A specialized implement designed to ensure fasteners are flush with or slightly below the surface of the material into which they are driven. This device, often pneumatic or manual, prevents damage to surrounding areas and allows for a smooth, professional appearance. For example, after installing trim, such a device can countersink nail heads, preparing the surface for filling and painting.

The utility of this type of device lies in its ability to create a uniform and aesthetically pleasing finish. Historically, achieving this level of precision required considerable skill and time. The introduction of specialized tools significantly reduces labor, increases efficiency, and minimizes the risk of imperfections. Benefits include improved aesthetics, reduced potential for snagging or injury from protruding fasteners, and enhanced adhesion of subsequent surface treatments.

The following sections will delve into the various types available, optimal usage techniques, safety considerations, and how to select the appropriate device for specific applications. This will equip the reader with a comprehensive understanding to maximize the value of this finishing process.

Tips for Optimal Use

Employing a fastener finishing device effectively requires careful consideration of material properties, device settings, and technique. The following tips will optimize performance and ensure a professional result.

Tip 1: Material Compatibility: Prioritize selecting the correct tip or setting based on the substrate’s density. Using excessive force on softwoods can result in overly deep impressions, while insufficient force on hardwoods may leave fasteners protruding.

Tip 2: Depth Adjustment: Fine-tune the depth setting prior to commencing work. Begin with a conservative setting and gradually increase it until the desired result is achieved. This prevents over-driving and subsequent material damage.

Tip 3: Consistent Pressure: Maintain consistent pressure during operation. Uneven pressure can lead to inconsistent fastener depth and an unprofessional appearance. Practice on scrap material to develop a consistent technique.

Tip 4: Surface Preparation: Ensure the work surface is clean and free of debris. Dust, chips, or other particles can interfere with proper seating of the device and result in a flawed finish.

Tip 5: Tool Maintenance: Regularly inspect and maintain the device according to the manufacturer’s recommendations. Clean the tip and ensure all moving parts are properly lubricated to prevent malfunctions and extend the lifespan of the device.

Tip 6: Safety Precautions: Always wear appropriate safety glasses to protect against flying debris. Avoid pointing the device at oneself or others, and disconnect the power source when not in use or performing maintenance.

Tip 7: Test Before Committing: Always test the adjustments on a piece of scrap of the same material you are working on before finishing the final work. This is a precautionary measure to avoid ruining the work.

Mastering these techniques will enhance the quality of finished projects, minimize material waste, and extend the operational life of the device. Proper application ensures structurally sound and visually appealing results.

The subsequent sections will address common troubleshooting scenarios and explore advanced techniques for specialized applications.

1. Precision Depth Setting

A precise depth setting is a fundamental feature of a nail finisher tool, directly influencing the quality and appearance of the finished surface. This setting dictates the force with which the nail is driven, thereby controlling how far below (or flush with) the material’s surface the nail head is positioned. Improper depth setting can cause nails to protrude, creating an unprofessional look and potential safety hazard, or conversely, be driven too deep, damaging the surrounding material and weakening the joint. For example, in cabinet making, if the depth is not accurately adjusted, nails might either mar the wood surface or remain exposed, requiring additional filling and sanding, increasing labor and material costs.

The ability to precisely control depth is often achieved through adjustable dials or mechanisms on the tool, allowing users to tailor the force to the density of the material being worked. Different wood types, such as soft pine versus hard oak, require markedly different depth settings to achieve a flush or slightly countersunk finish. Furthermore, the type of nail being used, such as a brad nail or finish nail, also influences the optimal depth setting. Modern pneumatic and cordless nail finisher tools offer sophisticated depth adjustment features, improving precision and consistency compared to traditional manual methods, leading to reduced rework and a higher quality result. The adjustement settings are critical for the overall finish of the tool.

In summary, precision depth setting on a nail finisher tool is essential for achieving professional-grade results, reducing material waste, and ensuring structural integrity. Its understanding and proper application are critical to successful woodworking and construction projects. Failure to manage this parameter leads to visible imperfections, safety risks, and potentially compromised structural integrity of the finished product. The ongoing development and refinement of depth adjustment mechanisms in these tools represent a key focus for manufacturers seeking to enhance user experience and improve the quality of finished projects.

2. Material Compatibility

Material compatibility is a paramount consideration when selecting and utilizing a nail finisher tool. The successful application of this tool hinges on matching its operational characteristics to the properties of the target material to prevent damage, ensure proper fastener seating, and achieve a professional finish.

- Wood Density and Hardness

Different wood species exhibit varying densities and hardness levels, directly impacting the force required for proper nail penetration. Softwoods, such as pine and fir, necessitate lower power settings to avoid over-driving the nail and creating unsightly depressions. Conversely, hardwoods, such as oak and maple, require greater force to ensure the nail is fully seated flush or slightly below the surface. Mismatched settings result in either protruding nails in hardwoods or excessive dimpling in softwoods.

- Material Thickness and Composition

The thickness of the material being fastened also influences the required nail finishing technique. Thin materials are more susceptible to splitting or blow-out if excessive force is applied. Composite materials, such as MDF or particleboard, have unique densities and binding properties that may require specific nail types and adjusted power settings to prevent delamination or surface damage. Choosing the appropriate nail length and gauge is critical to avoid the nail protruding through the back of the material.

- Nail Type and Material

The material composition of the nails themselves interacts with the material being fastened. Using hardened steel nails in softer woods can lead to bending or improper setting due to the wood’s inability to provide sufficient resistance. Conversely, softer nails in dense hardwoods may bend or break during driving. In corrosive environments or outdoor applications, stainless steel or coated nails are required to prevent rust and staining, maintaining structural integrity and aesthetics.

- Surface Finish and Coatings

The presence of surface finishes, such as paint, varnish, or laminate, affects the nail finisher’s performance. Coatings can cushion the impact, requiring a slight adjustment in depth setting. Conversely, certain finishes can be brittle and prone to chipping or cracking if the nail is over-driven. Care must be taken to avoid damaging the finish surrounding the nail hole.

Failure to account for material compatibility can lead to compromised structural integrity, aesthetic imperfections, and increased material waste. Careful consideration of these factors ensures the appropriate nail finisher tool and technique are selected, resulting in a high-quality, durable, and visually appealing finished product. It highlights the interdependency between the tool and the material worked on for a success project.

3. Air Pressure Control

Air pressure control is a critical parameter for pneumatic nail finisher tools, directly influencing the precision, consistency, and overall effectiveness of the fastening process. The ability to regulate air pressure ensures proper nail seating and prevents damage to the workpiece, making it a key feature for achieving professional results.

- Driving Force Modulation

Air pressure directly correlates with the driving force exerted by the nail finisher tool. Higher pressure translates to increased force, suitable for driving nails into denser materials like hardwoods. Conversely, lower pressure settings are necessary for softer woods to prevent over-driving and material damage. Precise control allows for adapting to varied material densities within a single project.

- Consistency in Nail Depth

Stable and consistent air pressure is essential for maintaining uniform nail depth across a series of fastenings. Fluctuations in pressure can lead to inconsistent results, with some nails protruding and others being driven too deep. Regulators within the tool maintain a constant pressure supply, mitigating variations and ensuring a professional, even finish.

- Tool Longevity and Maintenance

Operating a pneumatic nail finisher tool within its recommended pressure range prolongs its lifespan and minimizes maintenance requirements. Excessive pressure can strain internal components, leading to premature wear and potential malfunctions. Adhering to the manufacturer’s specifications optimizes performance and reduces the risk of costly repairs.

- Safety and User Control

Proper air pressure control enhances user safety by preventing unintended nail firing due to excessive force. A well-regulated system allows for greater precision and control over the tool, minimizing the risk of accidental injury or damage to the surrounding work area. Adjustable pressure settings enable users to adapt to specific task requirements, ensuring safe and efficient operation.

In summary, air pressure control is an indispensable aspect of pneumatic nail finisher tools, affecting not only the quality of the finished product but also the tool’s longevity and user safety. Accurate and consistent pressure regulation enables operators to achieve optimal results across a range of materials and applications.

4. Tip Design Variety

The variety in tip designs for nail finisher tools is a critical determinant of their versatility and effectiveness across diverse applications. The tip, being the direct interface between the tool and the work surface, significantly influences the precision and finish quality achieved. A range of tip designs addresses specific requirements related to material type, nail type, and desired aesthetic outcome.

- Flush Mount Tips

Flush mount tips are engineered to ensure that nail heads are driven perfectly flush with the surface of the material. These tips often feature a flat, broad surface to distribute the impact force evenly. An example would be their use in trim carpentry where a seamless transition between the trim and the wall is desired. Improper use or a worn tip can mar the wood surface. A flush mount tip ensures the correct finish.

- Non-Marring Tips

Non-marring tips are constructed from softer materials, such as rubber or plastic, to prevent damage to delicate surfaces. These tips are indispensable when working with pre-finished materials or surfaces susceptible to scratching. For example, when installing pre-finished hardwood flooring, a non-marring tip minimizes the risk of leaving unsightly marks around the nail heads, preserving the integrity of the finish. Using the non-marring tip ensure no dent or scratch happen on the work.

- Precision Point Tips

Precision point tips are characterized by their narrow, pointed design, enabling accurate nail placement in tight or difficult-to-reach areas. These tips are particularly useful when working on intricate trim details or in corners where a larger tip would be impractical. An instance of this would be when affixing delicate molding where accuracy trumps other concerns, preventing damage. Using precision tips ensure less error and material use.

- Adjustable Depth Tips

Adjustable depth tips allow users to fine-tune the depth to which the nail is driven, accommodating variations in material density and nail length. This adjustability is crucial for achieving a consistent, professional finish across a range of applications. For instance, when fastening trim to drywall, an adjustable depth tip ensures that the nail is driven deep enough to provide secure fastening without penetrating too far and damaging the underlying structure. Adjustable tips avoid the hassle and set the correct depth.

The availability of diverse tip designs transforms a general-purpose nail finisher tool into a highly adaptable instrument, capable of delivering superior results across a multitude of applications. Proper selection and utilization of these tips enhance both the aesthetic appeal and structural integrity of finished projects, demonstrating the importance of considering tip design variety when selecting a nail finisher tool.

5. Ergonomic Handle

The ergonomic handle on a nail finisher tool is a crucial design element that directly influences user comfort, control, and overall productivity. Prolonged use of these tools, common in construction and woodworking, can lead to fatigue and repetitive stress injuries. An ergonomically designed handle mitigates these risks by conforming to the natural contours of the hand, reducing strain on muscles and joints. The handle’s shape, grip material, and weight distribution contribute to its ergonomic properties. For instance, a handle with a non-slip grip allows for secure handling even in damp conditions, reducing the need for excessive force to maintain control. This, in turn, minimizes the risk of slippage, misfires, and potential injuries.

The benefits of an ergonomic handle extend beyond mere comfort. Improved grip and reduced fatigue translate to greater accuracy and precision during nail placement. This is particularly important in intricate trim work or projects requiring consistent nail depth. A poorly designed handle can lead to inconsistent nail depth and damage to the workpiece, resulting in rework and material waste. An ergonomic handle facilitates a more natural and balanced posture, further reducing strain on the user’s body. This is especially significant for tasks that involve repetitive movements and prolonged periods of standing or awkward positioning. Different handle designs cater to varying hand sizes and grip preferences, ensuring a comfortable and secure fit for a wide range of users. Some handles incorporate vibration-dampening features, further reducing fatigue and improving user experience.

In summary, the ergonomic handle is not merely an ancillary feature but an integral component of a nail finisher tool that directly impacts user well-being, productivity, and the quality of finished work. Selecting a tool with an ergonomically designed handle is a practical investment that promotes safety, reduces fatigue, and enhances overall efficiency on the job site or in the workshop. Challenges remain in balancing ergonomic design with tool durability and affordability, but ongoing research and development continue to drive improvements in this critical area. The design contributes greatly to less fatigue and higher performance rate.

6. Consistent Performance

Consistent performance in a nail finisher tool is not merely desirable, but essential for ensuring structural integrity, aesthetic quality, and efficient workflow in woodworking and construction projects. Deviation from consistent operation leads to defects, increased labor, and potential safety hazards. The following facets illuminate the critical components that contribute to, and are influenced by, performance consistency in these tools.

- Pneumatic System Stability

For pneumatic nail finisher tools, a stable and well-regulated pneumatic system is paramount for consistent nail driving force. Fluctuations in air pressure can result in nails being under-driven, requiring manual setting, or over-driven, causing damage to the surrounding material. A quality regulator and well-maintained compressor contribute significantly to consistent performance, ensuring each nail is set to the desired depth without variation.

- Mechanism Reliability

The internal driving mechanism of a nail finisher tool must exhibit reliability to ensure consistent performance. Components such as the piston, driver blade, and firing valve must operate with precision and repeatability. Wear and tear on these components, if left unaddressed, can lead to inconsistent firing, misfeeds, and reduced driving power, compromising the tool’s ability to consistently set nails to the correct depth.

- Depth Adjustment Accuracy

The accuracy and stability of the depth adjustment mechanism are crucial for achieving consistent performance, especially when working with varying material densities. A well-designed depth adjustment system allows for precise control over the driving depth and maintains its setting throughout extended use, preventing unwanted variations in nail placement. This feature is particularly important when working with expensive or delicate materials, where consistency is paramount to avoiding costly errors.

- Contact Trip Consistency

The contact trip mechanism, which initiates the nail driving sequence, must function consistently to ensure reliable operation. A worn or improperly adjusted contact trip can lead to inconsistent firing or accidental misfires, compromising both performance and safety. Regular inspection and maintenance of the contact trip mechanism are essential for maintaining consistent performance and preventing potential hazards.

These facets underscore the importance of consistent performance in nail finisher tools. Ensuring stability, accuracy, and reliability in these critical areas translates directly to improved efficiency, reduced rework, and enhanced safety in woodworking and construction applications. The initial investment in quality and consistent maintenance habits reduces total project cost.

7. Safety Mechanisms

Safety mechanisms are integral to the design and operation of nail finisher tools, serving to mitigate the inherent risks associated with high-speed fastener deployment. The primary function of these mechanisms is to prevent unintentional nail discharge, which could result in serious injury to the operator or bystanders. Contact actuation systems, for instance, necessitate that the tool’s nosepiece be firmly pressed against the work surface before firing, precluding accidental discharges into open air or unintended targets. Trigger locks further enhance safety by disabling the firing mechanism when the tool is not in active use, preventing inadvertent nail release during handling or transport. A real-world example is the use of sequential actuation modes, which require the nosepiece to be depressed before the trigger is pulled, offering an additional layer of protection compared to contact actuation systems that can fire simply by bumping the nosepiece against a surface while the trigger is engaged.

The efficacy of safety mechanisms directly correlates to the reduction of workplace accidents and injuries. Construction sites and woodworking shops, where nail finisher tools are commonly employed, present numerous potential hazards, including crowded work areas and distractions. Robust safety mechanisms provide a critical safeguard against these risks, minimizing the potential for nail gun-related injuries. Manufacturers continually refine safety features to enhance user protection while maintaining tool efficiency. Examples include adding directional exhaust ports to deflect air and debris away from the operator and incorporating adjustable depth settings to prevent nails from ricocheting off hard surfaces. Routine inspection and maintenance of these safety features are crucial for their continued effectiveness.

In conclusion, safety mechanisms are not optional add-ons but fundamental components of nail finisher tools, vital for ensuring operator well-being and preventing workplace accidents. Adherence to manufacturer guidelines regarding the use and maintenance of these mechanisms is paramount. Challenges remain in balancing safety enhancements with tool performance and user ergonomics. Ongoing research and development are focused on creating more intuitive and effective safety features to further minimize the risks associated with nail finisher tool operation.

Frequently Asked Questions About Nail Finisher Tools

This section addresses common inquiries regarding nail finisher tools, providing detailed explanations to enhance understanding and promote effective utilization.

Question 1: What distinguishes a nail finisher tool from a standard nail gun?

A nail finisher tool is specifically designed for precision work, focusing on achieving a smooth, nearly invisible finish. Standard nail guns are generally used for framing, roofing, and other applications where the aesthetic finish is less critical. The former typically employs smaller gauge nails and incorporates features for controlling nail depth to prevent damage to the surface material.

Question 2: What safety precautions must be observed when using a nail finisher tool?

Eye protection is mandatory to prevent injury from flying debris. The tool’s safety mechanism, usually a contact trip, must be properly engaged to prevent accidental firing. Hands and fingers must be kept clear of the nail discharge area. Disconnecting the air supply or battery when not in use is a prudent safety measure.

Question 3: How does one properly adjust the nail depth on a nail finisher tool?

The nail depth adjustment is typically controlled by a dial or knob on the tool. Starting with a shallow setting and gradually increasing it until the nail is flush or slightly below the surface of the material is recommended. Testing on scrap material of the same type is essential to determine the optimal setting and avoid over-driving the nails.

Question 4: What maintenance procedures are necessary for a nail finisher tool?

Regular cleaning of the tool’s nose and driver blade is essential to prevent jams. For pneumatic models, draining the air compressor tank to remove moisture and lubricating the tool’s internal components according to the manufacturer’s recommendations is necessary. Battery-powered models require proper battery storage and charging practices.

Question 5: Can a single nail finisher tool be used with various types of nails?

Most nail finisher tools are designed for specific nail gauges and lengths. Consulting the tool’s manual to determine the appropriate nail types is imperative. Using incorrect nails can cause jamming, damage to the tool, and compromise the quality of the finished product.

Question 6: What factors should be considered when selecting a nail finisher tool?

The intended application, frequency of use, and material types being fastened are key considerations. For heavy-duty applications, a pneumatic model may be preferable for its power and speed. For smaller projects or remote locations, a cordless model may offer greater convenience. Features such as adjustable depth settings, a no-mar tip, and an ergonomic handle should also be evaluated.

Proper understanding and adherence to these guidelines will ensure safe and effective operation of nail finisher tools, yielding professional results and minimizing the risk of accidents.

The subsequent section will address troubleshooting common issues encountered with nail finisher tools.

Conclusion

This exposition has detailed the functionality, benefits, and operational considerations surrounding the `nail finisher tool`. Key aspects covered included material compatibility, precision depth setting, safety mechanisms, and the significance of ergonomic design. The objective was to provide a comprehensive understanding for informed selection and effective utilization.

The inherent value of the `nail finisher tool` lies in its capacity to enhance project aesthetics, improve structural integrity, and streamline work processes. Continued adherence to safety protocols and informed application of best practices remain crucial for realizing the full potential of this specialized instrument.

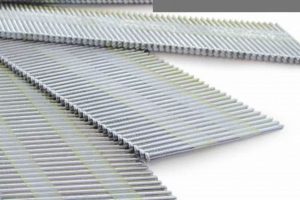

![Best DeWalt Finish Nailer Deals at Lowe's [Guide] Best Final Touch: Elevate Your Projects with Professional Finishing Best DeWalt Finish Nailer Deals at Lowe's [Guide] | Best Final Touch: Elevate Your Projects with Professional Finishing](https://bestfinaltouch.com/wp-content/uploads/2026/01/th-477-300x200.jpg)