, lighting fixtures, plumbing fixtures, and HVAC systems to ensure optimal functionality and convenience. Failing to adequately plan for these elements can result in inconvenient layouts and costly retrofitting.

- Code Adherence

Design optimization must always adhere to local building codes and regulations. This includes compliance with egress requirements, fire safety standards, and accessibility guidelines. For example, proper egress windows are a non-negotiable safety feature. Failure to comply with these codes can result in project delays, fines, and potentially unsafe living conditions.

These facets of design optimization are intrinsically linked to the success of any Indianapolis lower-level project. A well-optimized design not only enhances the usability and value of the space but also ensures compliance with local regulations and promotes long-term homeowner satisfaction. Considerations for universal design principles are paramount to ensure the remodeling is comfortable for all residents and visitors.

2. Code Compliance

Adherence to building codes is not merely a bureaucratic formality in Indianapolis lower-level projects; it represents a fundamental prerequisite for ensuring structural integrity, occupant safety, and legal compliance. The connection between code compliance and these projects is a direct cause-and-effect relationship: failure to comply results in potential hazards, project delays, and legal repercussions. Code compliance encompasses a range of critical areas, including structural support, fire safety, electrical wiring, plumbing, and ventilation. Neglecting any of these areas can lead to serious consequences, such as structural collapse, electrical fires, or carbon monoxide poisoning. Consider, for example, the requirement for proper egress windows in sleeping areas. This code exists to provide occupants with a safe escape route in the event of a fire, and its absence could have life-threatening consequences.

Furthermore, the City of Indianapolis enforces strict regulations regarding the alteration of existing structures. These regulations are in place to protect both the homeowner and the wider community. Obtaining the necessary permits and inspections is essential to verify that the work meets the minimum safety standards. Failure to do so can result in stop-work orders, fines, and even the forced demolition of non-compliant structures. The importance of code compliance is underscored by the fact that it is a legal requirement, and violations can result in significant financial penalties and legal liabilities. Moreover, a project completed without proper permits may negatively impact the property’s resale value.

In summary, code compliance is an integral and indispensable component. Prioritizing adherence to local building codes is not merely a matter of following regulations but a fundamental responsibility to ensure the safety, durability, and legality of these home improvements. A proactive approach to code compliance, including engaging qualified professionals familiar with Indianapolis-specific regulations, is essential for a successful and responsible project. It is an investment in the long-term value and safety of the property.

3. Moisture Mitigation

The correlation between effective moisture mitigation and successful Indianapolis lower-level renovations is undeniable. Subterranean environments, characteristic of many Indianapolis homes, are inherently susceptible to moisture intrusion from groundwater, hydrostatic pressure, and condensation. Ignoring these factors during the finishing process invariably leads to a cascade of problems, including mold growth, structural damage, and compromised indoor air quality. For instance, the application of drywall directly against a concrete foundation wall without a proper vapor barrier creates a breeding ground for mold, necessitating costly remediation and reconstruction in the future. Therefore, moisture mitigation is not merely an optional add-on; it constitutes a foundational element of any sound Indianapolis lower-level finishing strategy.

Practical applications of moisture mitigation strategies in these projects are varied and often interdependent. Exterior solutions may include improving drainage around the foundation, applying waterproof coatings to the exterior walls, and installing French drains to redirect groundwater away from the structure. Interior strategies encompass the use of vapor barriers, dehumidifiers, and sump pumps to control humidity levels and manage water intrusion. Selecting moisture-resistant materials, such as closed-cell spray foam insulation and inorganic flooring options, further minimizes the risk of moisture-related problems. A holistic approach, integrating both exterior and interior measures, is generally the most effective way to ensure a dry and healthy environment.

In conclusion, moisture mitigation is an indispensable component of lower-level finishing in Indianapolis. Its significance extends beyond mere cosmetic improvements, directly impacting the structural integrity, indoor air quality, and long-term value of the property. While challenges may arise in identifying and addressing all potential sources of moisture, a thorough assessment, combined with the implementation of appropriate mitigation strategies, is essential for creating a durable, comfortable, and healthy living space. Failing to prioritize moisture control can negate the benefits of the renovation and result in significant financial and health-related consequences.

4. Budget Management

Effective budget management is inextricably linked to the success of Indianapolis lower-level finishing projects. The financial planning phase directly determines the scope, quality, and ultimately, the feasibility of the entire endeavor. Insufficient budgeting can lead to project abandonment mid-construction, compromises in material quality, or unforeseen cost overruns that strain resources and delay completion. For instance, underestimating the cost of necessary electrical work or plumbing rerouting can quickly inflate expenses beyond initial projections, potentially forcing homeowners to scale back design plans or resort to less desirable materials.

A realistic budget necessitates detailed consideration of all project components, including materials, labor, permits, inspections, and contingency funds for unexpected issues. Obtaining multiple quotes from reputable contractors allows for a comprehensive comparison of pricing and services, enabling homeowners to make informed decisions that align with their financial constraints. Furthermore, prudent budgeting includes anticipating potential hidden costs, such as addressing pre-existing structural problems or unforeseen code compliance requirements. Proactive planning and diligent tracking of expenses throughout the project lifecycle are essential for maintaining financial stability and avoiding costly surprises. Regularly reviewing expenditures against the initial budget allows for timely adjustments and informed decision-making.

In conclusion, rigorous budget management is paramount for ensuring a successful and financially sound Indianapolis lower-level finishing project. By meticulously planning, obtaining competitive quotes, anticipating unforeseen costs, and diligently tracking expenses, homeowners can mitigate financial risks, maintain control over the project’s scope, and ultimately achieve their desired outcome without compromising quality or incurring unsustainable debt. Neglecting budgetary considerations can undermine the entire renovation, transforming a potentially rewarding investment into a stressful and costly endeavor.

5. Contractor Selection

The selection of a qualified contractor is a critical determinant in the success of any Indianapolis lower-level finishing project. The contractor’s expertise, experience, and adherence to ethical business practices directly impact the quality of workmanship, adherence to building codes, and overall project outcome. The subsequent discussion will explore key facets of contractor selection relevant to these projects.

- Licensing and Insurance Verification

Ensuring that a prospective contractor possesses the necessary licenses and insurance is paramount. Licensing demonstrates that the contractor has met the minimum qualifications required by the State of Indiana and the City of Indianapolis. Insurance, including both liability and worker’s compensation coverage, protects the homeowner from financial responsibility in the event of accidents or property damage during the project. Failure to verify these credentials can expose homeowners to significant legal and financial risks.

- Experience and Portfolio Review

A contractor’s experience in lower-level projects within the Indianapolis area is a strong indicator of their ability to navigate the unique challenges associated with these renovations. Reviewing a contractor’s portfolio of past projects provides visual evidence of their workmanship and design capabilities. Requesting references from previous clients allows for direct feedback on the contractor’s professionalism, communication, and adherence to project timelines and budgets. A contractor with a proven track record of successful lower-level transformations is more likely to deliver satisfactory results.

- Detailed Contract Negotiation

A comprehensive and well-defined contract is essential for protecting the interests of both the homeowner and the contractor. The contract should clearly outline the scope of work, materials to be used, project timeline, payment schedule, and dispute resolution mechanisms. Ambiguous or incomplete contracts can lead to misunderstandings, disagreements, and potential legal disputes. Seeking legal counsel to review the contract before signing can provide added protection and ensure that all terms are fair and reasonable.

- Communication and Project Management Skills

Effective communication and project management skills are critical for a smooth and successful renovation. A contractor who communicates clearly, responds promptly to inquiries, and provides regular updates on project progress is more likely to foster a positive working relationship. Strong project management skills ensure that the project stays on schedule, within budget, and adheres to all applicable building codes. A contractor’s ability to effectively coordinate subcontractors and manage logistical challenges is also essential for minimizing delays and disruptions.

In summary, the selection of a qualified contractor for an Indianapolis lower-level finishing project requires careful consideration of multiple factors. Verifying credentials, reviewing experience, negotiating a detailed contract, and assessing communication skills are all crucial steps in mitigating risks and ensuring a satisfactory project outcome. Investing time and effort in the contractor selection process can significantly enhance the likelihood of a successful and stress-free renovation experience.

Frequently Asked Questions

The following section addresses common inquiries regarding the process of completing subterranean living spaces in the Indianapolis metropolitan area. Information provided is intended to offer clarity on key aspects of these home improvement projects.

Question 1: What permits are required for finishing a lower level in Indianapolis?

Permits from the Department of Metropolitan Development are generally required for any structural, electrical, plumbing, or mechanical alterations. Specific requirements vary depending on the scope of the project. Consult with a qualified contractor and the Department of Metropolitan Development to determine the necessary permits.

Question 2: How can moisture be effectively mitigated in a lower level?

Effective moisture mitigation strategies include exterior waterproofing, interior vapor barriers, sump pump installation, and dehumidification systems. Addressing the source of moisture intrusion is crucial for long-term success. Professional assessment and implementation are often recommended.

Question 3: What are the building code requirements for egress windows in sleeping areas?

Egress windows in sleeping areas must meet minimum size requirements for both the window opening and the sill height. The window opening must provide a clear and unobstructed escape route in the event of a fire. Local building codes specify the exact dimensions and requirements.

Question 4: How does finishing a lower level impact property taxes?

Finishing a lower level typically increases the assessed value of the property, resulting in higher property taxes. The exact impact depends on the extent of the finished space and the assessed value per square foot in the area. Contact the Marion County Assessor’s office for detailed information.

Question 5: What is the typical cost per square foot for lower-level finishing in Indianapolis?

The cost per square foot varies widely depending on the complexity of the project, the quality of materials used, and the contractor selected. A range of $40 to $100 per square foot is a reasonable estimate for basic to mid-range finishes. Obtain multiple quotes for accurate pricing.

Question 6: How long does it typically take to finish a lower level?

The duration of a lower-level project depends on the size and complexity of the space. A typical project may take anywhere from four to twelve weeks to complete. Factors such as permitting delays, material availability, and contractor scheduling can impact the timeline.

Understanding these commonly asked questions can help Indianapolis homeowners prepare for a renovation. Thorough research and diligent planning are crucial for a successful undertaking.

The next section will explore the future trends shaping these home improvement projects.

Conclusion

This exploration of Indianapolis lower-level finishing underscores the necessity of meticulous planning, adherence to local codes, and skilled execution. Key elements such as design optimization, moisture mitigation, budgetary control, and qualified contractor selection emerge as critical determinants of project success. The information presented serves to illuminate the complexities inherent in these renovations.

Informed decision-making is paramount for homeowners contemplating such an undertaking. The long-term value and livability of a residence are directly affected by the quality and thoroughness of the work performed. A proactive and diligent approach is therefore strongly encouraged to ensure a favorable and sustainable outcome.