A cordless, battery-operated tool designed for driving finish nails into wood trim and other materials is offered at a major home improvement retailer. This type of tool employs a 20-volt battery system for power and is commonly used in carpentry and woodworking applications where a clean, professional finish is desired. It allows users to install molding, baseboards, and similar elements without the need for an air compressor or hoses.

The increasing popularity of cordless power tools stems from their enhanced portability and convenience. The elimination of cords and hoses streamlines workflow and increases safety on job sites. The availability of such a tool at a prominent retailer provides accessibility for both professional contractors and home improvement enthusiasts seeking efficient and reliable fastening solutions. The technological advancement in battery technology has made these tools a viable alternative to traditional pneumatic nailers.

This specific type of product opens a wide array of project possibilities. Further discussion will detail relevant features, application considerations, and purchasing factors related to selecting a suitable finish nailer. Understanding these elements is vital for optimizing its use and ensuring successful project outcomes.

Tips

The following points offer guidance for the effective use and maintenance of such fastening tools, as available at major retailers.

Tip 1: Battery Management: Ensure the 20-volt battery is fully charged prior to use. Consistent charging practices extend battery life and maintain optimal tool performance. Avoid deep discharging.

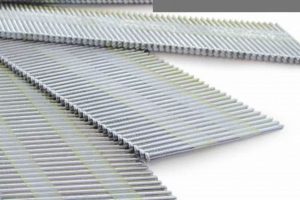

Tip 2: Nail Selection: Use the appropriate gauge and length of finish nails for the material being fastened. Incorrect nail selection can lead to splitting or inadequate holding power.

Tip 3: Depth Adjustment: Adjust the nail depth setting to ensure nails are driven flush with the surface without damaging the surrounding material. Test the setting on scrap material first.

Tip 4: Safety Precautions: Always wear appropriate eye protection when operating the tool. Follow all manufacturer-recommended safety guidelines to prevent injury.

Tip 5: Maintenance: Regularly clean the nailer’s firing mechanism and magazine to prevent jams and ensure smooth operation. Store in a dry environment.

Tip 6: Surface Preparation: Proper surface preparation, such as sanding or pre-drilling pilot holes in hardwoods, reduces the likelihood of splitting and improves nail placement accuracy.

Tip 7: Check Availability: Check “in store pickup” before going to your local store, this could save some wasted time of your day.

Adhering to these guidelines will contribute to improved performance, extended tool lifespan, and enhanced project outcomes.

With an understanding of these practical tips, further exploration can continue on selecting the correct model and understanding project specific nuances.

1. Cordless Convenience

Cordless convenience is a core attribute of the 20V finish nailer available at major retailers. This characteristic eliminates the need for compressed air lines, resulting in greater portability and ease of use on diverse job sites. This freedom enhances accessibility in spaces where pneumatic systems are impractical or unavailable, contributing directly to increased efficiency and versatility. This design enables streamlined workflow, reducing setup time and the physical constraints imposed by traditional air-powered tools.

The practical impact of this cordless design is evident in various applications. For instance, installation of trim in upper-level rooms or confined areas becomes significantly more manageable without the requirement for lengthy air hoses. Similarly, outdoor projects, such as deck construction or fence repair, benefit from the tool’s self-contained power source. The reduced risk of tripping hazards associated with air lines also contributes to enhanced safety on the worksite. Furthermore, reduced need to transport an air compressor make this option easier for smaller projects.

The integration of cordless technology provides a crucial advantage in terms of flexibility and mobility. This convenience factors significantly into the overall value proposition of such tools, especially for users who prioritize ease of transport and streamlined operation. While pneumatic nailers may offer certain advantages in specific high-volume applications, the cordless design’s benefits, specifically for a tool available at a common retail location, are substantial in projects where accessibility and maneuverability are paramount. A benefit is the ease of use for homeowner for small project.

2. Battery Runtime

Battery runtime represents a critical performance parameter for the 20V finish nailer available at major retailers. This factor dictates the tool’s operational lifespan on a single charge, directly impacting project completion time and overall user efficiency. Extended battery runtime minimizes workflow interruptions and enhances productivity, especially on jobsites where access to charging facilities may be limited.

- Amp-Hour (Ah) Rating Impact

The amp-hour (Ah) rating of the 20V battery directly influences runtime. A higher Ah rating translates to longer operational periods between charges. For example, a 5.0 Ah battery will generally provide more nailing cycles than a 2.0 Ah battery of the same voltage. This becomes crucial in larger projects demanding sustained tool usage.

- Load and Application Type

The type of material being fastened and the frequency of nail firing significantly affect battery consumption. Driving nails into hardwoods, compared to softwoods, requires more energy per nail, thus reducing runtime. Similarly, continuous, rapid firing drains the battery faster than intermittent use.

- Battery Technology and Efficiency

Advances in battery technology, such as lithium-ion chemistry, contribute to improved energy density and reduced self-discharge rates. Efficient motor designs within the nailer minimize energy wastage, thereby optimizing battery usage. These technological factors play a key role in maximizing runtime for any given battery capacity.

- Charging Time Considerations

Charging time complements runtime in evaluating overall productivity. Faster charging times minimize downtime, allowing users to quickly replenish battery power and resume work. The availability of rapid chargers, specifically designed for the 20V battery system, is a significant factor in reducing project interruptions. Different amp batteries could take longer to fully charge.

Understanding the interplay between battery runtime, battery capacity, and application demands is essential for selecting the appropriate 20V finish nailer configuration for specific project requirements. Retailers often offer different battery pack options alongside the tool, allowing users to customize their purchase based on their anticipated workload and usage patterns.

3. Nail Capacity

Nail capacity, in the context of a cordless finish nailer offered at major retailers, directly influences operational efficiency. It determines the number of nails the tool can hold within its magazine before requiring reloading. Insufficient nail capacity leads to frequent interruptions during projects, increasing overall task completion time. Conversely, a higher nail capacity streamlines workflow, minimizing downtime and enhancing productivity, particularly in applications involving extensive trim work or repetitive fastening tasks. The capacity of the nailer’s magazine needs to align with the demands of a project to ensure efficient use.

For example, consider a contractor installing baseboards in a large residential space. A finish nailer with a limited nail capacity, say, 50 nails, would necessitate frequent reloading, potentially adding significant time to the project. In contrast, a nailer capable of holding 100 or more nails would allow for longer, uninterrupted work periods. The practical implication is that contractors and serious DIYers benefit from tools equipped with higher nail capacity, as it reduces the frequency of stops to replenish the nail supply, optimizing work flow. Retailers often provide specifications regarding nail capacity, aiding in the selection process based on anticipated project scope.

Nail capacity represents a key factor in the overall utility of a cordless finish nailer. Proper understanding of nail capacity allows users to choose the best tool for their needs. Balancing nail capacity with other features, such as battery life and depth adjustment, enables users to select the most suitable tool for efficient project execution, which is enhanced by the availability of the tool at a common retail outlet, which can provide easy nail purchasing.

4. Depth Adjustment

Depth adjustment is a critical feature on the 20V finish nailer available at major retailers, enabling precise control over nail penetration depth. This functionality ensures consistent, professional results across varying material types and thicknesses, preventing both over-driving, which mars the surface, and under-driving, which leaves nail heads protruding. Proper depth adjustment is paramount for achieving a flush, aesthetically pleasing finish and maintaining the integrity of the workpiece.

- Dial-Based and Tool-Free Systems

Many models feature a dial-based or tool-free depth adjustment mechanism, allowing for quick and easy setting changes without the need for additional tools. This facilitates efficient adaptation to different materials and nail lengths, reducing downtime and improving overall productivity. Dial-based adjustments offer incremental control, while tool-free systems prioritize convenience and speed.

- Material-Specific Considerations

Different materials, such as hardwoods and softwoods, require varying nail penetration depths. Hardwoods necessitate greater force to achieve proper setting, while softwoods are more susceptible to over-driving. Precise depth adjustment allows users to tailor nail penetration to the specific material, minimizing surface damage and ensuring secure fastening. Understanding the material properties is crucial for optimal depth setting.

- Impact on Finish Quality

The quality of the finished product is directly influenced by the accuracy of the depth adjustment. Over-driven nails create unsightly depressions and potential structural weaknesses. Under-driven nails result in protruding heads that detract from the overall appearance and can pose safety hazards. Fine-tuning the depth setting is essential for achieving a clean, professional look and ensuring structural integrity.

- Consistency and Repeatability

A well-designed depth adjustment system provides consistent and repeatable results, ensuring that each nail is driven to the same depth. This is particularly important in projects requiring uniform appearance and consistent fastening performance. A reliable depth adjustment mechanism contributes to greater accuracy and reduces the likelihood of rework.

The ability to precisely control nail penetration depth is a distinguishing characteristic of a high-quality finish nailer. This feature, readily available on models sold at major retailers, allows users to optimize performance across a wide range of applications, ensuring professional results and minimizing material waste. Depth adjustment functionality, therefore, represents a significant factor in the overall value and utility of such tools, improving both project outcomes and user satisfaction.

5. Retail Availability

Retail availability is a core component of the “dewalt finish nailer 20v home depot” concept. The widespread accessibility of this tool at a major home improvement retailer significantly impacts its market reach and adoption. The retailers established distribution network, brand recognition, and customer base provide immediate access to both professional contractors and DIY enthusiasts. This facilitates easy product comparison, in-person evaluation, and immediate purchase, which accelerates the adoption of this tool in a way that may not occur with less accessible brands or distribution channels. For example, a contractor needing a replacement nailer can readily acquire it during a project, reducing downtime. Homeowners benefit from easily accessible tools for home improvement projects.

The retailer’s support infrastructure, including customer service, warranty processing, and tool repair services, further enhances the value proposition of the “dewalt finish nailer 20v home depot”. This provides a safety net for customers, fostering confidence in their purchase. The presence of knowledgeable staff capable of providing product guidance and troubleshooting assistance contributes to a more positive customer experience. Furthermore, the retailers online presence, with product reviews and instructional resources, further enhances the accessibility and usefulness of the tool. Seasonal sales, promotions, and bundle deals also increase its attractiveness.

In summary, the direct association between a specific tool and a widely accessible retail outlet is a major factor for market access and ease. This relationship ensures not only ease of product acquisition but also enhances customer confidence through established support structures. The availability contributes to a larger market adoption, turning what may be a standard tool into a highly available tool, for both professional and home users.

Frequently Asked Questions

The following addresses prevalent inquiries regarding the cordless finish nailer available at a prominent home improvement retailer. These responses aim to provide clarity on key features, operational aspects, and suitability for specific applications.

Question 1: What is the typical battery life of the 20V battery when using this finish nailer?

Battery life varies based on material density, nail length, and operating conditions. Driving longer nails into hardwoods will deplete the battery more rapidly than shorter nails into softwoods. A 5.0Ah battery generally provides substantially more runtime than a 2.0Ah battery. It is advised to consult the manufacturer’s specifications for precise estimates based on specific usage scenarios.

Question 2: Does this finish nailer require any specialized maintenance?

Regular cleaning of the nail magazine and driver blade area is essential to prevent jams. The tool should be stored in a dry environment to prevent corrosion. Periodically inspecting the battery terminals for cleanliness and proper contact is recommended. Refer to the manufacturers manual for detailed maintenance procedures.

Question 3: What gauge and length of finish nails are compatible with this tool?

This finish nailer typically accommodates 16-gauge finish nails ranging from 1-1/4 inches to 2-1/2 inches in length. Always confirm compatibility by consulting the manufacturers specifications to prevent damage to the tool or workpiece.

Question 4: Is the depth adjustment feature tool-free?

Many models offered at the major retailer feature a tool-free depth adjustment mechanism, allowing for convenient depth adjustments without the need for wrenches or screwdrivers. Confirm the specific model’s features to determine if it provides this convenience.

Question 5: Can this finish nailer be used for both trim work and furniture assembly?

This finish nailer is suitable for various applications, including trim work, cabinetry, furniture assembly, and crafting. However, the user must ensure that the nail length and gauge are appropriate for the specific application and material thickness.

Question 6: What safety precautions should be taken when operating this finish nailer?

Eye protection is mandatory during operation. Hands and fingers must be kept clear of the firing zone. Always disconnect the battery before performing maintenance or clearing jams. Follow all manufacturer-recommended safety guidelines outlined in the tool’s manual.

These answers clarify common considerations regarding this type of cordless fastening tool and facilitate informed decision-making prior to purchase. Consulting the manufacturer’s documentation for complete details is highly encouraged.

Following this detailed FAQ, understanding the comparison between different models is key.

Conclusion

The preceding exploration of the “dewalt finish nailer 20v home depot” concept highlights several key aspects: cordless convenience, battery runtime, nail capacity, depth adjustment, and retail availability. These elements collectively define the tool’s functionality, usability, and market accessibility. The integration of cordless technology and readily available retail channels contribute to enhanced efficiency and broader adoption.

Ultimately, the value proposition of the “dewalt finish nailer 20v home depot” is contingent on aligning its features with specific project demands and user priorities. A thorough assessment of workload, application type, and desired finish quality is essential for informed decision-making. Continued advancements in battery technology and tool design will likely further enhance the performance and versatility of cordless finish nailers, solidifying their position as a key tool for both professionals and homeowners.

![Best DeWalt Finish Nailer Deals at Lowe's [Guide] Best Final Touch: Elevate Your Projects with Professional Finishing Best DeWalt Finish Nailer Deals at Lowe's [Guide] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-477-300x200.jpg)